lock YAMAHA WR 250R 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: WR 250R, Model: YAMAHA WR 250R 2014Pages: 98, PDF Size: 2.68 MB

Page 64 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-22

1

2

3

4

56

7

8

9high-quality product.

Ride at moderate speeds after

changing a tire since the tire

surface must first be “broken

in” for it to develop its optimalcharacteristics.

EAU21944

Spoke wheels

WARNING

EWA10611

The wheels on this model are not de-

signed for use with tubeless tires.

Do not attempt to use tubeless tireson this model.

To maximize the performance, durabil-

ity, and safe operation of your motorcy-

cle, note the following points regarding

the specified wheels.

The wheel rims should be checked

for cracks, bends, warpage or oth-

er damage, and the spokes for

looseness or damage before each

ride. If any damage is found, have

a Yamaha dealer replace the

wheel. Do not attempt even the

smallest repair to the wheel. A de-

formed or cracked wheel must be

replaced.

The wheel should be balanced

whenever either the tire or wheel

has been changed or replaced. An

unbalanced wheel can result in

poor performance, adverse han-

dling characteristics, and a short-

ened tire life.

EAU48374

Adjusting the clutch lever free

playThe clutch lever free play should mea-

sure 10.0–15.0 mm (0.39–0.59 in) as

shown. Periodically check the clutch le-

ver free play and, if necessary, adjust it

as follows.

1. Slide the rubber cover back at the clutch lever.

2. Loosen the locknut.

3. To increase the clutch lever free play, turn the clutch lever free play

adjusting bolt in direction (a). To

decrease the clutch lever free play,

turn the adjusting bolt in direction

(b).

32D-9-EC.book 22 ページ 2013年6月25日 火曜日 午後4時16分

Page 65 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-23

2

3

4

567

8

9

TIPIf the specified clutch lever free play

could be obtained as described above,skip steps 4–7.4. Fully turn the adjusting bolt in di- rection (a) to loosen the clutch ca-

ble.

5. Slide the rubber cover back further down the clutch cable, and then

loosen the locknut.

6. To increase the clutch lever free play, turn the clutch lever free play

adjusting nut in direction (a). To

decrease the clutch lever free play, turn the adjusting nut in direction

(b).

7. Tighten the locknut at the clutch cable, and then slide the rubber

cover to its original position.

8. Tighten the locknut at the clutch le- ver, and then slide the rubber cov-

er to its original position.

EAU48443

Adjusting the brake lever free

playThe brake lever free play should mea-

sure 5.0–8.0 mm (0.20–0.31 in) as

shown. Periodically check the brake le-

ver free play and, if necessary, adjust it

as follows.1. Slide the rubber cover back at the brake lever.

2. Loosen the locknut.

3. To increase the brake lever free play, turn the brake lever free play

adjusting screw in direction (a). To

decrease the brake lever free play,

turn the adjusting screw in direc-

tion (b).

1. Clutch lever free play

2. Locknut (clutch lever)

3. Clutch lever free play adjusting bolt

4. Rubber cap

3

2

1

4

(a)(b)

1. Locknut (clutch cable)

2. Clutch lever free play adjusting nut

3. Rubber cover

1

2

3

(a)

(b)

32D-9-EC.book 23 ページ 2013年6月25日 火曜日 午後4時16分

Page 66 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-24

1

2

3

4

56

7

8

94. Tighten the locknut, and then slide

the rubber cover back to its original

position.

WARNING

EWA10631

After adjusting the brake lever

free play, check the free play

and make sure that the brake is

working properly.

A soft or spongy feeling in the

brake lever can indicate the

presence of air in the hydraulic

system. If there is air in the hy-

draulic system, have a Yamaha dealer bleed the system before

operating the motorcycle. Air in

the hydraulic system will dimin-

ish the braking performance,

which may result in loss of con-

trol and an accident.

EAU44821

Checking the shift pedalThe operation of the shift pedal should

be checked before each ride. If opera-

tion is not smooth, have a Yamaha

dealer check the vehicle.

