engine YAMAHA WR 250F 2017 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: WR 250F, Model: YAMAHA WR 250F 2017Pages: 432, PDF Size: 14.14 MB

Page 50 of 432

MOTORCYCLE CARE AND STORAGE

1-36

EAS2GBB058

MOTORCYCLE CARE AND STOR-

AGE

EAS2GBB059CARE

While the open design of a motorcycle reveals

the attractiveness of the technology, it also

makes it more vulnerable. Rust and corrosion

can develop even if high-quality components

are used. A rusty exhaust pipe may go unno-

ticed on a car, however, it detracts from the

overall appearance of a motorcycle. Frequent

and proper care does not only comply with the

terms of the warranty, but it will also keep your

motorcycle looking good, extend its life and op-

timize its performance.

Before cleaning

1. Cover the muffler outlet with a plastic bag af-

ter the engine has cooled down.

2. Make sure that all caps and covers as well

as all electrical couplers and connectors, in-

cluding the spark plug cap, are tightly in-

stalled.

3. Remove extremely stubborn dirt, like oil

burnt onto the crankcase, with a degreasing

agent and a brush, but never apply such

products onto seals, gaskets, sprockets, the

drive chain and wheel axles. Always rinse

the dirt and degreaser off with water.

Cleaning

ECA

NOTICE

• Avoid using strong acidic wheel cleaners,

especially on spoked wheels. If such prod-

ucts are used on hard-to-remove dirt, do

not leave the cleaner on the affected area

any longer than instructed. Also, thor-

oughly rinse the area off with water, imme-

diately dry it, and then apply a corrosion

protection spray.

• Improper cleaning can damage plastic

parts (such as cowlings, panels, wind-

shields, headlight lenses, meter lenses,

etc.) and the mufflers. Use only a soft,

clean cloth or sponge with water to clean

plastic. However, if the plastic parts can-

not be thoroughly cleaned with water, di-

luted mild detergent with water may be

used. Be sure to rinse off any detergent

residue using plenty of water, as it is

harmful to plastic parts.• Do not use any harsh chemical products

on plastic parts. Be sure to avoid using

cloths or sponges which have been in con-

tact with strong or abrasive cleaning prod-

ucts, solvent or thinner, fuel (gasoline),

rust removers or inhibitors, brake fluid,

antifreeze or electrolyte.

• Do not use high-pressure washers or

steam-jet cleaners since they cause water

seepage and deterioration in the following

areas: seals (of wheel and swingarm bear-

ings, fork and brakes), electric compo-

nents (couplers, connectors, instruments,

switches and lights), breather hoses and

vents.

• For motorcycles equipped with a wind-

shield: Do not use strong cleaners or hard

sponges as they will cause dulling or

scratching. Some cleaning compounds for

plastic may leave scratches on the wind-

shield. Test the product on a small hidden

part of the windshield to make sure that it

does not leave any marks. If the wind-

shield is scratched, use a quality plastic

polishing compound after washing.

After normal use

Remove dirt with warm water, a mild detergent,

and a soft, clean sponge, and then rinse thor-

oughly with clean water. Use a toothbrush or

bottlebrush for hard-to-reach areas. Stubborn

dirt and insects will come off more easily if the

area is covered with a wet cloth for a few min-

utes before cleaning.

After riding in the rain, near the sea or on salt-

sprayed roads

Since sea salt or salt sprayed on roads during

winter are extremely corrosive in combination

with water, carry out the following steps after

each ride in the rain, near the sea or on salt-

sprayed roads.

TIP

Salt sprayed on roads in the winter may remain

well into spring.

1. Clean the motorcycle with cold water and a

mild detergent, after the engine has cooled

down.

NOTICE: Do not use warm water since it

increases the corrosive action of the salt.

Page 51 of 432

MOTORCYCLE CARE AND STORAGE

1-37

2. Apply a corrosion protection spray on all

metal, including chrome- and nickel-plated,

surfaces to prevent corrosion.

After cleaning

1. Dry the motorcycle with a chamois or an ab-

sorbing cloth.

2. Immediately dry the drive chain and lubri-

cate it to prevent it from rusting.

3. Use a chrome polish to shine chrome, alumi-

num and stainless- steel parts, including the

exhaust system. (Even the thermally in-

duced discoloring of stainless- steel exhaust

systems can be removed through polishing.)

4. To prevent corrosion, it is recommended to

apply a corrosion protection spray on all

metal, including chrome- and nickel-plated,

surfaces.

5. Use spray oil as a universal cleaner to re-

move any remaining dirt.

6. Touch up minor paint damage caused by

stones, etc.

7. Wax all painted surfaces.

8. Let the motorcycle dry completely before

storing or covering it.

EWA

WARNING

Contaminants on the brakes or tires can

cause loss of control.

• Make sure that there is no oil or wax on the

brakes or tires.

• If necessary, clean the brake discs and

brake linings with a regular brake disc

cleaner or acetone, and wash the tires with

warm water and a mild detergent. Before

riding at higher speeds, test the motorcy-

cle’s braking performance and cornering

behavior.

ECA

NOTICE

• Apply spray oil and wax sparingly and

make sure to wipe off any excess.

• Never apply oil or wax to any rubber and

plastic parts, but treat them with a suitable

care product.

• Avoid using abrasive polishing com-

pounds as they will wear away the paint.

TIP

• Consult a Yamaha dealer for advice on what

products to use.

• Washing, rainy weather or humid climates

can cause the headlight lens to fog. Turning

the headlight on for a short period of time will

help remove the moisture from the lens.

EAS2GBB060STORAGE

Short-term

Always store your motorcycle in a cool, dry

place and, if necessary, protect it against dust

with a porous cover. Be sure the engine and the

exhaust system are cool before covering the

motorcycle.

