seat adjustment YAMAHA WR 250F 2016 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 250F, Model: YAMAHA WR 250F 2016Pages: 428, PDF Size: 14.13 MB

Page 119 of 428

ENGINE

3-19

4. Measure:

• Engine idling speed

Out of specification Regulate.

5. Adjust:

• Engine idling speed

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

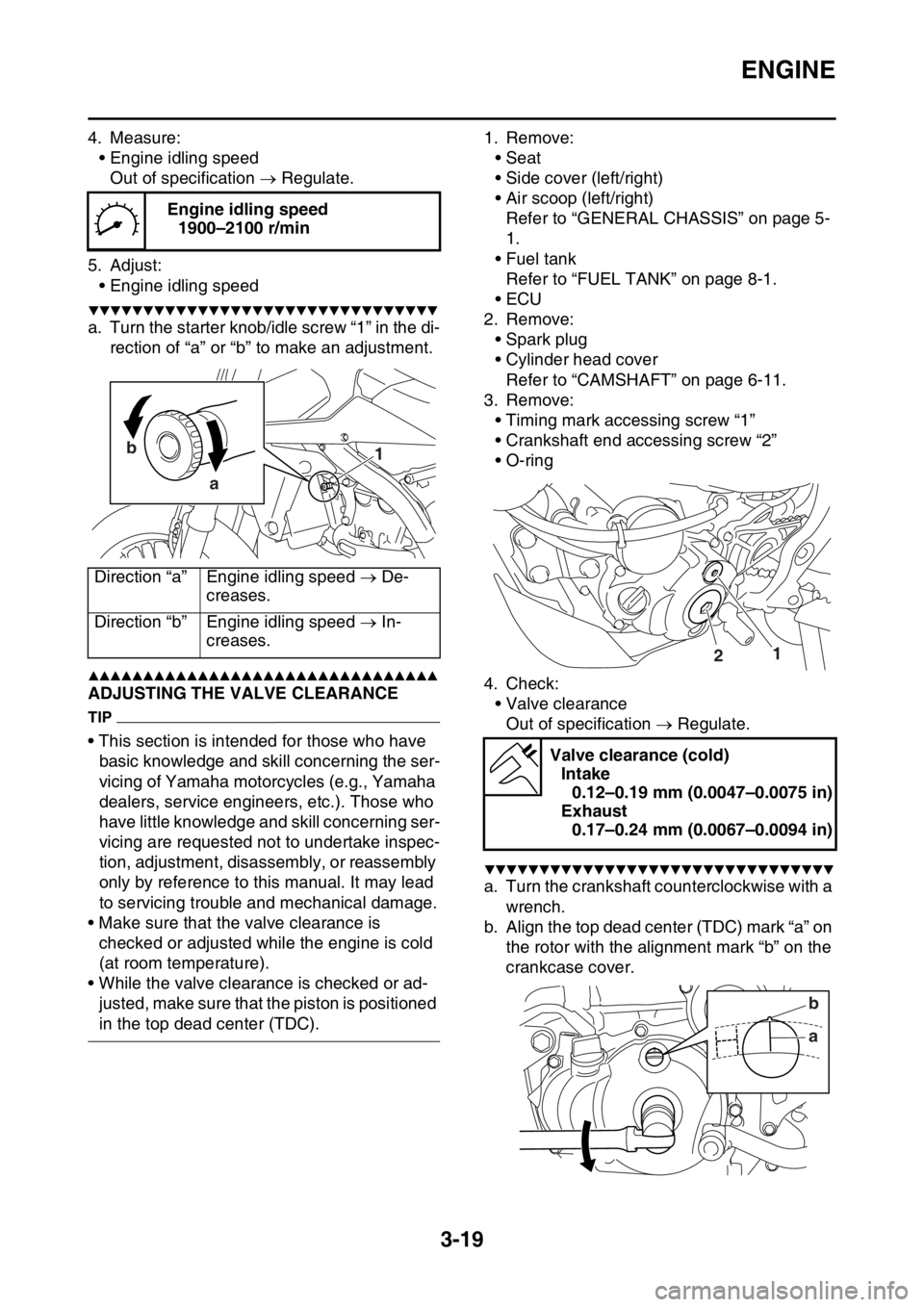

a. Turn the starter knob/idle screw “1” in the di-

rection of “a” or “b” to make an adjustment.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

ADJUSTING THE VALVE CLEARANCE

TIP

• This section is intended for those who have

basic knowledge and skill concerning the ser-

vicing of Yamaha motorcycles (e.g., Yamaha

dealers, service engineers, etc.). Those who

have little knowledge and skill concerning ser-

vicing are requested not to undertake inspec-

tion, adjustment, disassembly, or reassembly

only by reference to this manual. It may lead

to servicing trouble and mechanical damage.

• Make sure that the valve clearance is

checked or adjusted while the engine is cold

(at room temperature).

• While the valve clearance is checked or ad-

justed, make sure that the piston is positioned

in the top dead center (TDC).1. Remove:

• Seat

• Side cover (left/right)

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 5-

1.

• Fuel tank

Refer to “FUEL TANK” on page 8-1.

