ECU YAMAHA WR 250F 2008 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: WR 250F, Model: YAMAHA WR 250F 2008Pages: 224, PDF Size: 13.66 MB

Page 7 of 224

TO THE NEW OWNER

This manual will provide you with a

good basic understanding of fea-

tures, operation, and basic mainte-

nance and inspection items of this

machine. Please read this manual

carefully and completely before oper-

ating your new machine. If you have

any questions regarding the opera-

tion or maintenance of your machine,

please consult your Yamaha dealer.

This manual should be considered a

permanent part of this machine and

should remain with it even if the ma-

chine is subsequently sold.

NOTICE

Some data in this manual may be-

come outdated due to improve-

ments made to this model in the

future. If there is any question you

have regarding this manual or your

machine, please consult your

Yamaha dealer.

F.I.M. MACHINE WEIGHTS

Weights of machines without fuel

The minimum weights for motocross

machines are:

for the class 125 cc:

minimum 88 kg (194 lb)

for the class 250 cc:

minimum 98 kg (216 lb)

for the class 500 cc:

minimum 102 kg (225 lb)

In modifying your machine (e.g., for

weight reduction), take note of the

above limits of weight.

HOW TO USE THIS MANUAL

FINDING THE REQUIRED PAGE

1. This manual consists of seven chapters; "General Information",

"Specifications", "Regular inspec-

tion and adjustments", "Tuning",

"Engine", "Chassis" and "Electri-

cal". 2. The table of contents is at the be-

ginning of the manual. Look over

the general layout of the book be-

fore finding then required chapter

and item.

Bend the book at its edge, as

shown, to find the required fore

edge symbol mark and go to a

page for required item and de-

scription.

MANUAL FORMAT

All of the procedures in this manual

are organized in a sequential, step-

by-step format. The information has

been complied to provide the me-

chanic with an easy to read, handy

reference that contains comprehen-

sive explanations of all disassembly,

repair, assembly, and inspection op-

erations.

In this revised format, the condition of

a faulty component will precede an

arrow symbol and the course of ac-

tion required will follow the symbol,

e.g., •BearingsPitting/damage →Replace.

10. PROPERLY SECURE THE

MACHINE BEFORE TRANS-

PORTING IT.

When transporting the ma-

chine in another vehicle, al-

ways be sure it is properly

secured and in an upright po-

sition and that the fuel cock is

in the "OFF" position. Other-

wise, fuel may leak out of the

carburetor or fuel tank.

