clutch YAMAHA WR 250F 2008 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: WR 250F, Model: YAMAHA WR 250F 2008Pages: 224, PDF Size: 13.66 MB

Page 125 of 224

5-29

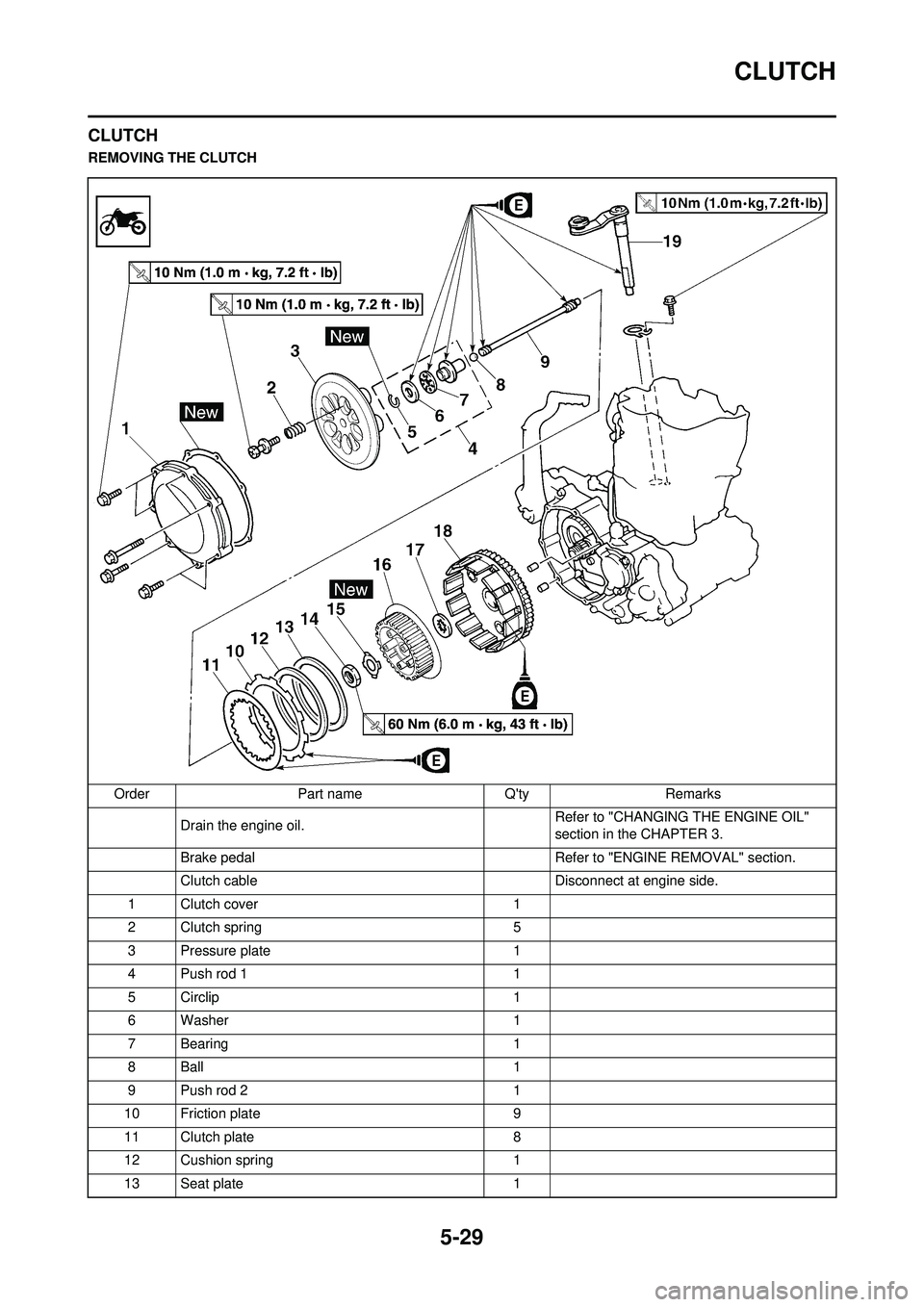

CLUTCH

CLUTCH

REMOVING THE CLUTCHOrder Part name Q'ty Remarks Drain the engine oil. Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

Brake pedal Refer to "ENGINE REMOVAL" section.

Clutch cable Disconnect at engine side.

