air suspension YAMAHA WR 250F 2008 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: WR 250F, Model: YAMAHA WR 250F 2008Pages: 224, PDF Size: 13.66 MB

Page 93 of 224

4-6

CHASSIS

A. Air spring characteristics in relation to oil level change

B. Load

C. Stroke

1. Max. oil level

2. Standard oil level

3. Min. oil level

ADJUSTING THE SPRING

PRELOAD

The spring preload is adjusted by in-

stalling the adjustment washer "1" be-

tween the fork spring "2" and damper

rod "3".

Do not install three or more adjust-

ment washers for each front fork.

Always adjust each front fork to

the same setting. Uneven adjust-

ment can cause poor handling and

loss of stability.

A. Load

B. Fork stroke

1. Without adjustment washer (standard)

2. 1 adjustment washer

3. 2 adjustment washers

SETTING OF SPRING AFTER

REPLACEMENT

As the front fork setting can be easily

affected by rear suspension, take

care so that the machine front and

rear are balanced (in position, etc.)

when setting the front fork.

1. Use of soft spring • Change the rebound damping.Turn out one or two clicks.

• Change the compression damp- ing.

Turn in one or two clicks.

Generally a soft spring gives a soft

riding feeling. Rebound damping

tends to become stronger and the

front fork may sink deeply over a se-

ries of gaps.

2. Use of stiff spring• Change the rebound damping.Turn in one or two clicks.

• Change the compression damp- ing.

Turn out one or two clicks.

Generally a stiff spring gives a stiff

riding feeling. Rebound damping

tends to become weaker, resulting in

lack of a sense of contact with the

road surface or in a vibrating handle-

bar.

FRONT FORK SETTING PARTS

• Adjustment washer "1" • Front fork spring "2"

The I.D. mark (slits) "a" is proved on

the end of the spring.

When using a spring with a spring

rate of 0.469 kg/mm, do not install

two or more adjustment washers

for each front fork.

REAR SUSPENSION SETTING

The rear suspension setting should

be made depending on the rider's

feeling of an actual run and the circuit

conditions.

The rear suspension setting includes

the following two factors:

1. Setting of spring preload

• Change the set length of the spring.

• Change the spring.

2. Setting of damping force • Change the rebound damping.

• Change the compression damp-

ing.

Standard washer quanti-

ty:

Zero adjustment wash-

ers

Extent of adjustment:

Zero–2 adjustment

washers

TYPE (thick- ness) PART NUMBER

T = 2.3 mm (0.09 in) 5XE-23364-00

TYPESPRI

NG

RATE SPRING

PART

NUMBER (-23141-) I.D.

MARK

(slits)