Page 15 of 224

1-5

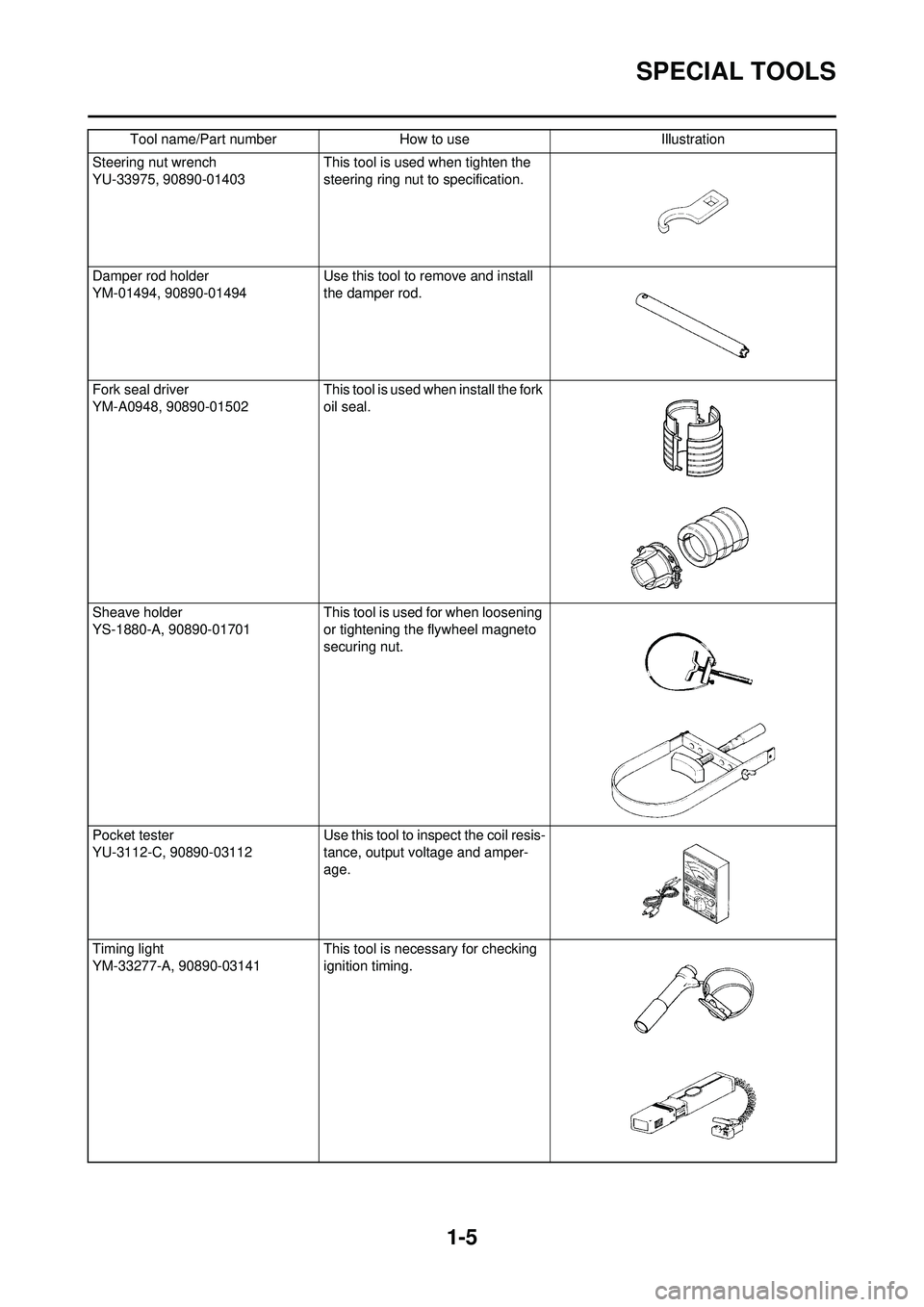

SPECIAL TOOLS

Steering nut wrench

YU-33975, 90890-01403 This tool is used when tighten the

steering ring nut to specification.

Damper rod holder

YM-01494, 90890-01494 Use this tool to remove and install

the damper rod.

Fork seal driver

YM-A0948, 90890-01502 This tool is used when install the fork

oil seal.

Sheave holder

YS-1880-A, 90890-01701 This tool is used for when loosening

or tightening the flywheel magneto

securing nut.

Pocket tester

YU-3112-C, 90890-03112 Use this tool to inspect the coil resis-

tance, output voltage and amper-

age.

Timing light

YM-33277-A, 90890-03141 This tool is necessary for checking

ignition timing.

