ESP YAMAHA WR 250F 2017 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: WR 250F, Model: YAMAHA WR 250F 2017Pages: 432, PDF Size: 14.14 MB

Page 50 of 432

MOTORCYCLE CARE AND STORAGE

1-36

EAS2GBB058

MOTORCYCLE CARE AND STOR-

AGE

EAS2GBB059CARE

While the open design of a motorcycle reveals

the attractiveness of the technology, it also

makes it more vulnerable. Rust and corrosion

can develop even if high-quality components

are used. A rusty exhaust pipe may go unno-

ticed on a car, however, it detracts from the

overall appearance of a motorcycle. Frequent

and proper care does not only comply with the

terms of the warranty, but it will also keep your

motorcycle looking good, extend its life and op-

timize its performance.

Before cleaning

1. Cover the muffler outlet with a plastic bag af-

ter the engine has cooled down.

2. Make sure that all caps and covers as well

as all electrical couplers and connectors, in-

cluding the spark plug cap, are tightly in-

stalled.

3. Remove extremely stubborn dirt, like oil

burnt onto the crankcase, with a degreasing

agent and a brush, but never apply such

products onto seals, gaskets, sprockets, the

drive chain and wheel axles. Always rinse

the dirt and degreaser off with water.

Cleaning

ECA

NOTICE

• Avoid using strong acidic wheel cleaners,

especially on spoked wheels. If such prod-

ucts are used on hard-to-remove dirt, do

not leave the cleaner on the affected area

any longer than instructed. Also, thor-

oughly rinse the area off with water, imme-

diately dry it, and then apply a corrosion

protection spray.

• Improper cleaning can damage plastic

parts (such as cowlings, panels, wind-

shields, headlight lenses, meter lenses,

etc.) and the mufflers. Use only a soft,

clean cloth or sponge with water to clean

plastic. However, if the plastic parts can-

not be thoroughly cleaned with water, di-

luted mild detergent with water may be

used. Be sure to rinse off any detergent

residue using plenty of water, as it is

harmful to plastic parts.• Do not use any harsh chemical products

on plastic parts. Be sure to avoid using

cloths or sponges which have been in con-

tact with strong or abrasive cleaning prod-

ucts, solvent or thinner, fuel (gasoline),

rust removers or inhibitors, brake fluid,

antifreeze or electrolyte.

• Do not use high-pressure washers or

steam-jet cleaners since they cause water

seepage and deterioration in the following

areas: seals (of wheel and swingarm bear-

ings, fork and brakes), electric compo-

nents (couplers, connectors, instruments,

switches and lights), breather hoses and

vents.

• For motorcycles equipped with a wind-

shield: Do not use strong cleaners or hard

sponges as they will cause dulling or

scratching. Some cleaning compounds for

plastic may leave scratches on the wind-

shield. Test the product on a small hidden

part of the windshield to make sure that it

does not leave any marks. If the wind-

shield is scratched, use a quality plastic

polishing compound after washing.

After normal use

Remove dirt with warm water, a mild detergent,

and a soft, clean sponge, and then rinse thor-

oughly with clean water. Use a toothbrush or

bottlebrush for hard-to-reach areas. Stubborn

dirt and insects will come off more easily if the

area is covered with a wet cloth for a few min-

utes before cleaning.

After riding in the rain, near the sea or on salt-

sprayed roads

Since sea salt or salt sprayed on roads during

winter are extremely corrosive in combination

with water, carry out the following steps after

each ride in the rain, near the sea or on salt-

sprayed roads.

TIP

Salt sprayed on roads in the winter may remain

well into spring.

1. Clean the motorcycle with cold water and a

mild detergent, after the engine has cooled

down.

NOTICE: Do not use warm water since it

increases the corrosive action of the salt.

Page 138 of 432

CHASSIS

3-38

c. Turn the front fork to the right and left a few

times, and make sure that the steering ro-

tates smoothly. If it does not turn smoothly,

remove the lower bracket and check the up-

per and lower bearings.

Refer to “STEERING HEAD” on page 5-53.

d. Loosen the ring nut fully turn and then tight-

en it to specification with a steering nut

wrench.

EWA

WARNING

Do not overtighten the lower ring nut.

e. Check the steering head for looseness or

binding by turning the front fork all the way in

both directions. If any binding is felt, remove

the lower bracket and check the upper and

lower bearings.

Refer to “STEERING HEAD” on page 5-53.

