tow YAMAHA WR 250F 2007 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: WR 250F, Model: YAMAHA WR 250F 2007Pages: 912, PDF Size: 23.95 MB

Page 54 of 912

1 - 29

GEN

INFO

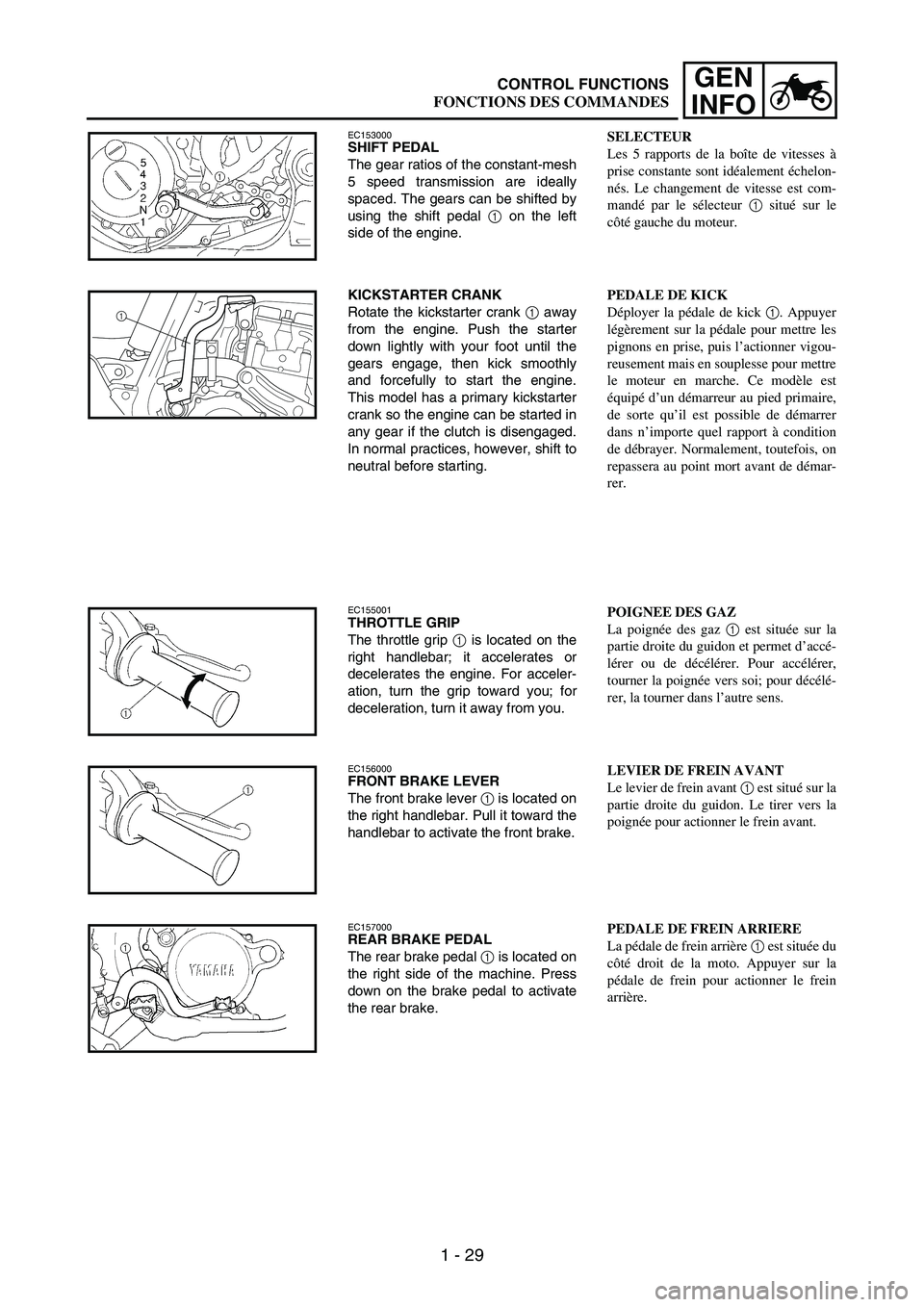

EC153000SHIFT PEDAL

The gear ratios of the constant-mesh

5 speed transmission are ideally

spaced. The gears can be shifted by

using the shift pedal

1 on the left

side of the engine.

KICKSTARTER CRANK

Rotate the kickstarter crank

1 away

from the engine. Push the starter

down lightly with your foot until the

gears engage, then kick smoothly

and forcefully to start the engine.

This model has a primary kickstarter

crank so the engine can be started in

any gear if the clutch is disengaged.

In normal practices, however, shift to

neutral before starting.

1

EC155001THROTTLE GRIP

The throttle grip

1 is located on the

right handlebar; it accelerates or

decelerates the engine. For acceler-

ation, turn the grip toward you; for

deceleration, turn it away from you.

EC156000FRONT BRAKE LEVER

The front brake lever

1 is located on

the right handlebar. Pull it toward the

handlebar to activate the front brake.

EC157000REAR BRAKE PEDAL

The rear brake pedal

1 is located on

the right side of the machine. Press

down on the brake pedal to activate

the rear brake.

