relay YAMAHA WR 250F 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 250F, Model: YAMAHA WR 250F 2016Pages: 428, PDF Size: 14.13 MB

Page 214 of 428

REAR SHOCK ABSORBER ASSEMBLY

5-60

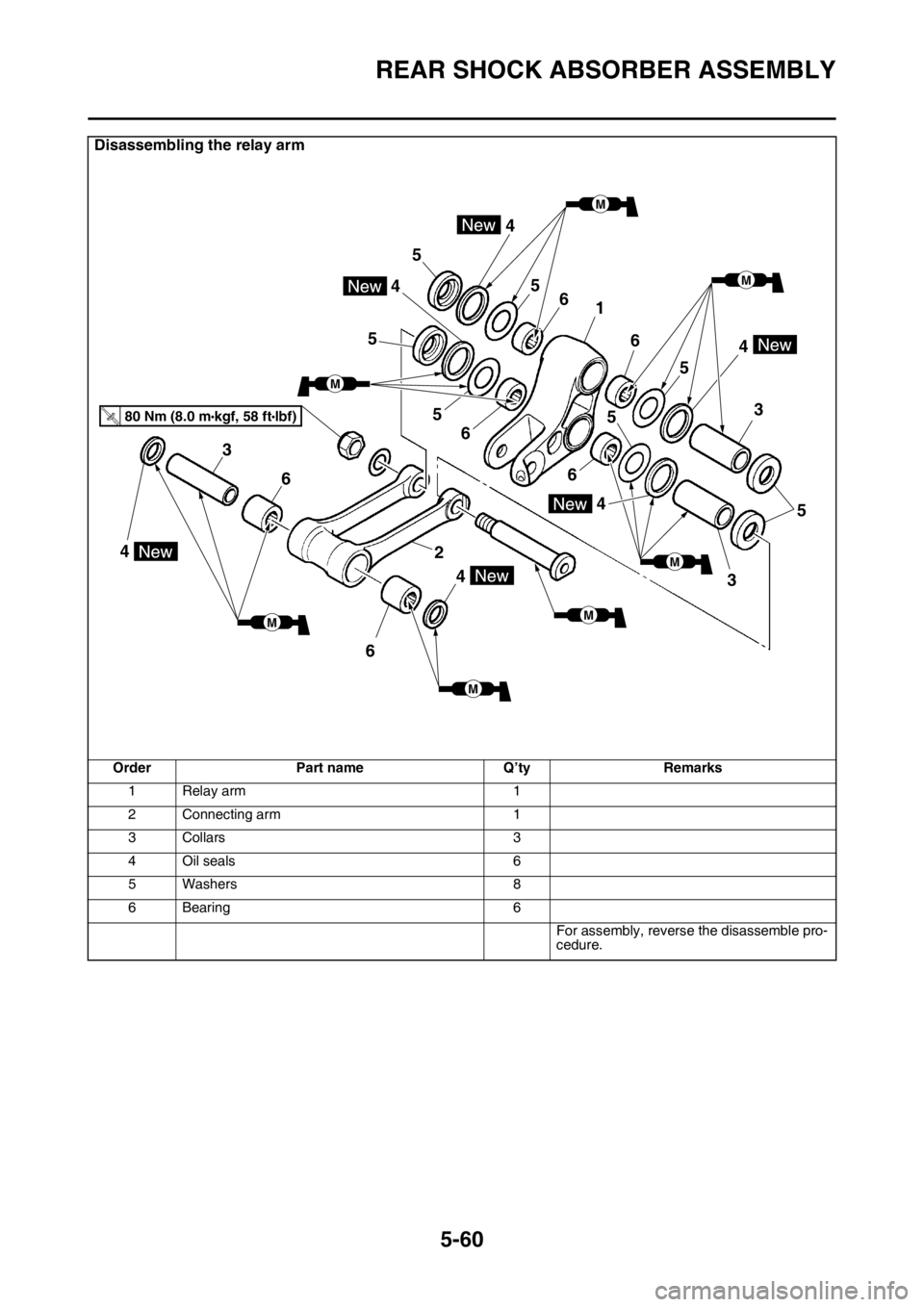

Disassembling the relay arm

Order Part name Q’ty Remarks

1 Relay arm 1

2 Connecting arm 1

3Collars 3

4Oil seals 6

5Washers 8

6 Bearing 6

For assembly, reverse the disassemble pro-

cedure.