ECA

NOTICE

• Storing the motorcycle in a poorly ventilat-

ed room or covering it with a tarp, while it

is still wet, will allow water and humidity to

seep in and cause rust.

• To prevent corrosion, avoid damp cellars,

stables (because of the presence of am-

monia) and areas where strong chemicals

are stored.

Long-term

Before storing your motorcycle for several

months:

1. Follow all the instructions in the “Care” sec-

tion of this chapter.

2. Fill up the fuel tank and add fuel stabilizer (if

available) to prevent the fuel tank from rust-

ing and the fuel from deteriorating.

3. Perform the following steps to protect the

cylinder, piston rings, etc. from corrosion.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the spark plug cap and spark plug.

b. Pour a teaspoonful of engine oil into the

spark plug bore.

c. Install the spark plug cap onto the spark

plug, and then place the spark plug on the

cylinder head so that the electrodes are

grounded. (This will limit sparking during the

next step.)

d. Turn the engine over several times with the

starter. (This will coat the cylinder wall with

oil.)

Page 52 of 432

MOTORCYCLE CARE AND STORAGE

1-38

e. Remove the spark plug cap from the spark

plug, and then install the spark plug and the

spark plug cap. WARNING! To prevent

damage or injury from sparking, make

sure to ground the spark plug electrodes

while turning the engine over.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

4. Lubricate all control cables and the pivoting

points of all levers and pedals as well as of

the sidestand/ centerstand.

5. Check and, if necessary, correct the tire air

pressure, and then lift the motorcycle so that

both of its wheels are off the ground. Alter-

natively, turn the wheels a little every month

in order to prevent the tires from becoming

degraded in one spot.

6. Cover the muffler outlet with a plastic bag to

prevent moisture from entering it.

7. Remove the battery and fully charge it. Store

it in a cool, dry place and charge it once a

month. Do not store the battery in an exces-

sively cold or warm place [less than 0 °C (30

°F) or more than 30 °C (90 °F)]. For more in-

formation on storing the battery, See page

9-69.

TIP

Make any necessary repairs before storing the

motorcycle.