SELECTEUR

Les 5 rapports de la boîte de vitesses à

prise constante sont idéalement échelon-

nés. Le changement de vitesse est com-

mandé par le sélecteur 1 situé sur le

côté gauche du moteur.

PEDALE DE KICK

Déployer la pédale de kick 1. Appuyer

légèrement sur la pédale pour mettre les

pignons en prise, puis l’actionner vigou-

reusement mais en souplesse pour mettre

le moteur en marche. Ce modèle est

équipé d’un démarreur au pied primaire,

de sorte qu’il est possible de démarrer

dans n’importe quel rapport à condition

de débrayer. Normalement, toutefois, on

repassera au point mort avant de démar-

rer.

POIGNEE DES GAZ

La poignée des gaz 1 est située sur la

partie droite du guidon et permet d’accé-

lérer ou de décélérer. Pour accélérer,

tourner la poignée vers soi; pour décélé-

rer, la tourner dans l’autre sens.

LEVIER DE FREIN AVANT

Le levier de frein avant 1 est situé sur la

partie droite du guidon. Le tirer vers la

poignée pour actionner le frein avant.

PEDALE DE FREIN ARRIERE

La pédale de frein arrière 1 est située du

côté droit de la moto. Appuyer sur la

pédale de frein pour actionner le frein

arrière.

CONTROL FUNCTIONS

FONCTIONS DES COMMANDES

Page 90 of 912

1 - 65

GEN

INFO

EC1B0000

CLEANING AND

STORAGE

EC1B1000CLEANING

Frequent cleaning of your machine

will enhance its appearance, main-

tain good overall performance, and

extend the life of many components.

1. Before washing the machine,

block off the end of the exhaust

pipe to prevent water from enter-

ing. A plastic bag secured with a

rubber band may be used for this

purpose.

2. If the engine is excessively

greasy, apply some degreaser to

it with a paint brush. Do not

apply degreaser to the chain,

sprockets, or wheel axles.

3. Rinse the dirt and degreaser off

with a garden hose; use only

enough pressure to do the job.

CAUTION:

Excessive hose pressure may

cause water seepage and contami-

nation of wheel bearings, front

forks, brakes and transmission

seals. Many expensive repair bills

have resulted from improper high

pressure detergent applications

such as those available in coin-

operated car washers.

4. After the majority of the dirt has

been hosed off, wash all sur-

faces with warm water and a

mild detergent. Use an old tooth-

brush to clean hard-to-reach

places.

5. Rinse the machine off immedi-

ately with clean water, and dry

all surfaces with a soft towel or

cloth.

6. Immediately after washing,

remove excess water from the

chain with a paper towel and

lubricate the chain to prevent

rust.

7. Clean the seat with a vinyl uphol-

stery cleaner to keep the cover

pliable and glossy.

8. Automotive wax may be applied

to all painted or chromed sur-

faces. Avoid combination

cleaner-waxes, as they may con-

tain abrasives.

9. After completing the above, start

the engine and allow it to idle for

several minutes.

NETTOYAGE ET

REMISAGE

NETTOYAGE

Un nettoyage fréquent de la moto préser-

vera son apparence, maintiendra ses bon-

nes performances et augmentera la durée

de vie de nombre de ses composants.

1. Avant de nettoyer la moto, couvrir

la sortie du tuyau d’échappement

pour éviter toute pénétration d’eau.

Un sachet en plastique retenu par un

élastique fera l’affaire.

2. Si le moteur est fortement encrassé,

appliquer un peu de dégraissant à

l’aide d’un pinceau. Eviter tout con-

tact avec la chaîne, les pignons ou

les axes de roue.

3. Rincer la saleté et le dégraissant au

tuyau d’arrosage, en utilisant juste

la pression nécessaire.

ATTENTION:

Une pression excessive risque de cau-

ser des infiltrations d’eau dans les

roulements des roues, la fourche

avant, les freins et les joints de la

transmission. L’emploi abusif de

détergents sous forte pression, tels que

ceux utilisés dans les portiques de

lavage automatique, est nuisible à la

moto et peut entraîner des réparations

onéreuses.

4. Après avoir éliminé le plus gros de

la saleté au tuyau d’arrosage, laver

toutes les surfaces à l’eau chaude

savonneuse (employer un détergent

doux). Une vieille brosse à dents

convient parfaitement pour nettoyer

les parties difficiles d’accès.

5. Rincer immédiatement la moto à

l’eau claire et sécher toutes les sur-

faces à l’aide d’une peau de cha-

mois, d’une serviette ou d’un

chiffon doux absorbant.

6. Sécher immédiatement la chaîne à

l’aide d’une serviette en papier et la

graisser afin de la protéger contre la

rouille.

7. Nettoyer la selle à l’aide d’un pro-

duit de nettoyage pour similicuir

afin de conserver intacts la sou-

plesse et le lustre de la housse.

8. Une cire pour carrosserie peut être

utilisée pour toutes les surfaces

peintes et chromées. Ne pas

employer de cires détergentes car

elles contiennent souvent des abra-

sifs.

9. Lorsque le nettoyage est terminé,

mettre le moteur en marche et le

laisser tourner au ralenti pendant

plusieurs minutes.

