engine oil YAMAHA WR 250R 2016 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 250R, Model: YAMAHA WR 250R 2016Pages: 100, PDF Size: 2.65 MB

Page 6 of 100

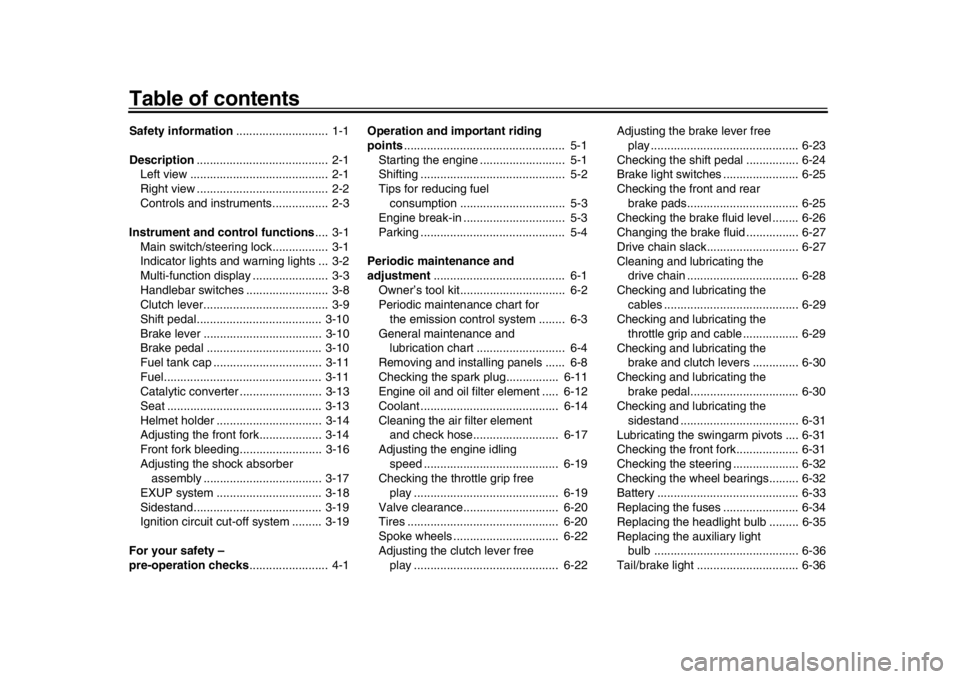

Table of contentsSafety information............................ 1-1

Description ........................................ 2-1

Left view .......................................... 2-1

Right view ........................................ 2-2

Controls and instrument s................. 2-3

Instrument and co ntrol functions.... 3-1

Main switch/steering lock................. 3-1

Indicator lights and warning lights ... 3-2

Multi-function display ....................... 3-3

Handlebar switches ......................... 3-8

Clutch lever...................................... 3-9

Shift pedal....... ............................. .. 3-10

Brake lever .................................... 3-10

Brake pedal ................................... 3-10

Fuel tank cap ................................. 3-11

Fuel................................................ 3-11

Catalytic converter ......................... 3-13

Seat ............................................... 3-13

Helmet holder ................................ 3-14

Adjusting the front fork................... 3-14

Front fork bleeding......................... 3-16

Adjusting the shock absorber assembly .................................... 3-17

EXUP system ................................ 3-18

Sidestand....................................... 3-19

Ignition circuit cut-of f system ......... 3-19

For your safety –

pre-operation checks ........................ 4-1Operation and important riding

points

................................................. 5-1

Starting the engine .......................... 5-1

Shifting ............................................ 5-2

Tips for reducing fuel consumption ................................ 5-3

Engine break-in ............................... 5-3

Parking ............................................ 5-4

Periodic maintenance and

adjustment ........................................ 6-1

Owner’s tool kit................................ 6-2

Periodic maintenance chart for the emission contro l system ........ 6-3

General maintenance and lubrication chart ........................... 6-4

Removing and installing panels ...... 6-8

Checking the spark plug................ 6-11

Engine oil and oil filter element ..... 6-12

Coolant .......................................... 6-14

Cleaning the air filter element and check hose.......................... 6-17

Adjusting the engine idling

speed ......................................... 6-19

Checking the throttle grip free

play ............................................ 6-19

Valve clearance............................. 6-20

Tires .............................................. 6-20

Spoke wheels .............. .................. 6-22

Adjusting the clutch lever free play ............................................ 6-22 Adjusting the brake lever free

play ............................................. 6-23

Checking the shift pedal ................ 6-24

Brake light switches ....................... 6-25

Checking the front and rear brake pads.................................. 6-25

Checking the brake fluid level ........ 6-26

Changing the brake fluid ................ 6-27

Drive chain slack............................ 6-27

Cleaning and lubricating the drive chain .................................. 6-28

Checking and lubricating the cables ......................................... 6-29

