stop start YAMAHA WR 250F 2013 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: WR 250F, Model: YAMAHA WR 250F 2013Pages: 232, PDF Size: 13.36 MB

Page 211 of 232

7-2

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

WIRING DIAGRAM

1. Headlight

2. Multi-function display

3. Engine stop switch

4. Clutch switch

5. Diode

6. Starter relay diode

7. Throttle position sensor

8. Starter relay

9. Fuse

10. Starting circuit cut-off relay

11. CDI unit

12. Taillight

13. Neutral switch

14. Starter motor

15. AC magneto

16. Rectifier/regulator

17. Ignition coil

18. Spark plug

19. Start switch

20. Main switch

21. Speed sensor

22. Battery

*1: For USA, CDN and EUROPE

*2: For AUS, NZ and ZACOLOR CODE

BBlack

Br Brown

Ch Chocolate

Dg Dark green

GGreen

Gy Gray

LBlue

O Orange

RRed

Sb Sky blue

WWhite

YYellow

B/L Black/Blue

B/W Black/White

L/B Blue/Black

L/R Blue/Red

L/Y Blue/Yellow

L/W Blue/White

R/B Red/Black

R/W Red/White

7

Page 213 of 232

7-4

IGNITION SYSTEM

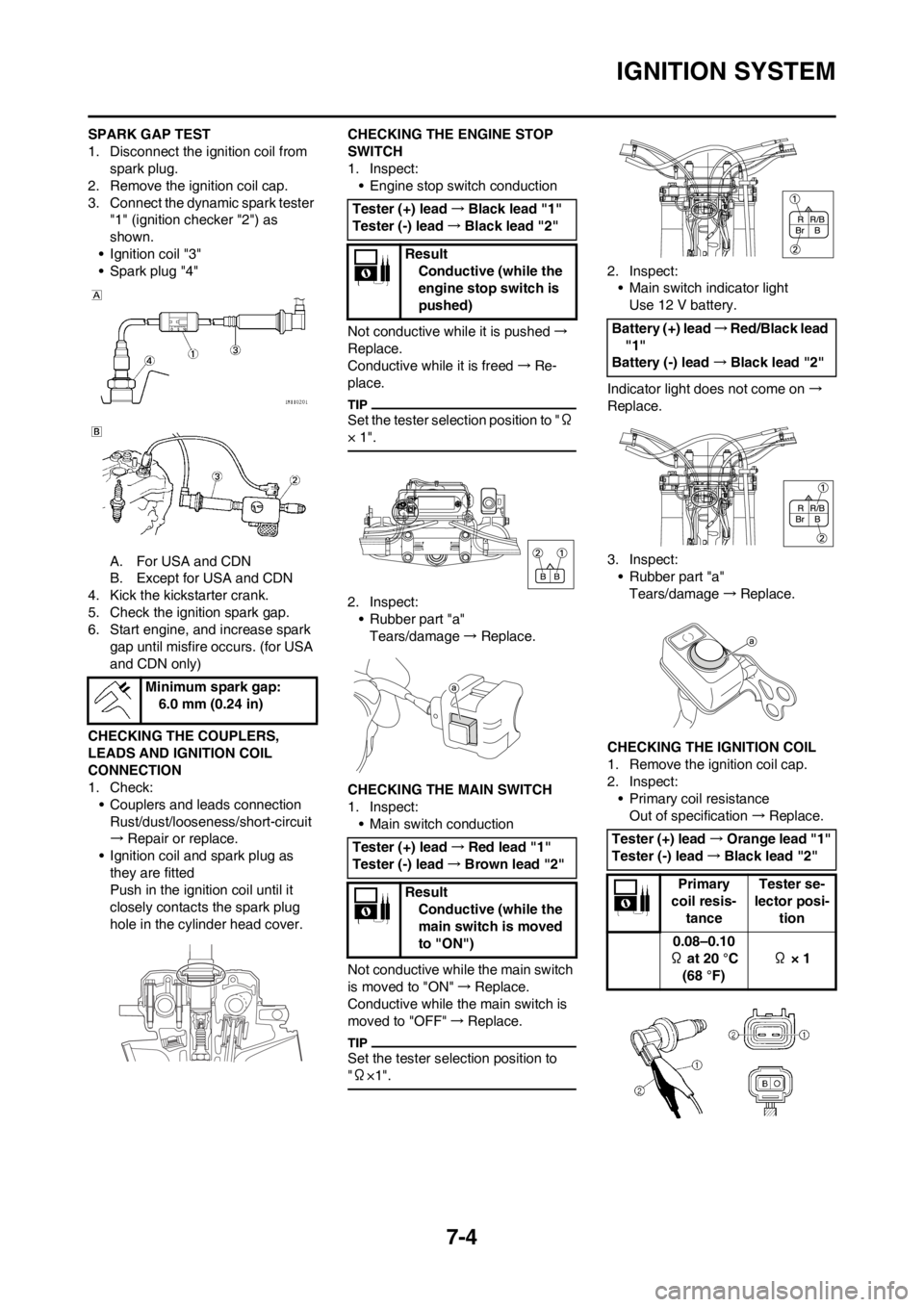

SPARK GAP TEST

1. Disconnect the ignition coil from

spark plug.

2. Remove the ignition coil cap.

3. Connect the dynamic spark tester

"1" (ignition checker "2") as

shown.

• Ignition coil "3"

• Spark plug "4"

A. For USA and CDN

B. Except for USA and CDN

4. Kick the kickstarter crank.

5. Check the ignition spark gap.

6. Start engine, and increase spark

gap until misfire occurs. (for USA

and CDN only)

CHECKING THE COUPLERS,

LEADS AND IGNITION COIL

CONNECTION

1. Check:

• Couplers and leads connection

Rust/dust/looseness/short-circuit

→Repair or replace.

• Ignition coil and spark plug as

they are fitted