•ECU

2. Remove:

• Spark plug

• Cylinder head cover

Refer to “CAMSHAFT” on page 6-11.

3. Remove:

• Timing mark accessing screw “1”

• Crankshaft end accessing screw “2”

• O-ring

4. Check:

• Valve clearance

Out of specification Regulate.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft counterclockwise with a

wrench.

b. Align the top dead center (TDC) mark “a” on

the rotor with the alignment mark “b” on the

crankcase cover. Engine idling speed

1900–2100 r/min

Direction “a” Engine idling speed De-

creases.

Direction “b” Engine idling speed In-

creases.

1 b

a

Valve clearance (cold)

Intake

0.12–0.19 mm (0.0047–0.0075 in)

Exhaust

0.17–0.24 mm (0.0067–0.0094 in)

12

ab

Page 133 of 428

CHASSIS

3-33

EAS2GB7116CHECKING THE SWINGARM OPERATION

1. Check:

• Swingarm smooth action

• Swingarm free play

Refer to “SWINGARM” on page 5-65.

EAS2GB7117CHECKING THE REAR SUSPENSION

1. Stand the vehicle upright on a level surface.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Check:

• Rear shock absorber assembly

Gas leaks/oil leaks Replace the rear

shock absorber assembly.

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-58.

3. Check:

• Rear shock absorber assembly smooth ac-

tion

• Rear suspension link smooth action

Sit astride the seat and shake your body up

and down several times to check whether

the rear shock absorber assembly operates

smoothly.

Unsmooth operation Correct or replace.

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-58.

EAS2GB7118ADJUSTING THE REAR SHOCK ABSORB-

ER ASSEMBLY

Use a suitable stand to raise the rear wheel off

the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.Spring preload

ECA

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

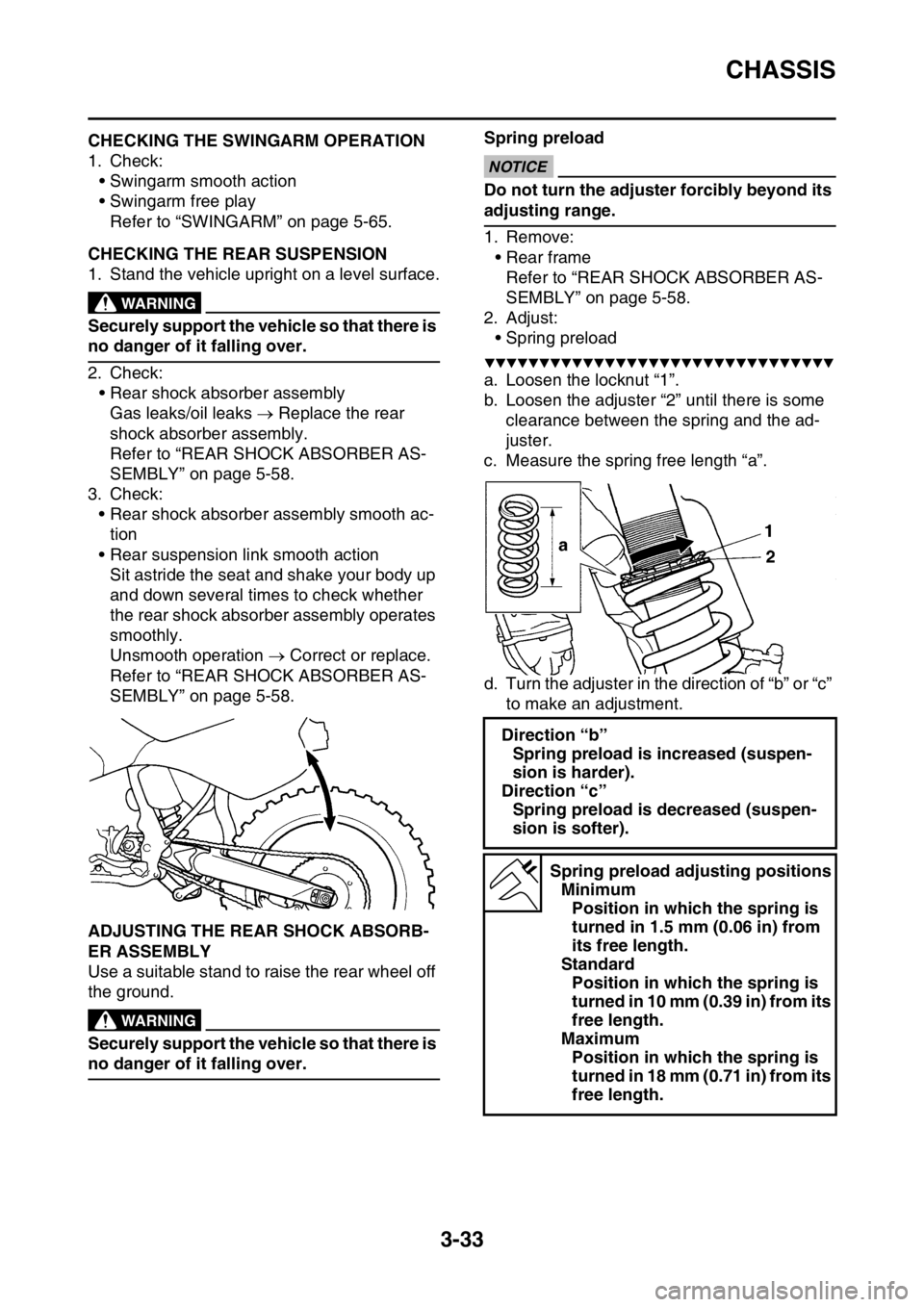

1. Remove:

• Rear frame

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-58.