1 Clutch cover 1

2 Clutch spring 5

3 Pressure plate 1

4 Push rod 1 1

5 Circlip 1

6 Washer 1

7 Bearing 1

8Ball 1

9 Push rod 2 1

10 Friction plate 9

11 Clutch plate 8

12 Cushion spring 1

13 Seat plate 1

Page 126 of 224

5-30

CLUTCH

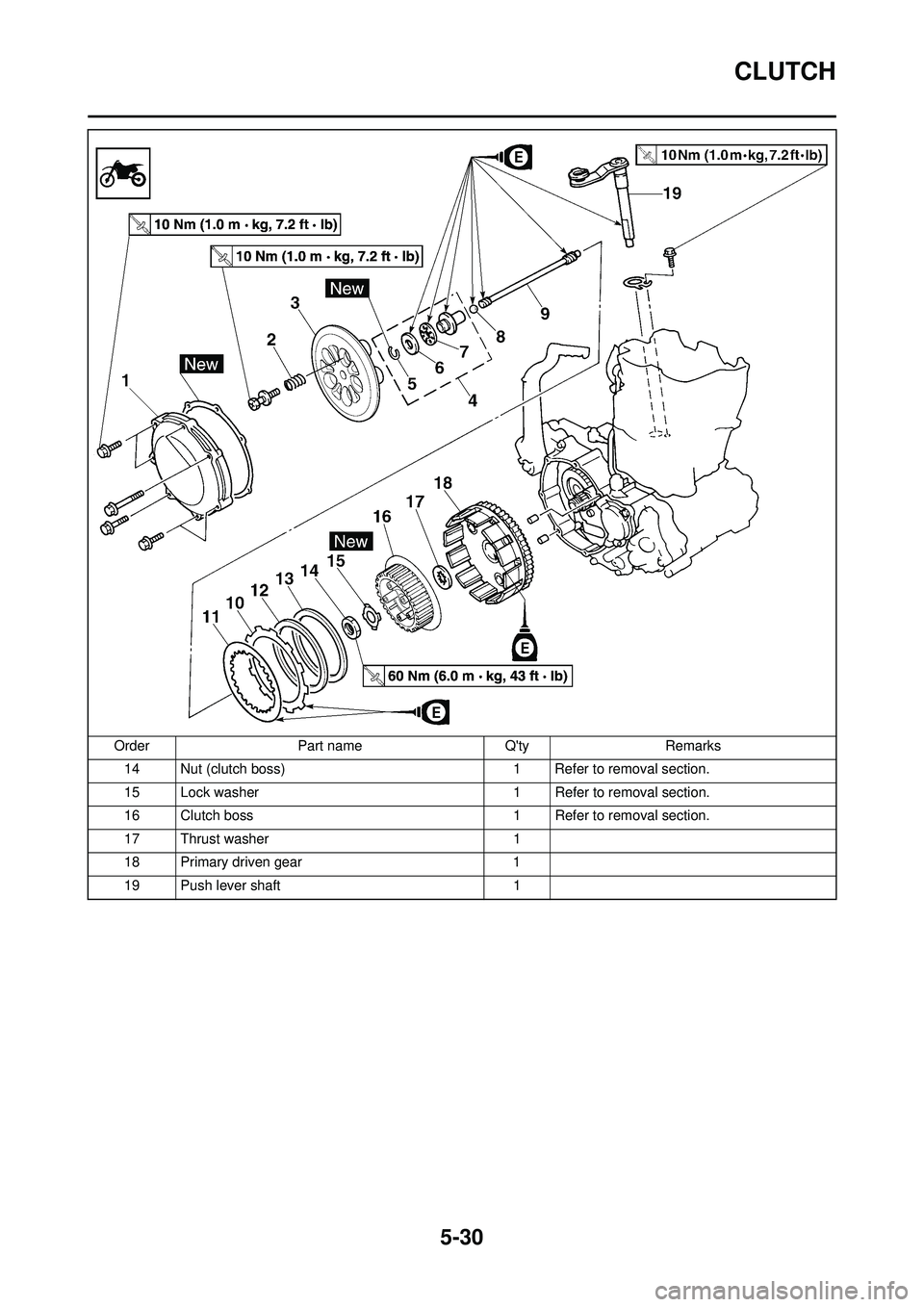

14 Nut (clutch boss)1 Refer to removal section.

15 Lock washer 1 Refer to removal section.

16 Clutch boss 1 Refer to removal section.

17 Thrust washer 1

18 Primary driven gear 1

19 Push lever shaft 1

Order

Part name Q'tyRemarks

Page 127 of 224

5-31

CLUTCH

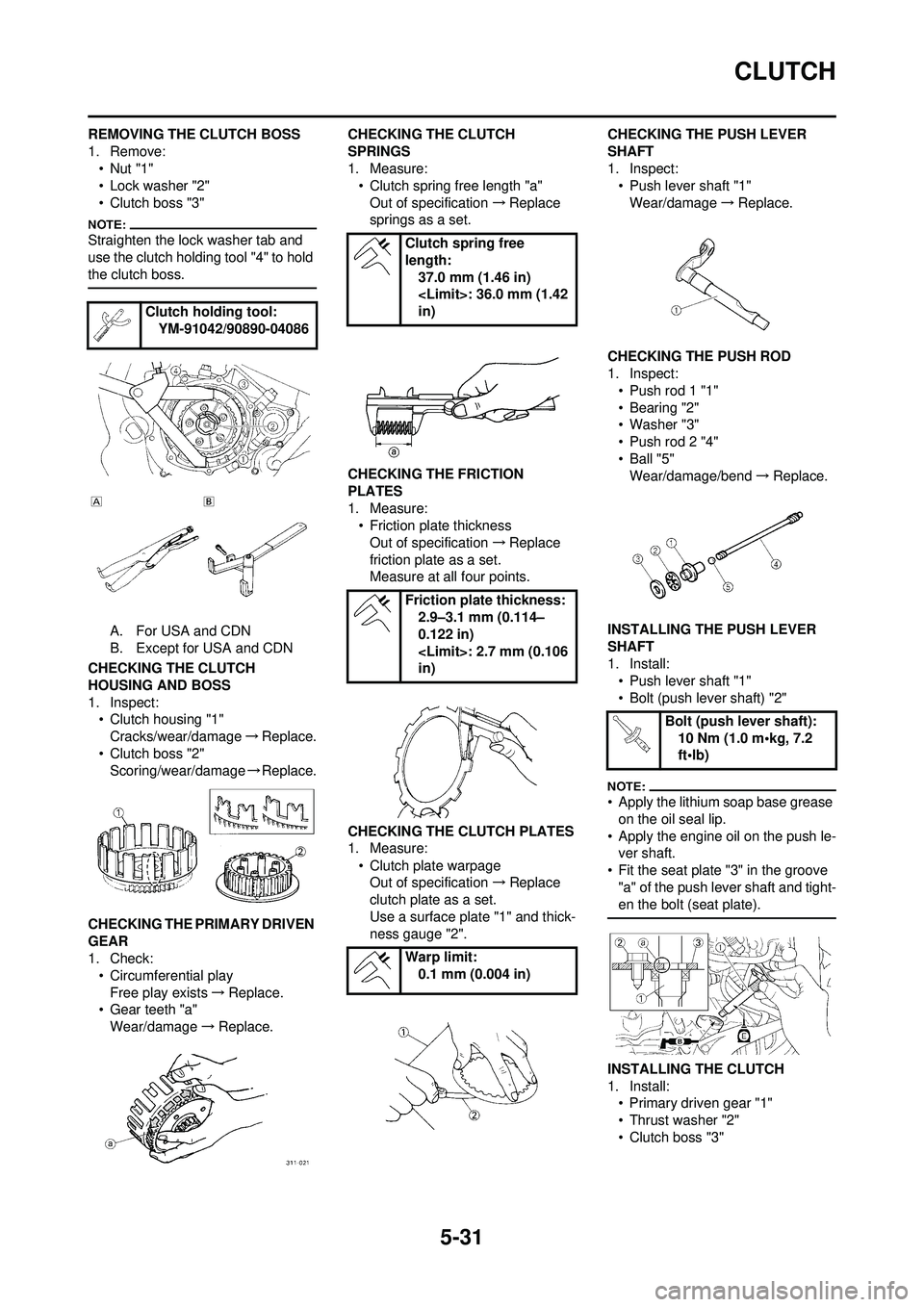

REMOVING THE CLUTCH BOSS

1. Remove:•Nut "1"

• Lock washer "2"

• Clutch boss "3"

Straighten the lock washer tab and

use the clutch holding tool "4" to hold

the clutch boss.