Tool name/Part number How to use Illustration

Page 16 of 224

1-6

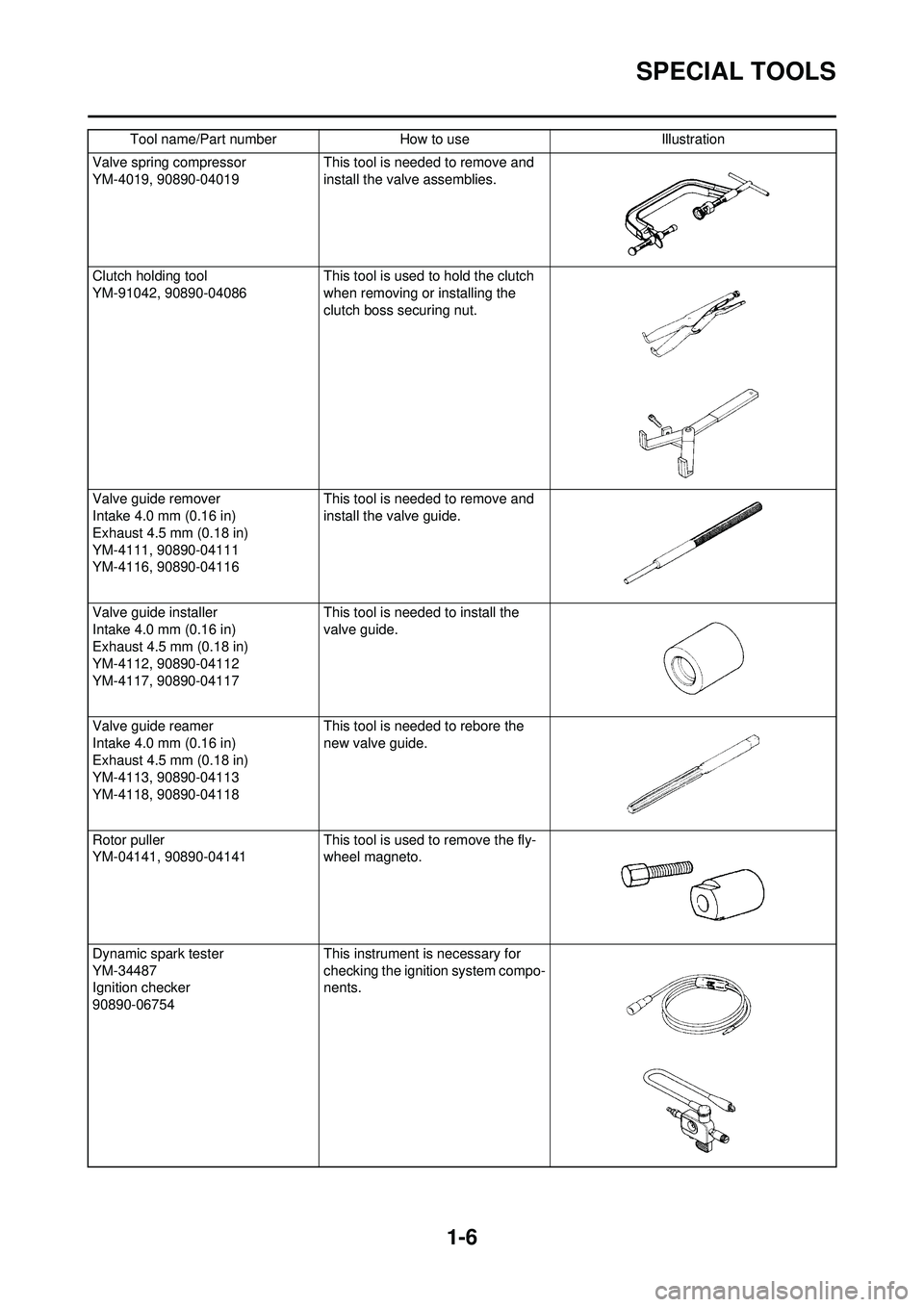

SPECIAL TOOLS

Valve spring compressor

YM-4019, 90890-04019 This tool is needed to remove and

install the valve assemblies.

Clutch holding tool

YM-91042, 90890-04086 This tool is used to hold the clutch

when removing or installing the

clutch boss securing nut.

Valve guide remover

Intake 4.0 mm (0.16 in)

Exhaust 4.5 mm (0.18 in)

YM-4111, 90890-04111

YM-4116, 90890-04116 This tool is needed to remove and

install the valve guide.

Valve guide installer

Intake 4.0 mm (0.16 in)

Exhaust 4.5 mm (0.18 in)

YM-4112, 90890-04112

YM-4117, 90890-04117 This tool is needed to install the

valve guide.

Valve guide reamer

Intake 4.0 mm (0.16 in)

Exhaust 4.5 mm (0.18 in)

YM-4113, 90890-04113

YM-4118, 90890-04118 This tool is needed to rebore the

new valve guide.

Rotor puller

YM-04141, 90890-04141 This tool is used to remove the fly-

wheel magneto.

Dynamic spark tester

YM-34487

Ignition checker

90890-06754 This instrument is necessary for

checking the ignition system compo-

nents.

Tool name/Part number

How to useIllustration

Page 27 of 224

1-17

CLEANING AND STORAGE

CLEANING AND STORAGE

CLEANING

Frequent cleaning of your machine

will enhance its appearance, maintain

good overall performance, and ex-

tend the life of many components.