2. Adjust:

• Spring preload

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the locknut “1”.

b. Loosen the adjuster “2” until there is some

clearance between the spring and the ad-

juster.

c. Measure the spring free length “a”.

d. Turn the adjuster in the direction of “b” or “c”

to make an adjustment.

Direction “b”

Spring preload is increased (suspen-

sion is harder).

Direction “c”

Spring preload is decreased (suspen-

sion is softer).

Spring preload adjusting positions

Minimum

Position in which the spring is

turned in 1.5 mm (0.06 in) from

its free length.

Standard

Position in which the spring is

turned in 10 mm (0.39 in) from its

free length.

Maximum

Position in which the spring is

turned in 18 mm (0.71 in) from its

free length.

Page 146 of 428

CHASSIS

4-3

TIP

Generally a stiff spring gives a stiff riding feel-

ing. Rebound damping tends to become weak-

er, resulting in lack of a sense of contact with

the road surface or in a vibrating handlebar.

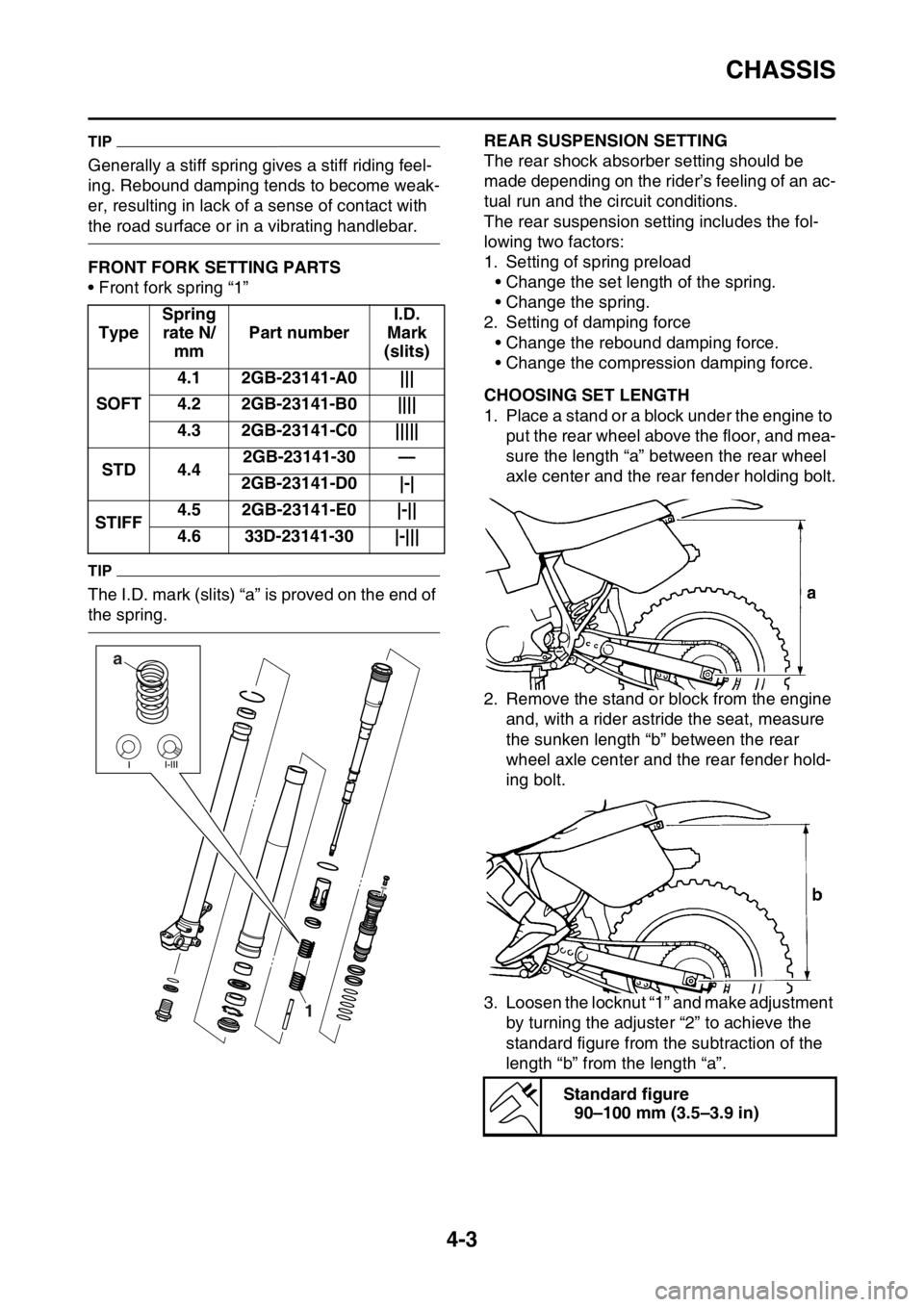

EAS2GB7143FRONT FORK SETTING PARTS

• Front fork spring “1”

TIP

The I.D. mark (slits) “a” is proved on the end of

the spring.

