lock YAMAHA WR 250F 2013 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: WR 250F, Model: YAMAHA WR 250F 2013Pages: 232, PDF Size: 13.36 MB

Page 92 of 232

3-33

ELECTRICAL

6. Install:

•Battery

• Battery band

7. Connect:

• Battery leads

(to the battery terminals)

First, connect the positive lead "1",

then the negative lead "2".

8. Check:

• Battery terminals

Dirt→Clean with a wire brush.

Loose connection→Connect

properly.

9. Lubricate:

• Battery terminal

10. Install:

• Seat

CHECKING THE FUSE

To avoid a short circuit, always set

the main switch to "OFF" when

checking or replacing a fuse.

1. Remove:

• Seat

• Fuse cover

2. Check:

• Continuity

Checking steps:

a. Remove the fuse "1".

b. Connect the pocket tester to the

fuse and check the continuity.

Set the pocket tester selector to " Ω×

1".

2. Reserve fuse

c. If the pocket tester indicates "∞",

replace the fuse.

3. Replace:

• Blown fuse

Replacement steps:

a. Set the main switch to "OFF".

b. Install a new fuse of the correct

amperage.

c. Set on the switches to verify if the

electrical circuit is operational.

d. If the fuse immediately blows

again, check the electrical circuit.

Never use a fuse with an amperage

rating other than that specified. Im-

provising or using a fuse with the

wrong amperage rating may cause

extensive damage to the electrical

system, cause the starting and ig-

nition systems to malfunction and

could possibly cause a fire.

4. Install:

• Fuse cover

•SeatREPLACING THE HEADLIGHT

BULBS

1. Remove:

• Headlight

Refer to "REMOVING THE SEAT,

FUEL TANK AND SIDE COV-

ERS" section.

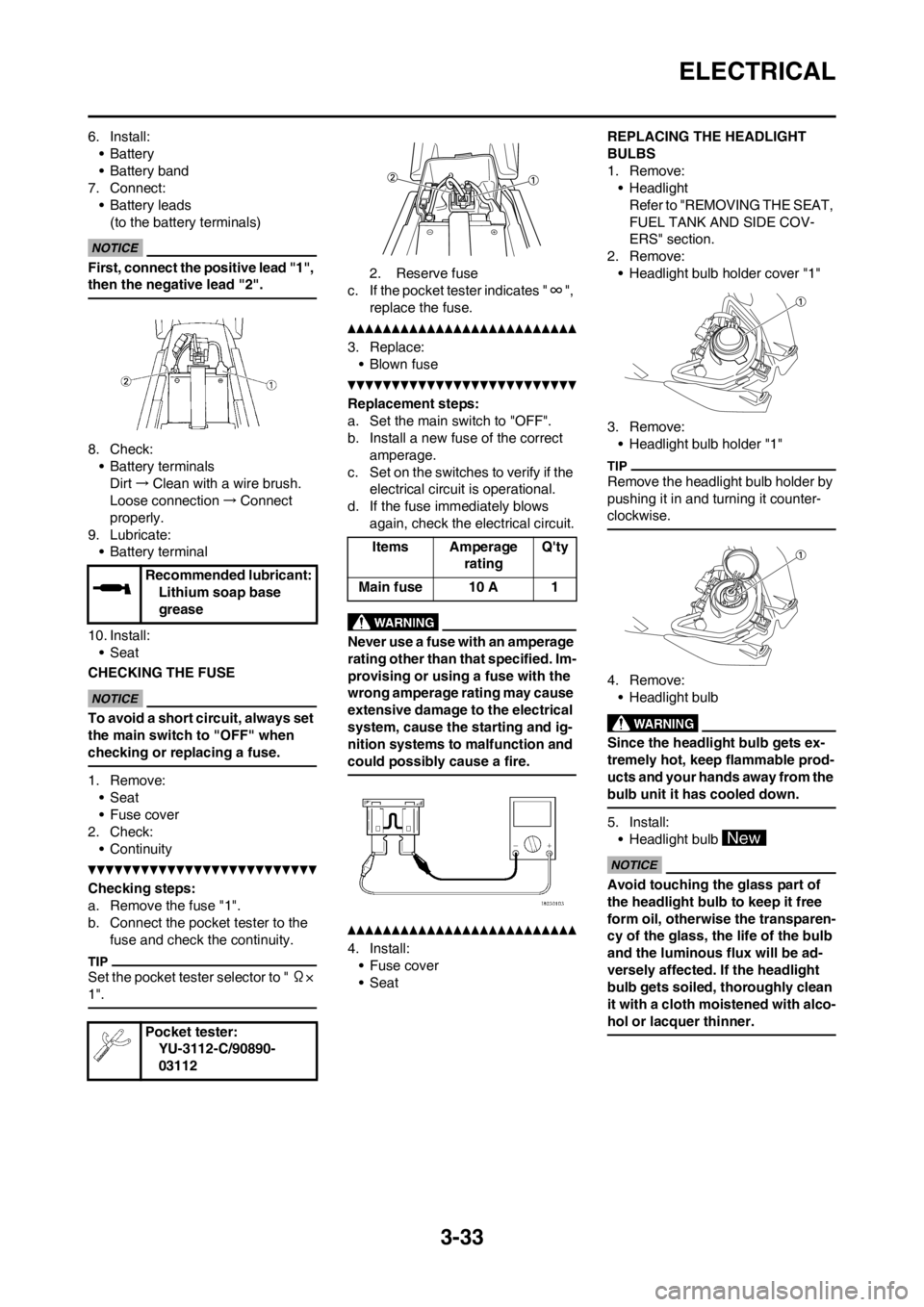

2. Remove:

• Headlight bulb holder cover "1"

3. Remove:

• Headlight bulb holder "1"

Remove the headlight bulb holder by

pushing it in and turning it counter-

clockwise.

4. Remove:

• Headlight bulb

Since the headlight bulb gets ex-

tremely hot, keep flammable prod-

ucts and your hands away from the

bulb unit it has cooled down.

5. Install:

• Headlight bulb

Avoid touching the glass part of

the headlight bulb to keep it free

form oil, otherwise the transparen-

cy of the glass, the life of the bulb

and the luminous flux will be ad-

versely affected. If the headlight

bulb gets soiled, thoroughly clean

it with a cloth moistened with alco-

hol or lacquer thinner.

Recommended lubricant:

Lithium soap base

grease

Pocket tester:

YU-3112-C/90890-

03112

Items Amperage

ratingQ'ty

Main fuse 10 A 1

Page 98 of 232

4-5

CHASSIS

CHASSIS

SELECTION OF THE SECONDARY

REDUCTION RATIO (SPROCKET)

• It is generally said that the second-

ary gear ratio should be reduced for

a longer straight portion of a speed

course and should be increased for

a course with many corners. Actual-

ly, however, as the speed depends

on the ground condition of the day

of the ride, be sure to run through

the circuit to set the machine suit-

able for the entire course.

• In actuality, it is very difficult to

achieve settings suitable for the en-

tire course and some settings may

be sacrificed. Thus, the settings

should be matched to the portion of

the course that has the greatest ef-

fect on the ride result. In such a

case, run through the entire course

while making notes of lap times to

find the best balance; then, deter-

mine the secondary reduction ratio.

• If a course has a long straight por-

tion where a machine can run at

maximum speed, the machine is

generally set such that it can devel-

op its maximum revolutions toward

the end of the straight line, with care

taken to avoid the engine over-rev-

ving.

Riding technique varies from rider to

rider and the performance of a ma-

chine also vary from machine to ma-

chine. Therefore, do not imitate other

rider's settings from the beginning but

choose your own setting according to

the level of your riding technique.