1. Before washing the machine, block off the end of the exhaust

pipe to prevent water from enter-

ing. A plastic bag secured with a

rubber band may be used for this

purpose.

2. If the engine is excessively greasy, apply some degreaser to

it with a paint brush. Do not apply

degreaser to the chain, sprockets,

or wheel axles.

3. Rinse the dirt and degreaser off with a garden hose; use only

enough pressure to do the job.

Excessive hose pressure may

cause water seepage and contami-

nation of wheel bearings, front

forks, brakes and transmission

seals. Many expensive repair bills

have resulted from improper high

pressure detergent applications

such as those available in coin-op-

erated car washers.

4. After the majority of the dirt has been hosed off, wash all surfaces

with warm water and a mild deter-

gent. Use an old toothbrush to

clean hard-to-reach places.

5. Rinse the machine off immediate- ly with clean water, and dry all

surfaces with a soft towel or cloth.

6. Immediately after washing, re- move excess water from the

chain with a paper towel and lubri-

cate the chain to prevent rust.

7. Clean the seat with a vinyl uphol- stery cleaner to keep the cover

pliable and glossy.

8. Automotive wax may be applied to all painted or chromed surfac-

es. Avoid combination cleaner-

waxes, as they may contain abra-

sives.

9. After completing the above, start the engine and allow it to idle for

several minutes. STORAGE

If your machine is to be stored for 60

days or more, some preventive mea-

sures must be taken to avoid deterio-

ration. After cleaning the machine

thoroughly, prepare it for storage as

follows:

1. Drain the fuel tank, fuel lines, and

the carburetor float bowl.

2. Remove the spark plug, pour a ta-

blespoon of SAE 10W-30 motor

oil in the spark plug hole, and re-

install the plug. With the engine

stop switch pushed in, kick the en-

gine over several times to coat the

cylinder walls with oil.

3. Remove the drive chain, clean it thoroughly with solvent, and lubri-

cate it. Reinstall the chain or store

it in a plastic bag tied to the frame.

4. Lubricate all control cables.

5. Block the frame up to raise the

wheels off the ground.

6. Tie a plastic bag over the exhaust pipe outlet to prevent moisture

from entering.

7. If the machine is to be stored in a humid or salt-air environment,

coat all exposed metal surfaces

with a film of light oil. Do not apply

oil to rubber parts or the seat cov-

er.

Make any necessary repairs before

the machine is stored.

Page 49 of 224

2-22

CABLE ROUTING DIAGRAM

A. Insert the end of the fuel tank breather hose into the hole in

the steering stem.

B. Fasten the throttle cable, hot

starter cable and rectifier/regula-

tor lead onto the frame. Locate

the clamp end facing the lower

side of the hot starter cable and

cut off the tie end.

C. Fasten the diode (at the mark-

ing), throttle cable and hot start-

er cable onto the frame. Locate

the clamp end facing toward the

lower right of the frame and with

the tie end facing downward.

D. Fasten the wire harness, throttle

position sensor lead, starter mo-

tor lead and negative battery

lead onto the frame. Pass the

clamp through the hole in the

stay (air cut-off valve). Locate

the clamp end facing toward the

lower side of the frame and cut

off the tie end.

E. Fasten the throttle position sen-

sor lead onto the frame. Locate

the clamp end facing toward the

lower side of the frame and cut

off the tie end.

F. Pass the carburetor breather hoses, carburetor overflow hose

and catch tank breather hose

between the connecting rod and

cross tube (frame).

G. Fasten the neutral switch lead and oil hose together with the

plastic locking ties and cut off

the tie ends.

H. Fasten the neutral switch lead

and AC magneto lead onto the

frame. Locate the clamp end

facing toward the outside of the

frame and tie end facing toward

the rear of the frame.

I. Pass the clutch cable through

the cable guide.

J. Fasten the starter motor lead, AC magneto lead and neutral

switch lead onto the frame. Lo-

cate the clamp end facing to-

ward the rear of the frame and

cut off the tie end.