A. For USA and CDN

B. Except for USA and CDN

CHECKING THE CLUTCH

HOUSING AND BOSS

1. Inspect: • Clutch housing "1"

Cracks/wear/damage →Replace.

• Clutch boss "2" Scoring/wear/damage →Replace.

CHECKING THE PRIMARY DRIVEN

GEAR

1. Check: • Circumferential play

Free play exists →Replace.

• Gear teeth "a" Wear/damage →Replace. CHECKING THE CLUTCH

SPRINGS

1. Measure:

• Clutch spring free length "a"

Out of specification →Replace

springs as a set.

CHECKING THE FRICTION

PLATES

1. Measure: • Friction plate thickness

Out of specification →Replace

friction plate as a set.

Measure at all four points.

CHECKING THE CLUTCH PLATES

1. Measure: • Clutch plate warpageOut of specification →Replace

clutch plate as a set.

Use a surface plate "1" and thick-

ness gauge "2". CHECKING THE PUSH LEVER

SHAFT

1. Inspect:

• Push lever shaft "1"

Wear/damage →Replace.

CHECKING THE PUSH ROD

1. Inspect: • Push rod 1 "1"

• Bearing "2"

• Washer "3"

• Push rod 2 "4"

•Ball "5"Wear/damage/bend →Replace.

INSTALLING THE PUSH LEVER

SHAFT

1. Install: • Push lever shaft "1"

• Bolt (push lever shaft) "2"

• Apply the lithium soap base grease

on the oil seal lip.

• Apply the engine oil on the push le- ver shaft.

• Fit the seat plate "3" in the groove "a" of the push lever shaft and tight-

en the bolt (seat plate).

INSTALLING THE CLUTCH

1. Install:• Primary driven gear "1"

• Thrust washer "2"

• Clutch boss "3"

Clutch holding tool:

YM-91042/90890-04086

Clutch spring free

length:

37.0 mm (1.46 in)

in)

Friction plate thickness: 2.9–3.1 mm (0.114–

0.122 in)

in)

Warp limit: 0.1 mm (0.004 in)

Bolt (push lever shaft): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 128 of 224

5-32

CLUTCH

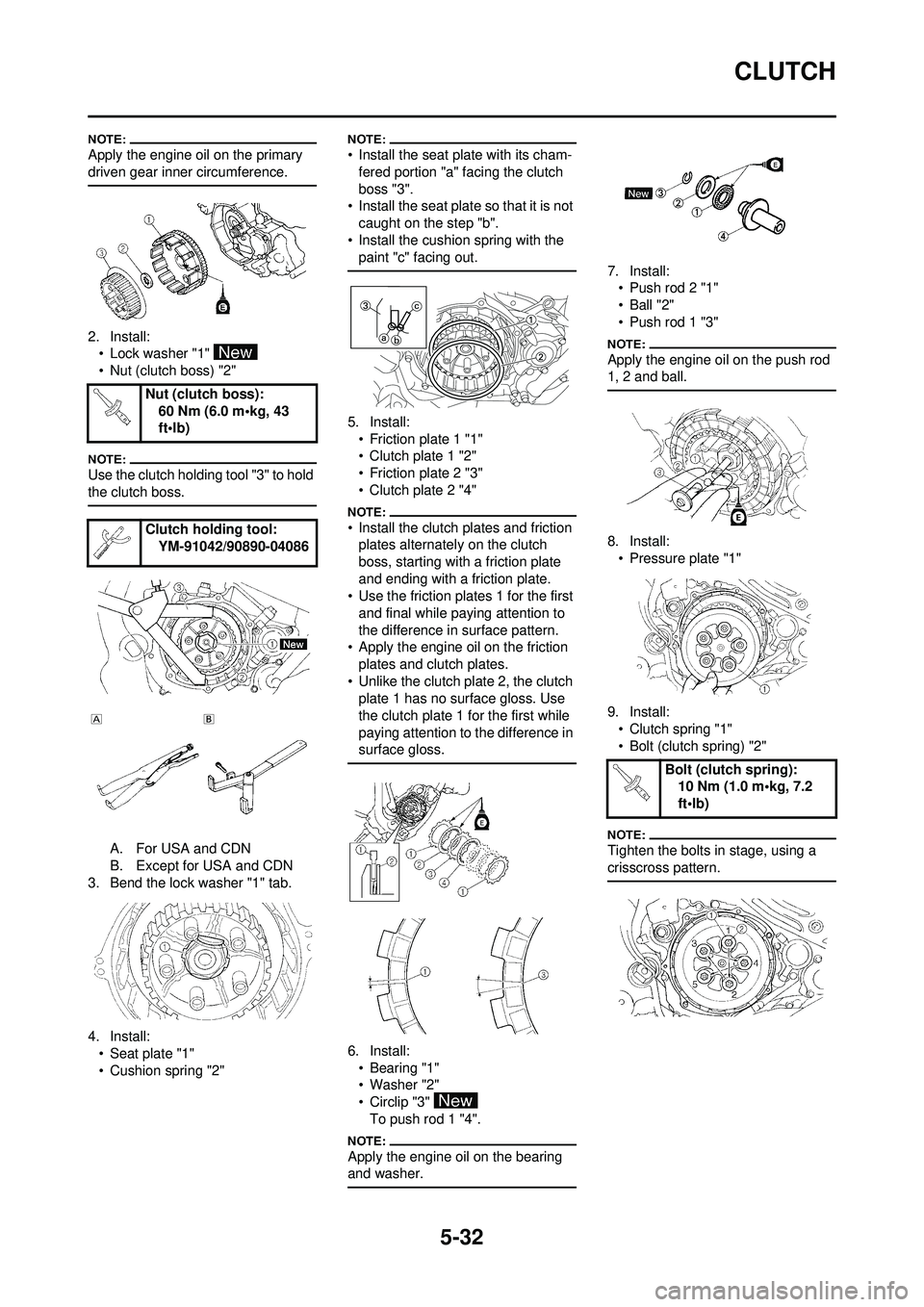

Apply the engine oil on the primary

driven gear inner circumference.