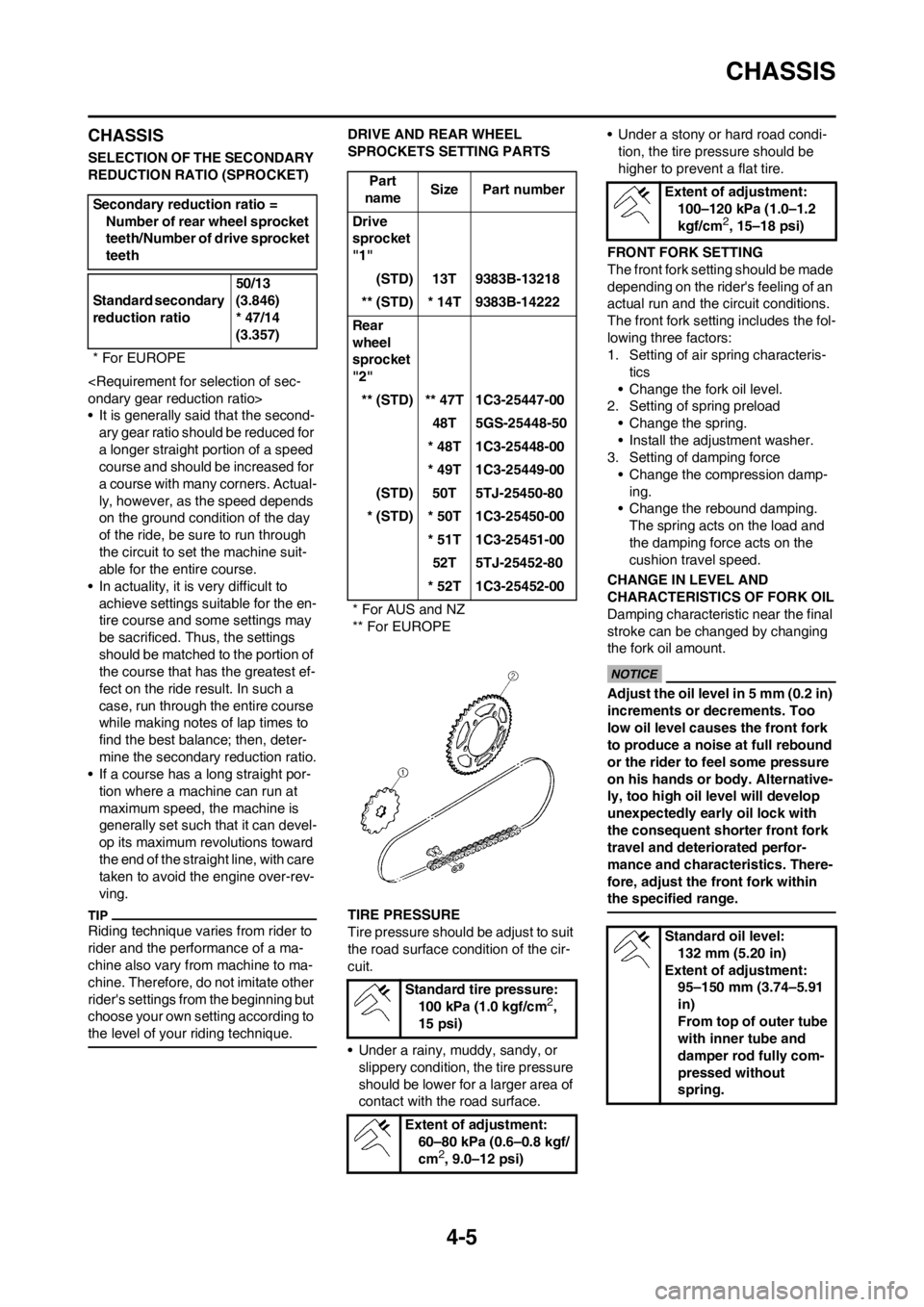

DRIVE AND REAR WHEEL

SPROCKETS SETTING PARTS

TIRE PRESSURE

Tire pressure should be adjust to suit

the road surface condition of the cir-

cuit.

• Under a rainy, muddy, sandy, or

slippery condition, the tire pressure

should be lower for a larger area of

contact with the road surface.• Under a stony or hard road condi-

tion, the tire pressure should be

higher to prevent a flat tire.

FRONT FORK SETTING

The front fork setting should be made

depending on the rider's feeling of an

actual run and the circuit conditions.

The front fork setting includes the fol-

lowing three factors:

1. Setting of air spring characteris-

tics

• Change the fork oil level.

2. Setting of spring preload

• Change the spring.

• Install the adjustment washer.

3. Setting of damping force

• Change the compression damp-

ing.

• Change the rebound damping.

The spring acts on the load and

the damping force acts on the

cushion travel speed.

CHANGE IN LEVEL AND

CHARACTERISTICS OF FORK OIL

Damping characteristic near the final

stroke can be changed by changing

the fork oil amount.

Adjust the oil level in 5 mm (0.2 in)

increments or decrements. Too

low oil level causes the front fork

to produce a noise at full rebound

or the rider to feel some pressure

on his hands or body. Alternative-

ly, too high oil level will develop

unexpectedly early oil lock with

the consequent shorter front fork

travel and deteriorated perfor-

mance and characteristics. There-

fore, adjust the front fork within

the specified range.

Secondary reduction ratio =

Number of rear wheel sprocket

teeth/Number of drive sprocket

teeth

Standard secondary

reduction ratio50/13

(3.846)

* 47/14

(3.357)

* For EUROPE

Part

nameSize Part number

Drive

sprocket

"1"

(STD) 13T 9383B-13218

** (STD) * 14T 9383B-14222

Rear

wheel

sprocket

"2"

** (STD) ** 47T 1C3-25447-00

48T 5GS-25448-50

* 48T 1C3-25448-00

* 49T 1C3-25449-00

(STD) 50T 5TJ-25450-80

* (STD) * 50T 1C3-25450-00

* 51T 1C3-25451-00

52T 5TJ-25452-80

* 52T 1C3-25452-00

* For AUS and NZ

** For EUROPE

Standard tire pressure:

100 kPa (1.0 kgf/cm

2,

15 psi)

Extent of adjustment:

60–80 kPa (0.6–0.8 kgf/

cm

2, 9.0–12 psi)

Extent of adjustment:

100–120 kPa (1.0–1.2

kgf/cm

2, 15–18 psi)

Standard oil level:

132 mm (5.20 in)

Extent of adjustment:

95–150 mm (3.74–5.91

in)

From top of outer tube

with inner tube and

damper rod fully com-

pressed without

spring.