Checking and lubricating the

throttle grip and cable ................. 6-29

Checking and lubricating the brake and clutch levers .............. 6-30

Checking and lubricating the brake pedal................................. 6-30

Checking and lubricating the

sidestand .................................... 6-31

Lubricating the swingarm pivots .... 6-31

Checking the front fork................... 6-31

Checking the steering .................... 6-32

Checking the wheel bearings......... 6-32

Battery ........................................... 6-33

Replacing the fuses ....................... 6-34

Replacing the headlight bulb ......... 6-35

Replacing the auxiliary light bulb ............................................ 6-36

Tail/brake light ............................... 6-36BN3-9-E0.book 1 ページ 2015年6月25日 木曜日 午前10時46分

Page 14 of 100

Description

2-2

12

3

4

5

6

7

8

9

10

11

12

EAU10421

Right view

3

1

2

9 7

6

5

8

4

1. Rear brake fluid reservoir (page 6-26)

2. Air filter element (page 6-17)

3. Rear brake light switch (page 6-25)

4. Fuel tank cap (page 3-11)

5. Bleed screw (page 3-16)

6. Engine oil filler cap (page 6-12)

7. Engine oil level check window (page 6-12)

8. Brake pedal (page 3-10) 9. Shock absorber assembly r

ebound damping force adjusting knob

(page 3-17)

BN3-9-E0.book 2 ページ 2015年6月25日 木曜日 午前10時46分

Page 36 of 100

4-1

1

2

34

5

6

7

8

9

10

11

12

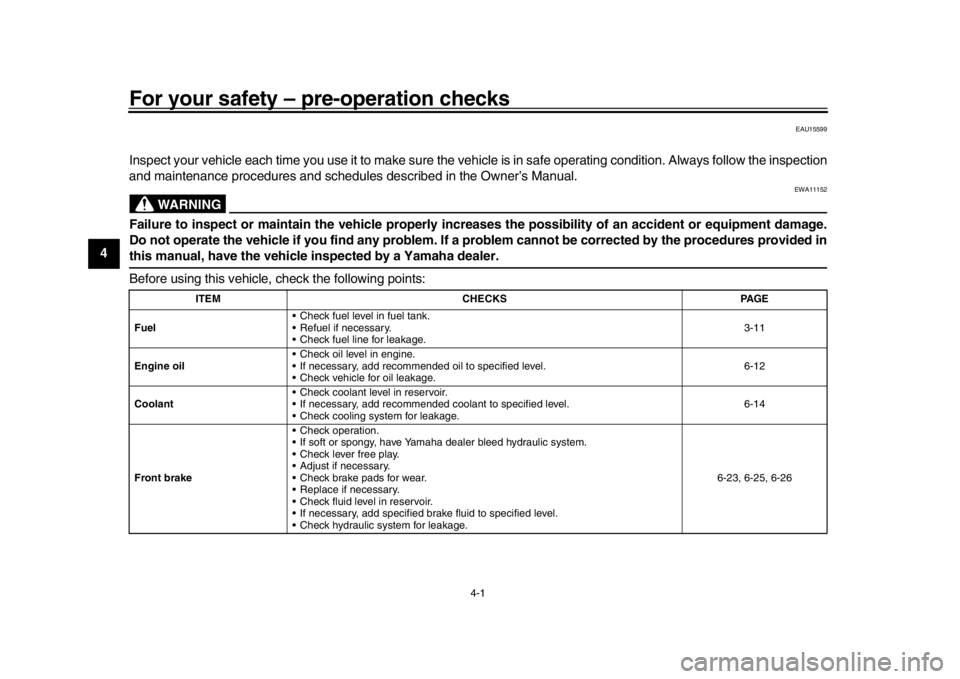

For your safety – pre-operation checks

EAU15599

Inspect your vehicle each time you use it to make sure the vehi cle is in safe operating condition. Always follow the inspection

and maintenance procedures and schedules described in the Owner’s Manual.

WARNING

EWA11152

Failure to inspect or maintain the vehicle properly increases the possibility of an accident or equipment damage.

Do not operate the vehicle if you find any problem. If a problem cannot be corrected by the procedures provided inthis manual, have the vehicle inspected by a Yamaha dealer.

Before using this vehicle, check the following points:

ITEM CHECKS PAGE

Fuel Check fuel level in fuel tank.

Refuel if necessary.

Check fuel line for leakage. 3-11

Engine oil Check oil level in engine.

If necessary, add recommended oil to specified level.