CLEANING AND STORAGE

NETTOYAGE ET REMISAGE

Page 196 of 912

2 - 103

SPECCABLE ROUTING DIAGRAM

ÈInsert the end of the fuel tank breather hose into the hole in the

steering stem.

ÉFasten the throttle cable, hot starter cable and rectifier/regula-

tor lead onto the frame. Locate the clamp end facing the lower

side of the hot starter cable and cut off the tie end.

ÊFasten the diode (at the marking), throttle cable and hot starter

cable onto the frame. Locate the clamp end facing toward the

lower right of the frame and with the tie end facing downward.

ËFasten the wire harness, throttle position sensor lead, starter

motor lead and negative battery lead onto the frame. Pass the

clamp through the hole in the stay (air cut-off valve). Locate the

clamp end facing toward the lower side of the frame and cut off

the tie end.ÌFasten the throttle position sensor lead onto the frame. Locate

the clamp end facing toward the lower side of the frame and

cut off the tie end.

ÍPass the carburetor breather hoses, carburetor overflow hose

and catch tank breather hose between the connecting rod and

cross tube (frame).

ÎFasten the neutral switch lead and oil hose together with the

plastic locking ties and cut off the tie ends.

ÏFasten the neutral switch lead and AC magneto lead onto the

frame. Locate the clamp end facing toward the outside of the

frame and tie end facing toward the rear of the frame.

Page 198 of 912

2 - 105

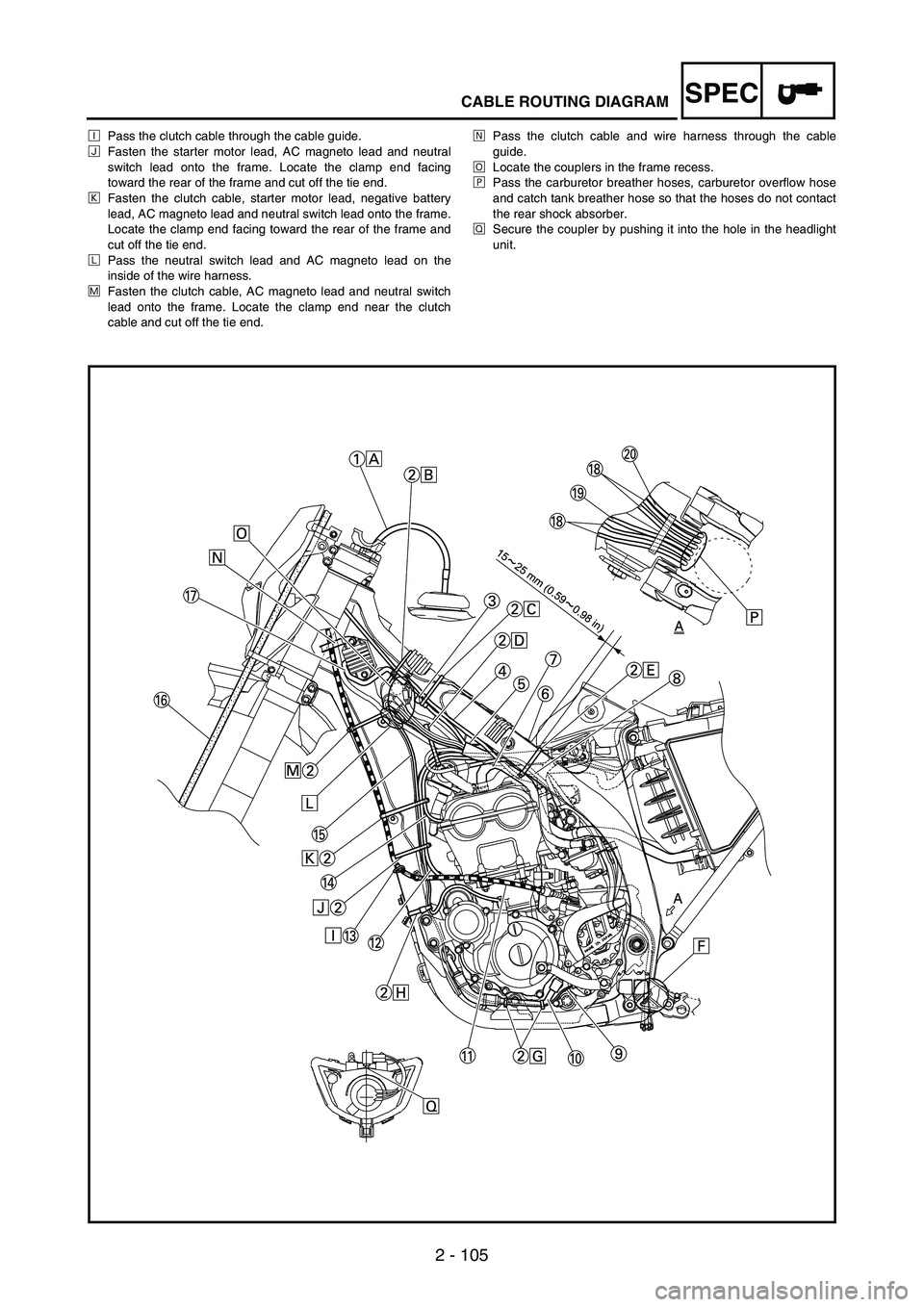

SPECCABLE ROUTING DIAGRAM

ÐPass the clutch cable through the cable guide.