2. Install:• Lock washer "1"

• Nut (clutch boss) "2"

Use the clutch holding tool "3" to hold

the clutch boss.

A. For USA and CDN

B. Except for USA and CDN

3. Bend the lock washer "1" tab.

4. Install: • Seat plate "1"

• Cushion spring "2"

• Install the seat plate with its cham-fered portion "a" facing the clutch

boss "3".

• Install the seat plate so that it is not caught on the step "b".

• Install the cushion spring with the paint "c" facing out.

5. Install:

• Friction plate 1 "1"

• Clutch plate 1 "2"

• Friction plate 2 "3"

• Clutch plate 2 "4"

• Install the clutch plates and friction plates alternately on the clutch

boss, starting with a friction plate

and ending with a friction plate.

• Use the friction plates 1 for the first and final while paying attention to

the difference in surface pattern.

• Apply the engine oil on the friction plates and clutch plates.

• Unlike the clutch pl ate 2, the clutch

plate 1 has no surface gloss. Use

the clutch plate 1 for the first while

paying attention to the difference in

surface gloss.

6. Install:

•Bearing "1"

• Washer "2"

• Circlip "3" To push rod 1 "4".

Apply the engine oil on the bearing

and washer.

7. Install:• Push rod 2 "1"

•Ball "2"

• Push rod 1 "3"

Apply the engine oil on the push rod

1, 2 and ball.

8. Install:• Pressure plate "1"

9. Install: • Clutch spring "1"

• Bolt (clutch spring) "2"

Tighten the bolts in stage, using a

crisscross pattern.

Nut (clutch boss): 60 Nm (6.0 m•kg, 43

ft•lb)

Clutch holding tool: YM-91042/90890-04086

Bolt (clutch spring):10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 129 of 224

5-33

CLUTCH

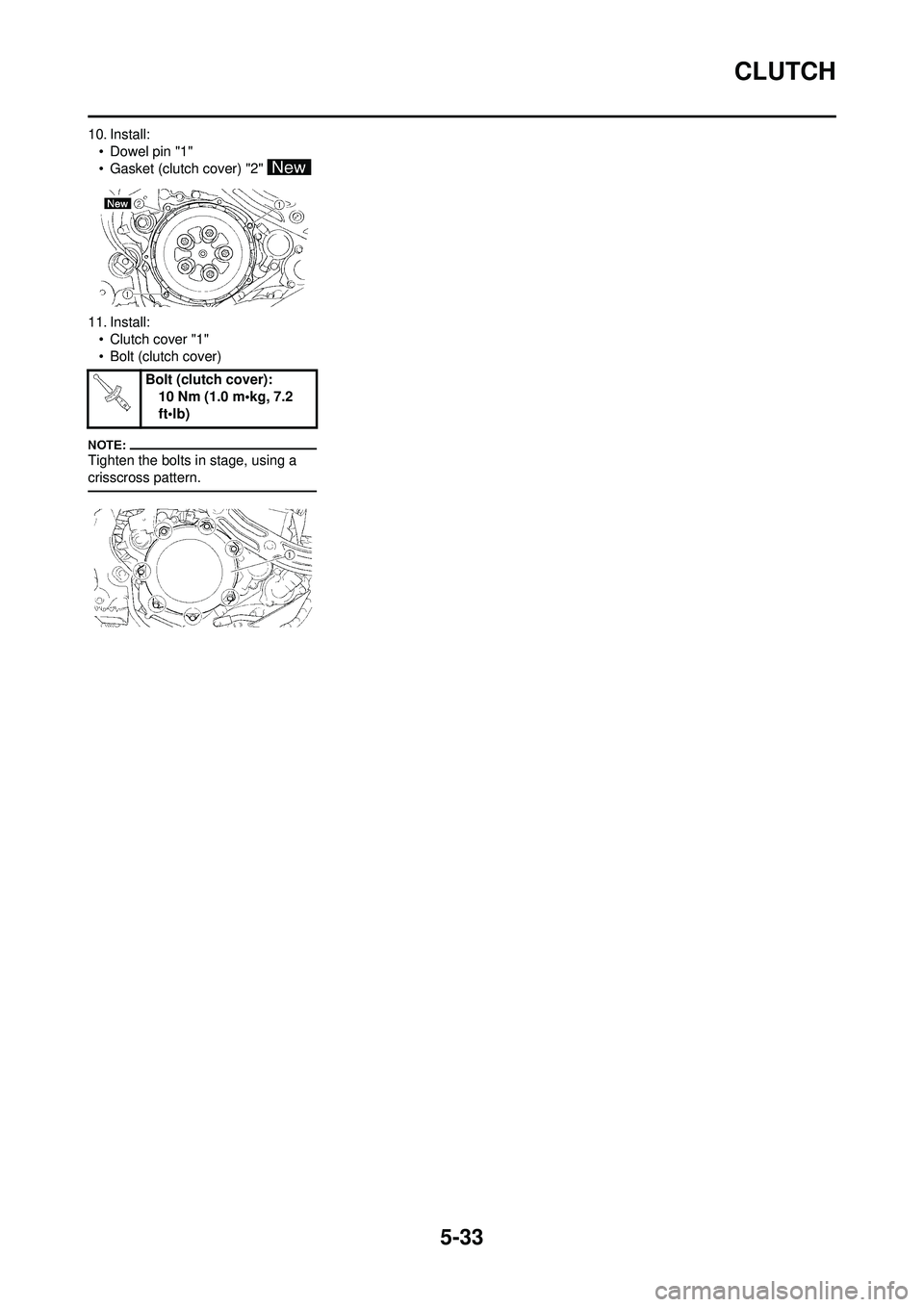

10. Install:• Dowel pin "1"

• Gasket (clutch cover) "2"

11. Install: • Clutch cover "1"

• Bolt (clutch cover)

Tighten the bolts in stage, using a

crisscross pattern.