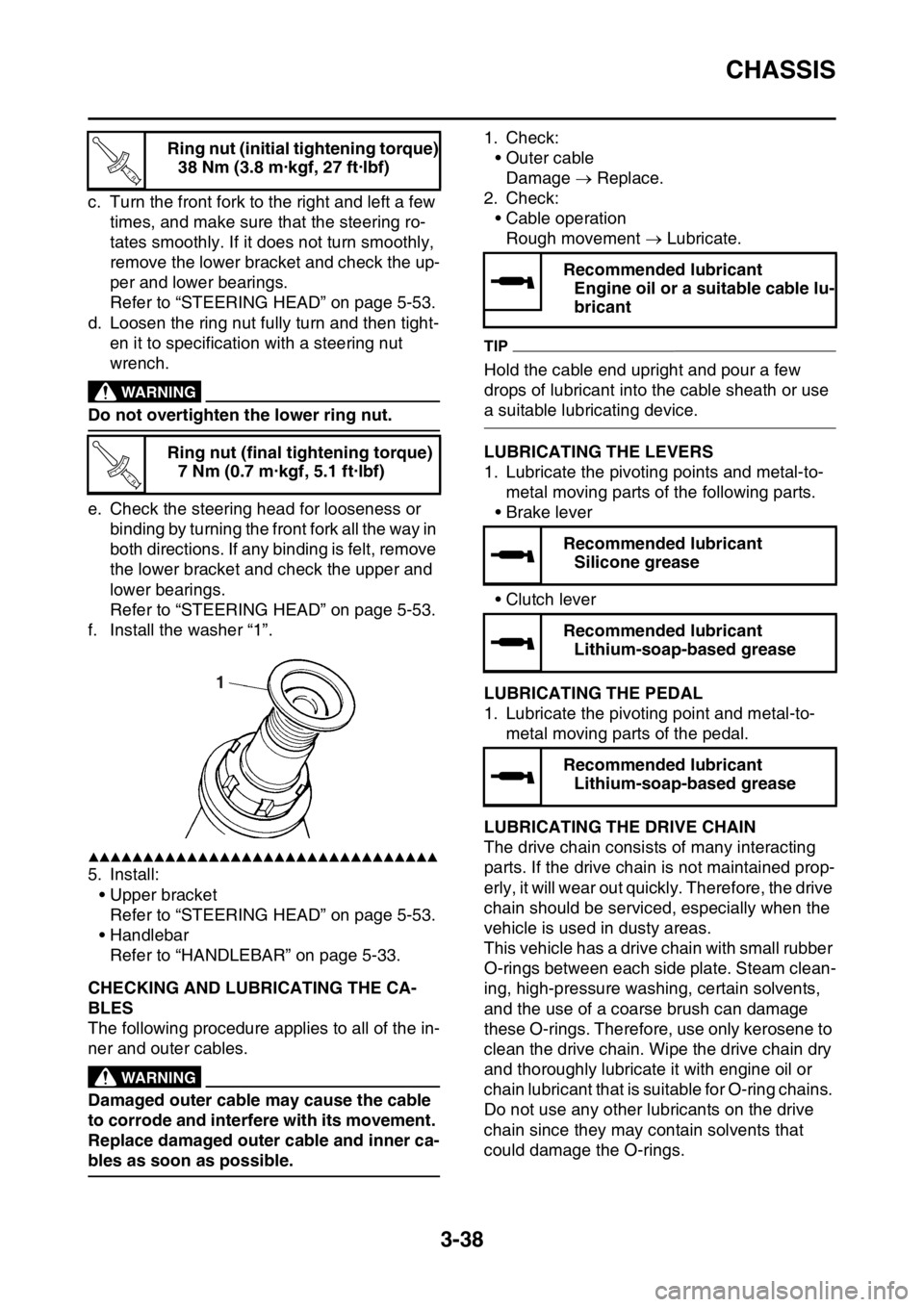

f. Install the washer “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Install:

• Upper bracket

Refer to “STEERING HEAD” on page 5-53.

• Handlebar

Refer to “HANDLEBAR” on page 5-33.

EAS2GBB124CHECKING AND LUBRICATING THE CA-

BLES

The following procedure applies to all of the in-

ner and outer cables.

EWA

WARNING

Damaged outer cable may cause the cable

to corrode and interfere with its movement.

Replace damaged outer cable and inner ca-

bles as soon as possible.1. Check:

• Outer cable

Damage Replace.

2. Check:

• Cable operation

Rough movement Lubricate.

TIP

Hold the cable end upright and pour a few

drops of lubricant into the cable sheath or use

a suitable lubricating device.

EAS2GBB125LUBRICATING THE LEVERS

1. Lubricate the pivoting points and metal-to-

metal moving parts of the following parts.

•Brake lever

• Clutch lever

EAS2GBB126LUBRICATING THE PEDAL

1. Lubricate the pivoting point and metal-to-

metal moving parts of the pedal.

EAS2GBB127LUBRICATING THE DRIVE CHAIN

The drive chain consists of many interacting

parts. If the drive chain is not maintained prop-

erly, it will wear out quickly. Therefore, the drive

chain should be serviced, especially when the

vehicle is used in dusty areas.

This vehicle has a drive chain with small rubber

O-rings between each side plate. Steam clean-

ing, high-pressure washing, certain solvents,

and the use of a coarse brush can damage

these O-rings. Therefore, use only kerosene to

clean the drive chain. Wipe the drive chain dry

and thoroughly lubricate it with engine oil or

chain lubricant that is suitable for O-ring chains.

Do not use any other lubricants on the drive

chain since they may contain solvents that

could damage the O-rings. Ring nut (initial tightening torque)

38 Nm (3.8 m·kgf, 27 ft·lbf)

Ring nut (final tightening torque)

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

T R..

T R..

1

Recommended lubricant

Engine oil or a suitable cable lu-

bricant

Recommended lubricant

Silicone grease

Recommended lubricant

Lithium-soap-based grease

Recommended lubricant

Lithium-soap-based grease

Page 146 of 432

CHASSIS

4-3

TIP

Generally a stiff spring gives a stiff riding feel-

ing. Rebound damping tends to become weak-

er, resulting in lack of a sense of contact with

the road surface or in a vibrating handlebar.