Page 53 of 432

2

SPECIFICATIONS

GENERAL SPECIFICATIONS......................................................................... 2-1

ENGINE SPECIFICATIONS............................................................................. 2-2

CHASSIS SPECIFICATIONS........................................................................... 2-7

ELECTRICAL SPECIFICATIONS.................................................................. 2-10

TIGHTENING TORQUES............................................................................... 2-12

GENERAL TIGHTENING TORQUE SPECIFICATIONS .......................... 2-12

ENGINE TIGHTENING TORQUES .......................................................... 2-13

CHASSIS TIGHTENING TORQUES ........................................................ 2-16

LUBRICATION POINTS AND LUBRICANT TYPES..................................... 2-20

ENGINE .................................................................................................... 2-20

CHASSIS .................................................................................................. 2-21

LUBRICATION SYSTEM CHART AND DIAGRAMS..................................... 2-23

LUBRICATION DIAGRAMS ..................................................................... 2-23

CABLE ROUTING DIAGRAM........................................................................ 2-31

Page 55 of 432

ENGINE SPECIFICATIONS

2-2

EAS2GBB062

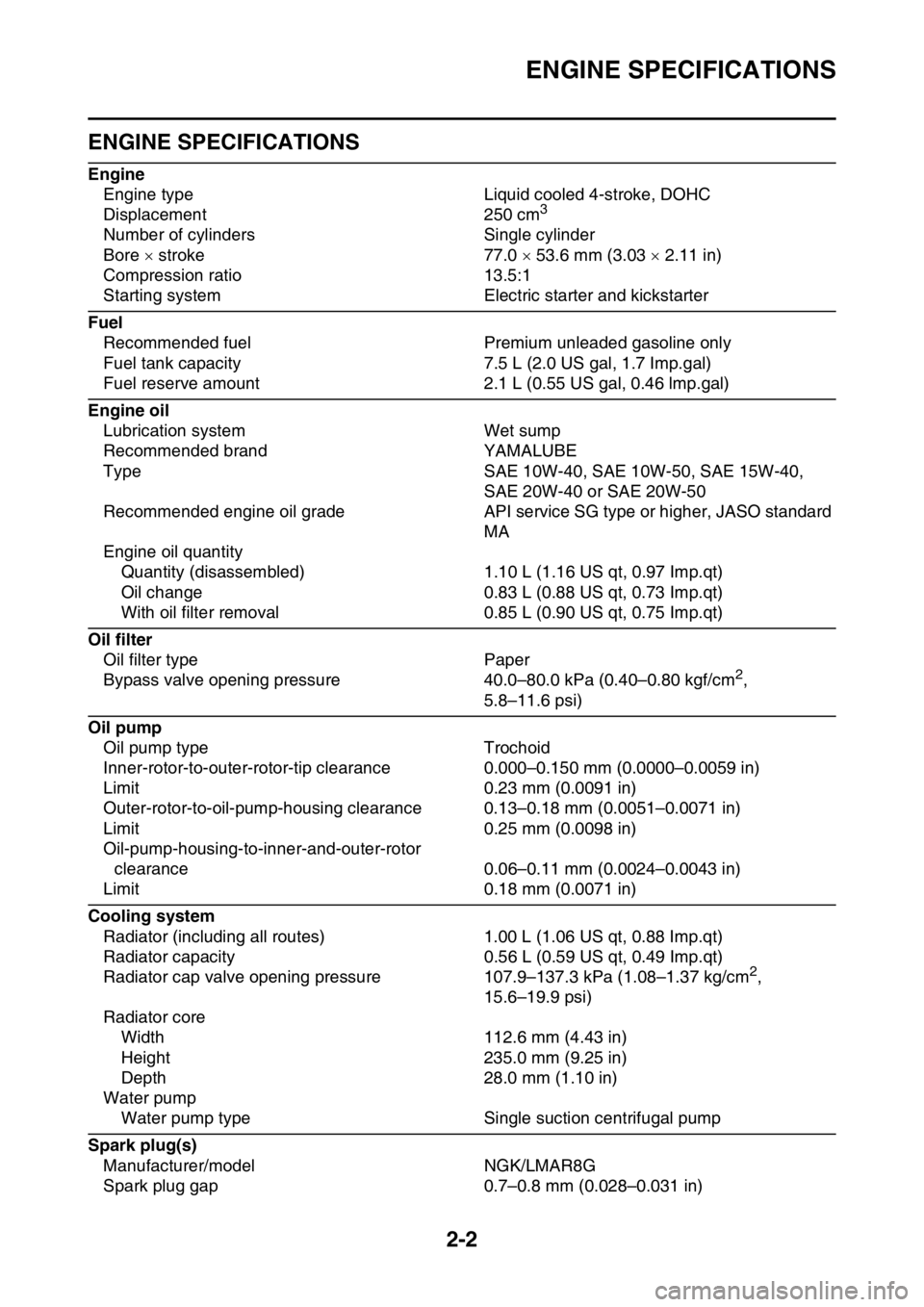

ENGINE SPECIFICATIONS

Engine

Engine type Liquid cooled 4-stroke, DOHC

Displacement 250 cm

3

Number of cylinders Single cylinder

Bore stroke 77.0 53.6 mm (3.03 2.11 in)

Compression ratio 13.5:1

Starting system Electric starter and kickstarter

Fuel

Recommended fuel Premium unleaded gasoline only

Fuel tank capacity 7.5 L (2.0 US gal, 1.7 Imp.gal)

Fuel reserve amount 2.1 L (0.55 US gal, 0.46 lmp.gal)

Engine oil

Lubrication system Wet sump

Recommended brand YAMALUBE

Type SAE 10W-40, SAE 10W-50, SAE 15W-40,

SAE 20W-40 or SAE 20W-50

Recommended engine oil grade API service SG type or higher, JASO standard

MA

Engine oil quantity

Quantity (disassembled) 1.10 L (1.16 US qt, 0.97 Imp.qt)

Oil change 0.83 L (0.88 US qt, 0.73 Imp.qt)

With oil filter removal 0.85 L (0.90 US qt, 0.75 Imp.qt)

Oil filter

Oil filter type Paper

Bypass valve opening pressure 40.0–80.0 kPa (0.40–0.80 kgf/cm

2,

5.8–11.6 psi)

Oil pump

Oil pump type Trochoid

Inner-rotor-to-outer-rotor-tip clearance 0.000–0.150 mm (0.0000–0.0059 in)

Limit 0.23 mm (0.0091 in)

Outer-rotor-to-oil-pump-housing clearance 0.13–0.18 mm (0.0051–0.0071 in)

Limit 0.25 mm (0.0098 in)

Oil-pump-housing-to-inner-and-outer-rotor

clearance 0.06–0.11 mm (0.0024–0.0043 in)

Limit 0.18 mm (0.0071 in)

Cooling system

Radiator (including all routes) 1.00 L (1.06 US qt, 0.88 Imp.qt)

Radiator capacity 0.56 L (0.59 US qt, 0.49 Imp.qt)

Radiator cap valve opening pressure 107.9–137.3 kPa (1.08–1.37 kg/cm

2,

15.6–19.9 psi)

Radiator core

Width 112.6 mm (4.43 in)

Height 235.0 mm (9.25 in)

Depth 28.0 mm (1.10 in)

Water pump

Water pump type Single suction centrifugal pump

Spark plug(s)

Manufacturer/model NGK/LMAR8G

Spark plug gap 0.7–0.8 mm (0.028–0.031 in)