EAS2GB7144REAR SUSPENSION SETTING

The rear shock absorber setting should be

made depending on the rider’s feeling of an ac-

tual run and the circuit conditions.

The rear suspension setting includes the fol-

lowing two factors:

1. Setting of spring preload

• Change the set length of the spring.

• Change the spring.

2. Setting of damping force

• Change the rebound damping force.

• Change the compression damping force.

EAS2GB7145CHOOSING SET LENGTH

1. Place a stand or a block under the engine to

put the rear wheel above the floor, and mea-

sure the length “a” between the rear wheel

axle center and the rear fender holding bolt.

2. Remove the stand or block from the engine

and, with a rider astride the seat, measure

the sunken length “b” between the rear

wheel axle center and the rear fender hold-

ing bolt.

3. Loosen the locknut “1” and make adjustment

by turning the adjuster “2” to achieve the

standard figure from the subtraction of the

length “b” from the length “a”. TypeSpring

rate N/

mmPart numberI.D.

Mark

(slits)

SOFT4.1 2GB-23141-A0 |||

4.2 2GB-23141-B0 ||||

4.3 2GB-23141-C0 |||||

STD 4.42GB-23141-30 —

2GB-23141-D0 |-|

STIFF4.5 2GB-23141-E0 |-||

4.6 33D-23141-30 |-|||

a

1

Standard figure

90–100 mm (3.5–3.9 in)