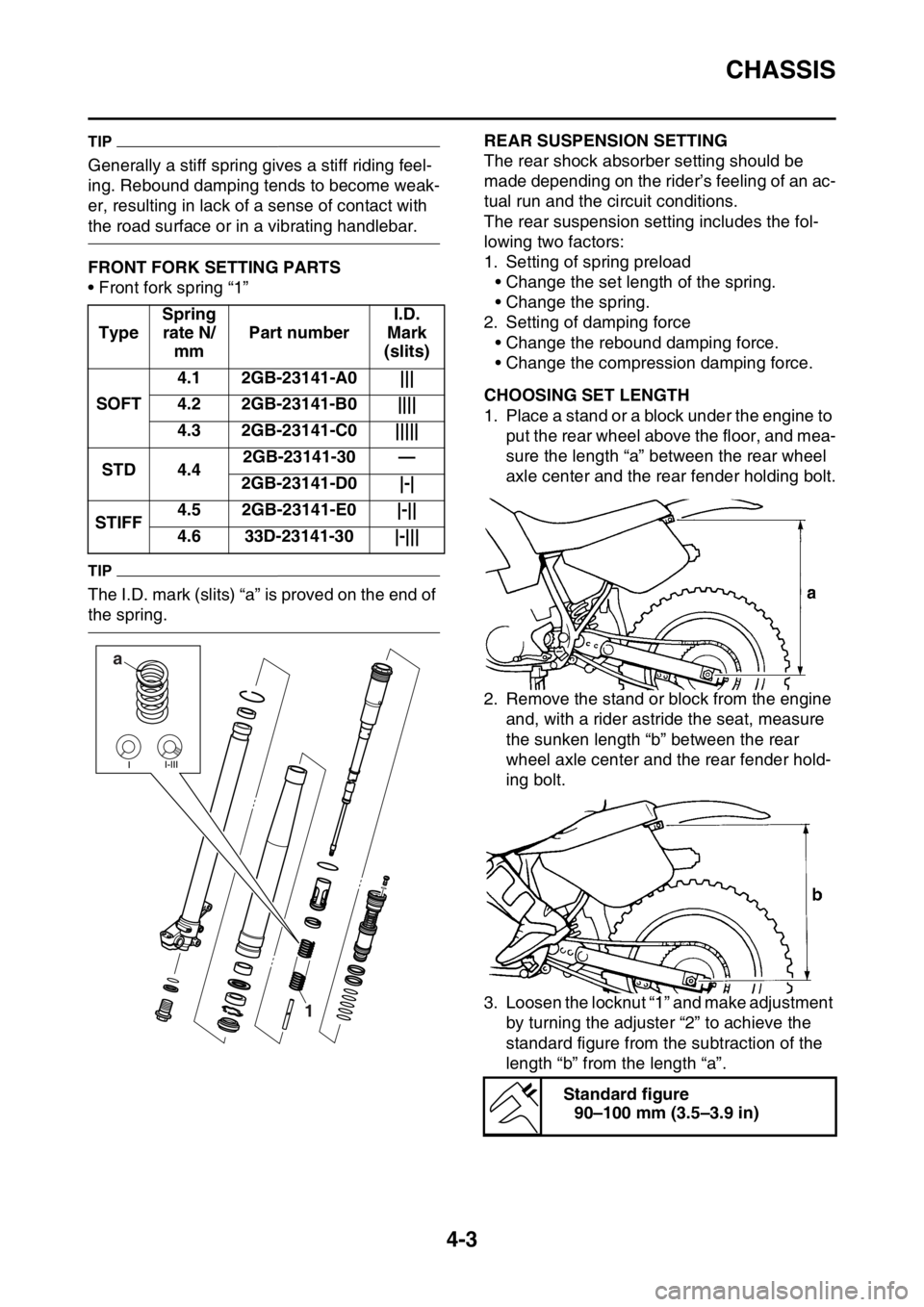

EAS2GBB143FRONT FORK SETTING PARTS

• Front fork spring “1”

TIP

The I.D. mark (slits) “a” is proved on the end of

the spring.

EAS2GBB144REAR SUSPENSION SETTING

The rear shock absorber setting should be

made depending on the rider’s feeling of an ac-

tual run and the circuit conditions.

The rear suspension setting includes the fol-

lowing two factors:

1. Setting of spring preload

• Change the set length of the spring.

• Change the spring.

2. Setting of damping force

• Change the rebound damping force.

• Change the compression damping force.

EAS2GBB145CHOOSING SET LENGTH

1. Place a stand or a block under the engine to

put the rear wheel above the floor, and mea-

sure the length “a” between the rear wheel

axle center and the rear fender holding bolt.

2. Remove the stand or block from the engine

and, with a rider astride the seat, measure

the sunken length “b” between the rear

wheel axle center and the rear fender hold-

ing bolt.

3. Loosen the locknut “1” and make adjustment

by turning the adjuster “2” to achieve the

standard figure from the subtraction of the

length “b” from the length “a”. TypeSpring

rate N/

mmPart numberI.D.

Mark

(slits)

SOFT4.1 2GB-23141-A0 |||

4.2 2GB-23141-B0 ||||

4.3 2GB-23141-C0 |||||

STD 4.42GB-23141-30 —

2GB-23141-D0 |-|

STIFF4.5 2GB-23141-E0 |-||

4.6 33D-23141-30 |-|||

a

1

Standard figure

90–100 mm (3.5–3.9 in)

Page 147 of 432

CHASSIS

4-4

TIP

• If the machine is new and after it is broken in,

the same set length of the spring may change

because of the initial fatigue, etc. of the

spring. Therefore, be sure to make reevalua-

tion.

• If the standard figure cannot be achieved by

adjusting the adjuster and changing the set

length, replace the spring with an optional one

and make readjustment.