Page 100 of 232

4-7

CHASSIS

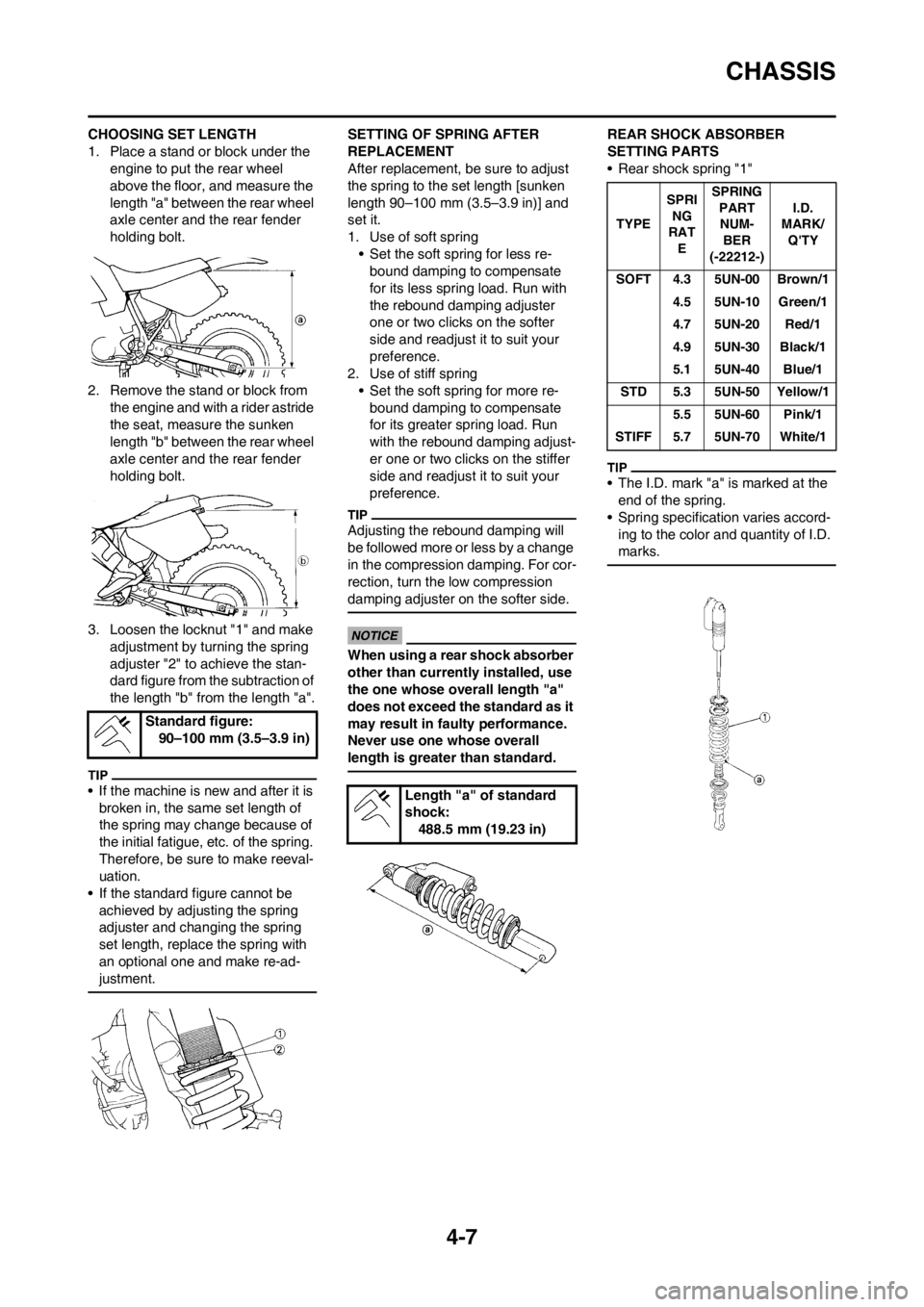

CHOOSING SET LENGTH

1. Place a stand or block under the

engine to put the rear wheel

above the floor, and measure the

length "a" between the rear wheel

axle center and the rear fender

holding bolt.

2. Remove the stand or block from

the engine and with a rider astride

the seat, measure the sunken

length "b" between the rear wheel

axle center and the rear fender

holding bolt.

3. Loosen the locknut "1" and make

adjustment by turning the spring

adjuster "2" to achieve the stan-

dard figure from the subtraction of

the length "b" from the length "a".

• If the machine is new and after it is

broken in, the same set length of

the spring may change because of

the initial fatigue, etc. of the spring.

Therefore, be sure to make reeval-

uation.

• If the standard figure cannot be

achieved by adjusting the spring

adjuster and changing the spring

set length, replace the spring with

an optional one and make re-ad-

justment.

SETTING OF SPRING AFTER

REPLACEMENT

After replacement, be sure to adjust

the spring to the set length [sunken

length 90–100 mm (3.5–3.9 in)] and

set it.

1. Use of soft spring

• Set the soft spring for less re-

bound damping to compensate

for its less spring load. Run with

the rebound damping adjuster

one or two clicks on the softer

side and readjust it to suit your

preference.

2. Use of stiff spring

• Set the soft spring for more re-

bound damping to compensate

for its greater spring load. Run

with the rebound damping adjust-

er one or two clicks on the stiffer

side and readjust it to suit your

preference.

Adjusting the rebound damping will

be followed more or less by a change

in the compression damping. For cor-

rection, turn the low compression

damping adjuster on the softer side.

When using a rear shock absorber

other than currently installed, use

the one whose overall length "a"

does not exceed the standard as it

may result in faulty performance.

Never use one whose overall

length is greater than standard.

REAR SHOCK ABSORBER

SETTING PARTS

• Rear shock spring "1"

• The I.D. mark "a" is marked at the

end of the spring.

• Spring specification varies accord-

ing to the color and quantity of I.D.

marks.

Standard figure:

90–100 mm (3.5–3.9 in)

Length "a" of standard

shock:

488.5 mm (19.23 in)

TYPESPRI

NG

RAT

ESPRING

PART

NUM-

BER

(-22212-)I.D.