5

3

5

6

165

4

5

5

4

5

6

6

5

4

3

2

4

6

6

3

4

4

T.R.80 Nm (8.0 mlbf) kgf, 58 ft

M

M

M

M

M MM

Page 216 of 428

REAR SHOCK ABSORBER ASSEMBLY

5-62

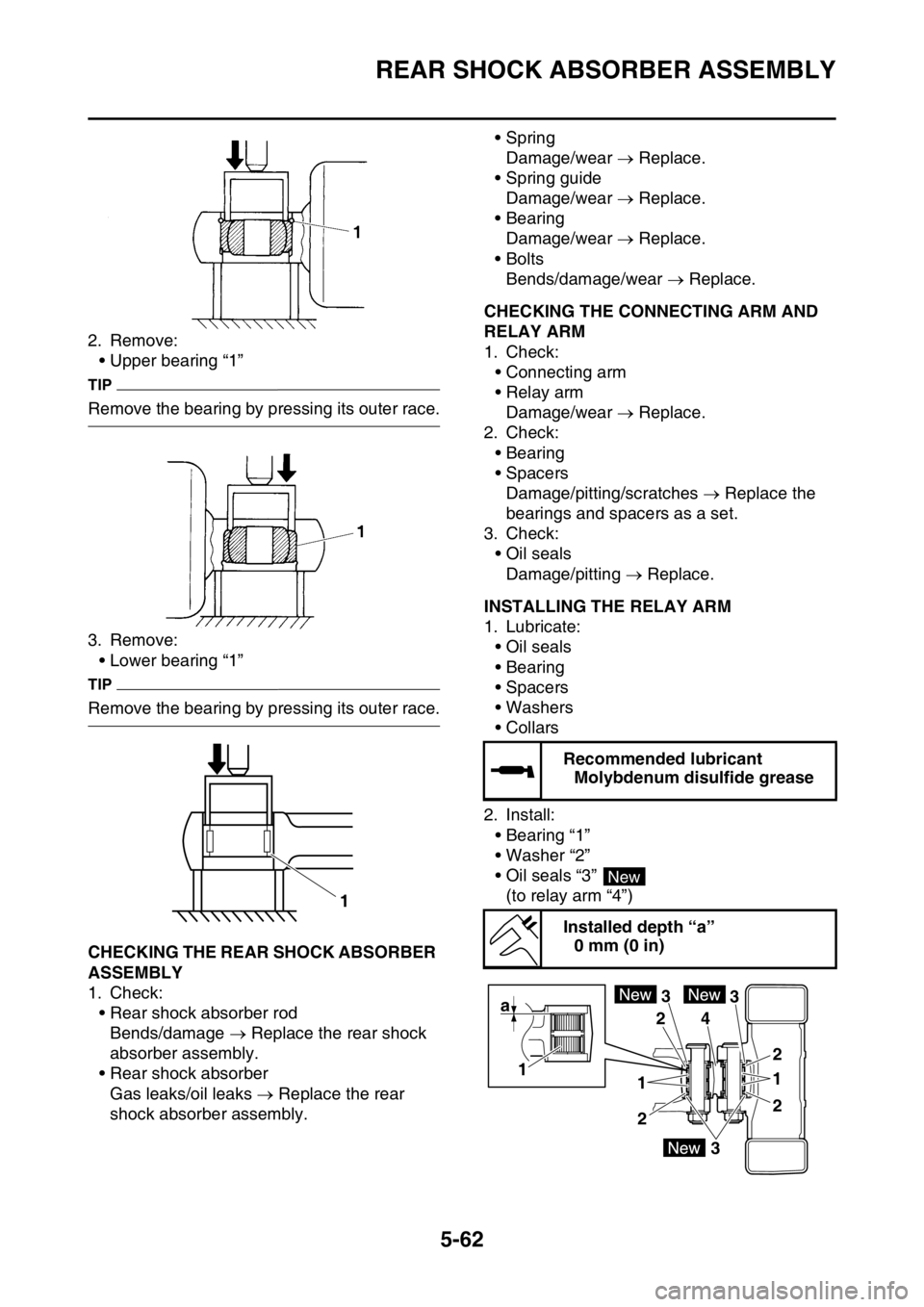

2. Remove:

• Upper bearing “1”

TIP

Remove the bearing by pressing its outer race.