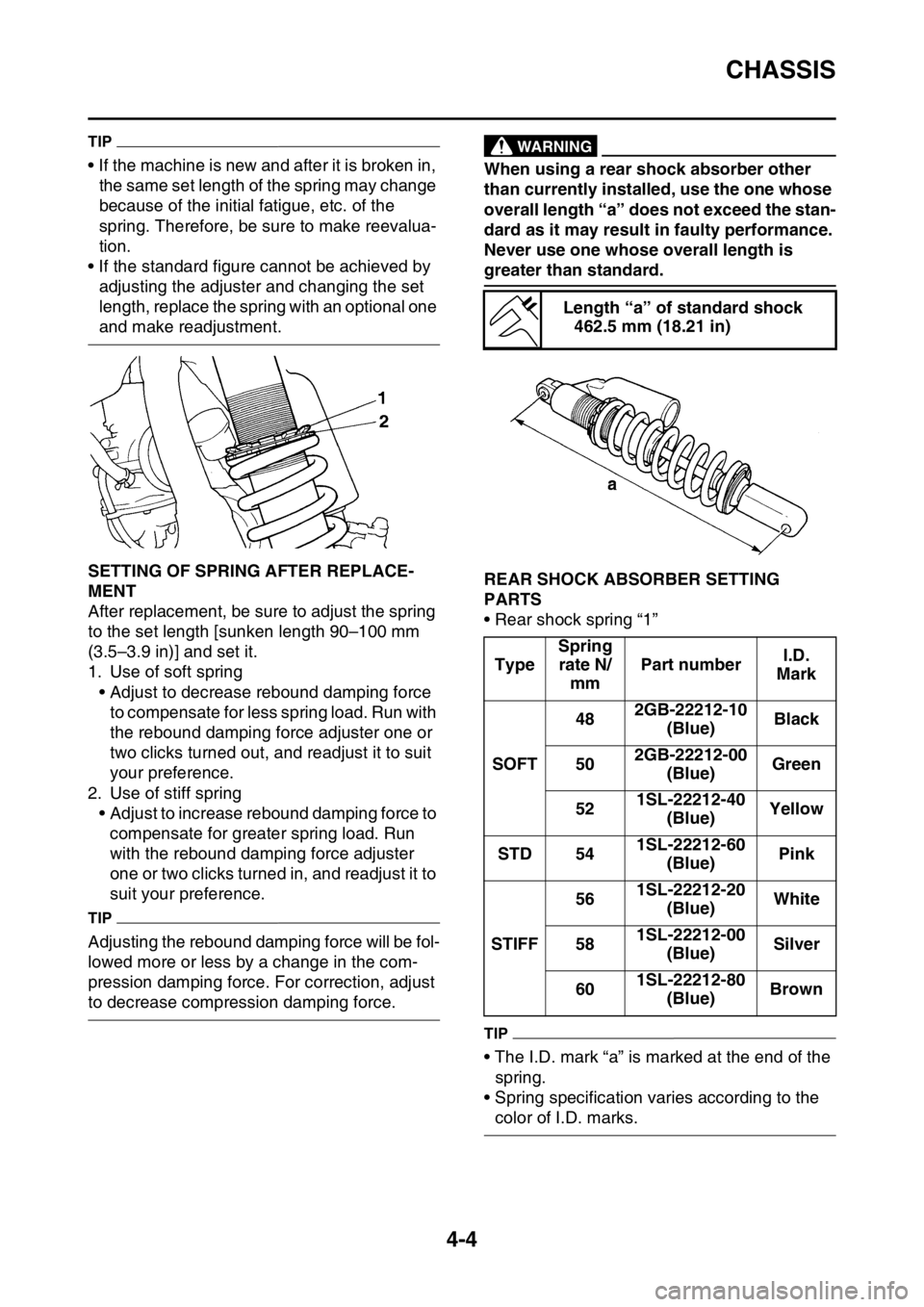

EAS2GBB146SETTING OF SPRING AFTER REPLACE-

MENT

After replacement, be sure to adjust the spring

to the set length [sunken length 90–100 mm

(3.5–3.9 in)] and set it.

1. Use of soft spring

• Adjust to decrease rebound damping force

to compensate for less spring load. Run with

the rebound damping force adjuster one or

two clicks turned out, and readjust it to suit

your preference.

2. Use of stiff spring

• Adjust to increase rebound damping force to

compensate for greater spring load. Run

with the rebound damping force adjuster

one or two clicks turned in, and readjust it to

suit your preference.

TIP

Adjusting the rebound damping force will be fol-

lowed more or less by a change in the com-

pression damping force. For correction, adjust

to decrease compression damping force.

EWA

WARNING

When using a rear shock absorber other

than currently installed, use the one whose

overall length “a” does not exceed the stan-

dard as it may result in faulty performance.

Never use one whose overall length is

greater than standard.

EAS2GBB147REAR SHOCK ABSORBER SETTING

PARTS

• Rear shock spring “1”

TIP

• The I.D. mark “a” is marked at the end of the

spring.

• Spring specification varies according to the

color of I.D. marks.

Length “a” of standard shock

462.5 mm (18.21 in)

TypeSpring

rate N/

mmPart numberI.D.