Page 150 of 428

CHASSIS

4-7

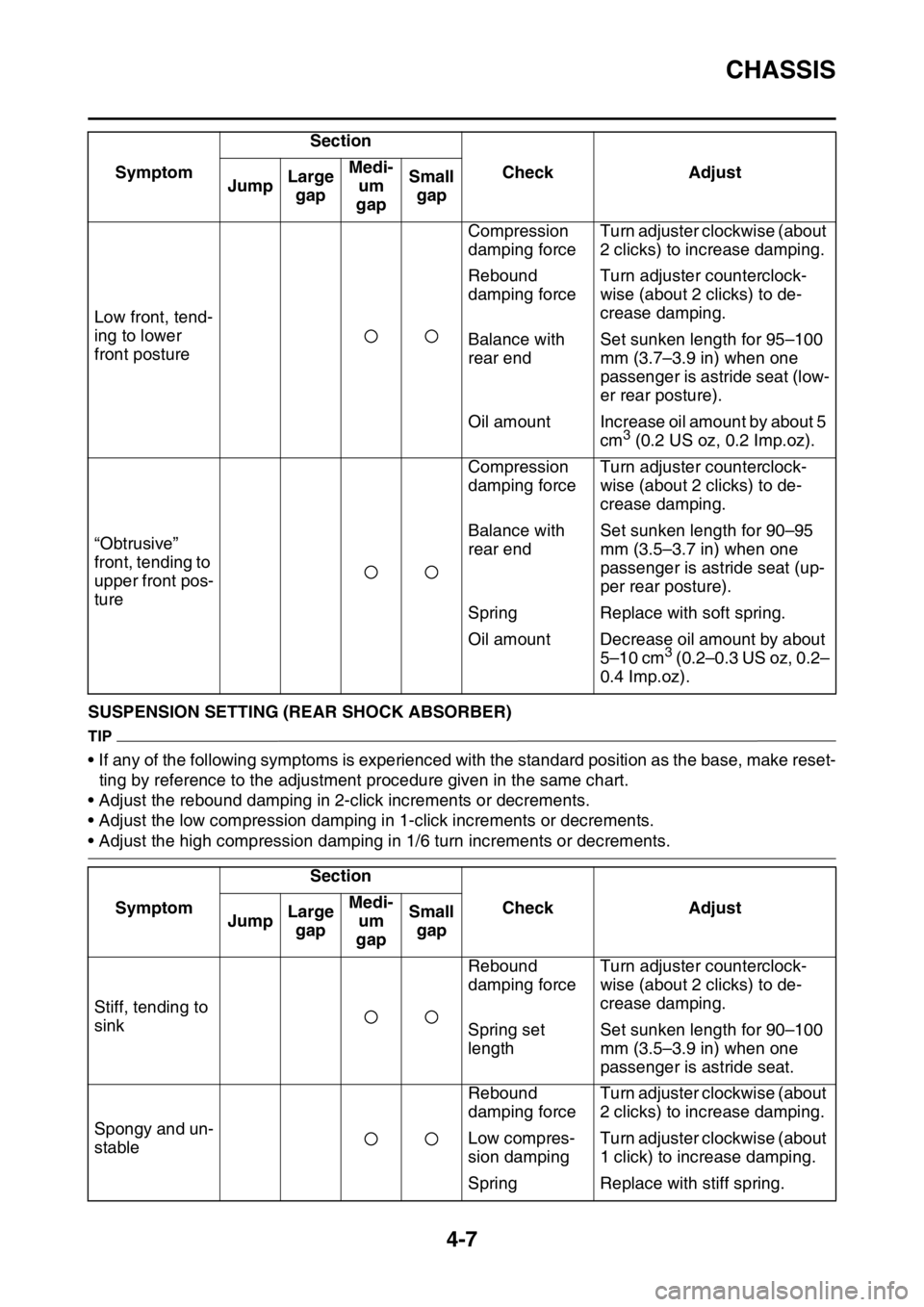

EAS2GB7149SUSPENSION SETTING (REAR SHOCK ABSORBER)

TIP

• If any of the following symptoms is experienced with the standard position as the base, make reset-

ting by reference to the adjustment procedure given in the same chart.

• Adjust the rebound damping in 2-click increments or decrements.

• Adjust the low compression damping in 1-click increments or decrements.

• Adjust the high compression damping in 1/6 turn increments or decrements. Low front, tend-

ing to lower

front postureCompression

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Rebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Balance with

rear endSet sunken length for 95–100

mm (3.7–3.9 in) when one

passenger is astride seat (low-

er rear posture).

Oil amount Increase oil amount by about 5

cm

3 (0.2 US oz, 0.2 Imp.oz).

“Obtrusive”

front, tending to

upper front pos-

tureCompression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Balance with

rear endSet sunken length for 90–95

mm (3.5–3.7 in) when one

passenger is astride seat (up-

per rear posture).

Spring Replace with soft spring.

Oil amount Decrease oil amount by about

5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Stiff, tending to

sinkRebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Spring set

lengthSet sunken length for 90–100

mm (3.5–3.9 in) when one

passenger is astride seat.

Spongy and un-

stableRebound

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Low compres-

sion dampingTurn adjuster clockwise (about

1 click) to increase damping.

Spring Replace with stiff spring. SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Page 155 of 428