3. Remove:

• Lower bearing “1”

TIP

Remove the bearing by pressing its outer race.

EAS2GB7212CHECKING THE REAR SHOCK ABSORBER

ASSEMBLY

1. Check:

• Rear shock absorber rod

Bends/damage Replace the rear shock

absorber assembly.

• Rear shock absorber

Gas leaks/oil leaks Replace the rear

shock absorber assembly.•Spring

Damage/wear Replace.

• Spring guide

Damage/wear Replace.

• Bearing

Damage/wear Replace.

•Bolts

Bends/damage/wear Replace.

EAS2GB7213CHECKING THE CONNECTING ARM AND

RELAY ARM

1. Check:

• Connecting arm

• Relay arm

Damage/wear Replace.

2. Check:

• Bearing

• Spacers

Damage/pitting/scratches Replace the

bearings and spacers as a set.

3. Check:

• Oil seals

Damage/pitting Replace.

EAS2GB7214INSTALLING THE RELAY ARM

1. Lubricate:

• Oil seals

• Bearing

• Spacers

• Washers

•Collars

2. Install:

• Bearing “1”

• Washer “2”

• Oil seals “3”

(to relay arm “4”)

1

Recommended lubricant

Molybdenum disulfide grease

Installed depth “a”

0 mm (0 in)

New

3 3

43

2 2

22

a

1

11

Page 217 of 428

REAR SHOCK ABSORBER ASSEMBLY

5-63

3. Install:

• Bearing “1”

• Oil seals “2”

(to connecting arm “3”)

EAS2GB7215INSTALLING THE REAR SHOCK ABSORB-

ER ASSEMBLY

1. Lubricate:

• Bearing (lower side)

•Dust seal

•Collars

• Bushing

ECA

NOTICE

Do not apply the grease to the bearing outer

race because it will wear the rear shock ab-

sorber surface on which the bearing is

press fitted.

2. Lubricate:

• O-ring

3. Install:

• Bearing

• Stopper ring

(to rear shock absorber assembly (upper

side))

TIP

• Install the bearing parallel until the stopper

ring groove appears by pressing its outer

race.

• After installing the stopper ring, push back the

bearing unit it contacts the stopper ring.4. Install:

• Bearing “1”

• Bushing “2”

• Collar “3”

• Dust seal “4”

(to rear shock absorber assembly (lower

side))

TIP

Install the dust seals with their lips facing in-

ward.

5. Lubricate:

• Connecting arm and frame bolt

• Relay arm and connecting arm bolt

• Relay arm and swingarm bolt

(circumference and threaded portion)

• Rear shock absorber assembly upper bolt

• Rear shock absorber assembly lower bolt

6. Install:

• Rear shock absorber assembly

TIP

• When installing the rear shock absorber as-

sembly, lift up the swingarm.

• Install the rear shock absorber assembly up-

per bolt, and connecting arm bolt (frame side)

from the right.

• Install the rear shock absorber assembly low-

er bolts, connecting arm bolt (relay arm side),

and relay arm bolt (swingarm side) from the

left.

7. Tighten:

• Rear shock absorber assembly upper bolt Installed depth “a”

0 mm (0 in)

Recommended lubricant

Molybdenum disulfide grease

Recommended lubricant

Lithium-soap-based grease

New

3

a 1

12

a

2

New

Installed depth “a”

4.25 mm (0.17 in)

Recommended lubricant

Molybdenum disulfide grease

Rear shock absorber assembly

upper bolt

56 Nm (5.6 m·kgf, 41 ft·lbf)

T R..

Page 218 of 428

REAR SHOCK ABSORBER ASSEMBLY

5-64

• Connecting arm bolt (frame side)

• Connecting arm bolt (relay arm side)

• Relay arm bolt (swingarm side)

• Rear shock absorber assembly lower boltConnecting arm bolt (frame side)

80 Nm (8.0 m·kgf, 58 ft·lbf)

Connecting arm bolt (relay arm

side)

80 Nm (8.0 m·kgf, 58 ft·lbf)

Relay arm bolt (swingarm side)

70 Nm (7.0 m·kgf, 51 ft·lbf)

Rear shock absorber assembly

lower bolt

53 Nm (5.3 m·kgf, 38 ft·lbf)

T R..

T R..

T R..

T R..