Mark

SOFT482GB-22212-10

(Blue)Black

502GB-22212-00

(Blue)Green

521SL-22212-40

(Blue)Yellow

STD 541SL-22212-60

(Blue)Pink

STIFF561SL-22212-20

(Blue)White

581SL-22212-00

(Blue)Silver

601SL-22212-80

(Blue)Brown

Page 164 of 432

REAR WHEEL

5-10

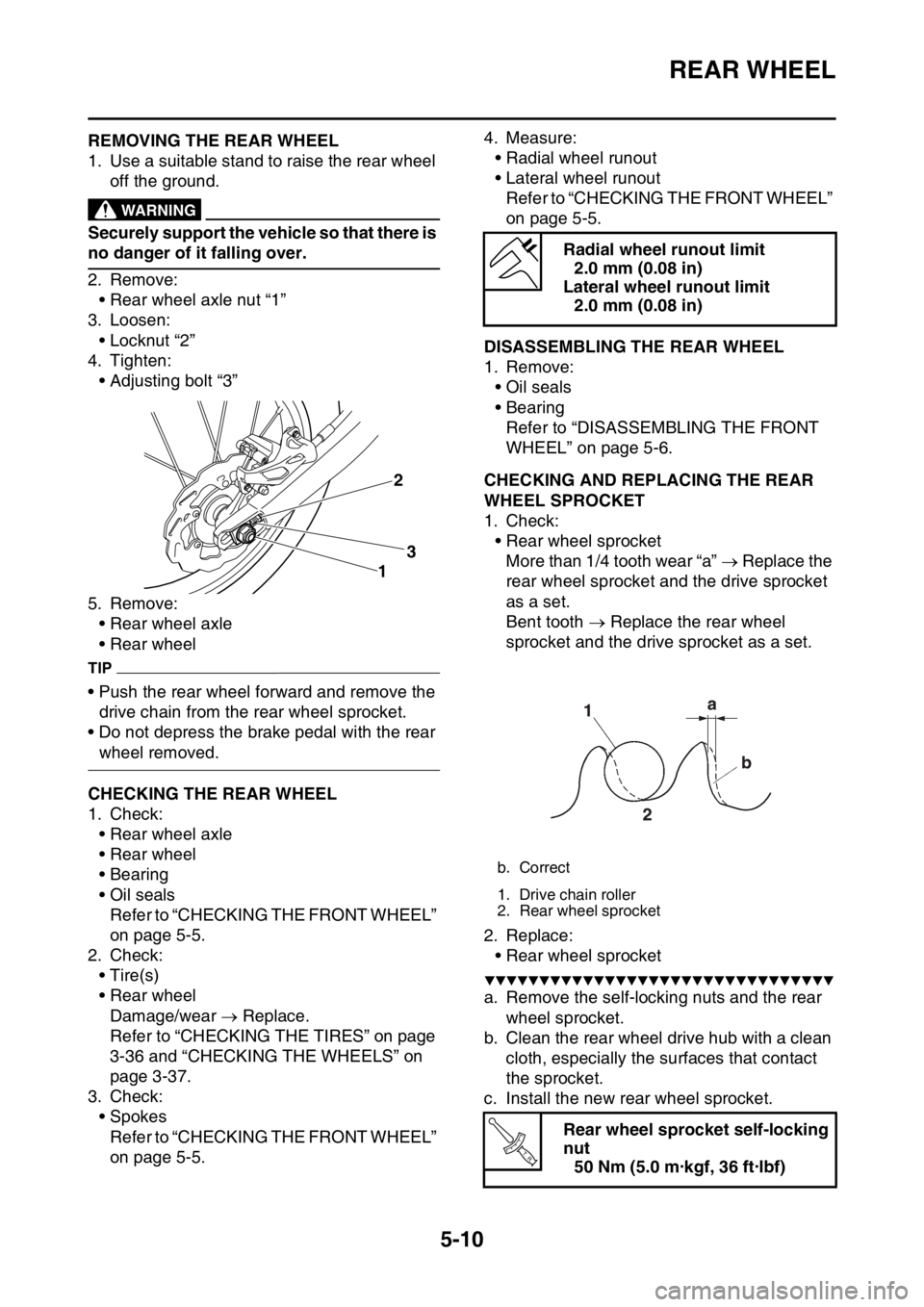

EAS2GBB161REMOVING THE REAR WHEEL

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:

• Rear wheel axle nut “1”

3. Loosen:

• Locknut “2”

4. Tighten:

• Adjusting bolt “3”

5. Remove:

• Rear wheel axle

• Rear wheel

TIP

• Push the rear wheel forward and remove the

drive chain from the rear wheel sprocket.

• Do not depress the brake pedal with the rear

wheel removed.

EAS2GBB162CHECKING THE REAR WHEEL

1. Check:

• Rear wheel axle

• Rear wheel

• Bearing

• Oil seals

Refer to “CHECKING THE FRONT WHEEL”

on page 5-5.

2. Check:

•Tire(s)

• Rear wheel

Damage/wear Replace.

Refer to “CHECKING THE TIRES” on page

3-36 and “CHECKING THE WHEELS” on

page 3-37.

3. Check:

• Spokes

Refer to “CHECKING THE FRONT WHEEL”

on page 5-5.4. Measure:

• Radial wheel runout

• Lateral wheel runout

Refer to “CHECKING THE FRONT WHEEL”

on page 5-5.

EAS2GBB163DISASSEMBLING THE REAR WHEEL

1. Remove:

• Oil seals

• Bearing

Refer to “DISASSEMBLING THE FRONT

WHEEL” on page 5-6.

EAS2GBB164CHECKING AND REPLACING THE REAR

WHEEL SPROCKET

1. Check:

• Rear wheel sprocket

More than 1/4 tooth wear “a” Replace the

rear wheel sprocket and the drive sprocket

as a set.

Bent tooth Replace the rear wheel

sprocket and the drive sprocket as a set.

2. Replace:

• Rear wheel sprocket

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the self-locking nuts and the rear

wheel sprocket.

b. Clean the rear wheel drive hub with a clean

cloth, especially the surfaces that contact

the sprocket.

c. Install the new rear wheel sprocket.

3

12

Radial wheel runout limit

2.0 mm (0.08 in)

Lateral wheel runout limit

2.0 mm (0.08 in)

b. Correct

1. Drive chain roller

2. Rear wheel sprocket

Rear wheel sprocket self-locking

nut

50 Nm (5.0 m·kgf, 36 ft·lbf)

T R..