Page 56 of 432

ENGINE SPECIFICATIONS

2-3

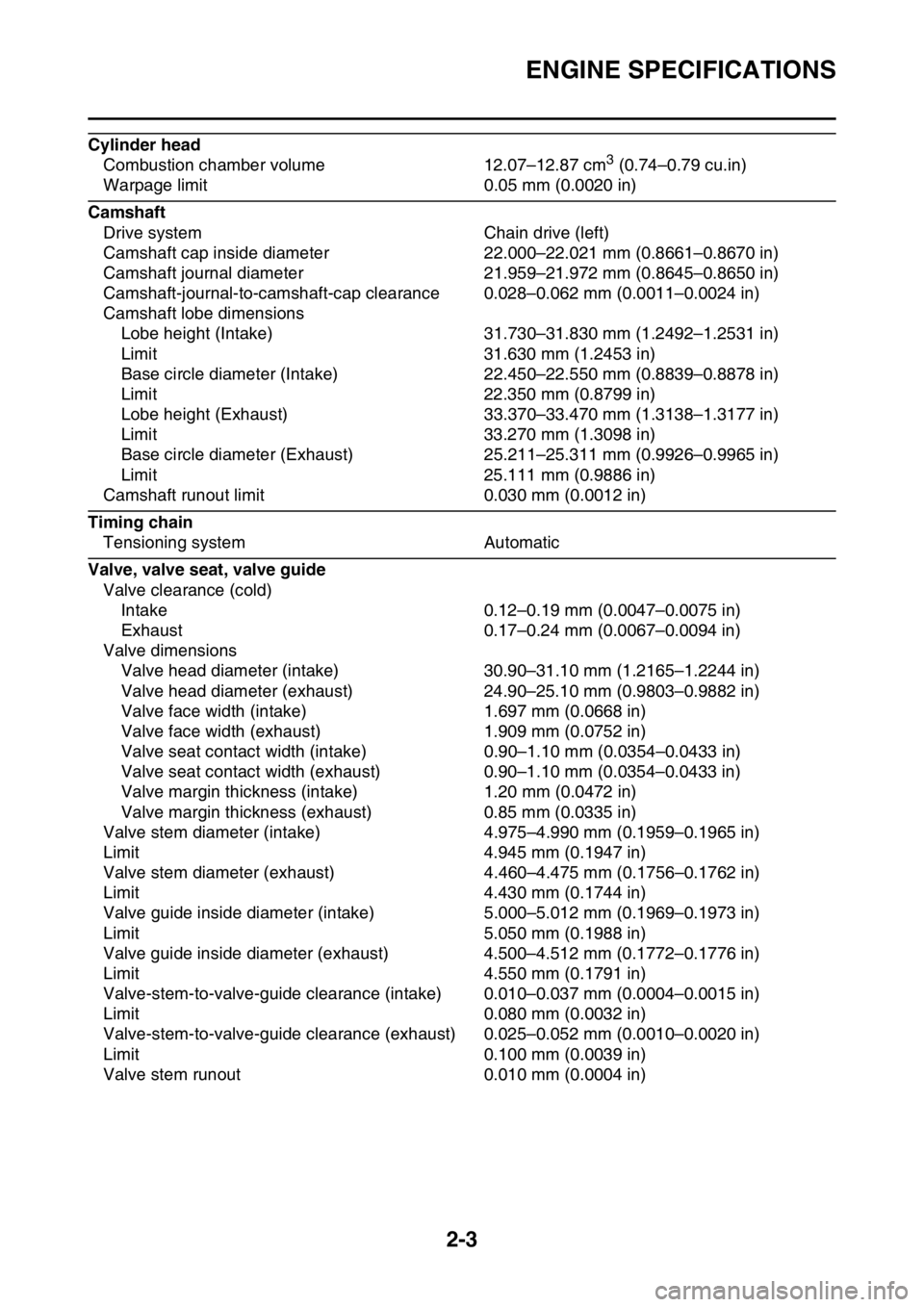

Cylinder head

Combustion chamber volume 12.07–12.87 cm3 (0.74–0.79 cu.in)

Warpage limit 0.05 mm (0.0020 in)

Camshaft

Drive system Chain drive (left)

Camshaft cap inside diameter 22.000–22.021 mm (0.8661–0.8670 in)

Camshaft journal diameter 21.959–21.972 mm (0.8645–0.8650 in)

Camshaft-journal-to-camshaft-cap clearance 0.028–0.062 mm (0.0011–0.0024 in)

Camshaft lobe dimensions

Lobe height (Intake) 31.730–31.830 mm (1.2492–1.2531 in)

Limit 31.630 mm (1.2453 in)

Base circle diameter (Intake) 22.450–22.550 mm (0.8839–0.8878 in)

Limit 22.350 mm (0.8799 in)

Lobe height (Exhaust) 33.370–33.470 mm (1.3138–1.3177 in)

Limit 33.270 mm (1.3098 in)

Base circle diameter (Exhaust) 25.211–25.311 mm (0.9926–0.9965 in)

Limit 25.111 mm (0.9886 in)

Camshaft runout limit 0.030 mm (0.0012 in)

Timing chain

Tensioning system Automatic

Valve, valve seat, valve guide

Valve clearance (cold)

Intake 0.12–0.19 mm (0.0047–0.0075 in)

Exhaust 0.17–0.24 mm (0.0067–0.0094 in)

Valve dimensions

Valve head diameter (intake) 30.90–31.10 mm (1.2165–1.2244 in)

Valve head diameter (exhaust) 24.90–25.10 mm (0.9803–0.9882 in)

Valve face width (intake) 1.697 mm (0.0668 in)

Valve face width (exhaust) 1.909 mm (0.0752 in)

Valve seat contact width (intake) 0.90–1.10 mm (0.0354–0.0433 in)

Valve seat contact width (exhaust) 0.90–1.10 mm (0.0354–0.0433 in)

Valve margin thickness (intake) 1.20 mm (0.0472 in)

Valve margin thickness (exhaust) 0.85 mm (0.0335 in)

Valve stem diameter (intake) 4.975–4.990 mm (0.1959–0.1965 in)

Limit 4.945 mm (0.1947 in)

Valve stem diameter (exhaust) 4.460–4.475 mm (0.1756–0.1762 in)

Limit 4.430 mm (0.1744 in)

Valve guide inside diameter (intake) 5.000–5.012 mm (0.1969–0.1973 in)

Limit 5.050 mm (0.1988 in)

Valve guide inside diameter (exhaust) 4.500–4.512 mm (0.1772–0.1776 in)

Limit 4.550 mm (0.1791 in)

Valve-stem-to-valve-guide clearance (intake) 0.010–0.037 mm (0.0004–0.0015 in)

Limit 0.080 mm (0.0032 in)

Valve-stem-to-valve-guide clearance (exhaust) 0.025–0.052 mm (0.0010–0.0020 in)

Limit 0.100 mm (0.0039 in)

Valve stem runout 0.010 mm (0.0004 in)