Page 323 of 428

FUEL TANK

8-4

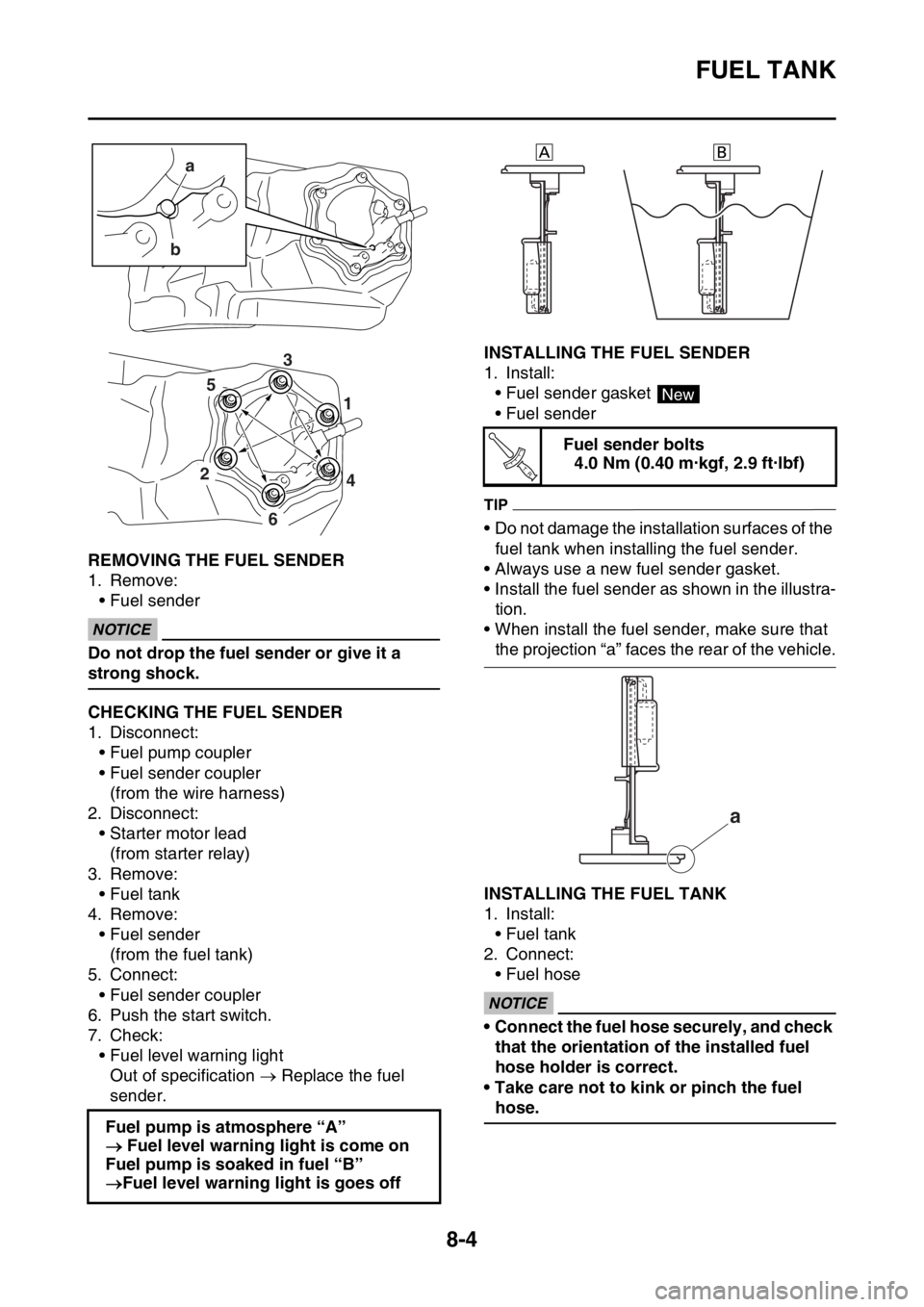

EAS2GB7344REMOVING THE FUEL SENDER

1. Remove:

• Fuel sender

ECA

NOTICE

Do not drop the fuel sender or give it a

strong shock.

EAS2GB7345CHECKING THE FUEL SENDER

1. Disconnect:

• Fuel pump coupler

• Fuel sender coupler

(from the wire harness)

2. Disconnect:

• Starter motor lead

(from starter relay)

3. Remove:

• Fuel tank

4. Remove:

• Fuel sender

(from the fuel tank)

5. Connect:

• Fuel sender coupler

6. Push the start switch.

7. Check:

• Fuel level warning light

Out of specification Replace the fuel

sender.