Page 215 of 432

REAR SHOCK ABSORBER ASSEMBLY

5-61

EAS2GBB208HANDLING THE REAR SHOCK ABSORBEREWA

WARNING

This rear shock absorber contains highly

compressed nitrogen gas. Before handling

the rear shock absorber, read and make

sure that you understand the following in-

formation. The manufacturer cannot be held

responsible for property damage or person-

al injury that may result from improper han-

dling of the rear shock absorber.

• Do not tamper or attempt to open the rear

shock absorber.

• Do not subject the rear shock absorber to

an open flame or any other source of high

heat. High heat can cause an explosion

due to excessive gas pressure.

• Do not deform or damage the rear shock

absorber in any way. Rear shock absorber

damage will result in poor damping perfor-

mance.

TIP

A break-in is required up to about 50 km of run-

ning.

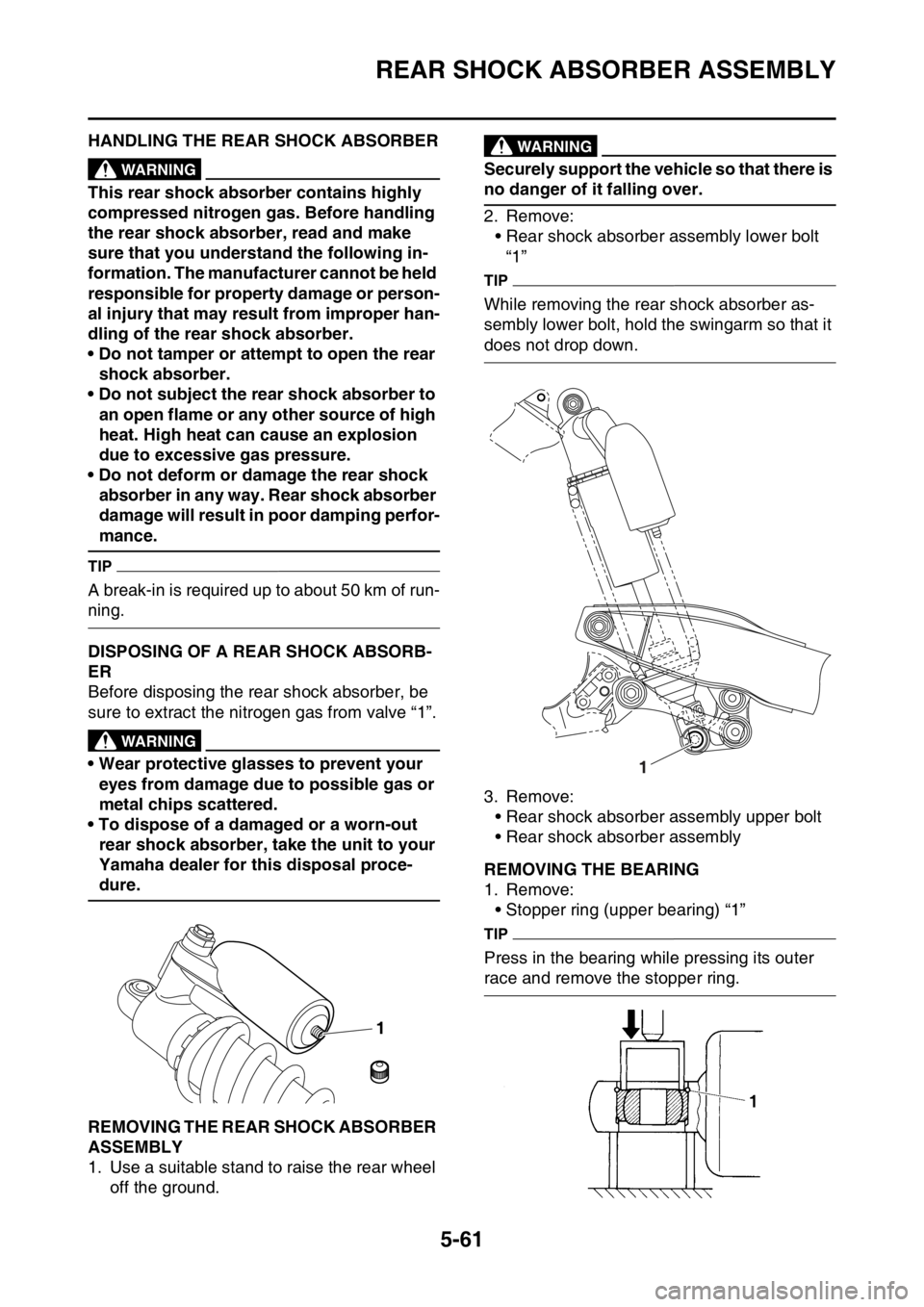

EAS2GBB209DISPOSING OF A REAR SHOCK ABSORB-

ER

Before disposing the rear shock absorber, be

sure to extract the nitrogen gas from valve “1”.

EWA

WARNING

• Wear protective glasses to prevent your

eyes from damage due to possible gas or

metal chips scattered.

• To dispose of a damaged or a worn-out

rear shock absorber, take the unit to your

Yamaha dealer for this disposal proce-

dure.

EAS2GBB210REMOVING THE REAR SHOCK ABSORBER

ASSEMBLY

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:

• Rear shock absorber assembly lower bolt

“1”

TIP

While removing the rear shock absorber as-

sembly lower bolt, hold the swingarm so that it

does not drop down.