ÑFasten the starter motor lead, AC magneto lead and neutral

switch lead onto the frame. Locate the clamp end facing

toward the rear of the frame and cut off the tie end.

ÒFasten the clutch cable, starter motor lead, negative battery

lead, AC magneto lead and neutral switch lead onto the frame.

Locate the clamp end facing toward the rear of the frame and

cut off the tie end.

ÓPass the neutral switch lead and AC magneto lead on the

inside of the wire harness.

ÔFasten the clutch cable, AC magneto lead and neutral switch

lead onto the frame. Locate the clamp end near the clutch

cable and cut off the tie end.ÕPass the clutch cable and wire harness through the cable

guide.

ÖLocate the couplers in the frame recess.

×Pass the carburetor breather hoses, carburetor overflow hose

and catch tank breather hose so that the hoses do not contact

the rear shock absorber.

ØSecure the coupler by pushing it into the hole in the headlight

unit.

Page 200 of 912

2 - 107

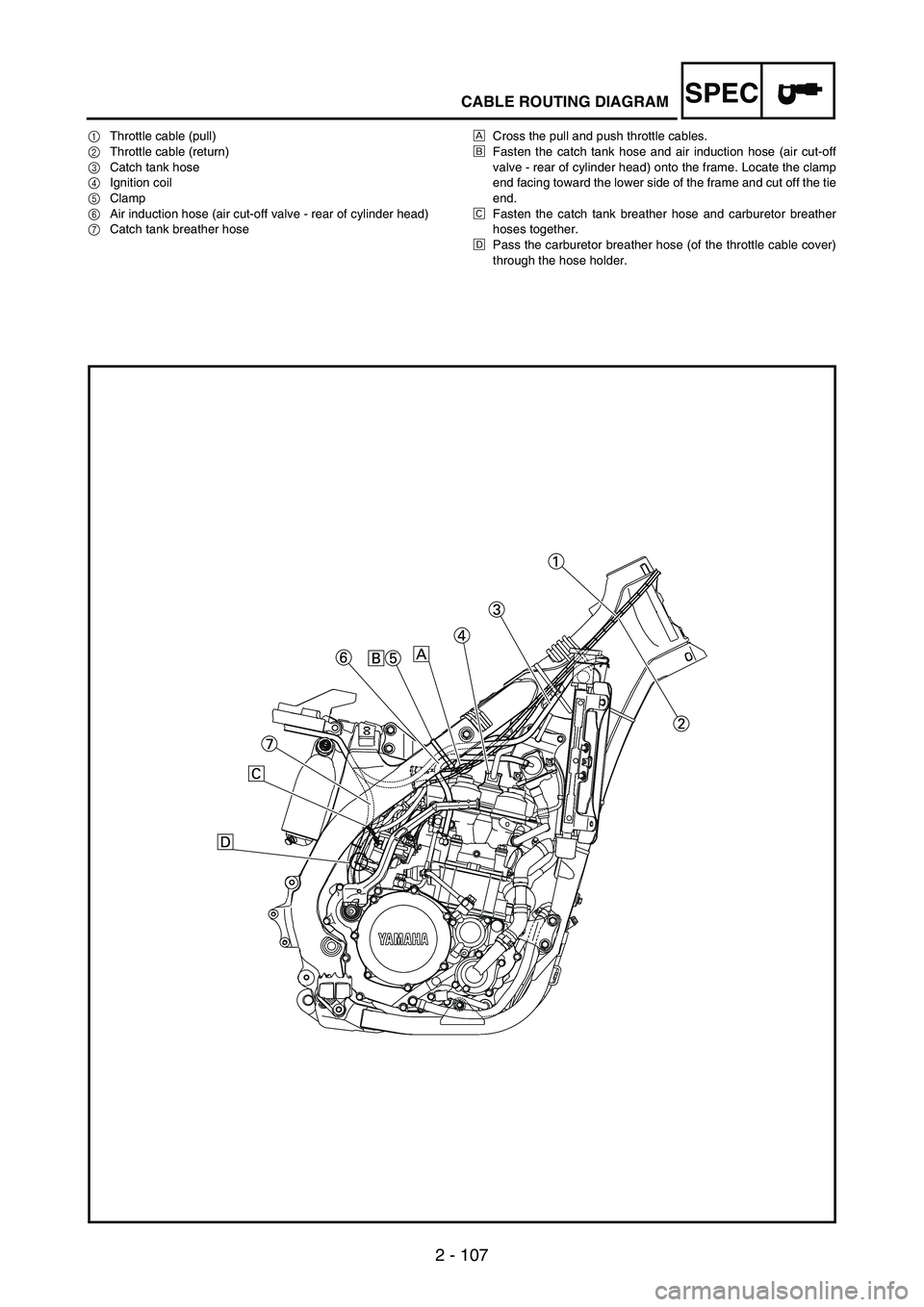

SPECCABLE ROUTING DIAGRAM

1Throttle cable (pull)

2Throttle cable (return)

3Catch tank hose

4Ignition coil

5Clamp

6Air induction hose (air cut-off valve - rear of cylinder head)

7Catch tank breather hoseÈCross the pull and push throttle cables.