EAS2GB7346INSTALLING THE FUEL SENDER

1. Install:

• Fuel sender gasket

• Fuel sender

TIP

• Do not damage the installation surfaces of the

fuel tank when installing the fuel sender.

• Always use a new fuel sender gasket.

• Install the fuel sender as shown in the illustra-

tion.

• When install the fuel sender, make sure that

the projection “a” faces the rear of the vehicle.

EAS2GB7347INSTALLING THE FUEL TANK

1. Install:

• Fuel tank

2. Connect:

• Fuel hose

ECA

NOTICE

• Connect the fuel hose securely, and check

that the orientation of the installed fuel

hose holder is correct.

• Take care not to kink or pinch the fuel

hose.

Fuel pump is atmosphere “A”

Fuel level warning light is come on

Fuel pump is soaked in fuel “B”

Fuel level warning light is goes off

a

b

4 1

2

6

53

Fuel sender bolts

4.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

New

T R..

a

Page 332 of 428

ELECTRICAL COMPONENTS....................................................................... 9-60

CHECKING THE SWITCHES .................................................................. 9-64

CHECKING THE BULBS AND BULB SOCKETS .................................... 9-67

CHECKING THE FUSES ......................................................................... 9-68

CHECKING AND CHARGING THE BATTERY ........................................ 9-69

CHECKING THE RELAYS ....................................................................... 9-72

CHECKING THE DIODE .......................................................................... 9-73

CHECKING THE IGNITION SPARK GAP................................................ 9-73

CHECKING THE SPARK PLUG CAP ...................................................... 9-73

CHECKING THE IGNITION COIL ............................................................ 9-74

CHECKING THE CRANKSHAFT POSITION SENSOR........................... 9-74

CHECKING THE LEAN ANGLE SENSOR............................................... 9-75

CHECKING THE STARTER MOTOR OPERATION ................................ 9-75

CHECKING THE STATOR COIL ............................................................. 9-76

CHECKING THE RECTIFIER/REGULATOR ........................................... 9-76

CHECKING THE SPEED SENSOR ......................................................... 9-77

CHECKING THE FUEL SENDER ............................................................ 9-77

CHECKING THE RESISTER ................................................................... 9-77

CHECKING THE RADIATOR FAN MOTOR ............................................ 9-78

CHECKING THE COOLANT TEMPERATURE SENSOR........................ 9-78

CHECKING THE THROTTLE POSITION SENSOR ................................ 9-79

CHECKING THE THROTTLE POSITION SENSOR INPUT VOLTAGE .. 9-79

CHECKING THE INTAKE AIR PRESSURE SENSOR ............................ 9-80

CHECKING THE INTAKE AIR TEMPERATURE SENSOR ..................... 9-80

CHECKING THE FUEL INJECTOR ......................................................... 9-81

Page 335 of 428

IGNITION SYSTEM

9-3

1. Joint connector

2. Joint connector

4. AC magneto

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

22.ECU (engine control unit)

23.Ignition coil

24.Spark plug

30.Joint connector

35.Lean angle sensor

36.Engine stop switch

48.Frame ground

49.Ignition coil sub-lead

Page 339 of 428

ELECTRIC STARTING SYSTEM

9-7

1. Joint connector

2. Joint connector

3. Joint connector

7. Main relay

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

13.Starter motor

14.Starter relay diode

22.ECU (engine control unit)