1. Locknut

2. Brake lever free play adjusting screw

3. Brake lever free play

4. Rubber cover

3

1

2

4

(b)

(a)

32D-9-EC.book 24 ページ 2013年6月25日 火曜日 午後4時16分

Page 68 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-26

1

2

3

4

56

7

8

9

EAU22582

Checking the brake fluid levelBefore riding, check that the brake fluid

is above the minimum level mark.

Check the brake fluid level with the top

of the reservoir level. Replenish the

brake fluid if necessary.

Front brakeRear brake

WARNING

EWA15991

Improper maintenance can result in

loss of braking ability. Observe

these precautions:

Insufficient brake fluid may al-

low air to enter the brake sys-

tem, reducing braking

performance.

Clean the filler cap before re-

moving. Use only DOT 4 brake

fluid from a sealed container.

Use only the specified brake flu-

id; otherwise, the rubber sealsmay deteriorate, causing leak-

age.

Refill with the same type of

brake fluid. Adding a brake fluid

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water does not

enter the brake fluid reservoir

when refilling. Water will signifi-

cantly lower the boiling point of

the fluid and may result in vaporlock.

NOTICE

ECA17641

Brake fluid may damage painted sur-

faces or plastic parts. Always cleanup spilled fluid immediately.

As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake sys-

tem leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brake

fluid level goes down suddenly, have a

Yamaha dealer check the cause before

further riding.

1. Minimum level mark1

1. Minimum level markSpecified brake fluid:

DOT 41

32D-9-EC.book 26 ページ 2013年6月25日 火曜日 午後4時16分

Page 69 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-27

2

3

4

567

8

9

EAU22733

Changing the brake fluidHave a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the master cylinders and calipers as

well as the brake hoses replaced at the

intervals listed below or whenever they

are damaged or leaking.

Oil seals: Replace every two

years.

Brake hoses: Replace every four

years.

EAU22762

Drive chain slackThe drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU47223

To check the drive chain slack1. Place the motorcycle on the sides- tand.TIPWhen checking and adjusting the drive

chain slack, there should be no weighton the motorcycle.

2. Shift the transmission into the neu- tral position.

3. Push on the drive chain at the cen- ter point between the chain ten-

sioner and the chain support

mounting bolt with a force of 50 N

(5.0 kgf, 11 lbf).

4. Measure drive chain slack be- tween the swingarm and the top of

the chain link closest to the swing-

arm as shown. 5. If the drive chain slack is incorrect,

adjust it as follows.

EAU34318

To adjust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack.1. Loosen the axle nut and the lock- nut on each side of the swingarm.

2. To tighten the drive chain, turn the drive chain slack adjusting bolt on

each side of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting bolt on each side

of the swingarm in direction (b),

and then push the rear wheel for-

Drive chain slack:8.0–13.0 mm (0.31–0.51 in)

1. Drive chain slack

2. Chain support mounting bolt

3. Chain tensioner

1

3

2

32D-9-EC.book 27 ページ 2013年6月25日 火曜日 午後4時16分

Page 70 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-28

1

2

3

4

56

7

8

9ward.

NOTICE: Improper drive

chain slack will overload the en-

gine as well as other vital parts

of the motorcycle and can lead

to chain slippage or breakage.

To prevent this from occurring,

keep the drive chain slack with-

in the specified limits.

[ECA10572]

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain pullers are in the sameposition for proper wheel alignment. 3. Tighten the axle nut, then the lock-

nuts to their specified torques.

4. Make sure that the drive chain pull- ers are in the same position, the

drive chain slack is correct, and

the drive chain moves smoothly.

EAU23026

Cleaning and lubricating the

drive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must be lubricated

after washing the motorcycle, ridingin the rain or riding in wet areas.