ÉFasten the catch tank hose and air induction hose (air cut-off

valve - rear of cylinder head) onto the frame. Locate the clamp

end facing toward the lower side of the frame and cut off the tie

end.

ÊFasten the catch tank breather hose and carburetor breather

hoses together.

ËPass the carburetor breather hose (of the throttle cable cover)

through the hose holder.

Page 204 of 912

SPEC

2 - 111

CABLE ROUTING DIAGRAM

1Clamp

2Positive battery lead

3Battery

4Negative battery lead

5Taillight coupler

6CDI unit coupler (6-pin)

7CDI unit coupler (3-pin)

8CDI unit coupler (6-pin)ÈFasten the wire harness, negative battery lead and starter

motor lead to the upper engine bracket (left side). Locate the

clamp end facing toward the upper side of the frame with the

tie end cut off on the inside of the frame.

ÉFasten the wire harness, negative battery lead and starter

motor lead to the upper engine bracket (left side). Locate the

clamp end facing toward the upper side of the frame with the

tie end cut off on the inside of the frame. Clamp the wire har-

ness and negative lead at the marking.

ÊPass the starter motor lead through the hole in the relay

holder.

ËFit the cover securely.

ÌConnect the wire harness to the starter relay.

Page 206 of 912

SPEC

2 - 113

CABLE ROUTING DIAGRAM

ÍFasten the catch tank breather hose

and catch tank hose to the rear frame.

Clamp them close to where they are

joined to the frame. Fasten the pipe

tightly enough not to crush it. Locate the

clamp end facing toward the rear of the

frame with the tie end facing downward.

ÎFasten the (three) CDI unit leads and

taillight lead to the rear frame. Locate

the clamp end facing toward the upper

side of the frame and cut off the tie end.

ÏConnect the negative battery lead to

the battery negative terminal.

ÐConnect the negative battery lead to

the wire harness.ÑFasten the wire harness to the rear

frame. Locate the clamp end facing

toward the upper side of the frame and

the tie end toward the inside of the

frame. Clamp the wire harness at the

marking.

ÒPass the wire harness, starter relay

lead, starting circuit cut-off relay lead

and negative battery lead through the

hole in the relay holder.

ÓFasten the (three) CDI unit leads and

taillight lead to the rear frame. Locate

the clamp end facing toward the lower

side of the frame and cut off the tie end.ÔFasten the taillight lead to the rear

frame. Locate the clamp end facing

toward the upper side of the frame and

cut off the time end.

ÕDo not allow the taillight lead to

slacken.

ÖLocate the CDI unit lead between the

CDI unit and rear fender.

×Locate the CDI unit coupler in the clear-

ance between the upper side of the CDI

unit and lower side of the catch tank

stay.

ØLocate the CDI unit lead between the

CDI unit and rear frame.