Page 57 of 432

ENGINE SPECIFICATIONS

2-4

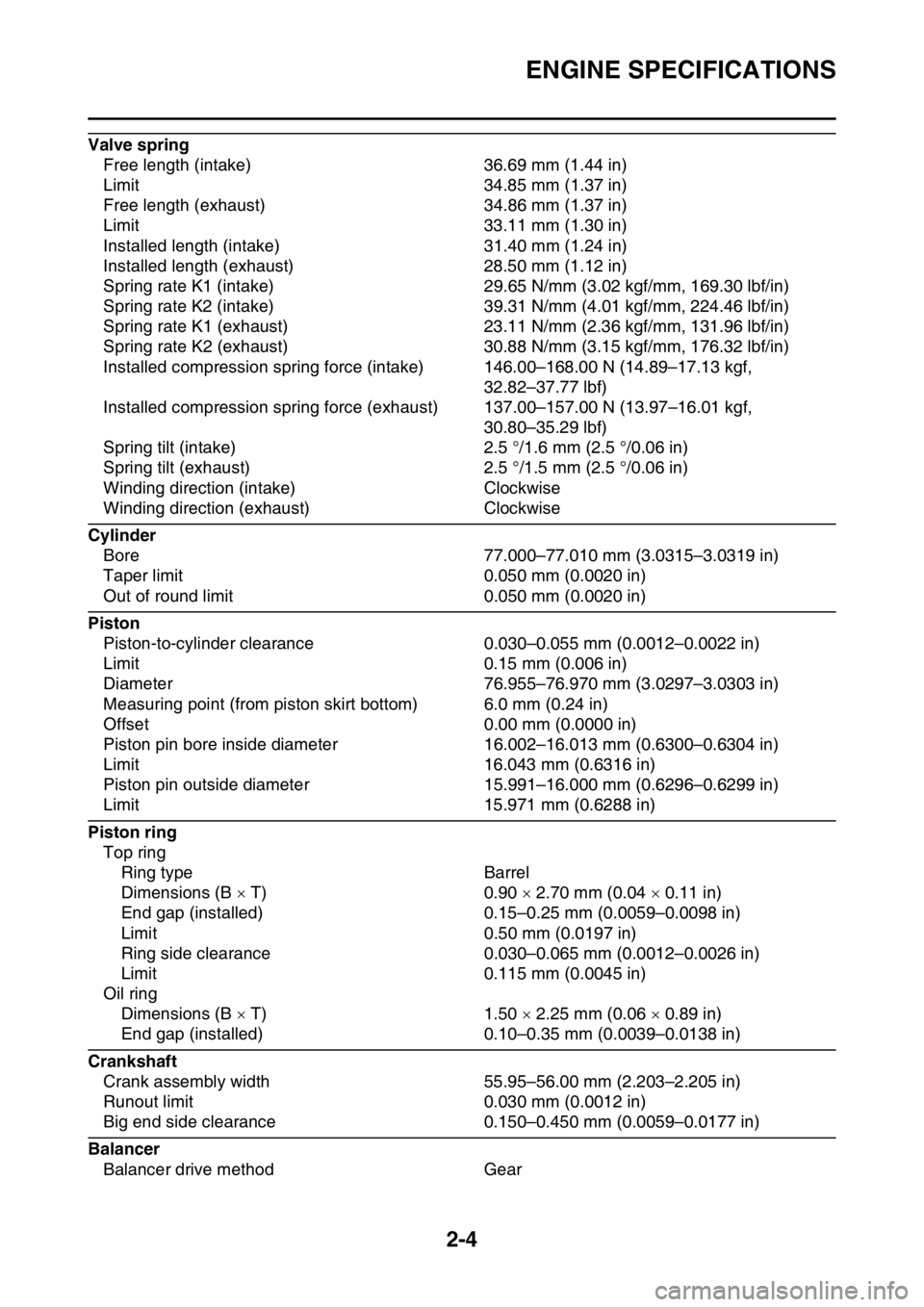

Valve spring

Free length (intake) 36.69 mm (1.44 in)

Limit 34.85 mm (1.37 in)

Free length (exhaust) 34.86 mm (1.37 in)

Limit 33.11 mm (1.30 in)

Installed length (intake) 31.40 mm (1.24 in)

Installed length (exhaust) 28.50 mm (1.12 in)

Spring rate K1 (intake) 29.65 N/mm (3.02 kgf/mm, 169.30 lbf/in)

Spring rate K2 (intake) 39.31 N/mm (4.01 kgf/mm, 224.46 lbf/in)

Spring rate K1 (exhaust) 23.11 N/mm (2.36 kgf/mm, 131.96 lbf/in)

Spring rate K2 (exhaust) 30.88 N/mm (3.15 kgf/mm, 176.32 lbf/in)

Installed compression spring force (intake) 146.00–168.00 N (14.89–17.13 kgf,

32.82–37.77 lbf)

Installed compression spring force (exhaust) 137.00–157.00 N (13.97–16.01 kgf,

30.80–35.29 lbf)

Spring tilt (intake) 2.5 °/1.6 mm (2.5 °/0.06 in)

Spring tilt (exhaust) 2.5 °/1.5 mm (2.5 °/0.06 in)

Winding direction (intake) Clockwise

Winding direction (exhaust) Clockwise

Cylinder

Bore 77.000–77.010 mm (3.0315–3.0319 in)

Taper limit 0.050 mm (0.0020 in)

Out of round limit 0.050 mm (0.0020 in)

Piston

Piston-to-cylinder clearance 0.030–0.055 mm (0.0012–0.0022 in)

Limit 0.15 mm (0.006 in)

Diameter 76.955–76.970 mm (3.0297–3.0303 in)

Measuring point (from piston skirt bottom) 6.0 mm (0.24 in)

Offset 0.00 mm (0.0000 in)

Piston pin bore inside diameter 16.002–16.013 mm (0.6300–0.6304 in)

Limit 16.043 mm (0.6316 in)

Piston pin outside diameter 15.991–16.000 mm (0.6296–0.6299 in)

Limit 15.971 mm (0.6288 in)

Piston ring

Top ring

Ring type Barrel

Dimensions (B T) 0.90 2.70 mm (0.04 0.11 in)

End gap (installed) 0.15–0.25 mm (0.0059–0.0098 in)

Limit 0.50 mm (0.0197 in)

Ring side clearance 0.030–0.065 mm (0.0012–0.0026 in)

Limit 0.115 mm (0.0045 in)