Bolt (clutch cover): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 134 of 224

5-38

BALANCER

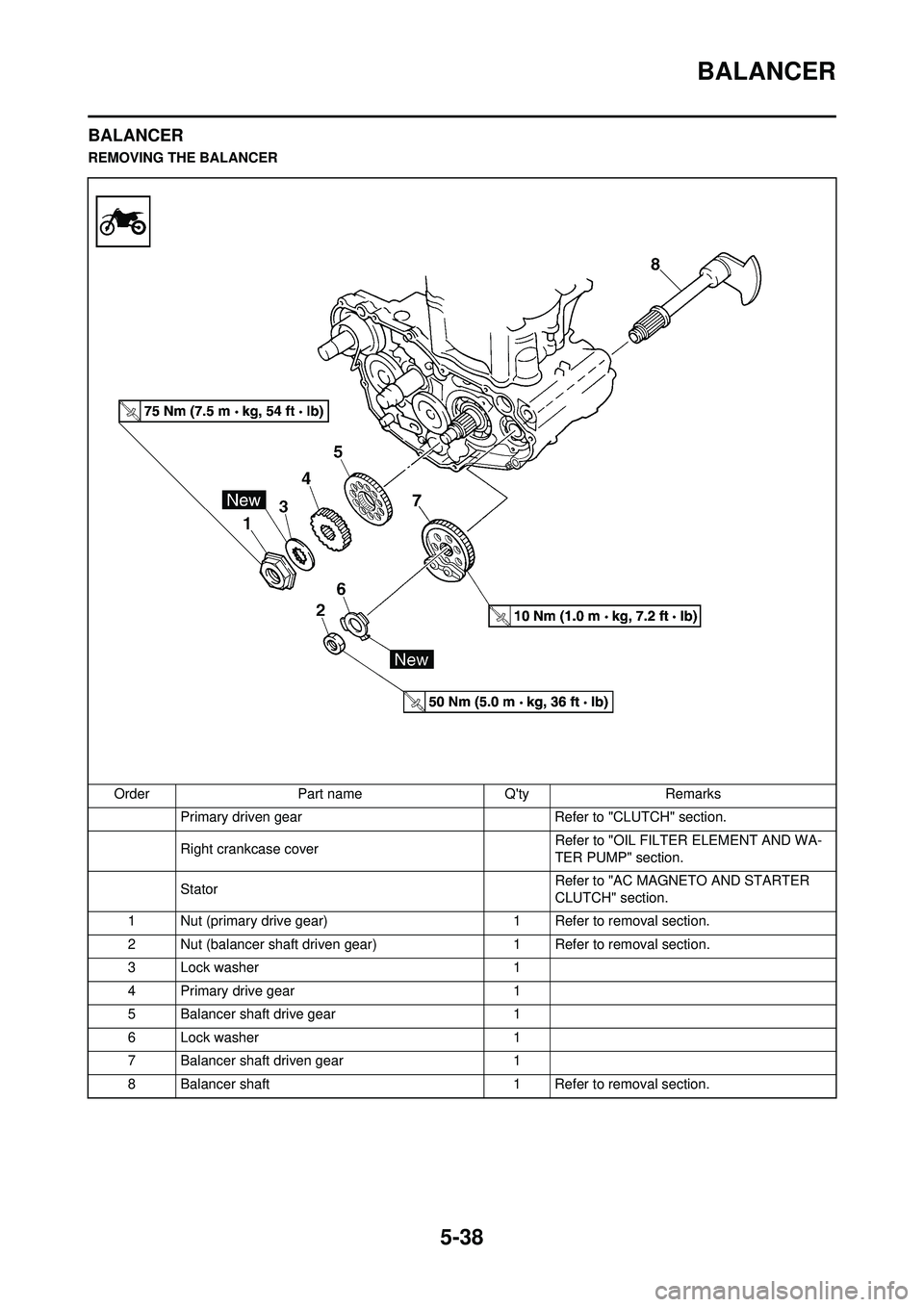

BALANCER

REMOVING THE BALANCEROrder Part name Q'ty Remarks Primary driven gear Refer to "CLUTCH" section.

Right crankcase cover Refer to "OIL FILTER ELEMENT AND WA-

TER PUMP" section.

Stator Refer to "AC MAGNETO AND STARTER

CLUTCH" section.