K. Fasten the clutch cable, starter motor lead, negative battery

lead, AC magneto lead and neu-

tral switch lead onto the frame.

Locate the clamp end facing to-

ward the rear of the frame and

cut off the tie end.

L. Pass the neutral switch lead and

AC magneto lead on the inside

of the wire harness. M. Fasten the clutch cable, AC

magneto lead and neutral switch

lead onto the frame. Locate the

clamp end near the clutch cable

and cut off the tie end.

N. Pass the clutch cable and wire harness through the cable

guide.

O. Locate the couplers in the frame recess.

P. Pass the carburetor breather hoses, carburetor overflow hose

and catch tank breather hose so

that the hoses do not contact the

rear shock absorber.

Q. Secure the coupler by pushing it

into the hole in the headlight

unit.

Page 53 of 224

2-26

CABLE ROUTING DIAGRAM

C. Pass the starter motor lead through the hole in the relay

holder.

D. Fit the cover securely.

E. Connect the wire harness to the starter relay.

F. Fasten the catch tank breather

hose and catch tank hose to the

rear frame. Clamp them close to

where they are joined to the

frame. Fasten the pipe tightly

enough not to crush it. Locate

the clamp end facing toward the

rear of the frame with the tie end

facing downward.

G. Fasten the (three) CDI unit leads

and taillight lead to the rear

frame. Locate the clamp end

facing toward the upper side of

the frame and cut off the tie end.

H. Connect the negative battery lead to the battery negative ter-

minal.

I. Connect the negative battery lead to the wire harness.

J. Fasten the wire harness to the rear frame. Locate the clamp

end facing toward the upper side

of the frame and the tie end to-

ward the inside of the frame.

Clamp the wire harness at the

marking.

K. Pass the wire harness, starter relay lead, starting circuit cut-off

relay lead and negative battery

lead through the hole in the relay

holder.

L. Fasten the (three) CDI unit leads and taillight lead to the rear

frame. Locate the clamp end

facing toward the lower side of

the frame and cut off the tie end.

M. Fasten the taillight lead to the rear frame. Locate the clamp

end facing toward the upper side

of the frame and cut off the tie

end.

N. Do not allow the taillight lead to

slacken.

O. Locate the CDI unit lead be- tween the CDI unit and rear

fender.

P. Locate the CDI unit coupler in the clearance between the up-

per side of the CDI unit and low-

er side of the catch tank stay.

Q. Locate the CDI unit lead be-

tween the CDI unit and rear

frame.

Page 54 of 224

2-27

CABLE ROUTING DIAGRAM

1. Throttle cable

2. Clamp

3. Brake hose

4. Clutch cable

5. Hose guide

6. Main switch coupler

7. Wire harness

8. Headlight coupler

9. Hot starter cable

10. Multi-function display bracket

11. Main switch12. Upper bracket

13. Clutch switch coupler

14. Engine stop switch coupler

15. Multi-function display coupler

16. Start switch coupler

17. Speed sensor coupler

18. Speed sensor lead

A. Fasten the star

t switch lead to

the handlebar with the plastic

bands. B. Fasten the engine stop switch

lead and clutch switch lead to

the handlebar with the plastic

bands.

C. Pass the brake hose through

the hose guides.

D. Secure the coupler by inserting it into the multi-function display

bracket.

Page 55 of 224

2-28

CABLE ROUTING DIAGRAM

E. Pass the throttle cables, clutch cable and hot starter cable be-

tween the upper bracket and

multi-function display bracket.

F. Fasten the multi-function display leads to the bracket. Cut off the

tie end.

G. Secure the coupler by pushing it into the hole in the multi-function

display bracket.

H. Secure the wire harness clip by pushing it into the hole in the

multi-function display bracket on

the inside.

I. Fasten the wire harness to the multi-function display bracket.

Cut off the tie end.

J. Fasten the main switch lead (wire harness side) to the multi-

function display br acket. Locate

the clamp end facing toward the

lower side of the frame and cut

off the tie end.

K. Pass the speed sensor lead through the guide on the outside

of the front fork.