Oil ring

Dimensions (B T) 1.50 2.25 mm (0.06 0.89 in)

End gap (installed) 0.10–0.35 mm (0.0039–0.0138 in)

Crankshaft

Crank assembly width 55.95–56.00 mm (2.203–2.205 in)

Runout limit 0.030 mm (0.0012 in)

Big end side clearance 0.150–0.450 mm (0.0059–0.0177 in)

Balancer

Balancer drive method Gear

Page 58 of 432

ENGINE SPECIFICATIONS

2-5

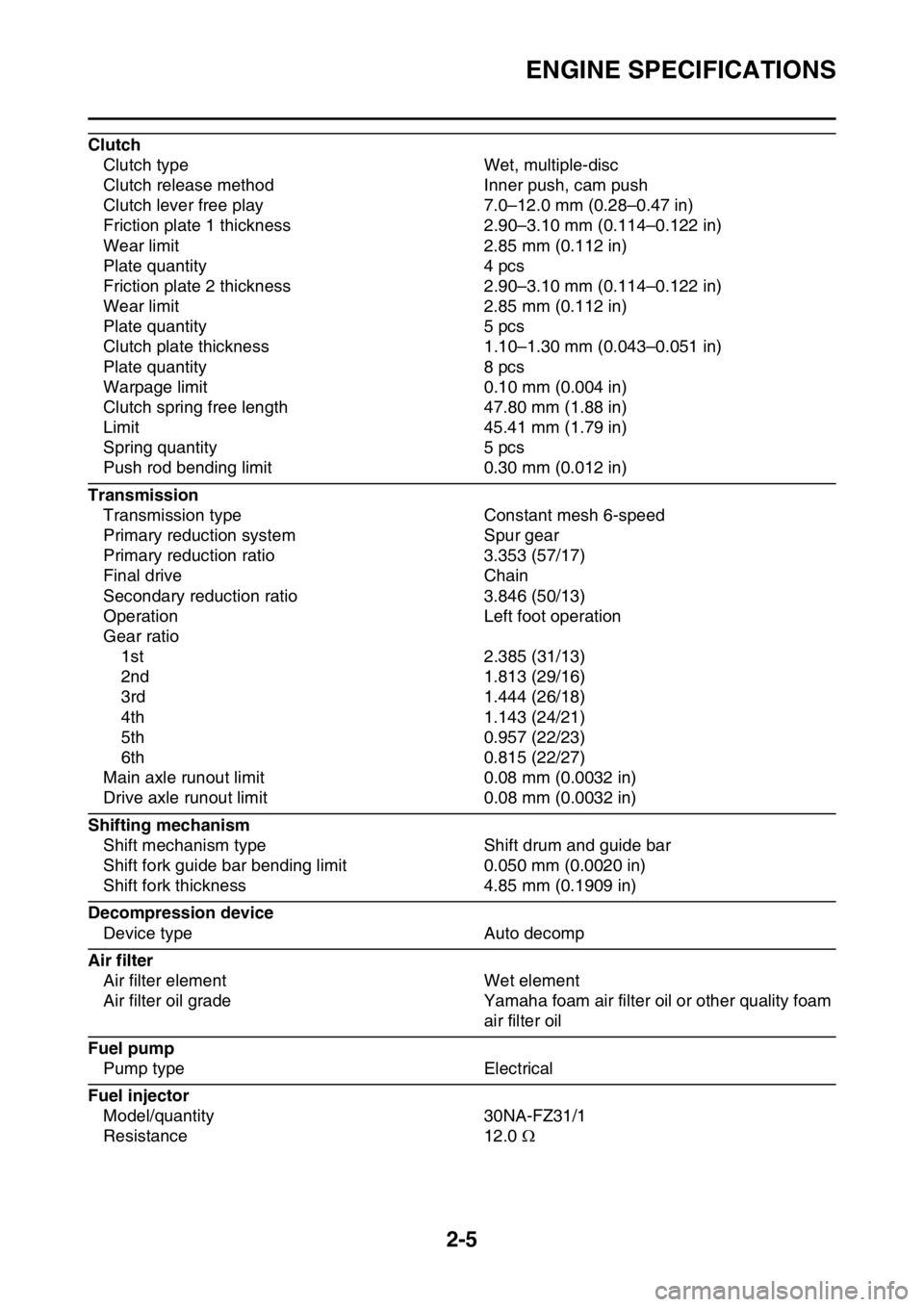

Clutch

Clutch type Wet, multiple-disc

Clutch release method Inner push, cam push

Clutch lever free play 7.0–12.0 mm (0.28–0.47 in)

Friction plate 1 thickness 2.90–3.10 mm (0.114–0.122 in)

Wear limit 2.85 mm (0.112 in)

Plate quantity 4 pcs

Friction plate 2 thickness 2.90–3.10 mm (0.114–0.122 in)

Wear limit 2.85 mm (0.112 in)

Plate quantity 5 pcs

Clutch plate thickness 1.10–1.30 mm (0.043–0.051 in)

Plate quantity 8 pcs

Warpage limit 0.10 mm (0.004 in)

Clutch spring free length 47.80 mm (1.88 in)

Limit 45.41 mm (1.79 in)

Spring quantity 5 pcs

Push rod bending limit 0.30 mm (0.012 in)

Transmission

Transmission type Constant mesh 6-speed

Primary reduction system Spur gear

Primary reduction ratio 3.353 (57/17)

Final drive Chain

Secondary reduction ratio 3.846 (50/13)

Operation Left foot operation

Gear ratio

1st 2.385 (31/13)

2nd 1.813 (29/16)

3rd 1.444 (26/18)

4th 1.143 (24/21)

5th 0.957 (22/23)

6th 0.815 (22/27)

Main axle runout limit 0.08 mm (0.0032 in)