Push in the ignition coil until it

closely contacts the spark plug

hole in the cylinder head cover.CHECKING THE ENGINE STOP

SWITCH

1. Inspect:

• Engine stop switch conduction

Not conductive while it is pushed→

Replace.

Conductive while it is freed→Re-

place.

Set the tester selection position to "Ω

× 1".

2. Inspect:

• Rubber part "a"

Tears/damage→ Replace.

CHECKING THE MAIN SWITCH

1. Inspect:

• Main switch conduction

Not conductive while the main switch

is moved to "ON"→Replace.

Conductive while the main switch is

moved to "OFF"→Replace.

Set the tester selection position to

"Ω×1".

2. Inspect:

• Main switch indicator light

Use 12 V battery.

Indicator light does not come on→

Replace.

3. Inspect:

• Rubber part "a"

Tears/damage→Replace.

CHECKING THE IGNITION COIL

1. Remove the ignition coil cap.

2. Inspect:

• Primary coil resistance

Out of specification→Replace. Minimum spark gap:

6.0 mm (0.24 in)

Tester (+) lead→Black lead "1"

Tester (-) lead→Black lead "2"

Result

Conductive (while the

engine stop switch is

pushed)

Tester (+) lead→Red lead "1"

Tester (-) lead→Brown lead "2"

Result

Conductive (while the

main switch is moved

to "ON")

Battery (+) lead→Red/Black lead

"1"

Battery (-) lead→Black lead "2"

Tester (+) lead→Orange lead "1"

Tester (-) lead→Black lead "2"

Primary

coil resis-

tanceTester se-

lector posi-

tion

0.08–0.10

Ω at 20 °C

(68 °F) Ω × 1

Page 225 of 232

7-16

THROTTLE POSITION SENSOR SYSTEM

HANDLING NOTE

Do not loosen the screw (throttle

position sensor) "1" except when

changing the throttle position sen-

sor due to failure because it will

cause a drop in engine perfor-

mance.