Page 210 of 912

2 - 117

SPECCABLE ROUTING DIAGRAM

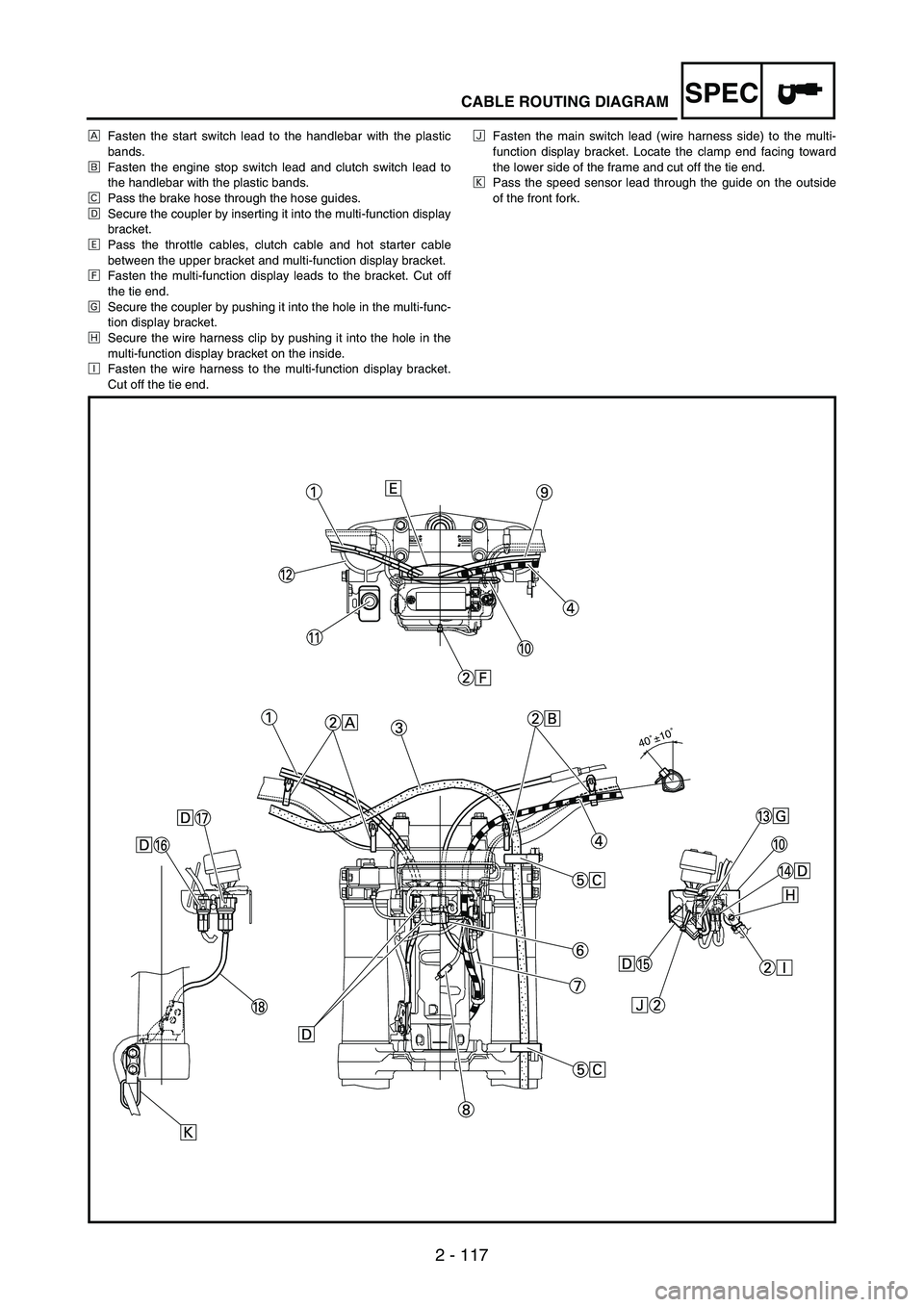

ÈFasten the start switch lead to the handlebar with the plastic

bands.

ÉFasten the engine stop switch lead and clutch switch lead to

the handlebar with the plastic bands.

ÊPass the brake hose through the hose guides.

ËSecure the coupler by inserting it into the multi-function display

bracket.

ÌPass the throttle cables, clutch cable and hot starter cable

between the upper bracket and multi-function display bracket.

ÍFasten the multi-function display leads to the bracket. Cut off

the tie end.

ÎSecure the coupler by pushing it into the hole in the multi-func-

tion display bracket.

ÏSecure the wire harness clip by pushing it into the hole in the

multi-function display bracket on the inside.

ÐFasten the wire harness to the multi-function display bracket.

Cut off the tie end.ÑFasten the main switch lead (wire harness side) to the multi-

function display bracket. Locate the clamp end facing toward

the lower side of the frame and cut off the tie end.

ÒPass the speed sensor lead through the guide on the outside

of the front fork.