Drive axle runout limit 0.08 mm (0.0032 in)

Shifting mechanism

Shift mechanism type Shift drum and guide bar

Shift fork guide bar bending limit 0.050 mm (0.0020 in)

Shift fork thickness 4.85 mm (0.1909 in)

Decompression device

Device type Auto decomp

Air filter

Air filter element Wet element

Air filter oil grade Yamaha foam air filter oil or other quality foam

air filter oil

Fuel pump

Pump type Electrical

Fuel injector

Model/quantity 30NA-FZ31/1

Resistance 12.0

Page 59 of 432

ENGINE SPECIFICATIONS

2-6

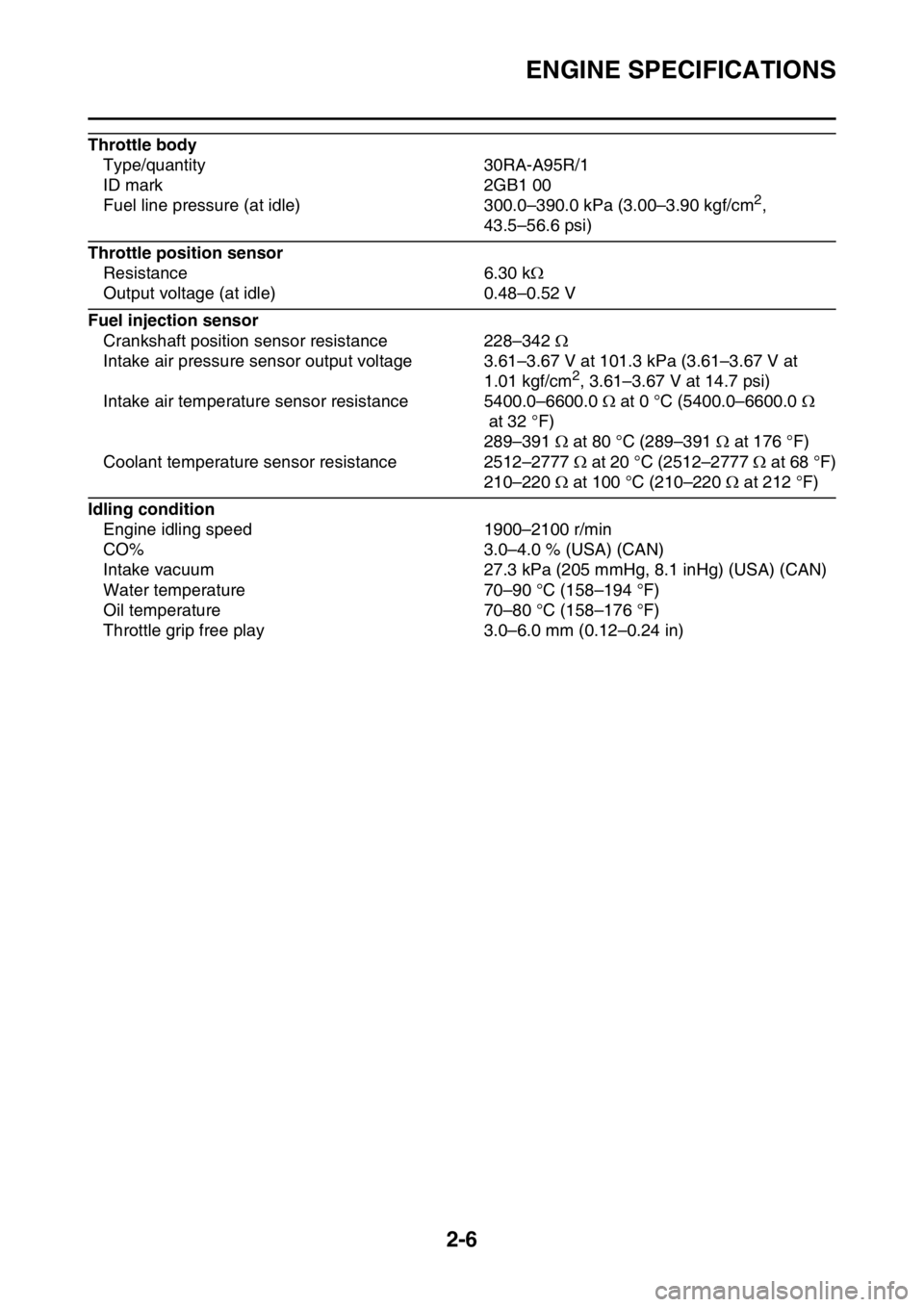

Throttle body

Type/quantity 30RA-A95R/1

ID mark 2GB1 00

Fuel line pressure (at idle) 300.0–390.0 kPa (3.00–3.90 kgf/cm

2,

43.5–56.6 psi)

Throttle position sensor

Resistance 6.30 k

Output voltage (at idle) 0.48–0.52 V

Fuel injection sensor

Crankshaft position sensor resistance 228–342

Intake air pressure sensor output voltage 3.61–3.67 V at 101.3 kPa (3.61–3.67 V at

1.01 kgf/cm

2, 3.61–3.67 V at 14.7 psi)

Intake air temperature sensor resistance 5400.0–6600.0 at 0 °C (5400.0–6600.0

at 32 °F)

289–391 at 80 °C (289–391 at 176 °F)

Coolant temperature sensor resistance 2512–2777 at 20 °C (2512–2777 at 68 °F)

210–220 at 100 °C (210–220 at 212 °F)

Idling condition

Engine idling speed 1900–2100 r/min

CO% 3.0–4.0 % (USA) (CAN)

Intake vacuum 27.3 kPa (205 mmHg, 8.1 inHg) (USA) (CAN)

Water temperature 70–90 °C (158–194 °F)