SOFT 0.408 5TJ-00 |

0.418 5TJ-10 ||

0.428 5TJ-20 |||

0.438 5TJ-30 ||||

STD 0.449 5TJ-A0 —

STIFF 0.459 5TJ-50 |-|

0.469 5TJ-60 |-||

Page 181 of 224

6-20

FRONT FORK

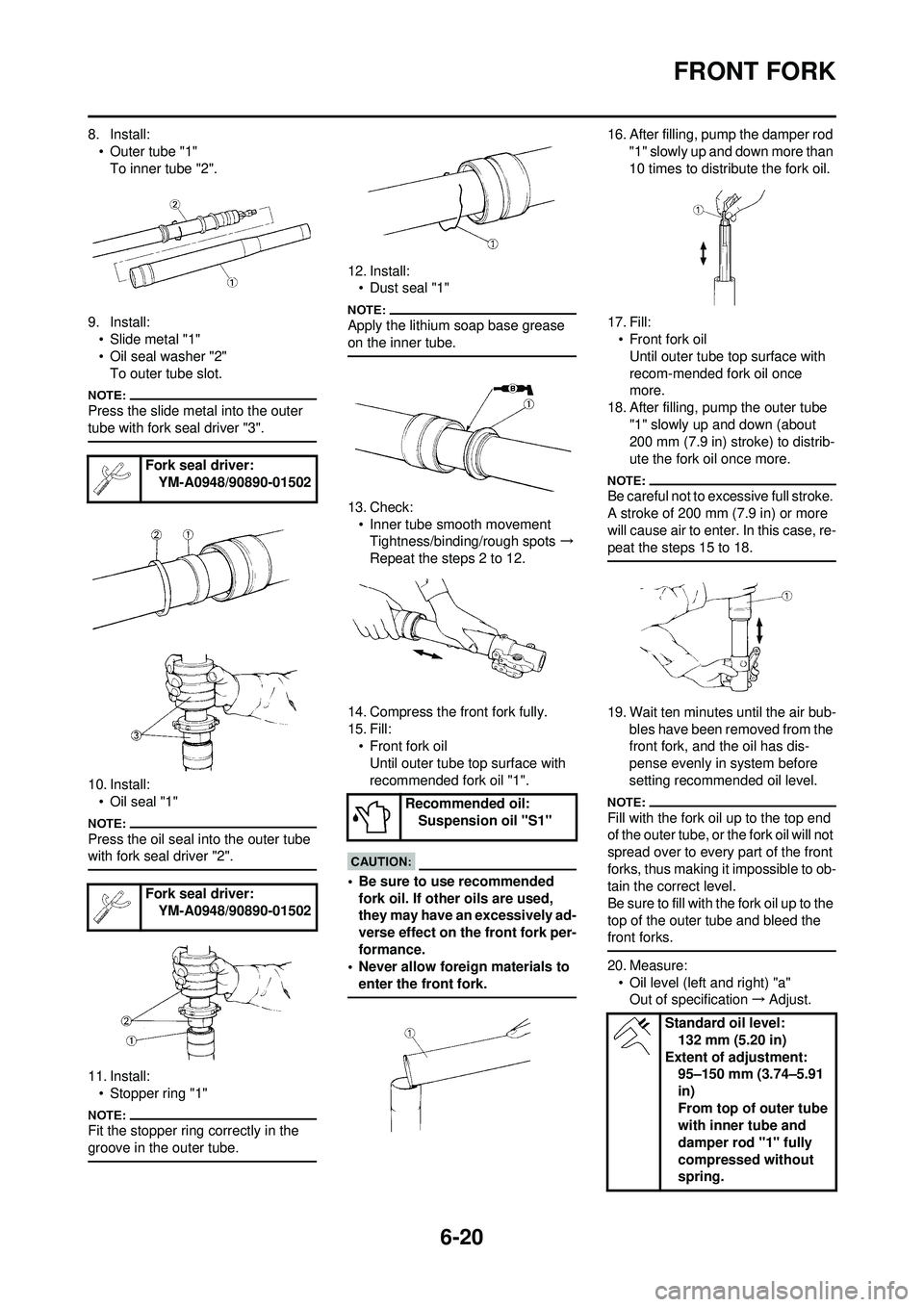

8. Install:• Outer tube "1"To inner tube "2".

9. Install: • Slide metal "1"

• Oil seal washer "2"To outer tube slot.

Press the slide metal into the outer

tube with fork seal driver "3".

10. Install:

• Oil seal "1"

Press the oil seal into the outer tube

with fork seal driver "2".

11. Install:• Stopper ring "1"

Fit the stopper ring correctly in the

groove in the outer tube.

12. Install:• Dust seal "1"

Apply the lithium soap base grease

on the inner tube.

13. Check:

• Inner tube smooth movementTightness/binding/rough spots →

Repeat the steps 2 to 12.

14. Compress the front fork fully.

15. Fill: • Front fork oilUntil outer tube top surface with

recommended fork oil "1".

• Be sure to use recommended

fork oil. If other oils are used,

they may have an excessively ad-

verse effect on the front fork per-

formance.

• Never allow foreign materials to enter the front fork.

16. After filling, pump the damper rod

"1" slowly up and down more than

10 times to distribute the fork oil.

17. Fill: • Front fork oil

Until outer tube top surface with

recom-mended fork oil once

more.

18. After filling, pump the outer tube "1" slowly up and down (about

200 mm (7.9 in) stroke) to distrib-

ute the fork oil once more.

Be careful not to ex cessive full stroke.

A stroke of 200 mm (7.9 in) or more

will cause air to enter. In this case, re-

peat the steps 15 to 18.

19. Wait ten minutes until the air bub-

bles have been removed from the

front fork, and the oil has dis-

pense evenly in system before

setting recommended oil level.

Fill with the fork oil up to the top end

of the outer tube, or the fork oil will not

spread over to every part of the front

forks, thus making it impossible to ob-

tain the correct level.

Be sure to fill with the fork oil up to the

top of the outer tube and bleed the

front forks.

20. Measure:• Oil level (left and right) "a" Out of specification →Adjust.

Fork seal driver:

YM-A0948/90890-01502

Fork seal driver: YM-A0948/90890-01502

Recommended oil:Suspension oil "S1"

Standard oil level:

132 mm (5.20 in)

Extent of adjustment: 95–150 mm (3.74–5.91

in)

From top of outer tube

with inner tube and

damper rod "1" fully

compressed without

spring.