Check vehicle for oil leakage. 6-12

Coolant Check coolant level in reservoir.

If necessary, add recommended coolant to specified level.

Check cooling system for leakage. 6-14

Front brake Check operation.

If soft or spongy, have Yamaha dealer bleed hydraulic system.

Check lever free play.

Adjust if necessary.

Check brake pads for wear.

Replace if necessary.

Check fluid level in reservoir.

If necessary, add specified brake fluid to specified level.

Check hydraulic system for leakage. 6-23, 6-25, 6-26

BN3-9-E0.book 1 ページ 2015年6月25日 木曜日 午前10時46分

Page 41 of 100

Operation and important riding points

5-3

1

2

3

456

7

8

9

10

11

12

EAU16811

Tips for reducing fuel

consumptionFuel consumption depends largely on

your riding style. Consider the following

tips to reduce fuel consumption:

Shift up swiftly, and avoid high en-

gine speeds during acceleration.

Do not rev the engine while shifting

down, and avoid high engine

speeds with no load on the engine.

Turn the engine off instead of let-

ting it idle for an extended length of

time (e.g., in traffic jams, at traffic

lights or at railroad crossings).

EAU16842

Engine break-inThere is never a more important period

in the life of your engine than the period

between 0 and 1600 km (1000 mi). For

this reason, you should read the follow-

ing material carefully.

Since the engine is brand new, do not

put an excessive load on it for the first

1600 km (1000 mi). The various parts in

the engine wear and polish themselves

to the correct operating clearances.

During this period, prolonged full-throt-

tle operation or any condition that might

result in engine overheating must be

avoided.

EAU17024

0–1000 km (0–600 mi)

Avoid prolonged operation above 1/3

throttle. NOTICE: After 1000 km (600

mi) of operation, the engine oil must

be changed, and the oil filter car-

tridge or element replaced.

[ECA11283]

1000–1600 km (600–1000 mi)

Avoid prolonged operation above 1/2 throttle.

1600 km (1000 mi) and beyond

The vehicle can now be operated nor-

mally.

NOTICE

ECA10271

If any engine trouble should occur

during the engine break-in period,

immediately have a Yamaha dealercheck the vehicle.

BN3-9-E0.book 3 ページ 2015年6月25日 木曜日 午前10時46分

Page 48 of 100

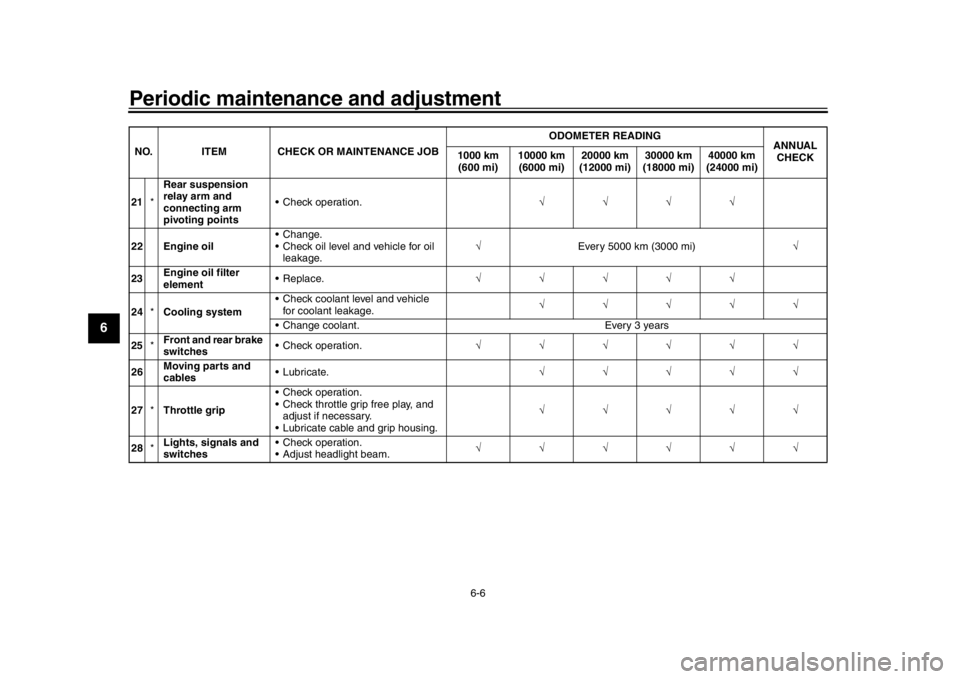

Periodic maintenance and adjustment

6-6

1

2

3

4

56

7

8

9

10

11

12

21 *Rear suspension

relay arm and

connecting arm

pivoting points Check operation.