GENERAL CHASSIS

5-1

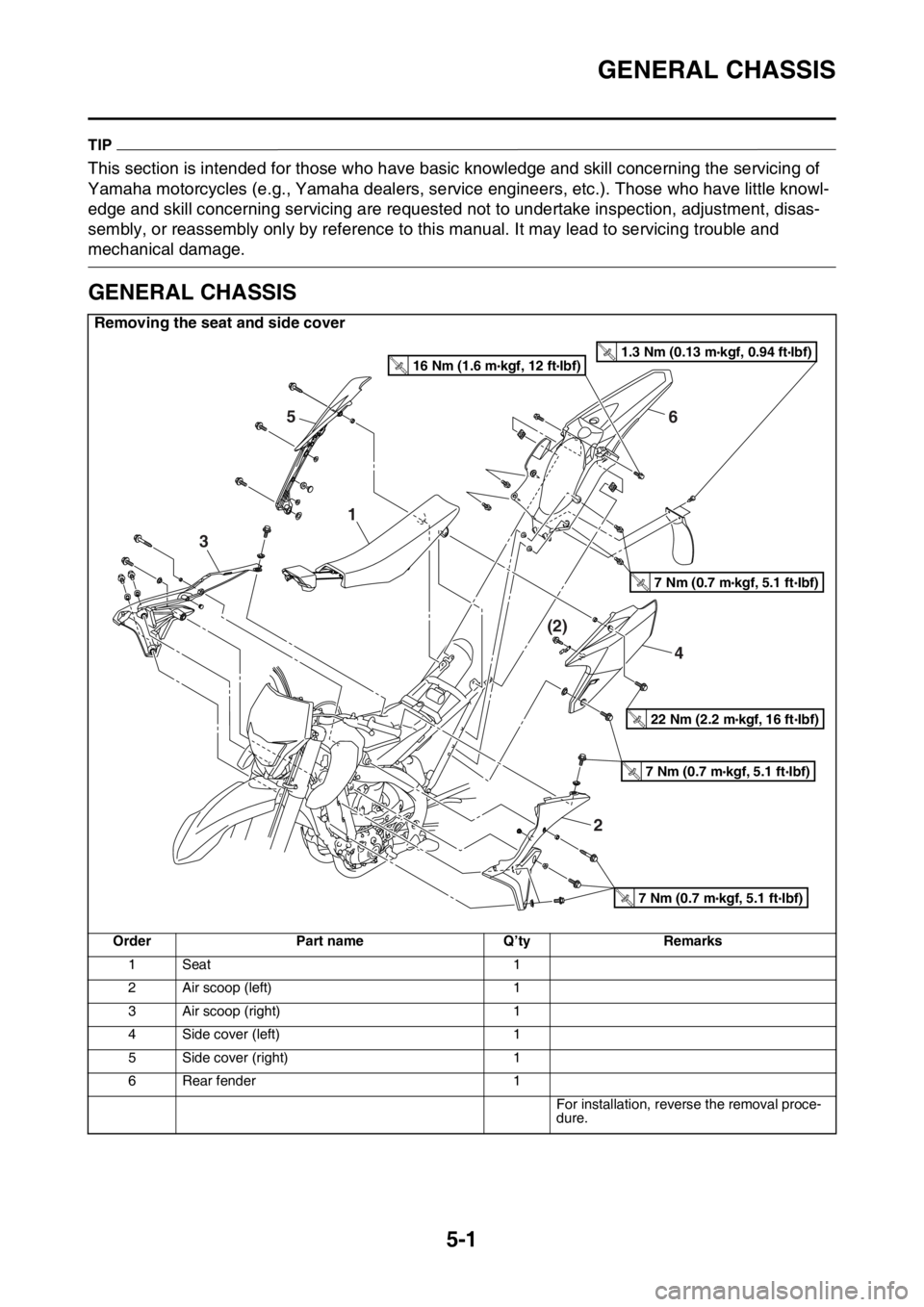

EAS2GB7150

TIP

This section is intended for those who have basic knowledge and skill concerning the servicing of

Yamaha motorcycles (e.g., Yamaha dealers, service engineers, etc.). Those who have little knowl-

edge and skill concerning servicing are requested not to undertake inspection, adjustment, disas-

sembly, or reassembly only by reference to this manual. It may lead to servicing trouble and

mechanical damage.

EAS2GB7151

GENERAL CHASSIS

Removing the seat and side cover

Order Part name Q’ty Remarks

1 Seat 1

2 Air scoop (left) 1

3 Air scoop (right) 1

4 Side cover (left) 1

5 Side cover (right) 1

6 Rear fender 1

For installation, reverse the removal proce-

dure.

4 (2)