1. Clean the drive chain with kero- sene and a small soft brush.

NOTICE: To prevent damaging

the O-rings, do not clean the

drive chain with steam cleaners,

high-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

engine oil or any other lubri-

cants for the drive chain, as they

1. Axle nut

2. Locknut

3. Drive chain slack adjusting bolt

4. Alignment marks

5. Drive chain puller15

32

4

(b)

(a)

Tightening torques:

Axle nut:125 Nm (12.5 m·kgf, 90 ft·lbf)

Locknut: 16 Nm (1.6 m·kgf, 12 ft·lbf)

32D-9-EC.book 28 ページ 2013年6月25日 火曜日 午後4時16分

Page 79 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-37

2

3

4

567

8

9

EAU24205

Replacing a turn signal light

bulb1. Remove the turn signal light lensby removing the screw.

2. Remove the burnt-out bulb by pushing it in and turning it counter-

clockwise. 3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the screw. NOTICE: Do not over-

tighten the screw, otherwise the

lens may break.

[ECA11192] EAU24314

Replacing the license plate

light bulb1. Remove the license plate light unit

by removing the screws.

2. Remove the license plate light bulb socket (together with the bulb) by

pulling it out.

1. Screw

2. Turn signal light lens

1

2

1. Turn signal light bulb

1

1. Screw

1

32D-9-EC.book 37 ページ 2013年6月25日 火曜日 午後4時16分

Page 82 of 98

![YAMAHA WR 250R 2014 User Guide PERIODIC MAINTENANCE AND ADJUSTMENT

6-40

1

2

3

4

56

7

8

9installing the spacers, be sure

to install them on the correct

side.

[ECA17701]

2. Lift the wheel up between the fork

legs.TIPMake sure that th YAMAHA WR 250R 2014 User Guide PERIODIC MAINTENANCE AND ADJUSTMENT

6-40

1

2

3

4

56

7

8

9installing the spacers, be sure

to install them on the correct

side.

[ECA17701]

2. Lift the wheel up between the fork

legs.TIPMake sure that th](/img/51/52355/w960_52355-81.png)

PERIODIC MAINTENANCE AND ADJUSTMENT

6-40

1

2

3

4

56

7

8

9installing the spacers, be sure

to install them on the correct

side.

[ECA17701]

2. Lift the wheel up between the fork

legs.TIPMake sure that there is enough space

between the brake pads before install-

ing the brake caliper onto the brakedisc.

3. Insert the wheel axle from the right-hand side.

4. Install the axle nut.

5. Lower the front wheel so that it is

on the ground, and then put the

sidestand down.

6. Tighten the axle nut to the speci- fied torque.

7. Tighten the front wheel axle pinch bolts to the specified torque, and

then install the rubber cap. 8. Push down hard on the handlebar

several times to check for proper

fork operation.

EAU25081

Rear wheel

EAU56691

To remove the rear wheel

WARNING

EWA10822

To avoid injury, securely support the

vehicle so there is no danger of itfalling over.

1. Loosen the axle nut.

2. Lift the rear wheel off the ground according to the procedure on

page 6-38.

3. Remove the axle nut and washer.

4. Loosen the locknut on each side of

Tightening torque: Axle nut:63 Nm (6.3 m·kgf, 46 ft·lbf)

Tightening torque: Front wheel axle pinch bolt:23 Nm (2.3 m·kgf, 17 ft·lbf)