1 Nut (primary drive gear) 1 R efer to removal section.

2 Nut (balancer shaft driven gear) 1 Refer to removal section.

3 Lock washer 1

4 Primary drive gear 1

5 Balancer shaft drive gear 1

6 Lock washer 1

7 Balancer shaft driven gear 1

8 Balancer shaft 1 Refer to removal section.

Page 136 of 224

5-40

OIL PUMP

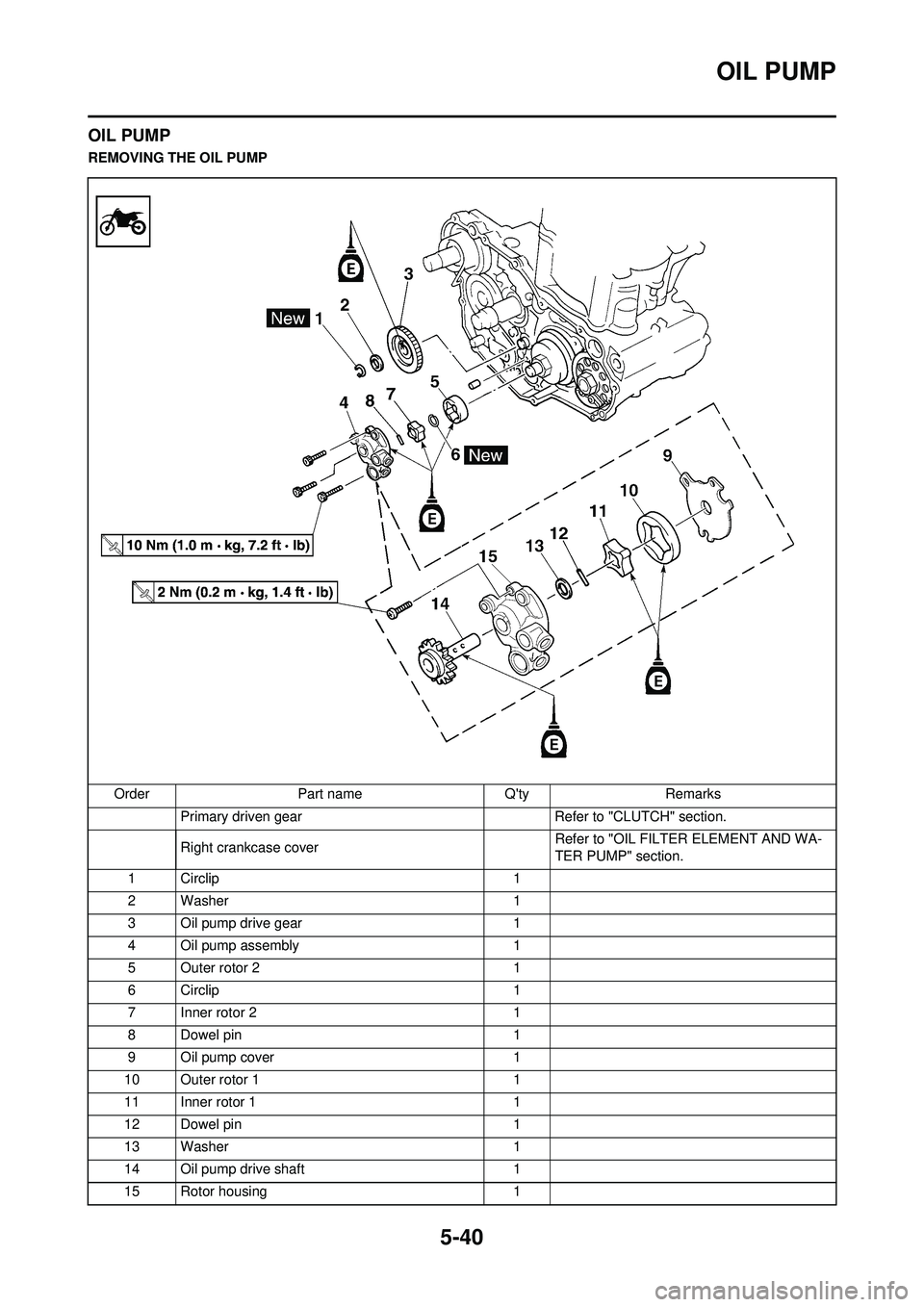

OIL PUMP

REMOVING THE OIL PUMPOrder Part name Q'ty Remarks Primary driven gear Refer to "CLUTCH" section.

Right crankcase cover Refer to "OIL FILTER ELEMENT AND WA-

TER PUMP" section.