Page 120 of 224

5-24

VALVES AND VALVE SPRINGS

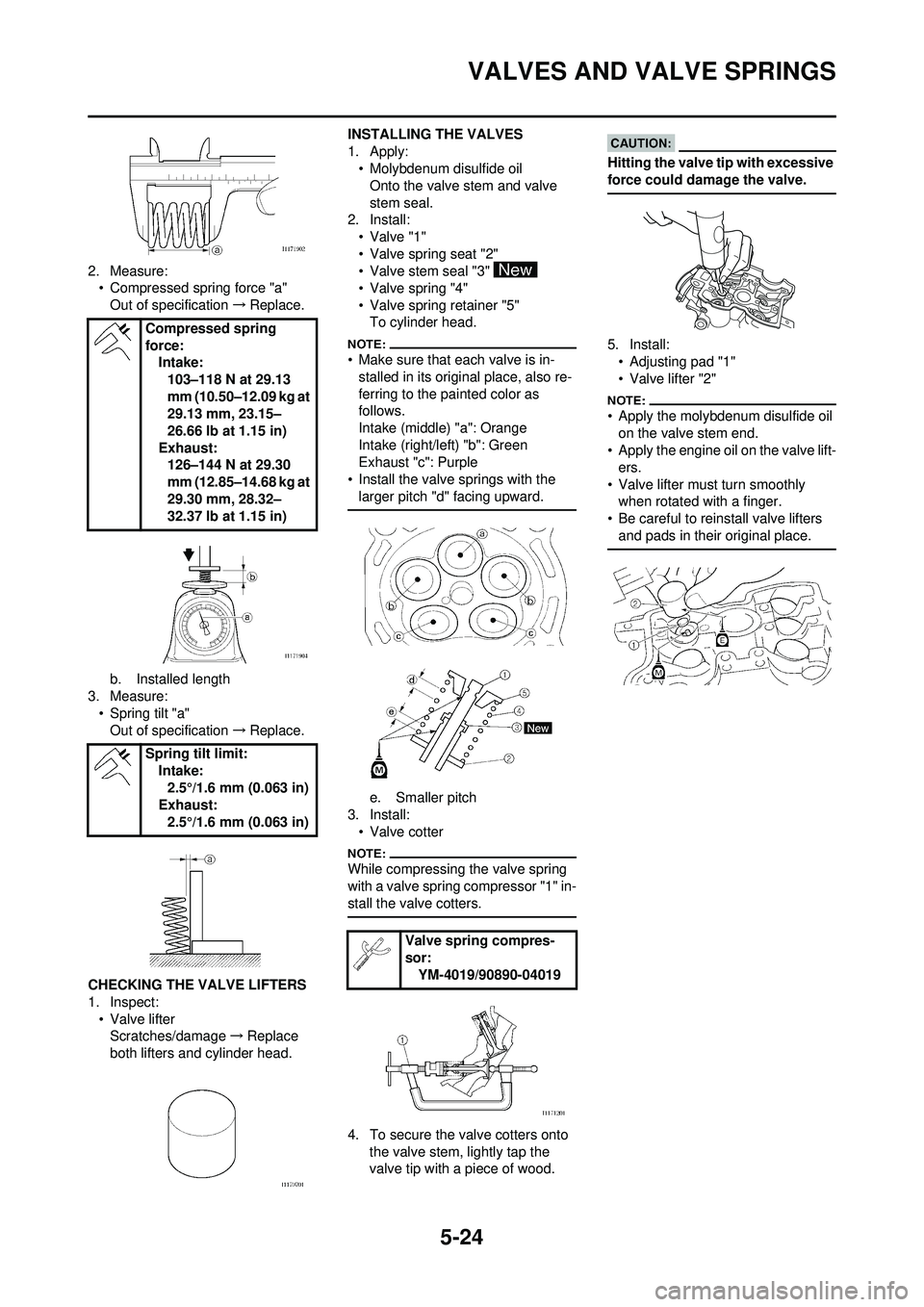

2. Measure:• Compressed spring force "a"

Out of specification →Replace.

b. Installed length

3. Measure: • Spring tilt "a"

Out of specification →Replace.

CHECKING THE VALVE LIFTERS

1. Inspect: • Valve lifterScratches/damage →Replace

both lifters and cylinder head. INSTALLING THE VALVES

1. Apply:

• Molybdenum disulfide oilOnto the valve stem and valve

stem seal.