MARK/

Q'TY

SOFT 4.3 5UN-00 Brown/1

4.5 5UN-10 Green/1

4.7 5UN-20 Red/1

4.9 5UN-30 Black/1

5.1 5UN-40 Blue/1

STD 5.3 5UN-50 Yellow/1

5.5 5UN-60 Pink/1

STIFF 5.7 5UN-70 White/1

Page 102 of 232

4-9

CHASSIS

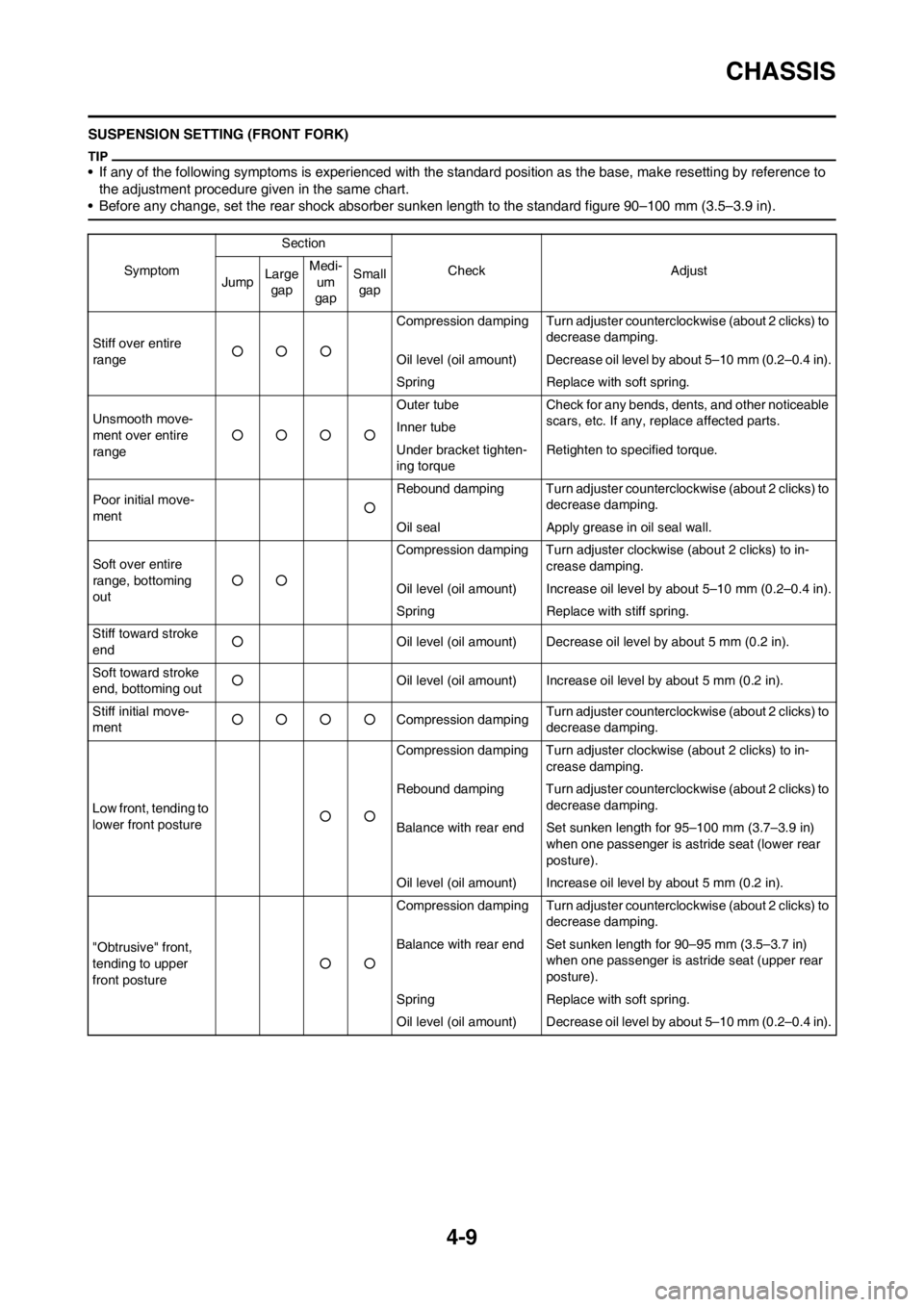

SUSPENSION SETTING (FRONT FORK)

• If any of the following symptoms is experienced with the standard position as the base, make resetting by reference to

the adjustment procedure given in the same chart.

• Before any change, set the rear shock absorber sunken length to the standard figure 90–100 mm (3.5–3.9 in).

SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Stiff over entire

range○○○Compression damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Oil level (oil amount) Decrease oil level by about 5–10 mm (0.2–0.4 in).

Spring Replace with soft spring.

Unsmooth move-

ment over entire

range○○○○Outer tube Check for any bends, dents, and other noticeable

scars, etc. If any, replace affected parts.

Inner tube

Under bracket tighten-

ing torqueRetighten to specified torque.

Poor initial move-

ment○Rebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Oil seal Apply grease in oil seal wall.

Soft over entire

range, bottoming

out○○Compression damping Turn adjuster clockwise (about 2 clicks) to in-

crease damping.

Oil level (oil amount) Increase oil level by about 5–10 mm (0.2–0.4 in).

Spring Replace with stiff spring.

Stiff toward stroke

end○Oil level (oil amount) Decrease oil level by about 5 mm (0.2 in).

Soft toward stroke

end, bottoming out○Oil level (oil amount) Increase oil level by about 5 mm (0.2 in).

Stiff initial move-

ment○○○○Compression dampingTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Low front, tending to

lower front posture○○Compression damping Turn adjuster clockwise (about 2 clicks) to in-

crease damping.

Rebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Balance with rear end Set sunken length for 95–100 mm (3.7–3.9 in)

when one passenger is astride seat (lower rear

posture).

Oil level (oil amount) Increase oil level by about 5 mm (0.2 in).

"Obtrusive" front,

tending to upper

front posture○○Compression damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Balance with rear end Set sunken length for 90–95 mm (3.5–3.7 in)

when one passenger is astride seat (upper rear

posture).

Spring Replace with soft spring.

Oil level (oil amount) Decrease oil level by about 5–10 mm (0.2–0.4 in).

Page 103 of 232

4-10

CHASSIS

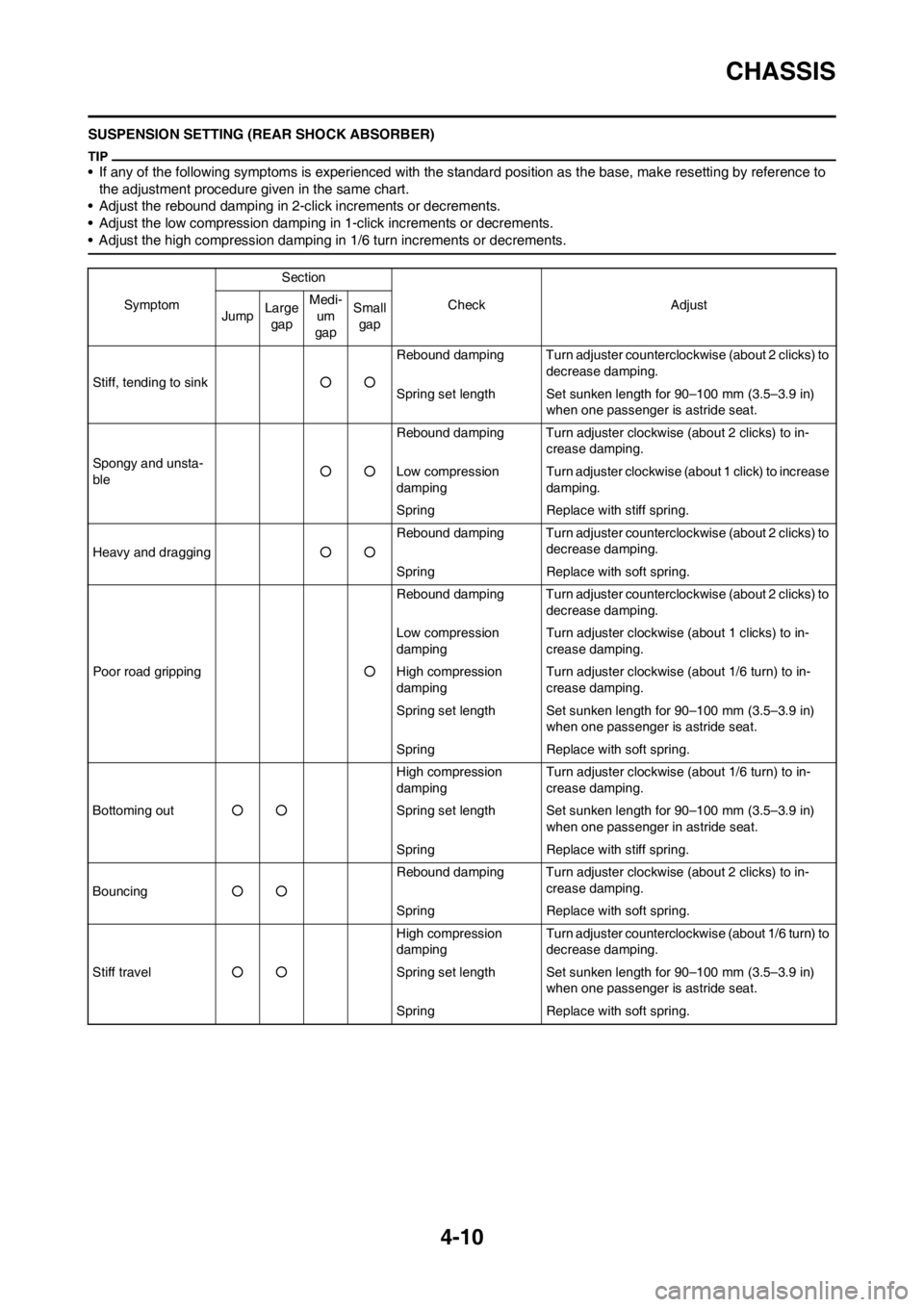

SUSPENSION SETTING (REAR SHOCK ABSORBER)

• If any of the following symptoms is experienced with the standard position as the base, make resetting by reference to

the adjustment procedure given in the same chart.