1 Circlip 1

2 Washer 1

3 Oil pump drive gear 1

4 Oil pump assembly 1

5 Outer rotor 2 1

6 Circlip 1

7 Inner rotor 2 1

8 Dowel pin 1

9 Oil pump cover 1

10 Outer rotor 1 1

11 Inner rotor 1 1

12 Dowel pin 1

13 Washer 1

14 Oil pump drive shaft 1

15 Rotor housing 1

Page 142 of 224

5-46

KICK SHAFT AND SHIFT SHAFT

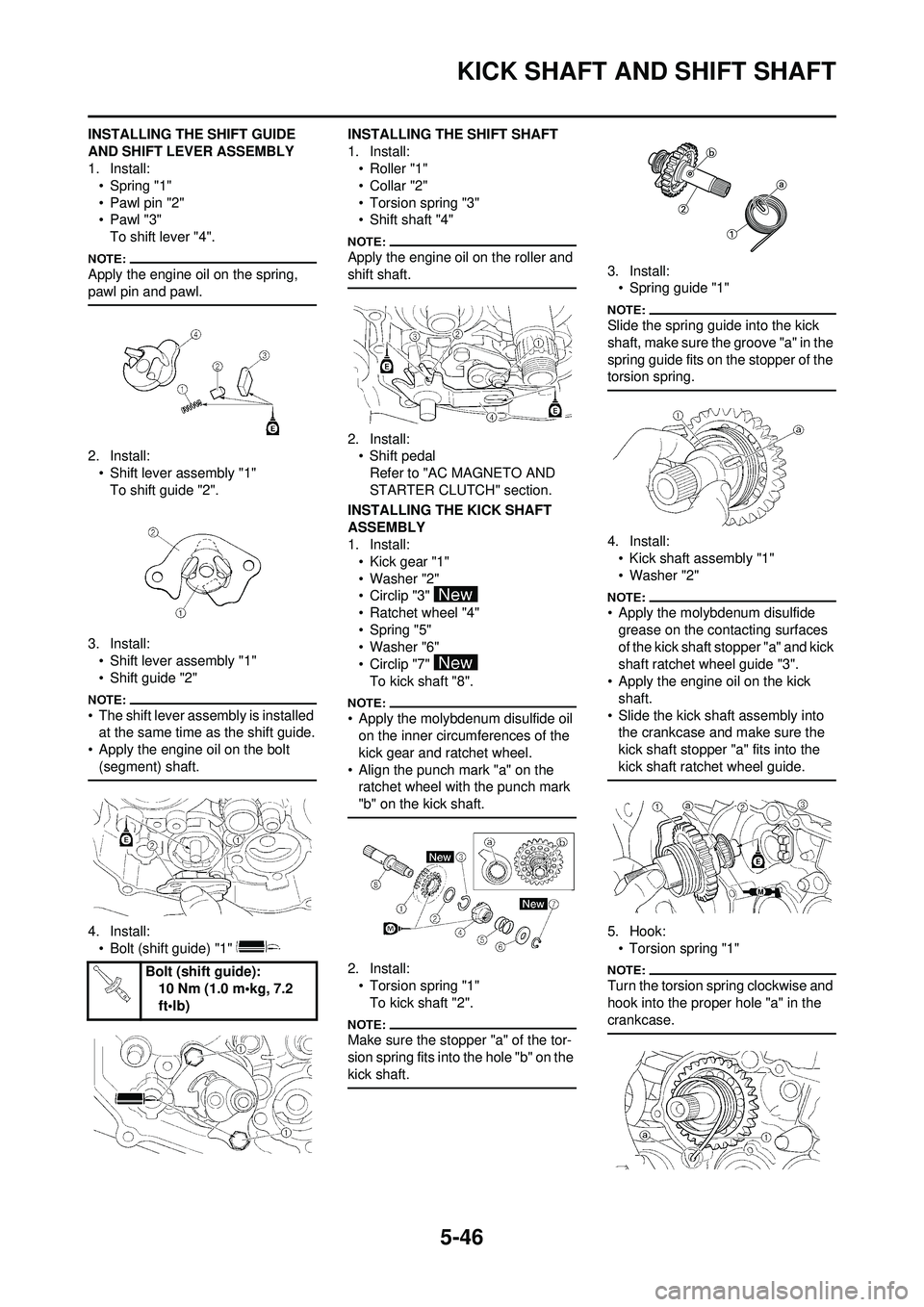

INSTALLING THE SHIFT GUIDE

AND SHIFT LEVER ASSEMBLY

1. Install:• Spring "1"

• Pawl pin "2"

•Pawl "3"To shift lever "4".

Apply the engine oil on the spring,

pawl pin and pawl.

2. Install:• Shift lever assembly "1"

To shift guide "2".

3. Install: • Shift lever assembly "1"

• Shift guide "2"

• The shift lever assembly is installed at the same time as the shift guide.

• Apply the engine oil on the bolt

(segment) shaft.

4. Install:• Bolt (shift guide) "1" INSTALLING TH

E SHIFT SHAFT

1. Install: • Roller "1"

• Collar "2"

• Torsion spring "3"

• Shift shaft "4"

Apply the engine oil on the roller and

shift shaft.

2. Install:• Shift pedalRefer to "AC MAGNETO AND

STARTER CLUTCH" section.

INSTALLING THE KICK SHAFT

ASSEMBLY

1. Install: • Kick gear "1"

• Washer "2"

• Circlip "3"

• Ratchet wheel "4"

• Spring "5"

• Washer "6"

• Circlip "7" To kick shaft "8".

• Apply the molybdenum disulfide oil on the inner circumferences of the

kick gear and ratchet wheel.

• Align the punch mark "a" on the ratchet wheel with the punch mark

"b" on the kick shaft.

2. Install:• Torsion spring "1"

To kick shaft "2".

Make sure the stopper "a" of the tor-

sion spring fits into the hole "b" on the

kick shaft.

3. Install:• Spring guide "1"

Slide the spring guide into the kick

shaft, make sure the groove "a" in the

spring guide fits on the stopper of the

torsion spring.

4. Install:• Kick shaft assembly "1"

• Washer "2"

• Apply the molybdenum disulfide

grease on the contacting surfaces

of the kick shaft stopper "a" and kick

shaft ratchet wheel guide "3".

• Apply the engine oil on the kick shaft.

• Slide the kick shaft assembly into the crankcase and make sure the

kick shaft stopper "a" fits into the

kick shaft ratchet wheel guide.

5. Hook:• Torsion spring "1"

Turn the torsion spring clockwise and

hook into the proper hole "a" in the

crankcase.Bolt (shift guide):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 144 of 224