40˚±10˚

Page 244 of 912

3 - 33

INSP

ADJ

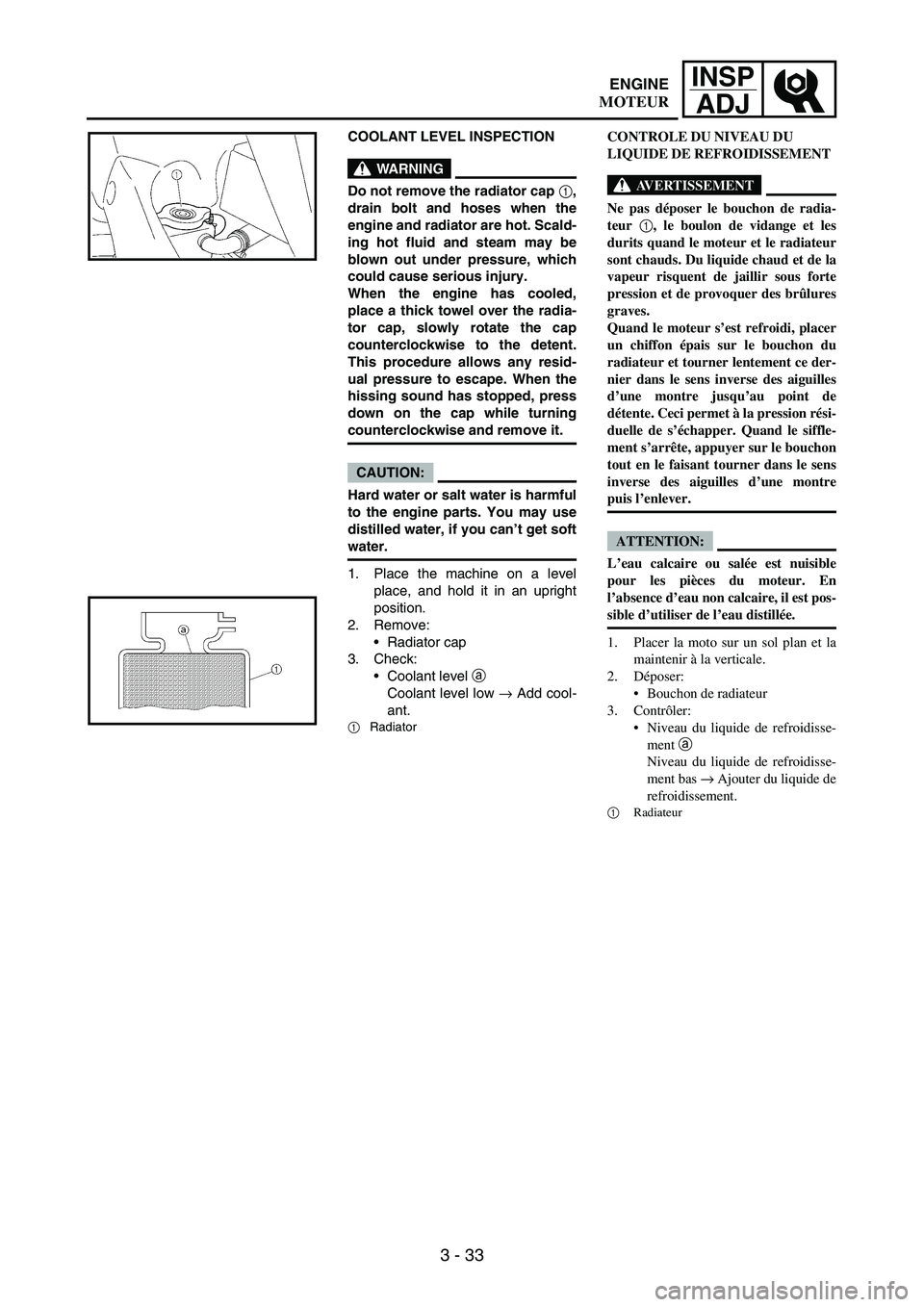

COOLANT LEVEL INSPECTION

WARNING

Do not remove the radiator cap 1,

drain bolt and hoses when the

engine and radiator are hot. Scald-

ing hot fluid and steam may be

blown out under pressure, which

could cause serious injury.

When the engine has cooled,

place a thick towel over the radia-

tor cap, slowly rotate the cap

counterclockwise to the detent.

This procedure allows any resid-

ual pressure to escape. When the

hissing sound has stopped, press

down on the cap while turning

counterclockwise and remove it.

CAUTION:

Hard water or salt water is harmful

to the engine parts. You may use

distilled water, if you can’t get soft

water.

1. Place the machine on a level

place, and hold it in an upright

position.

2. Remove:

Radiator cap

3. Check:

Coolant level

a

Coolant level low

→ Add cool-

ant.

1Radiator

CONTROLE DU NIVEAU DU

LIQUIDE DE REFROIDISSEMENT

AVERTISSEMENT

Ne pas déposer le bouchon de radia-

teur 1, le boulon de vidange et les

durits quand le moteur et le radiateur

sont chauds. Du liquide chaud et de la

vapeur risquent de jaillir sous forte

pression et de provoquer des brûlures

graves.

Quand le moteur s’est refroidi, placer

un chiffon épais sur le bouchon du

radiateur et tourner lentement ce der-

nier dans le sens inverse des aiguilles

d’une montre jusqu’au point de

détente. Ceci permet à la pression rési-

duelle de s’échapper. Quand le siffle-

ment s’arrête, appuyer sur le bouchon

tout en le faisant tourner dans le sens

inverse des aiguilles d’une montre

puis l’enlever.

ATTENTION:

L’eau calcaire ou salée est nuisible

pour les pièces du moteur. En

l’absence d’eau non calcaire, il est pos-

sible d’utiliser de l’eau distillée.

1. Placer la moto sur un sol plan et la

maintenir à la verticale.

2. Déposer:

Bouchon de radiateur

3. Contrôler:

Niveau du liquide de refroidisse-

ment a

Niveau du liquide de refroidisse-

ment bas → Ajouter du liquide de

refroidissement.