• Adjust the rebound damping in 2-click increments or decrements.

• Adjust the low compression damping in 1-click increments or decrements.

• Adjust the high compression damping in 1/6 turn increments or decrements.

SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Stiff, tending to sink○○Rebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Spring set length Set sunken length for 90–100 mm (3.5–3.9 in)

when one passenger is astride seat.

Spongy and unsta-

ble○○Rebound damping Turn adjuster clockwise (about 2 clicks) to in-

crease damping.

Low compression

dampingTurn adjuster clockwise (about 1 click) to increase

damping.

Spring Replace with stiff spring.

Heavy and dragging○○Rebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Spring Replace with soft spring.

Poor road gripping○Rebound damping Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Low compression

dampingTurn adjuster clockwise (about 1 clicks) to in-

crease damping.

High compression

dampingTurn adjuster clockwise (about 1/6 turn) to in-

crease damping.

Spring set length Set sunken length for 90–100 mm (3.5–3.9 in)

when one passenger is astride seat.

Spring Replace with soft spring.

Bottoming out○○High compression

dampingTurn adjuster clockwise (about 1/6 turn) to in-

crease damping.

Spring set length Set sunken length for 90–100 mm (3.5–3.9 in)

when one passenger in astride seat.

Spring Replace with stiff spring.

Bouncing○○Rebound damping Turn adjuster clockwise (about 2 clicks) to in-

crease damping.

Spring Replace with soft spring.

Stiff travel○○High compression

dampingTurn adjuster counterclockwise (about 1/6 turn) to

decrease damping.

Spring set length Set sunken length for 90–100 mm (3.5–3.9 in)

when one passenger is astride seat.

Spring Replace with soft spring.

Page 106 of 232

5-3

RADIATOR

HANDLING NOTE

Do not remove the radiator cap

when the engine and radiator are

hot. Scalding hot fluid and steam

may be blown out under pressure,

which could cause serious injury.

When the engine has cooled, open

the radiator cap by the following

procedure:

Place a thick rag, like a towel, over

the radiator cap, slowly rotate the

cap counterclockwise to the de-

tent. This procedure allows any re-

sidual pressure to escape. When

the hissing sound has stopped,

press down on the cap while turn-

ing counterclockwise and remove

it.

CHECKING THE RADIATOR

1. Inspect:

• Radiator core "1"

Obstruction→Blow out with com-

pressed air through rear of the ra-

diator.

Bent fin→Repair/replace.

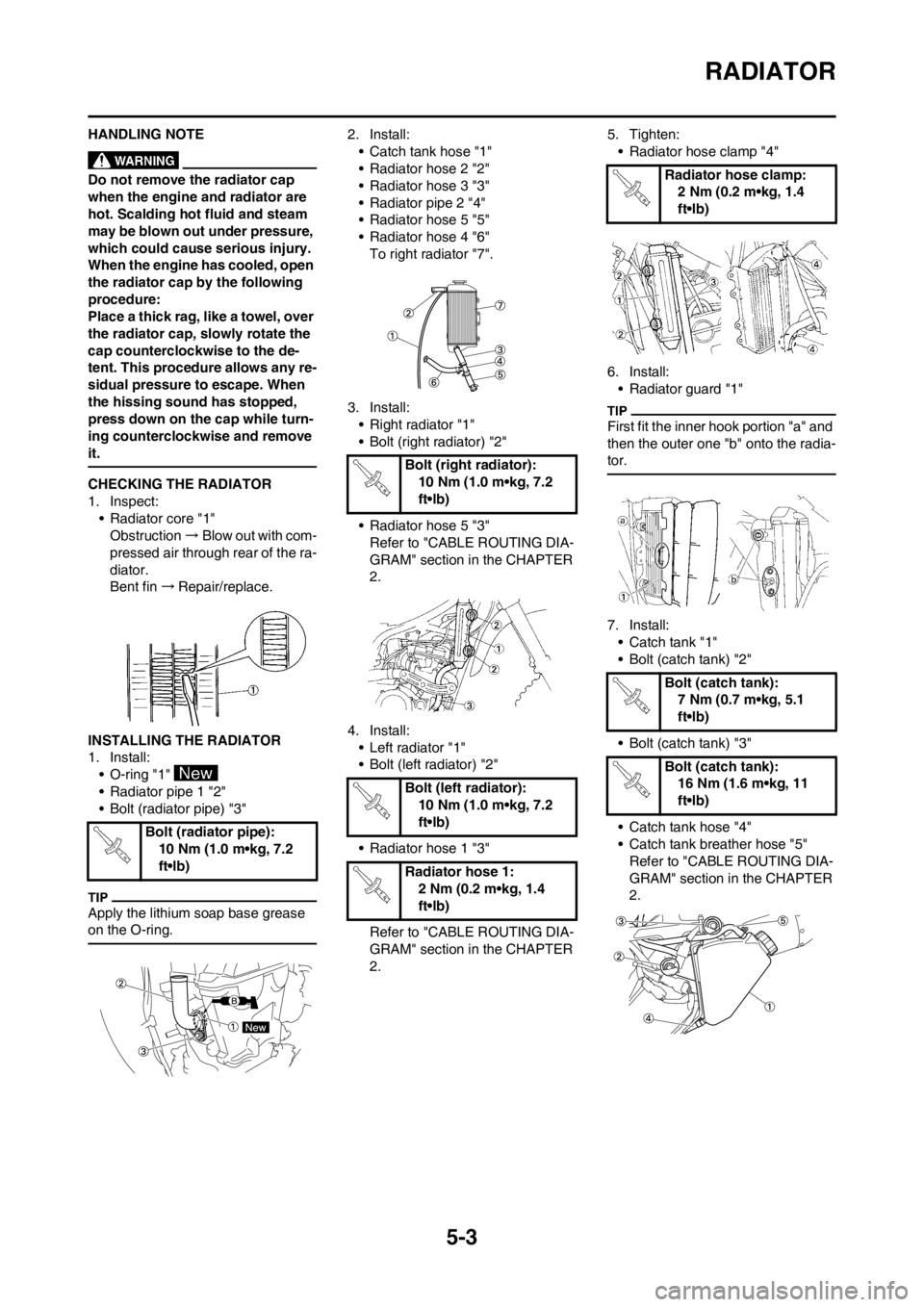

INSTALLING THE RADIATOR

1. Install:

• O-ring "1"

• Radiator pipe 1 "2"

• Bolt (radiator pipe) "3"

Apply the lithium soap base grease

on the O-ring.

2. Install:

• Catch tank hose "1"

• Radiator hose 2 "2"

• Radiator hose 3 "3"

• Radiator pipe 2 "4"

• Radiator hose 5 "5"

• Radiator hose 4 "6"

To right radiator "7".

3. Install:

• Right radiator "1"

• Bolt (right radiator) "2"

• Radiator hose 5 "3"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.

4. Install:

• Left radiator "1"

• Bolt (left radiator) "2"

• Radiator hose 1 "3"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.5. Tighten:

• Radiator hose clamp "4"

6. Install:

• Radiator guard "1"

First fit the inner hook portion "a" and

then the outer one "b" onto the radia-

tor.