5-48

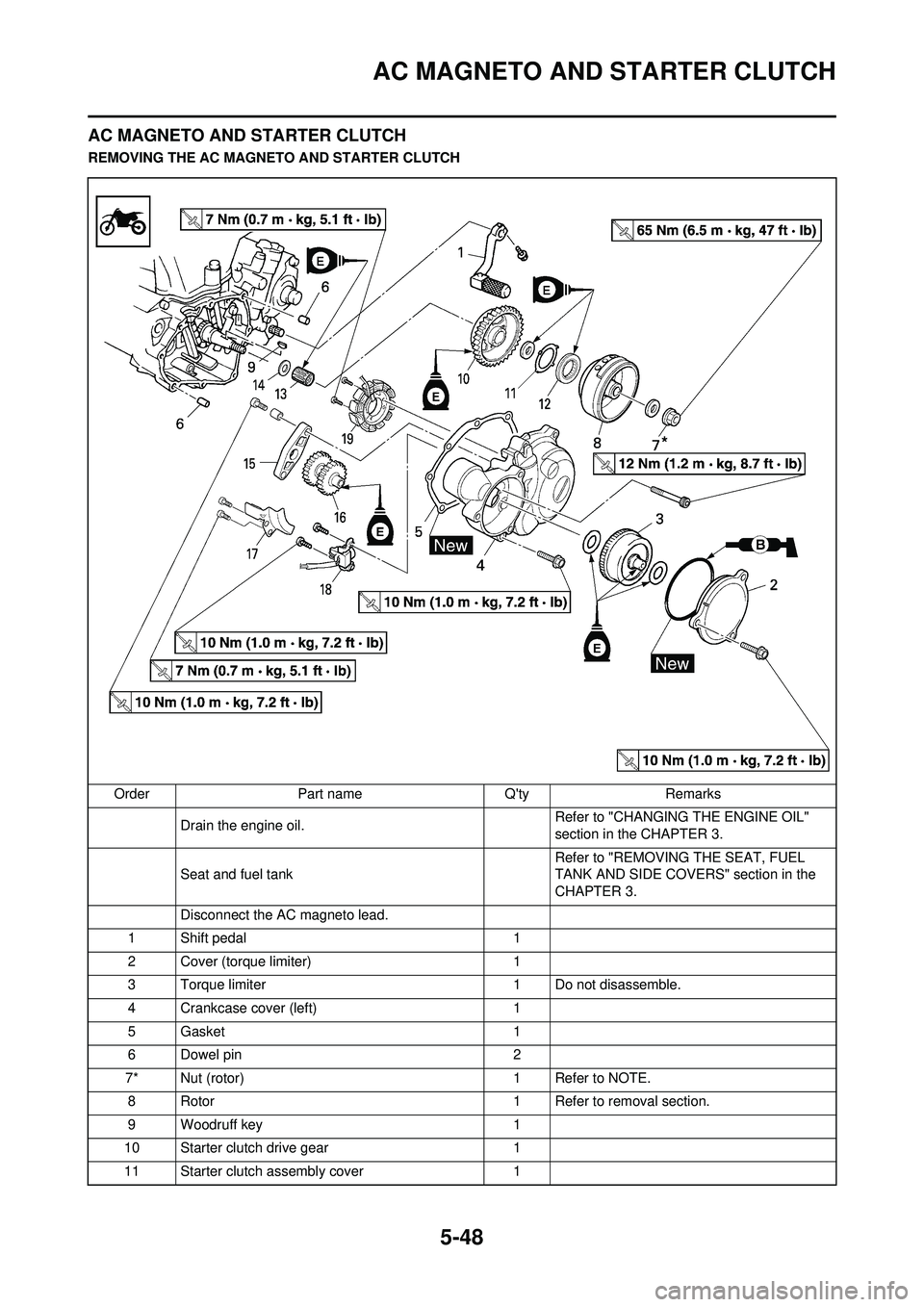

AC MAGNETO AND STARTER CLUTCH

AC MAGNETO AND STARTER CLUTCH

REMOVING THE AC MAGNETO AND STARTER CLUTCHOrder Part name Q'ty Remarks Drain the engine oil. Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

Seat and fuel tank Refer to "REMOVING THE SEAT, FUEL

TANK AND SIDE COVERS" section in the

CHAPTER 3.

Disconnect the AC magneto lead.

1 Shift pedal 1

2 Cover (torque limiter) 1

3 Torque limiter 1 Do not disassemble.

4 Crankcase cover (left) 1

5 Gasket 1

6 Dowel pin 2

7* Nut (rotor) 1 Refer to NOTE.

8 Rotor 1 Refer to removal section.

9 Woodruff key 1

10 Starter clutch drive gear 1

11 Starter clutch assembly cover 1

Page 145 of 224

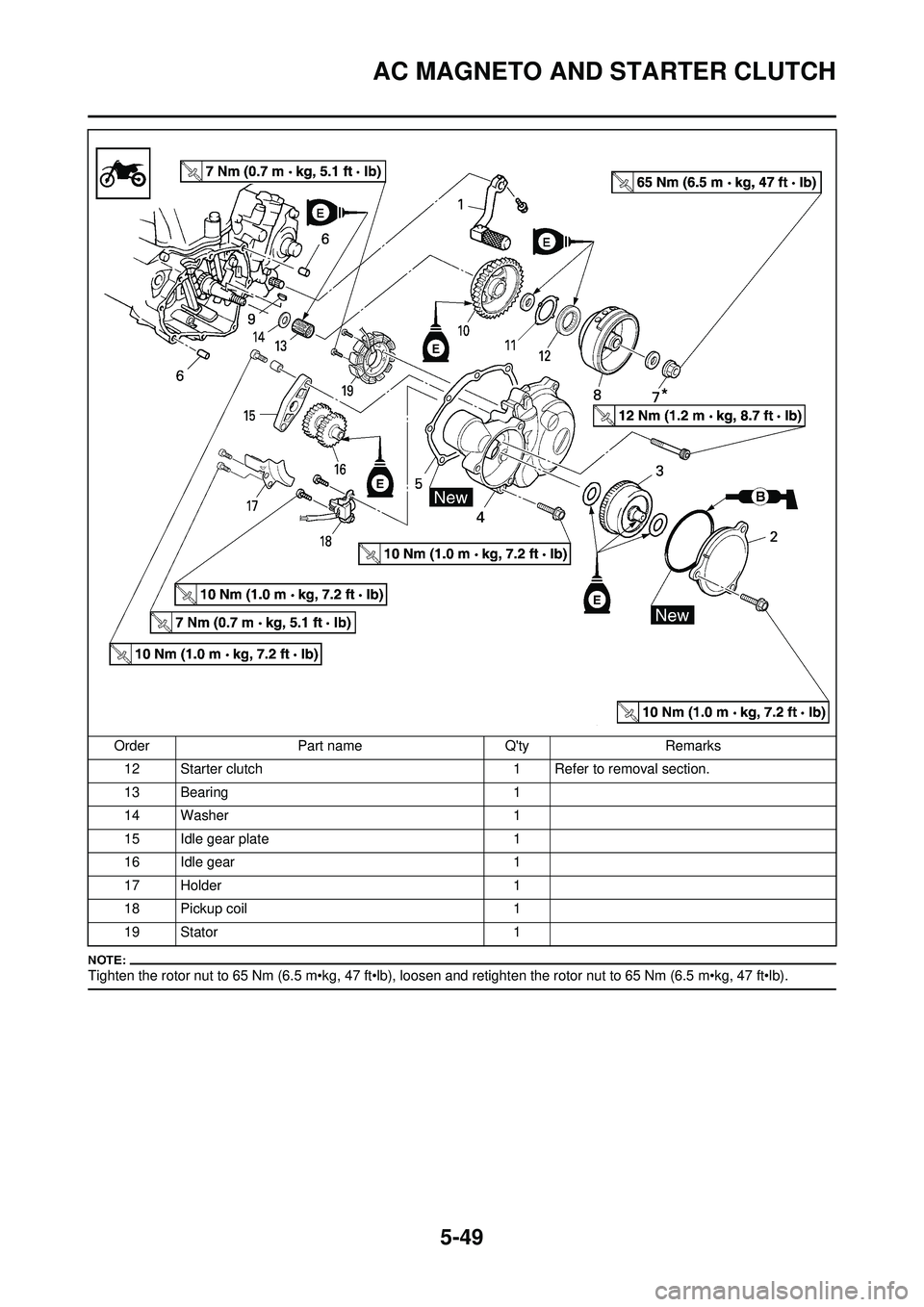

5-49

AC MAGNETO AND STARTER CLUTCH

Tighten the rotor nut to 65 Nm (6.5 m•kg, 47 ft•lb), loosen and retighten the rotor nut to 65 Nm (6.5 m•kg, 47 ft•lb).

12 Starter clutch1 Refer to removal section.

13 Bearing 1

14 Washer 1

15 Idle gear plate 1

16 Idle gear 1

17 Holder 1

18 Pickup coil 1

19 Stator 1

Order

Part name Q'tyRemarks