1. Axle nut

2. Washer1

2

32D-9-EC.book 40 ページ 2013年6月25日 火曜日 午後4時16分

Page 83 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-41

2

3

4

567

8

9

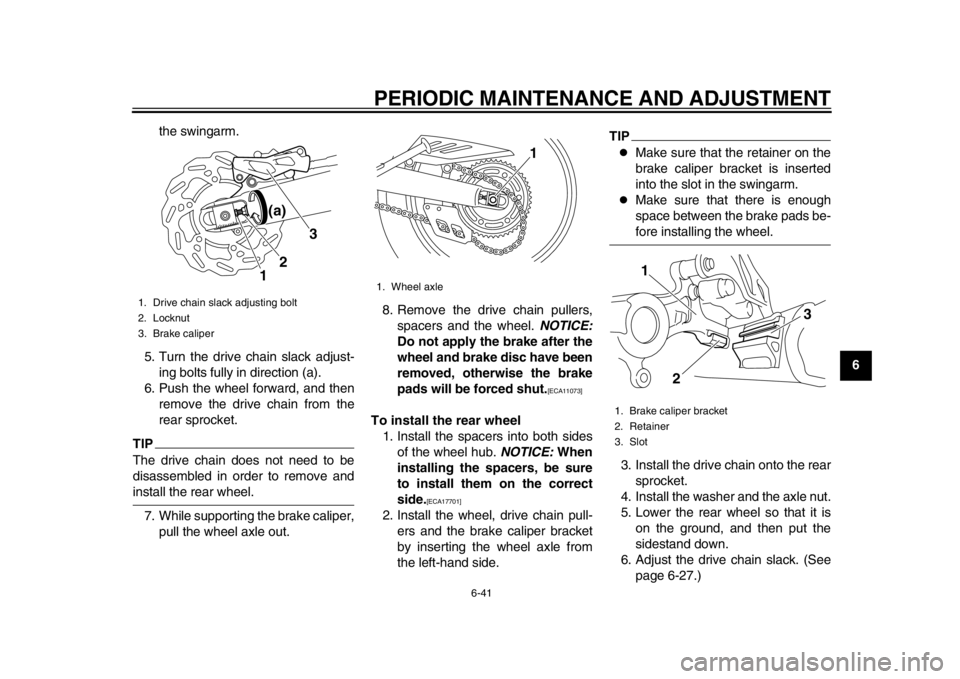

the swingarm.

5. Turn the drive chain slack adjust- ing bolts fully in direction (a).

6. Push the wheel forward, and then remove the drive chain from the

rear sprocket.

TIPThe drive chain does not need to be

disassembled in order to remove andinstall the rear wheel.

7. While supporting the brake caliper, pull the wheel axle out. 8. Remove the drive chain pullers,

spacers and the wheel. NOTICE:

Do not apply the brake after the

wheel and brake disc have been

removed, otherwise the brake

pads will be forced shut.

[ECA11073]

To install the rear wheel 1. Install the spacers into both sides of the wheel hub. NOTICE: When

installing the spacers, be sure

to install them on the correct

side.

[ECA17701]

2. Install the wheel, drive chain pull- ers and the brake caliper bracket

by inserting the wheel axle from

the left-hand side.

TIP

Make sure that the retainer on the

brake caliper bracket is inserted

into the slot in the swingarm.

Make sure that there is enough

space between the brake pads be-fore installing the wheel.

3. Install the drive chain onto the rear sprocket.

4. Install the washer and the axle nut.

5. Lower the rear wheel so that it is on the ground, and then put the

sidestand down.

6. Adjust the drive chain slack. (See page 6-27.)

1. Drive chain slack adjusting bolt

2. Locknut

3. Brake caliper

1 2

3

(a)

1. Wheel axle

1

1. Brake caliper bracket

2. Retainer

3. Slot

1

2

3

32D-9-EC.book 41 ページ 2013年6月25日 火曜日 午後4時16分

Page 84 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-42

1

2

3

4

56

7

8

97. Tighten the axle nut, and then the

locknuts to their specified torques.

EAU25872

TroubleshootingAlthough Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur dur-

ing operation. Any problem in the fuel,

compression, or ignition systems, for

example, can cause poor starting and

loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look like

Yamaha parts, but they are often inferi-

or, have a shorter service life and can

lead to expensive repair bills.

WARNING

EWA15142

When checking the fuel system, do

not smoke, and make sure there are

no open flames or sparks in the ar-

ea, including pilot lights from water heaters or furnaces. Gasoline or

gasoline vapors can ignite or ex-

plode, causing severe injury or

property damage.

Tightening torques:

Axle nut:125 Nm (12.5 m·kgf, 90 ft·lbf)

Locknut: 16 Nm (1.6 m·kgf, 12 ft·lbf)

32D-9-EC.book 42 ページ 2013年6月25日 火曜日 午後4時16分