65

1

3

2

7 Nm (0.7 m kgf, 5.1 ft Ibf)T.R.

7 Nm (0.7 m kgf, 5.1 ft Ibf)T.R.

7 Nm (0.7 m kgf, 5.1 ft Ibf)T.R.

22 Nm (2.2 m kgf, 16 ft Ibf)T.R.

1.3 Nm (0.13 m kgf, 0.94 ft Ibf)T.R.16 Nm (1.6 m kgf, 12 ft Ibf)T.R.

Page 312 of 428

RADIATOR

7-1

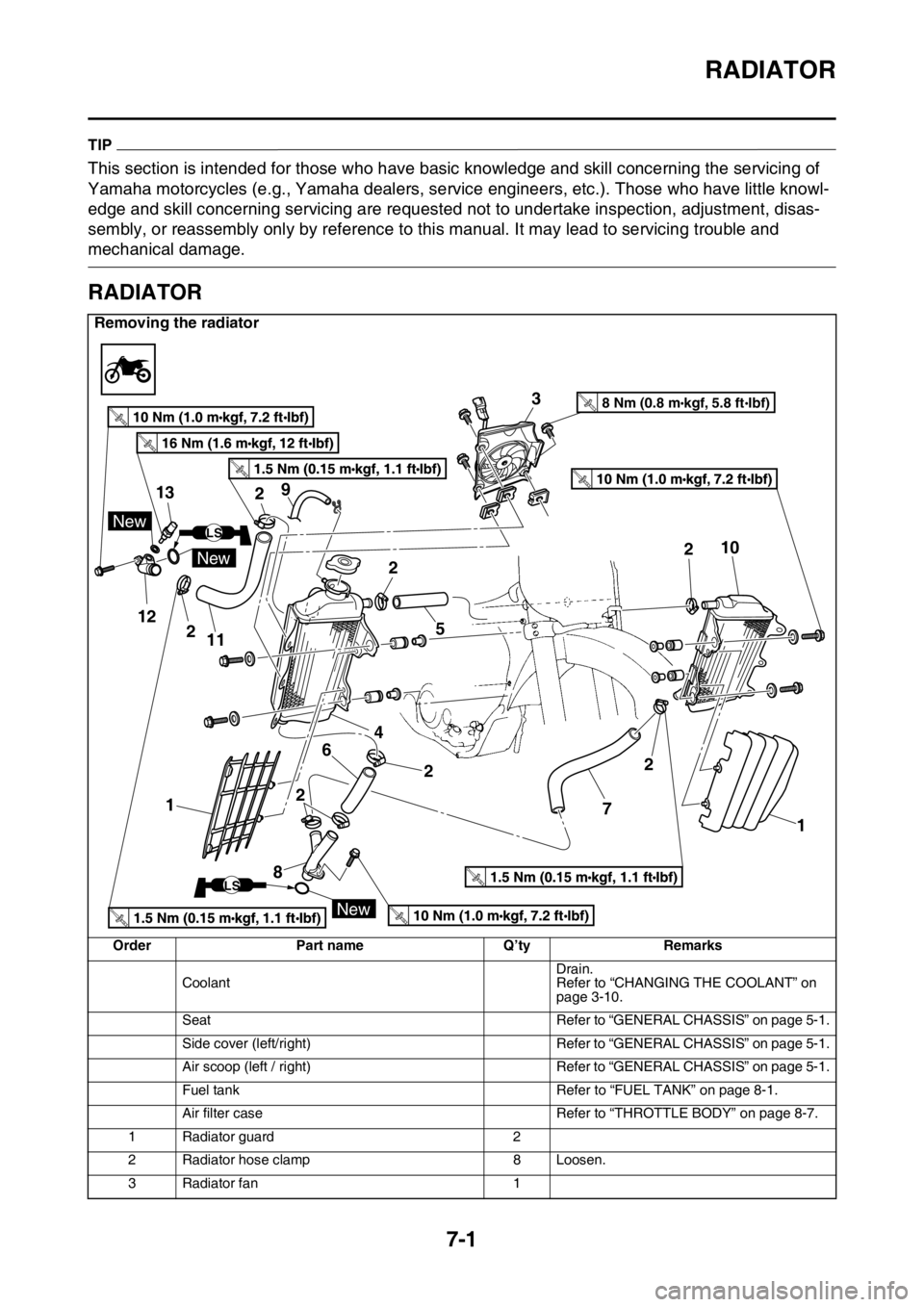

EAS2GB7328

TIP

This section is intended for those who have basic knowledge and skill concerning the servicing of

Yamaha motorcycles (e.g., Yamaha dealers, service engineers, etc.). Those who have little knowl-

edge and skill concerning servicing are requested not to undertake inspection, adjustment, disas-

sembly, or reassembly only by reference to this manual. It may lead to servicing trouble and

mechanical damage.

EAS2GB7329

RADIATOR

Removing the radiator

Order Part name Q’ty Remarks

CoolantDrain.

Refer to “CHANGING THE COOLANT” on

page 3-10.

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left / right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

Air filter case Refer to “THROTTLE BODY” on page 8-7.