Oil temperature 70–80 °C (158–176 °F)

Throttle grip free play 3.0–6.0 mm (0.12–0.24 in)

Page 63 of 432

ELECTRICAL SPECIFICATIONS

2-10

EAS2GBB064

ELECTRICAL SPECIFICATIONS

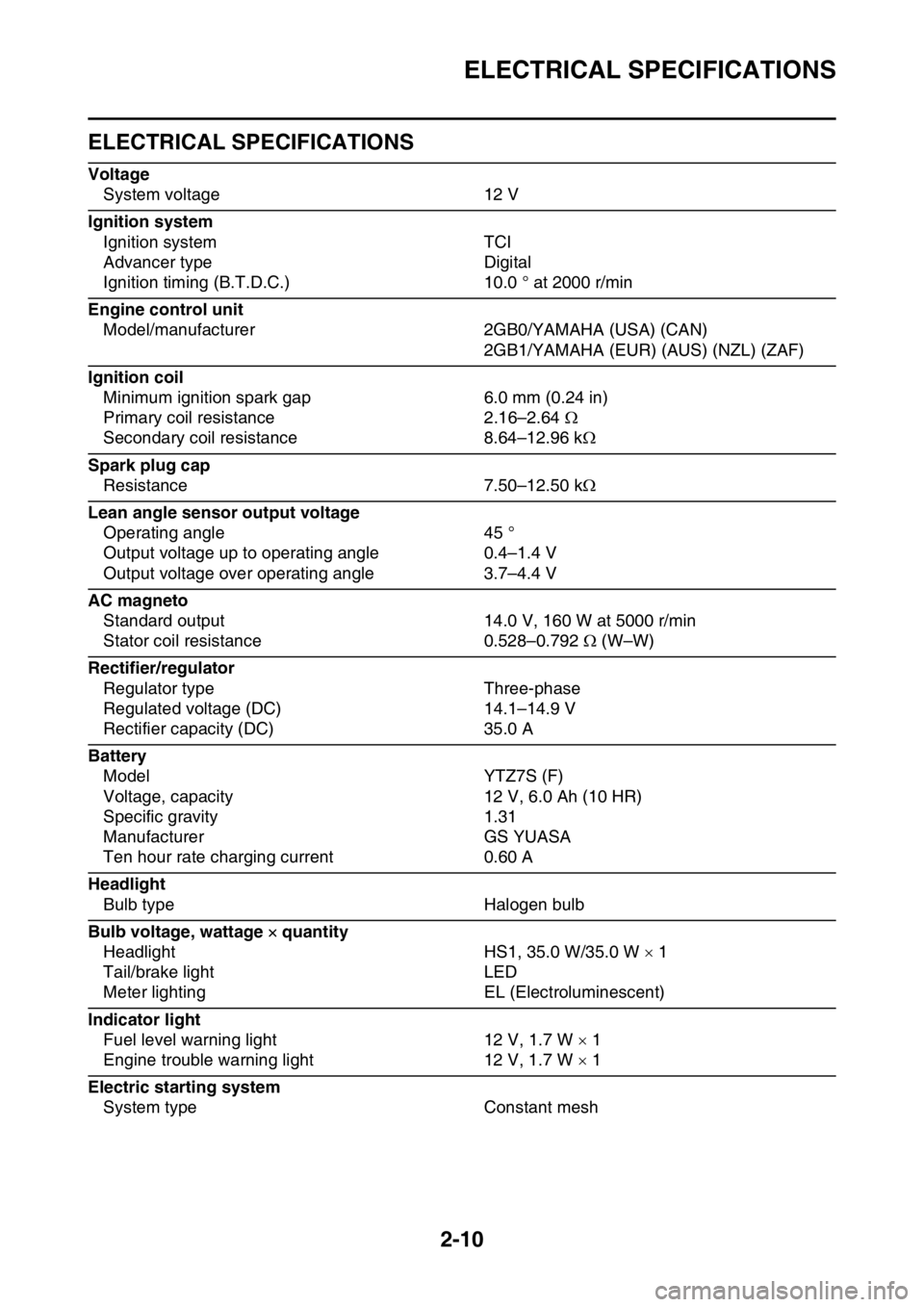

Voltage

System voltage 12 V

Ignition system

Ignition system TCI

Advancer type Digital

Ignition timing (B.T.D.C.) 10.0 ° at 2000 r/min

Engine control unit

Model/manufacturer 2GB0/YAMAHA (USA) (CAN)

2GB1/YAMAHA (EUR) (AUS) (NZL) (ZAF)

Ignition coil

Minimum ignition spark gap 6.0 mm (0.24 in)

Primary coil resistance 2.16–2.64

Secondary coil resistance 8.64–12.96 k

Spark plug cap

Resistance 7.50–12.50 k

Lean angle sensor output voltage

Operating angle 45 °

Output voltage up to operating angle 0.4–1.4 V

Output voltage over operating angle 3.7–4.4 V

AC magneto

Standard output 14.0 V, 160 W at 5000 r/min

Stator coil resistance 0.528–0.792 (W–W)

Rectifier/regulator

Regulator type Three-phase

Regulated voltage (DC) 14.1–14.9 V

Rectifier capacity (DC) 35.0 A

Battery

Model YTZ7S (F)

Voltage, capacity 12 V, 6.0 Ah (10 HR)

Specific gravity 1.31

Manufacturer GS YUASA

Ten hour rate charging current 0.60 A

Headlight

Bulb type Halogen bulb

Bulb voltage, wattage quantity

Headlight HS1, 35.0 W/35.0 W 1

Tail/brake light LED

Meter lighting EL (Electroluminescent)

Indicator light

Fuel level warning light 12 V, 1.7 W 1

Engine trouble warning light 12 V, 1.7 W 1

Electric starting system

System type Constant mesh