2. Install: • Valve "1"

• Valve spring seat "2"

• Valve stem seal "3"

• Valve spring "4"

• Valve spring retainer "5"To cylinder head.

• Make sure that each valve is in-stalled in its original place, also re-

ferring to the painted color as

follows.

Intake (middle) "a": Orange

Intake (right/left) "b": Green

Exhaust "c": Purple

• Install the valve springs with the

larger pitch "d" facing upward.

e. Smaller pitch

3. Install:

• Valve cotter

While compressing the valve spring

with a valve spring compressor "1" in-

stall the valve cotters.

4. To secure the va lve cotters onto

the valve stem, lightly tap the

valve tip with a piece of wood.

Hitting the valve tip with excessive

force could damage the valve.

5. Install: • Adjusting pad "1"

• Valve lifter "2"

• Apply the molybdenum disulfide oil

on the valve stem end.

• Apply the engine oil on the valve lift- ers.

• Valve lifter must turn smoothly when rotated with a finger.

• Be careful to reinstall valve lifters and pads in their original place.

Compressed spring

force: Intake:

103–118 N at 29.13

mm (10.50–12.09 kg at

29.13 mm, 23.15–

26.66 lb at 1.15 in)

Exhaust: 126–144 N at 29.30

mm (12.85–14.68 kg at

29.30 mm, 28.32–

32.37 lb at 1.15 in)

Spring tilt limit: Intake:2.5°/1.6 mm (0.063 in)

Exhaust: 2.5°/1.6 mm (0.063 in)

Valve spring compres-

sor:

YM-4019/90890-04019

Page 151 of 224

5-55

ENGINE REMOVAL

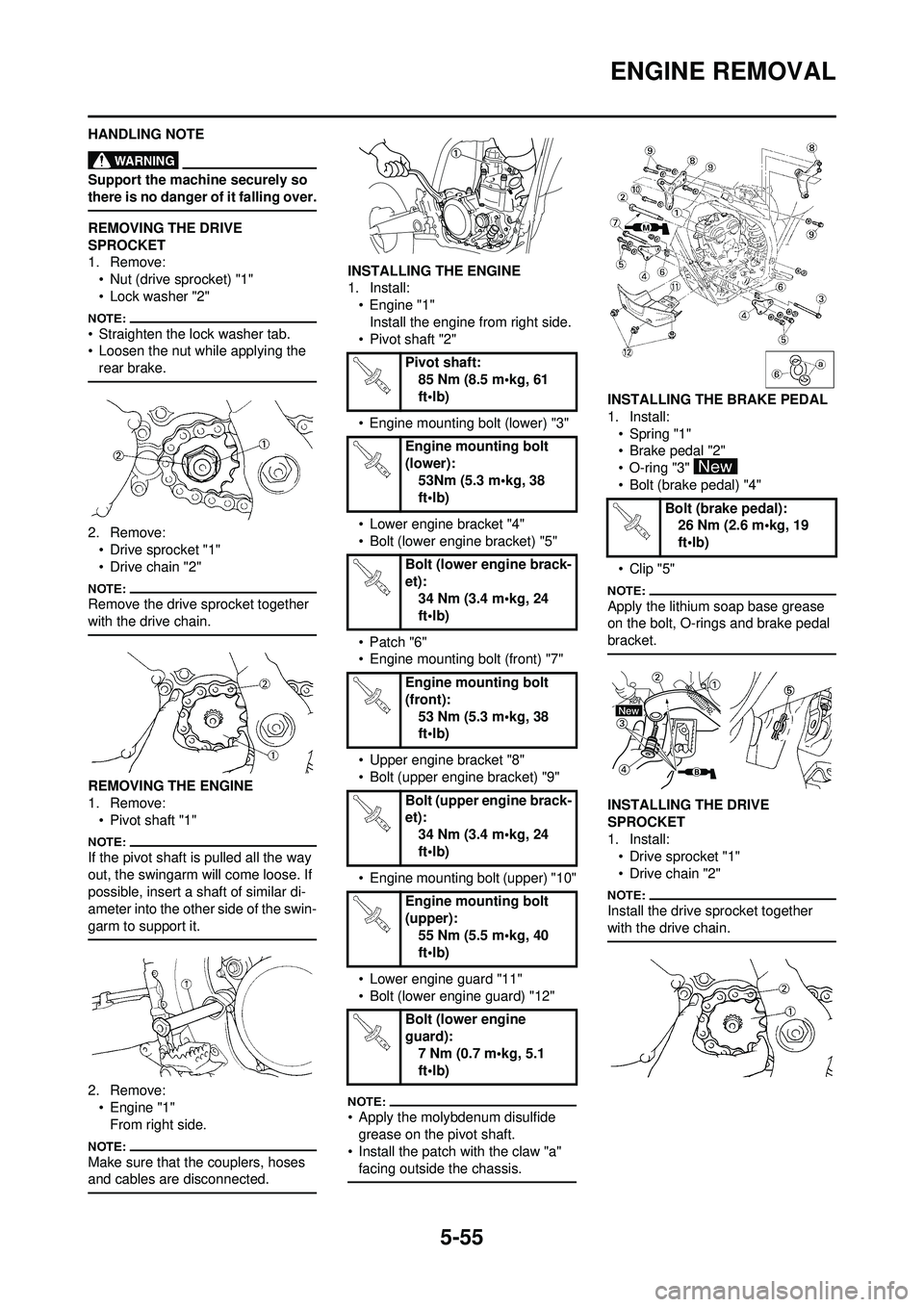

HANDLING NOTE

Support the machine securely so

there is no danger of it falling over.

REMOVING THE DRIVE

SPROCKET

1. Remove:• Nut (drive sprocket) "1"

• Lock washer "2"

• Straighten the lock washer tab.

• Loosen the nut while applying the rear brake.

2. Remove:• Drive sprocket "1"

• Drive chain "2"

Remove the drive sprocket together

with the drive chain.

REMOVING THE ENGINE

1. Remove:• Pivot shaft "1"

If the pivot shaft is pulled all the way

out, the swingarm will come loose. If

possible, insert a sh aft of similar di-

ameter into the other side of the swin-

garm to support it.

2. Remove:

• Engine "1"From right side.

Make sure that the couplers, hoses

and cables are disconnected.

INSTALLING THE ENGINE

1. Install:

• Engine "1"Install the engine from right side.

• Pivot shaft "2"

• Engine mounting bolt (lower) "3"

• Lower engine bracket "4"

• Bolt (lower engine bracket) "5"

• Patch "6"

• Engine mounting bolt (front) "7"

• Upper engine bracket "8"

• Bolt (upper engine bracket) "9"

• Engine mounting bolt (upper) "10"

• Lower engine guard "11"

• Bolt (lower engine guard) "12"

• Apply the molybdenum disulfide grease on the pivot shaft.

• Install the patch with the claw "a"

facing outside the chassis.

INSTALLING THE BRAKE PEDAL

1. Install:• Spring "1"

• Brake pedal "2"

• O-ring "3"

• Bolt (brake pedal) "4"

• Clip "5"

Apply the lithium soap base grease

on the bolt, O-rings and brake pedal

bracket.

INSTALLING THE DRIVE

SPROCKET

1. Install:• Drive sprocket "1"

• Drive chain "2"

Install the drive sprocket together

with the drive chain.

Pivot shaft:

85 Nm (8.5 m•kg, 61

ft•lb)

Engine mounting bolt

(lower): 53Nm (5.3 m•kg, 38

ft•lb)

Bolt (lower engine brack-

et): 34 Nm (3.4 m•kg, 24

ft•lb)

Engine mounting bolt

(front): 53 Nm (5.3 m•kg, 38

ft•lb)

Bolt (upper engine brack-

et): 34 Nm (3.4 m•kg, 24

ft•lb)

Engine mounting bolt

(upper): 55 Nm (5.5 m•kg, 40

ft•lb)

Bolt (lower engine

guard): 7 Nm (0.7 m•kg, 5.1

ft•lb)

Bolt (brake pedal): 26 Nm (2.6 m•kg, 19

ft•lb)