7. Install:

• Catch tank "1"

• Bolt (catch tank) "2"

• Bolt (catch tank) "3"

• Catch tank hose "4"

• Catch tank breather hose "5"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2. Bolt (radiator pipe):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (right radiator):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (left radiator):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Radiator hose 1:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Radiator hose clamp:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Bolt (catch tank):

7 Nm (0.7 m•kg, 5.1

ft•lb)

Bolt (catch tank):

16 Nm (1.6 m•kg, 11

ft•lb)

Page 119 of 232

5-16

CAMSHAFTS

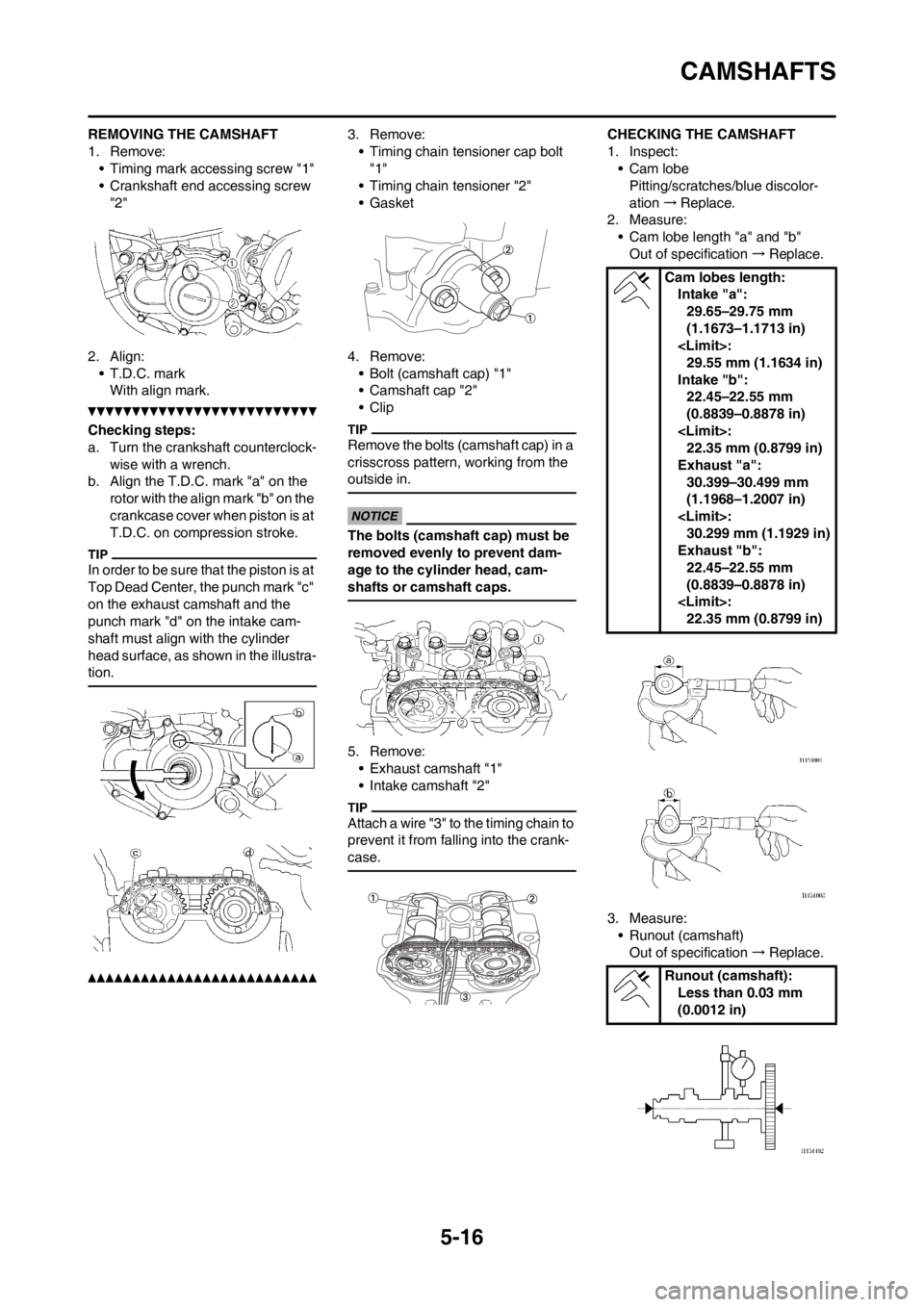

REMOVING THE CAMSHAFT

1. Remove:

• Timing mark accessing screw "1"

• Crankshaft end accessing screw

"2"

2. Align:

• T.D.C. mark

With align mark.

Checking steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

b. Align the T.D.C. mark "a" on the

rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke.

In order to be sure that the piston is at

Top Dead Center, the punch mark "c"

on the exhaust camshaft and the

punch mark "d" on the intake cam-

shaft must align with the cylinder

head surface, as shown in the illustra-

tion.

3. Remove:

• Timing chain tensioner cap bolt

"1"

• Timing chain tensioner "2"

• Gasket

4. Remove:

• Bolt (camshaft cap) "1"

• Camshaft cap "2"

• Clip

Remove the bolts (camshaft cap) in a

crisscross pattern, working from the

outside in.

The bolts (camshaft cap) must be

removed evenly to prevent dam-

age to the cylinder head, cam-

shafts or camshaft caps.

5. Remove:

• Exhaust camshaft "1"

• Intake camshaft "2"

Attach a wire "3" to the timing chain to

prevent it from falling into the crank-

case.

CHECKING THE CAMSHAFT

1. Inspect:

•Cam lobe

Pitting/scratches/blue discolor-

ation→Replace.

2. Measure:

• Cam lobe length "a" and "b"

Out of specification→Replace.

3. Measure:

• Runout (camshaft)

Out of specification→Replace.

Cam lobes length:

Intake "a":

29.65–29.75 mm

(1.1673–1.1713 in)

29.55 mm (1.1634 in)

Intake "b":

22.45–22.55 mm

(0.8839–0.8878 in)

22.35 mm (0.8799 in)

Exhaust "a":

30.399–30.499 mm

(1.1968–1.2007 in)

30.299 mm (1.1929 in)

Exhaust "b":

22.45–22.55 mm

(0.8839–0.8878 in)

22.35 mm (0.8799 in)

Runout (camshaft):

Less than 0.03 mm

(0.0012 in)