3. Remove:

• Rear shock absorber assembly upper bolt

• Rear shock absorber assembly

EAS2GBB211REMOVING THE BEARING

1. Remove:

• Stopper ring (upper bearing) “1”

TIP

Press in the bearing while pressing its outer

race and remove the stopper ring.

1

1

Page 239 of 432

ENGINE REMOVAL

6-10

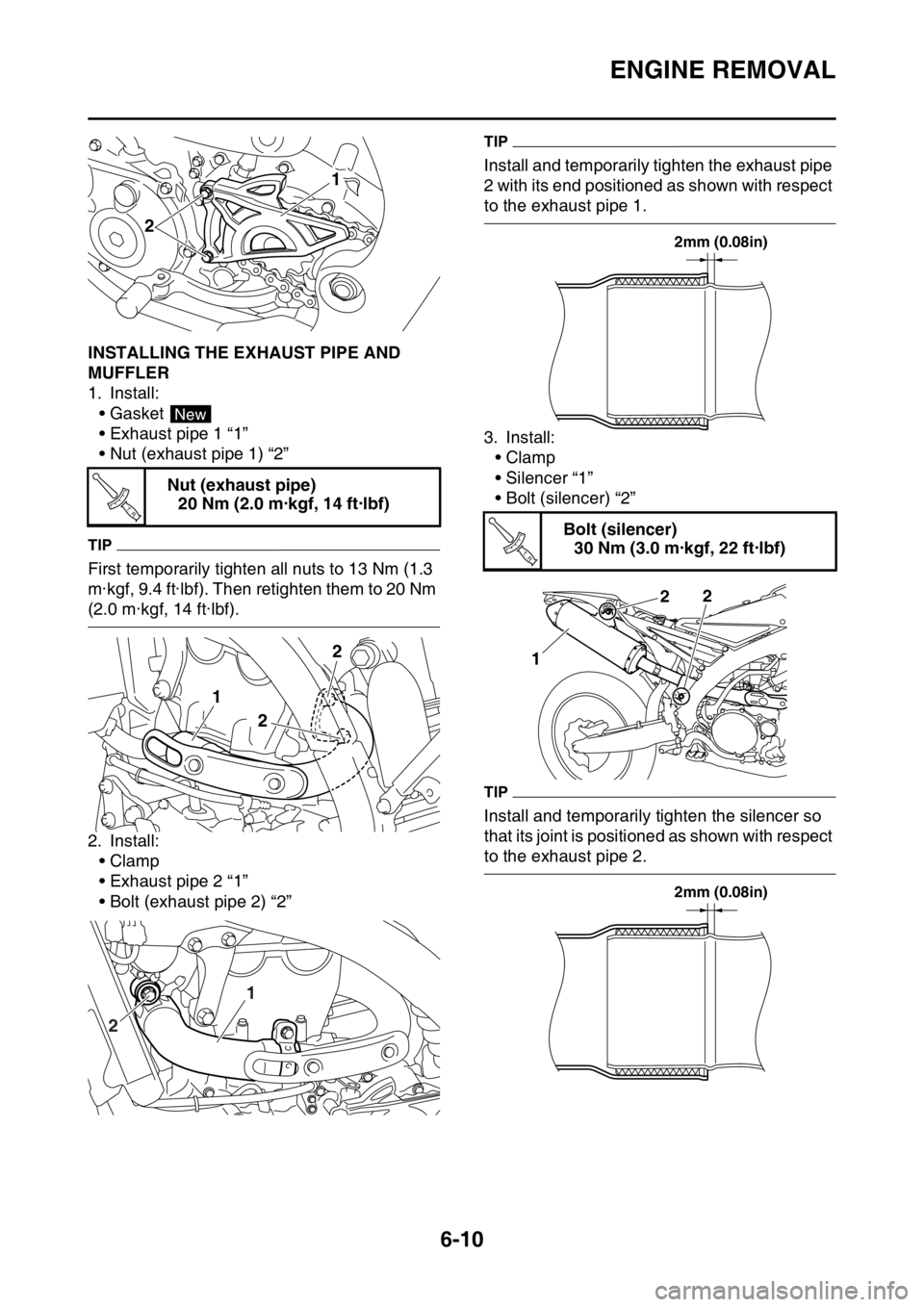

EAS2GBB236INSTALLING THE EXHAUST PIPE AND

MUFFLER

1. Install:

•Gasket

• Exhaust pipe 1 “1”

• Nut (exhaust pipe 1) “2”

TIP

First temporarily tighten all nuts to 13 Nm (1.3

m·kgf, 9.4 ft·lbf). Then retighten them to 20 Nm

(2.0 m·kgf, 14 ft·lbf).

2. Install:

•Clamp

• Exhaust pipe 2 “1”

• Bolt (exhaust pipe 2) “2”

TIP

Install and temporarily tighten the exhaust pipe

2 with its end positioned as shown with respect

to the exhaust pipe 1.

3. Install:

•Clamp

• Silencer “1”

• Bolt (silencer) “2”

TIP

Install and temporarily tighten the silencer so

that its joint is positioned as shown with respect

to the exhaust pipe 2. Nut (exhaust pipe)

20 Nm (2.0 m·kgf, 14 ft·lbf)

21

New

T R..

1

22

1

2

Bolt (silencer)

30 Nm (3.0 m·kgf, 22 ft·lbf)

2mm (0.08in)

T R..