CHECKING THE COUPLERS AND

LEADS CONNECTION

1. Check:

• Couplers and leads connection

Rust/dust/looseness/short-circuit

→Repair or replace.

CHECKING THE THROTTLE

POSITION SENSOR COIL

1. Inspect:

• Throttle position sensor coil resis-

tance

Out of specification→Replace.

2. Loosen:

• Throttle stop screw "1"

Turn out the throttle stop screw until

the throttle shaft is in the full close po-

sition.

3. Inspect:

• Throttle position sensor coil vari-

able resistance

Check that the resistance in in-

creased as the throttle grip is

moved from the full close position

to the full open position.

Out of specification→Replace.

CHANGING AND ADJUSTING THE

THROTTLE POSITION SENSOR

1. Remove:

• Throttle position sensor coupler

• Carburetor

2. Remove:

• Screw (throttle position sensor)

"1"

• Throttle position sensor "2"

Loosen the screw (throttle position

sensor) using the T25 bit.

3. Replace:

• Throttle position sensor4. Install:

• Throttle position sensor "1"

• Screw (throttle position sensor)

"2"

• Align the slot "a" in the throttle posi-

tion sensor with the projection "b"

on the carburetor.

• Temporarily tighten the screw

(throttle position sensor).

5. Install:

•Carburetor

• Throttle position sensor coupler

6. Adjust:

• Engine idling speed

Refer to "ADJUSTING THE EN-

GINE IDLING SPEED" section in

the CHAPTER 3.

7. Insert the thin electric conductors

"2" (lead) into the throttle position

sensor coupler "1", as shown, and

connect the tester to them.

• Do not insert the electric conduc-

tors more than required because

it may reduce the waterproof

function of the coupler.

• Make sure that a short-circuit

does not develop between the

terminals because it may cause

damage to electrical compo-

nents.

8. Start the engine. Tester (+) lead→Blue lead "1"

Tester (-) lead→Black lead "2"

Throttle po-

sition sen-

sor coil

resistanceTester se-

lector posi-

tion

4–6 kΩ at

20°C (68 °F) kΩ×1

Tester (+) lead→Yellow lead "1"

Tester (-) lead→Black lead "2"

Throttle posi-

tion sensor coil

variable resis-

tanceTester

selec-

tor po-

sition

Full

closedFull

opene

d

kΩ×1

Zero –3

kΩat

20°C

(68 °F)4–6

kΩat

20 °C

(68 °F)

Tester (+) lead→Yellow lead "3"

Tester (-) lead→Black lead "4"

Page 226 of 232

7-17

THROTTLE POSITION SENSOR SYSTEM

9. Adjust:

• Throttle position sensor output

voltage

Adjustment steps:

a. Adjust the installation angle of the

throttle position sensor "1" to ob-

tain the specified output voltage.

Measure the output voltage accurate-

ly with a digital electronic voltmeter

that gives an easy reading of a small

voltage.

10. Put the aligning marks "a" on the

throttle position sensor and car-

buretor.

11. Stop the engine.

12. Remove the carburetor.

13. Tighten:

• Screw (throttle position sensor)

"1"

Tighten the screw (throttle position

sensor) using the T25 bit.

14. Install the carburetor.CHECKING THE THROTTLE

POSITION SENSOR INPUT

VOLTAGE

1. Disconnect the throttle position

sensor coupler.

2. Start the engine.

3. Inspect:

• Throttle position sensor input volt-

age

Out of specification→Replace the

CDI unit.

Throttle po-

sition sen-

sor output

voltageTester se-

lector posi-

tion

0.58–0.78 V DCV

Tester (+) lead→Blue lead "1"

Tester (-) lead→Black/Blue lead

"2"

Throttle po-

sition sen-

sor input

voltage Tester se-

lector posi-

tion

4–6 V DCV-20