1 Radiator guard 2

2 Radiator hose clamp 8 Loosen.

3 Radiator fan 1

12

13

New

New

New

LS

LS

3

458 Nm (0.8 m kgf, 5.8 ft Ibf)T.R.

6

7

89

10

112

2

2

2 22 2

1 1

Page 320 of 428

FUEL TANK

8-1

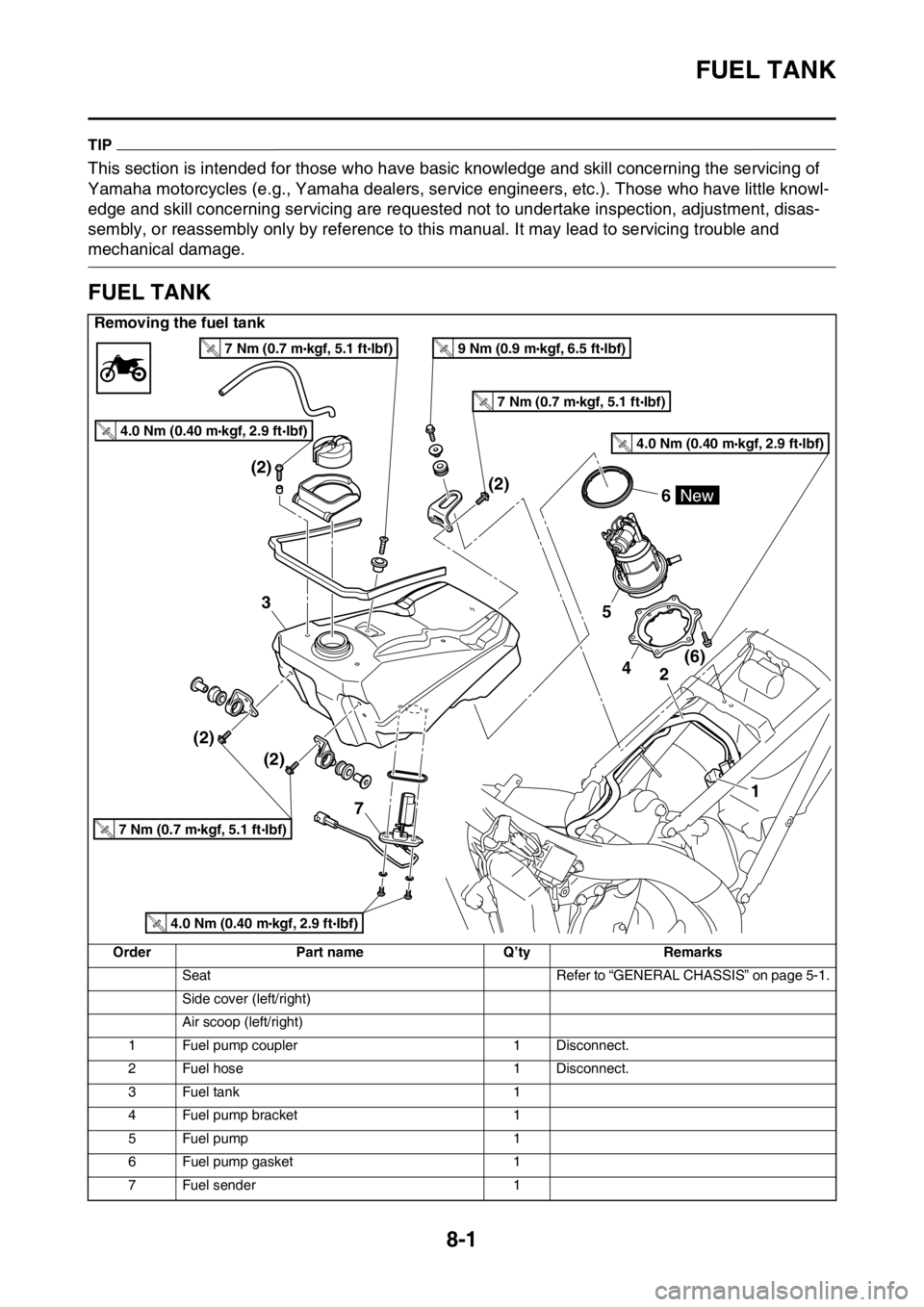

EAS2GB7338

TIP

This section is intended for those who have basic knowledge and skill concerning the servicing of

Yamaha motorcycles (e.g., Yamaha dealers, service engineers, etc.). Those who have little knowl-

edge and skill concerning servicing are requested not to undertake inspection, adjustment, disas-

sembly, or reassembly only by reference to this manual. It may lead to servicing trouble and

mechanical damage.

EAS2GB7339

FUEL TANK

Removing the fuel tank

Order Part name Q’ty Remarks

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left/right)

Air scoop (left/right)

1 Fuel pump coupler 1 Disconnect.

2 Fuel hose 1 Disconnect.

3Fuel tank 1

4 Fuel pump bracket 1

5 Fuel pump 1

6 Fuel pump gasket 1

7 Fuel sender 1

4(6) (2)

(2) (2)(2)2

5

6

3

1

New

4.0 Nm (0.40 m kgf, 2.9 ft Ibf)T.R.

7 Nm (0.7 m kgf, 5.1 ft Ibf)T.R.

7 Nm (0.7 m kgf, 5.1 ft Ibf)T.R.

7 Nm (0.7 m kgf, 5.1 ft Ibf)T.R.

9 Nm (0.9 m kgf, 6.5 ft Ibf)T.R.

4.0 Nm (0.40 m kgf, 2.9 ft Ibf)T.R.

4.0 Nm (0.40 m kgf, 2.9 ft Ibf)T.R.

7

Page 416 of 428

TROUBLESHOOTING

10-1

EAS2GB7405

TROUBLESHOOTING

EAS2GB7406GENERAL INFORMATION

TIP

The following guide for troubleshooting does

not cover all the possible causes of trouble. It

should be helpful, however, as a guide to basic

troubleshooting. Refer to the relative procedure

in this manual for checks, adjustments, and re-

placement of parts.

EAS2GB7407STARTING FAILURES

Engine

1. Cylinder and cylinder head

• Loose spark plug

• Loose cylinder head or cylinder

• Damaged cylinder head gasket

• Damaged cylinder gasket

• Worn or damaged cylinder

• Incorrect valve clearance

• Improperly sealed valve

• Incorrect valve-to-valve-seat contact

• Incorrect valve timing

• Faulty valve spring

• Seized valve

2. Piston and piston ring(s)

• Improperly installed piston ring

• Damaged, worn or fatigued piston ring

• Seized piston ring

• Seized or damaged piston

3. Air filter

• Improperly installed air filter

• Clogged air filter element

4. Crankcase and crankshaft

• Improperly assembled crankcase

• Seized crankshaft

Fuel system

1. Fuel tank

• Empty fuel tank

• Clogged fuel tank breather hose

• Deteriorated or contaminated fuel

• Clogged or damaged fuel hose

2. Fuel pump

• Faulty fuel pump

3. Throttle body

• Deteriorated or contaminated fuel

• Sucked-in air

Electrical system

1. Spark plug

• Incorrect spark plug gap• Incorrect spark plug heat range

• Fouled spark plug

• Worn or damaged electrode

• Worn or damaged insulator

2. Ignition coil

• Cracked or broken ignition coil body

• Broken or shorted primary or secondary

coils

3. Ignition system

• Faulty ECU

• Faulty crankshaft position sensor

• Broken generator rotor woodruff key

4. Switches and wiring

• Faulty ECU

• Faulty engine stop switch

• Broken or shorted wiring

• Faulty neutral switch

• Improperly grounded circuit

• Loose connections

EAS2GB7408INCORRECT ENGINE IDLING SPEED

Engine

1. Cylinder and cylinder head

• Incorrect valve clearance

• Damaged valve train components

2. Air filter

• Clogged air filter element

Fuel system

1. Throttle body

• Damaged or loose throttle body joint

• Improperly synchronized throttle bodies

• Improper throttle cable free play

• Flooded throttle body

Electrical system

1. Spark plug

• Incorrect spark plug gap

• Incorrect spark plug heat range

• Fouled spark plug

• Worn or damaged electrode

• Worn or damaged insulator

• Faulty spark plug cap

2. Ignition coil

• Broken or shorted primary or secondary

coils

• Cracked or broken ignition coil

3. Ignition system

• Faulty ECU

• Faulty crankshaft position sensor

• Broken generator rotor woodruff key