1

22

2mm (0.08in)

Page 403 of 432

ELECTRICAL COMPONENTS

9-67

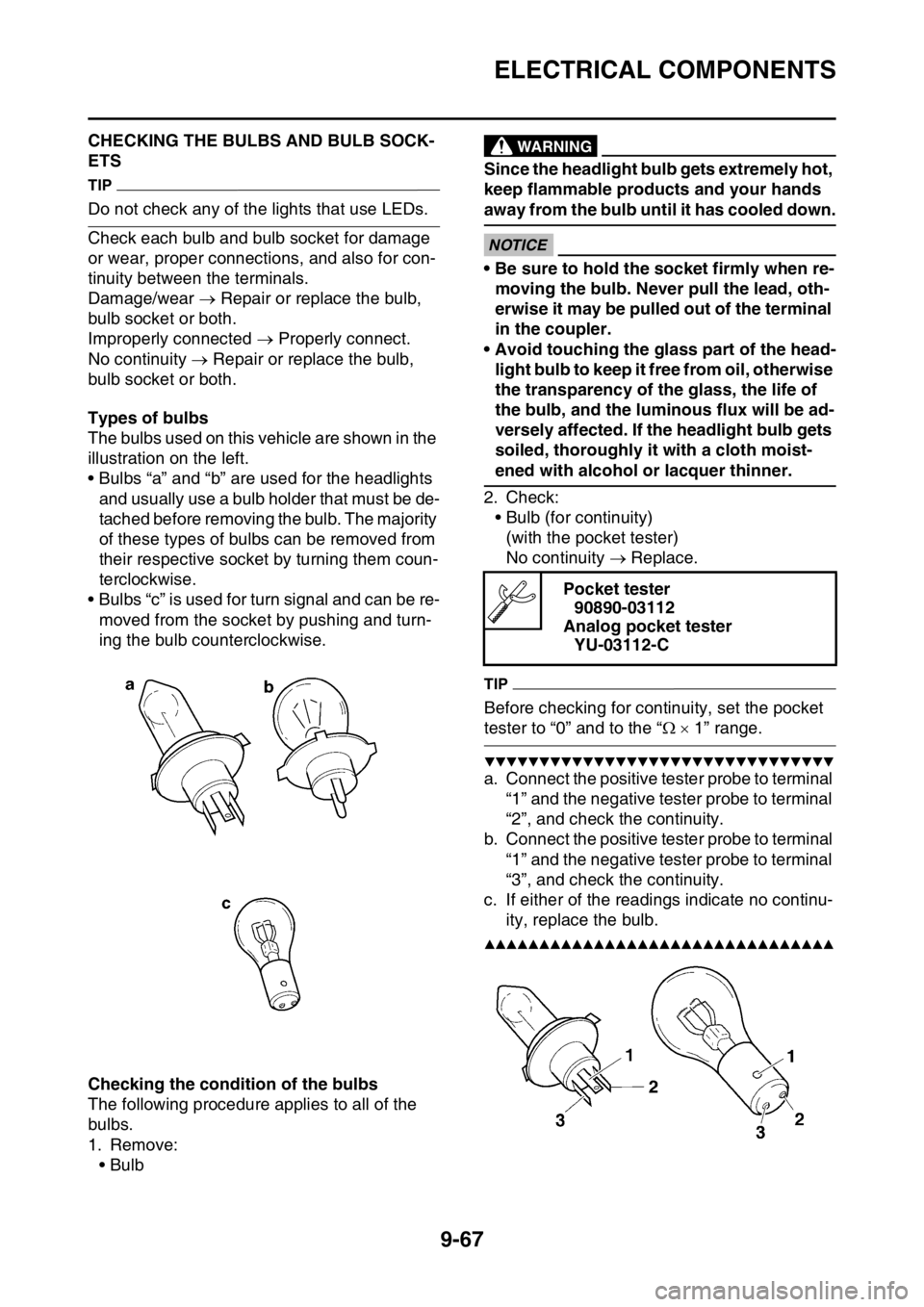

EAS27990CHECKING THE BULBS AND BULB SOCK-

ETS

TIP

Do not check any of the lights that use LEDs.

Check each bulb and bulb socket for damage

or wear, proper connections, and also for con-

tinuity between the terminals.

Damage/wear Repair or replace the bulb,

bulb socket or both.

Improperly connected Properly connect.

No continuity Repair or replace the bulb,

bulb socket or both.

Types of bulbs

The bulbs used on this vehicle are shown in the

illustration on the left.

• Bulbs “a” and “b” are used for the headlights

and usually use a bulb holder that must be de-

tached before removing the bulb. The majority

of these types of bulbs can be removed from

their respective socket by turning them coun-

terclockwise.

• Bulbs “c” is used for turn signal and can be re-

moved from the socket by pushing and turn-

ing the bulb counterclockwise.

Checking the condition of the bulbs

The following procedure applies to all of the

bulbs.

1. Remove:

•Bulb

EWA

WARNING

Since the headlight bulb gets extremely hot,

keep flammable products and your hands

away from the bulb until it has cooled down.

ECA

NOTICE

• Be sure to hold the socket firmly when re-

moving the bulb. Never pull the lead, oth-

erwise it may be pulled out of the terminal

in the coupler.

• Avoid touching the glass part of the head-

light bulb to keep it free from oil, otherwise

the transparency of the glass, the life of

the bulb, and the luminous flux will be ad-

versely affected. If the headlight bulb gets

soiled, thoroughly it with a cloth moist-

ened with alcohol or lacquer thinner.

2. Check:

• Bulb (for continuity)

(with the pocket tester)

No continuity Replace.

TIP

Before checking for continuity, set the pocket

tester to “0” and to the “ 1” range.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the positive tester probe to terminal

“1” and the negative tester probe to terminal

“2”, and check the continuity.

b. Connect the positive tester probe to terminal

“1” and the negative tester probe to terminal

“3”, and check the continuity.

c. If either of the readings indicate no continu-

ity, replace the bulb.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C