Page 120 of 232

5-17

CAMSHAFTS

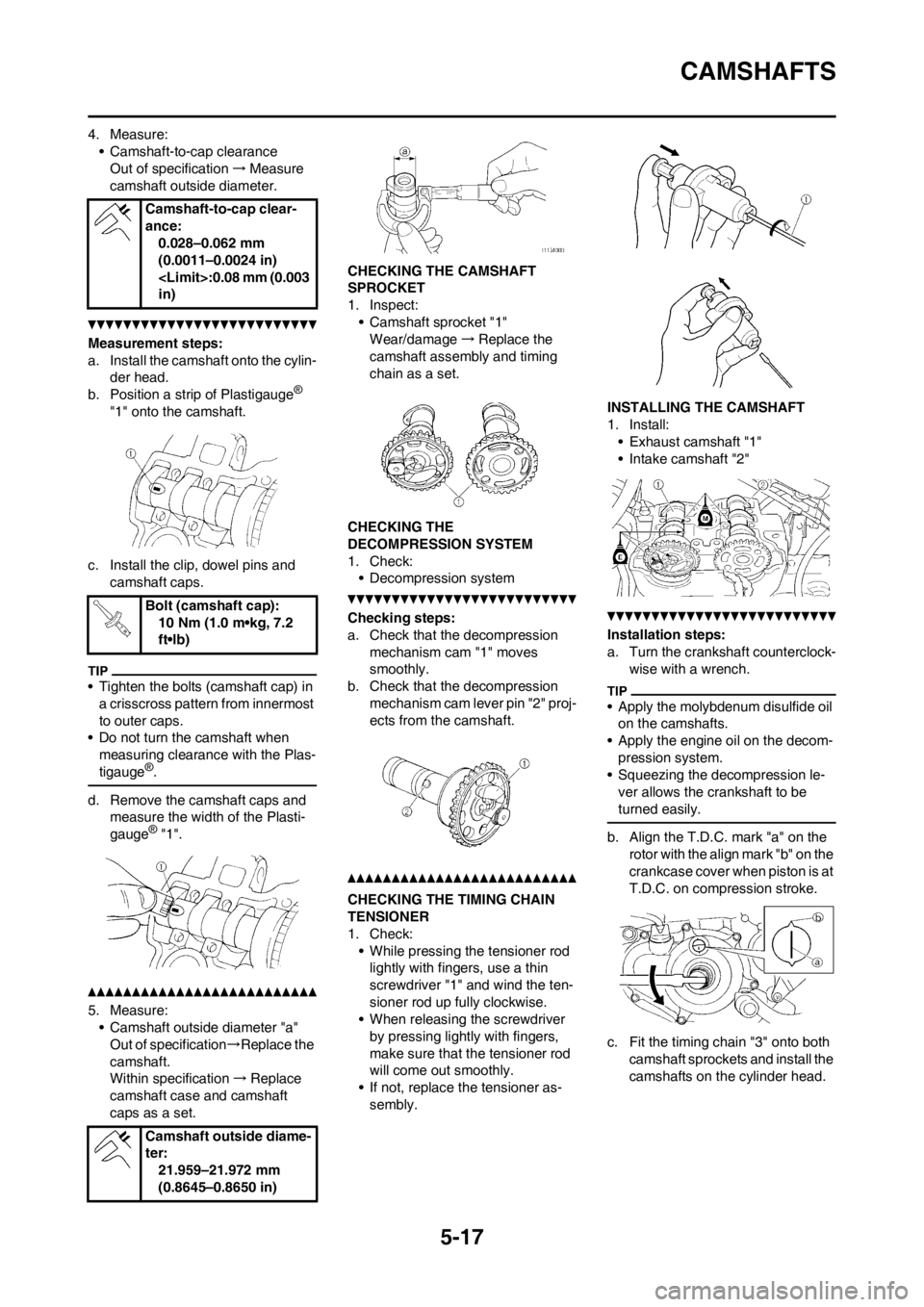

4. Measure:

• Camshaft-to-cap clearance

Out of specification→Measure

camshaft outside diameter.

Measurement steps:

a. Install the camshaft onto the cylin-

der head.

b. Position a strip of Plastigauge

®

"1" onto the camshaft.

c. Install the clip, dowel pins and

camshaft caps.

• Tighten the bolts (camshaft cap) in

a crisscross pattern from innermost

to outer caps.

• Do not turn the camshaft when

measuring clearance with the Plas-

tigauge

®.

d. Remove the camshaft caps and

measure the width of the Plasti-

gauge

® "1".

5. Measure:

• Camshaft outside diameter "a"

Out of specification→Replace the

camshaft.

Within specification→Replace

camshaft case and camshaft

caps as a set.CHECKING THE CAMSHAFT

SPROCKET

1. Inspect:

• Camshaft sprocket "1"

Wear/damage→Replace the

camshaft assembly and timing

chain as a set.

CHECKING THE

DECOMPRESSION SYSTEM

1. Check:

• Decompression system

Checking steps:

a. Check that the decompression

mechanism cam "1" moves

smoothly.

b. Check that the decompression

mechanism cam lever pin "2" proj-

ects from the camshaft.

CHECKING THE TIMING CHAIN

TENSIONER

1. Check:

• While pressing the tensioner rod

lightly with fingers, use a thin

screwdriver "1" and wind the ten-

sioner rod up fully clockwise.

• When releasing the screwdriver

by pressing lightly with fingers,

make sure that the tensioner rod

will come out smoothly.

• If not, replace the tensioner as-

sembly.INSTALLING THE CAMSHAFT

1. Install:

• Exhaust camshaft "1"

• Intake camshaft "2"

Installation steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

• Apply the molybdenum disulfide oil

on the camshafts.

• Apply the engine oil on the decom-

pression system.

• Squeezing the decompression le-

ver allows the crankshaft to be

turned easily.

b. Align the T.D.C. mark "a" on the

rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke.

c. Fit the timing chain "3" onto both

camshaft sprockets and install the

camshafts on the cylinder head. Camshaft-to-cap clear-

ance:

0.028–0.062 mm

(0.0011–0.0024 in)

in)

Bolt (camshaft cap):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Camshaft outside diame-

ter:

21.959–21.972 mm

(0.8645–0.8650 in)