30.Joint connector

36.Engine stop switch

37.Neutral switch

38.Diode

39.Starting circuit cut-off relay

40.Clutch switch

41.Start switch

48.Frame ground

Page 340 of 428

ELECTRIC STARTING SYSTEM

9-8

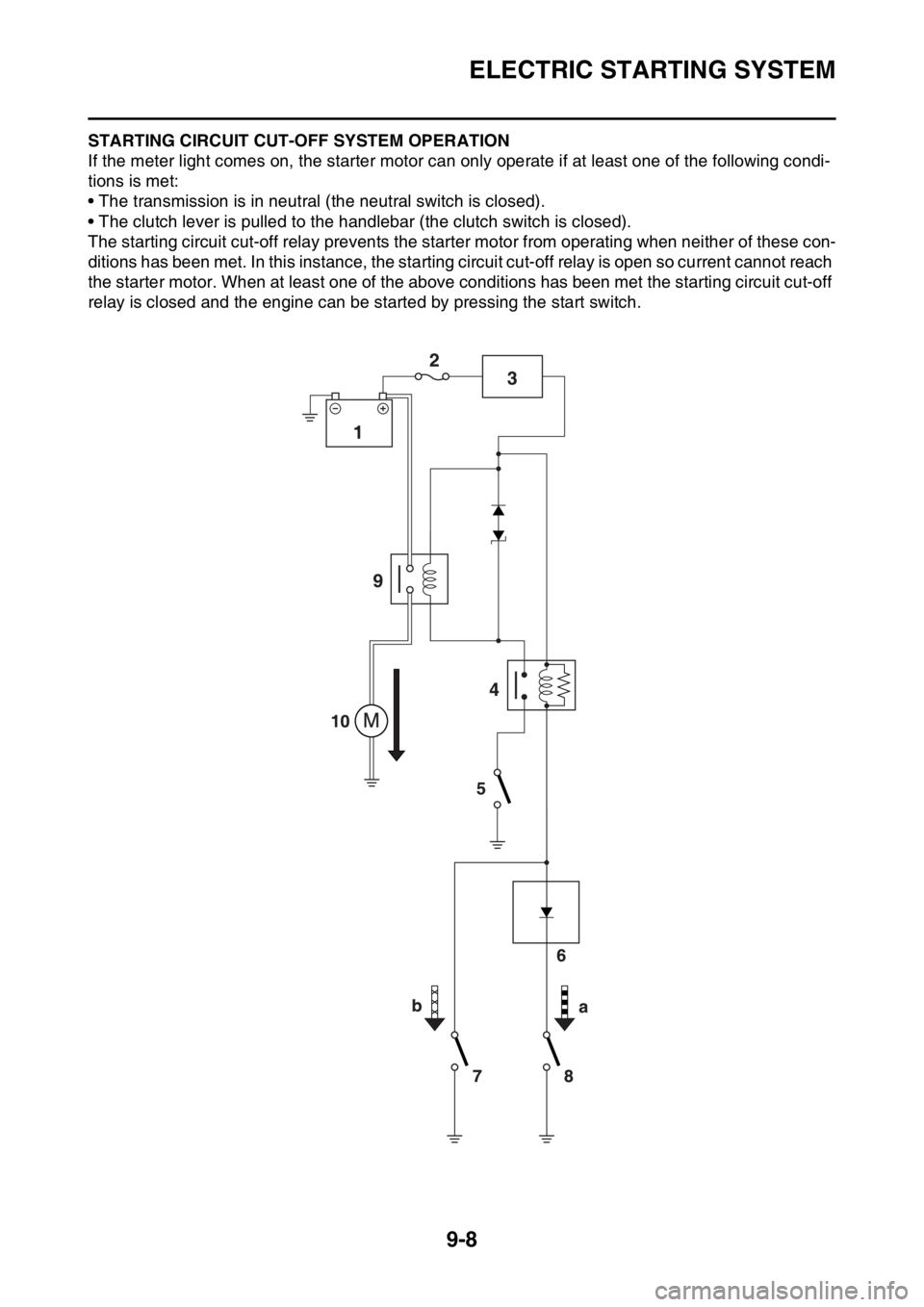

EAS2GB7361STARTING CIRCUIT CUT-OFF SYSTEM OPERATION

If the meter light comes on, the starter motor can only operate if at least one of the following condi-

tions is met:

• The transmission is in neutral (the neutral switch is closed).

• The clutch lever is pulled to the handlebar (the clutch switch is closed).

The starting circuit cut-off relay prevents the starter motor from operating when neither of these con-

ditions has been met. In this instance, the starting circuit cut-off relay is open so current cannot reach

the starter motor. When at least one of the above conditions has been met the starting circuit cut-off

relay is closed and the engine can be started by pressing the start switch.

Page 341 of 428

ELECTRIC STARTING SYSTEM

9-9

a. WHEN THE TRANSMISSION IS IN NEU-

TRAL

b. WHEN THE CLUTCH LEVER IS PULLED

TO THE HANDLEBAR

1. Battery

2. Main fuse

3. Main relay

4. Starting circuit cut-off relay

5. Start switch

6. Diode

7. Clutch switch

8. Neutral switch

9. Starter relay

10.Starter motor