1

Radiateur

ENGINE

MOTEUR

Page 288 of 912

3 - 77

INSP

ADJ

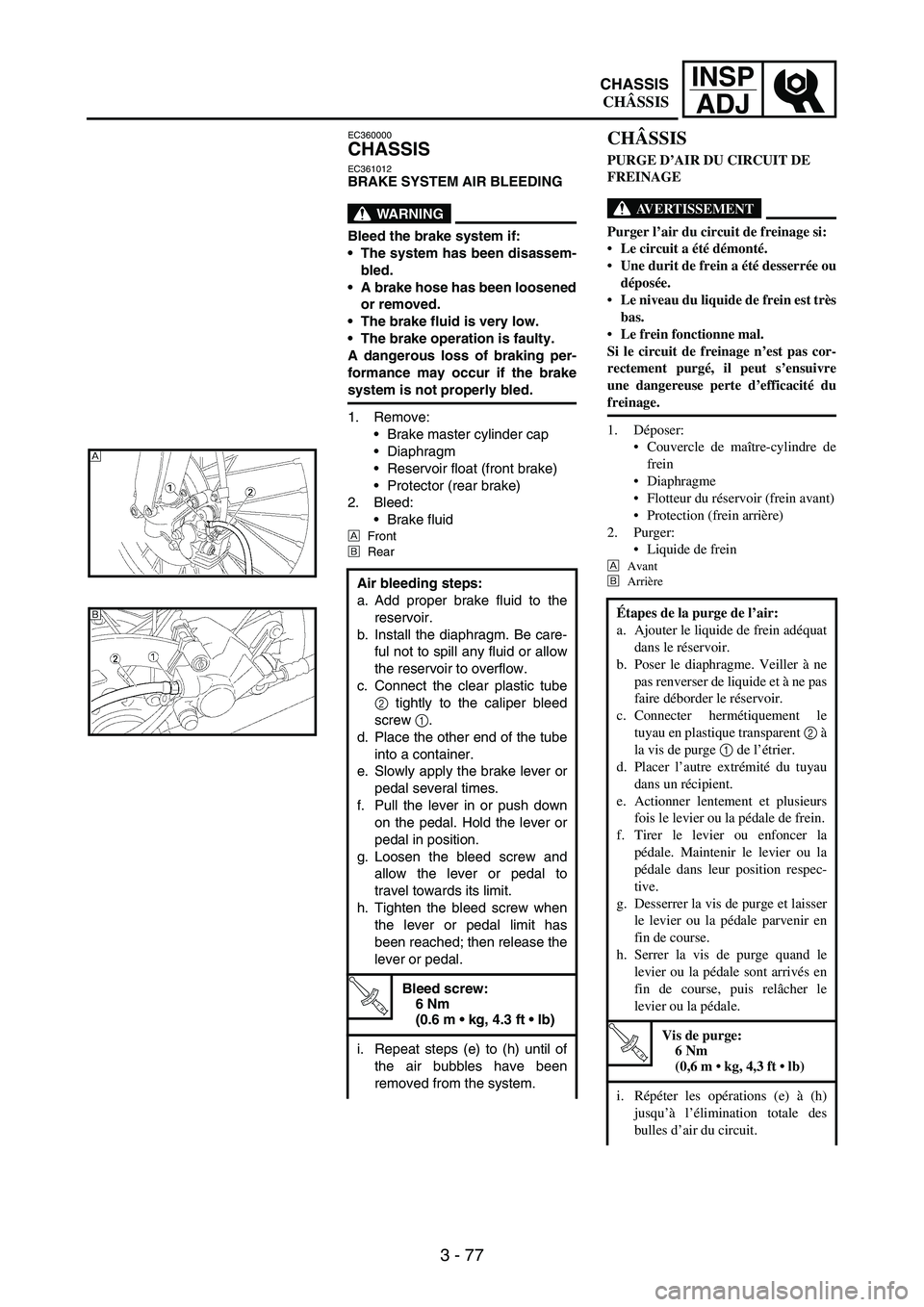

EC360000

CHASSIS

EC361012BRAKE SYSTEM AIR BLEEDING

WARNING

Bleed the brake system if:

The system has been disassem-

bled.

A brake hose has been loosened

or removed.

The brake fluid is very low.

The brake operation is faulty.

A dangerous loss of braking per-

formance may occur if the brake

system is not properly bled.

1. Remove:

Brake master cylinder cap

Diaphragm

Reservoir float (front brake)

Protector (rear brake)

2. Bleed:

Brake fluid

ÈFront

ÉRear

Air bleeding steps:

a. Add proper brake fluid to the

reservoir.

b. Install the diaphragm. Be care-

ful not to spill any fluid or allow

the reservoir to overflow.

c. Connect the clear plastic tube

2 tightly to the caliper bleed

screw

1.

d. Place the other end of the tube

into a container.

e. Slowly apply the brake lever or

pedal several times.

f. Pull the lever in or push down

on the pedal. Hold the lever or

pedal in position.

g. Loosen the bleed screw and

allow the lever or pedal to

travel towards its limit.

h. Tighten the bleed screw when

the lever or pedal limit has

been reached; then release the

lever or pedal.

T R..

Bleed screw:

6 Nm

(0.6 m kg, 4.3 ft lb)

i. Repeat steps (e) to (h) until of

the air bubbles have been

removed from the system.

È

É

CHÂSSIS

PURGE D’AIR DU CIRCUIT DE

FREINAGE

AVERTISSEMENT

Purger l’air du circuit de freinage si:

Le circuit a été démonté.

Une durit de frein a été desserrée ou

déposée.

Le niveau du liquide de frein est très

bas.

Le frein fonctionne mal.

Si le circuit de freinage n’est pas cor-

rectement purgé, il peut s’ensuivre

une dangereuse perte d’efficacité du

freinage.

1. Déposer:

Couvercle de maître-cylindre de

frein

Diaphragme

Flotteur du réservoir (frein avant)

Protection (frein arrière)

2. Purger:

Liquide de frein

È

Avant

É

Arrière

Étapes de la purge de l’air:

a. Ajouter le liquide de frein adéquat

dans le réservoir.

b. Poser le diaphragme. Veiller à ne

pas renverser de liquide et à ne pas

faire déborder le réservoir.

c. Connecter hermétiquement le

tuyau en plastique transparent 2 à

la vis de purge 1 de l’étrier.

d. Placer l’autre extrémité du tuyau

dans un récipient.

e. Actionner lentement et plusieurs

fois le levier ou la pédale de frein.

f. Tirer le levier ou enfoncer la

pédale. Maintenir le levier ou la

pédale dans leur position respec-

tive.

g. Desserrer la vis de purge et laisser

le levier ou la pédale parvenir en

fin de course.

h. Serrer la vis de purge quand le

levier ou la pédale sont arrivés en

fin de course, puis relâcher le

levier ou la pédale.

T R..

Vis de purge:

6 Nm

(0,6 m kg, 4,3 ft lb)

i. Répéter les opérations (e) à (h)

jusqu’à l’élimination totale des

bulles d’air du circuit.

CHASSIS

CHÂSSIS