Page 121 of 232

5-18

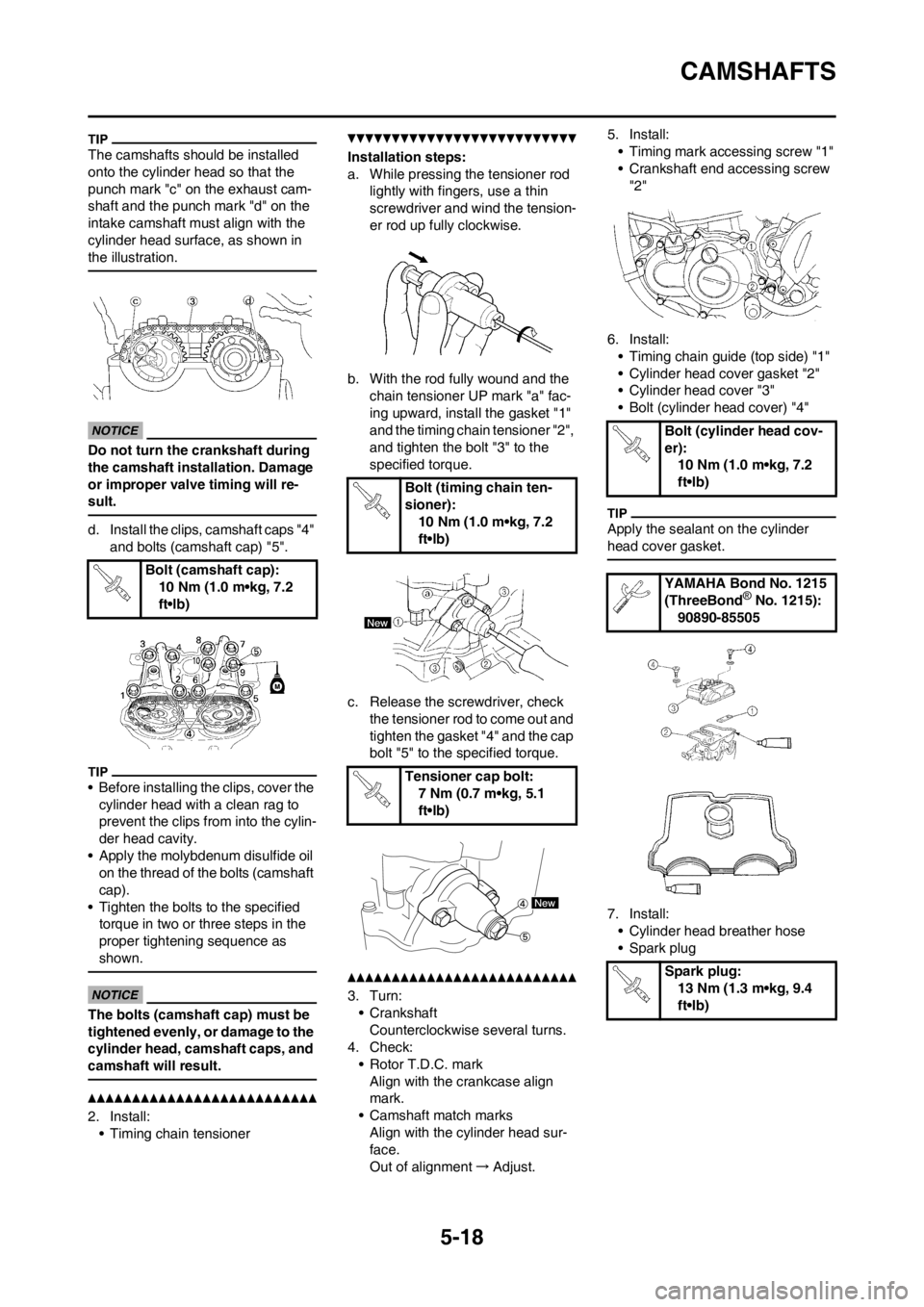

CAMSHAFTS

The camshafts should be installed

onto the cylinder head so that the

punch mark "c" on the exhaust cam-

shaft and the punch mark "d" on the

intake camshaft must align with the

cylinder head surface, as shown in

the illustration.

Do not turn the crankshaft during

the camshaft installation. Damage

or improper valve timing will re-

sult.

d. Install the clips, camshaft caps "4"

and bolts (camshaft cap) "5".

• Before installing the clips, cover the

cylinder head with a clean rag to

prevent the clips from into the cylin-

der head cavity.

• Apply the molybdenum disulfide oil

on the thread of the bolts (camshaft

cap).

• Tighten the bolts to the specified

torque in two or three steps in the

proper tightening sequence as

shown.

The bolts (camshaft cap) must be

tightened evenly, or damage to the

cylinder head, camshaft caps, and

camshaft will result.

2. Install:

• Timing chain tensioner

Installation steps:

a. While pressing the tensioner rod

lightly with fingers, use a thin

screwdriver and wind the tension-

er rod up fully clockwise.

b. With the rod fully wound and the

chain tensioner UP mark "a" fac-

ing upward, install the gasket "1"

and the timing chain tensioner "2",

and tighten the bolt "3" to the

specified torque.

c. Release the screwdriver, check

the tensioner rod to come out and

tighten the gasket "4" and the cap

bolt "5" to the specified torque.

3. Turn:

• Crankshaft

Counterclockwise several turns.

4. Check:

• Rotor T.D.C. mark

Align with the crankcase align

mark.

• Camshaft match marks

Align with the cylinder head sur-

face.

Out of alignment→Adjust.5. Install:

• Timing mark accessing screw "1"

• Crankshaft end accessing screw

"2"

6. Install:

• Timing chain guide (top side) "1"

• Cylinder head cover gasket "2"

• Cylinder head cover "3"

• Bolt (cylinder head cover) "4"

Apply the sealant on the cylinder

head cover gasket.

7. Install:

• Cylinder head breather hose

• Spark plug Bolt (camshaft cap):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (timing chain ten-

sioner):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Tensioner cap bolt:

7 Nm (0.7 m•kg, 5.1

ft•lb)

Bolt (cylinder head cov-

er):

10 Nm (1.0 m•kg, 7.2

ft•lb)

YAMAHA Bond No. 1215

(ThreeBond

® No. 1215):

90890-85505

Spark plug:

13 Nm (1.3 m•kg, 9.4

ft•lb)

Page 133 of 232

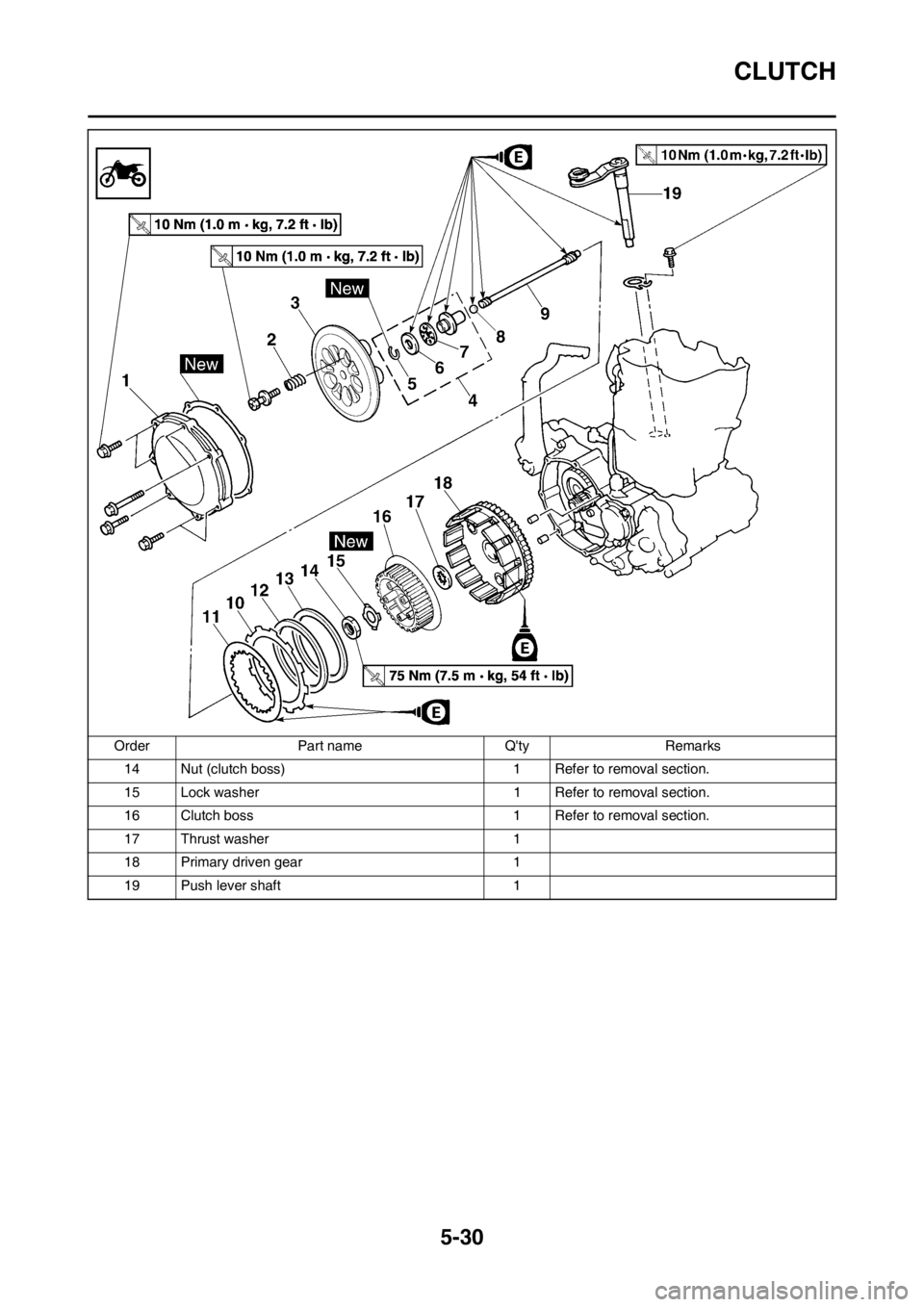

5-30

CLUTCH

14 Nut (clutch boss) 1 Refer to removal section.

15 Lock washer 1 Refer to removal section.

16 Clutch boss 1 Refer to removal section.

17 Thrust washer 1

18 Primary driven gear 1

19 Push lever shaft 1 Order Part name Q'ty Remarks