22 Engine oil Change.

Check oil level and vehicle for oil

leakage.

Every 5000 km (3000 mi)

23 Engine oil filter

element

24 *Cooling system Check coolant level and vehicle

for coolant leakage.

Change coolant. Every 3 years

25 *Front and rear brake

switches Check operation.

26 Moving parts and

cables Lubricate.

27 *Throttle grip Check operation.

Check throttle grip free play, and

adjust if necessary.

Lubricate cable and grip housing.

28 *Lights, signals and

switches Check operation.

Adjust headlight beam.

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)BN3-9-E0.book 6 ページ 2015年6月25日 木曜日 午前10時46分

Page 53 of 100

Periodic maintenance and adjustment6-11

1

2

3

4

567

8

9

10

11

12

EAU48341

Checking the spark plugThe spark plug is an important engine

component, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark plug to slowly erode, it

should be removed and checked in ac-

cordance with the periodic mainte-

nance and lubrication chart. In addition,

the condition of the spark plug can re-

veal the condition of the engine.

The porcelain insulator around the cen-

ter electrode of the spark plug should

be a medium-to-light tan (the ideal color

when the vehicle is ridden normally). If

the spark plug shows a distinctly differ-

ent color, the engine could be operating

improperly. Do not attempt to diagnose

such problems yourself. Instead, have

a Yamaha dealer check the vehicle.

If the spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced.

Before installing a spark plug, the spark

plug gap should be measured with a wire thickness gauge and, if necessary,

adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and then

wipe off any grime from the spark plug

threads.

TIPIf a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn

past finger tight. However, the spark

plug should be tightened to the speci-

fied torque as soon as possible.NOTICE

ECA10841

Do not use any tools to remove or in-

stall the spark plug cap, otherwise

the ignition coil coupler may get

damaged. The spark plug cap may

be difficult to remove because the

rubber seal on the end of the cap fits

tightly. To remove the spark plug

cap, simply twist it back and forth

while pulling it out; to install it, twistit back and forth while pushing it in.

Specified spark plug:

NGK/CR9EK

1. Spark plug gapSpark plug gap:0.6–0.7 mm (0.024–0.028 in)

Tightening torque: Spark plug:13 Nm (1.3 m·kgf, 9.4 ft·lbf)11

BN3-9-E0.book 11 ページ 2015年6月25日 木曜日 午前10時46分

Page 54 of 100

Periodic maintenance and adjustment

6-12

1

2

3

4

56

7

8

9

10

11

12

EAU45145

Engine oil and oil filter

elementThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart.

To check the engine oil level 1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes until the oil set- tles, and then check the oil level

through the check window located

at the bottom-right side of the

crankcase.TIPThe engine oil should be between theminimum and maximum level marks. 4. If the engine oil is below the mini-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

To change the engine oil (with or

without oil filter element replace-

ment) 1. Place the vehicle on a level sur- face.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Place an oil pan under the engine to collect the used oil.

4. Remove the engine oil filler cap, the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.

TIPSkip steps 5–8 if the oil filter element isnot being replaced.

5. Remove the oil filter element cover by removing the bolts.

1. Engine oil filler cap

2. Maximum level mark

3. Minimum level mark

4. Engine oil level check window

1

2

3 4

1. Engine oil drain bolt

2. Gasket

12

BN3-9-E0.book 12 ページ 2015年6月25日 木曜日 午前10時46分

Page 55 of 100

Periodic maintenance and adjustment6-13

1

2

3

4

567

8

9

10

11

12

6. Remove the oil filter element and

O-rings.

7. Install a new oil filter element and new O-rings.

TIPMake sure that the O-rings are properlyseated.

8. Install the oil filter element cover by installing the bolts, then tightening

them to the specified torque.

9. Install the engine oil drain bolt and its new gasket, and then tighten

the bolt to the specified torque.

10. Refill with the specified amount of the recommended engine oil, and

then install and tighten the oil filler

cap.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-tem have cooled down.NOTICE

ECA11621

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a high-

er quality than specified. In

addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

Make sure that no foreign mate-rial enters the crankcase.

11. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking, im-

mediately turn the engine off and

check for the cause.

12. Turn the engine off, wait a few min- utes until the oil settles, and then

check the oil level and correct it if

necessary.

1. Oil filter element cover

2. Oil filter element cover bolt

1. O-ring

2. Oil filter element

1

2

1

2

Tightening torque:Oil filter element cover bolt:

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Tightening torque: Engine oil drain bolt:20 Nm (2.0 m·kgf, 14 ft·lbf)

Recommended oil: See page 8-1.

Oil quantity: Oil change:

1.30 L (1.37 US qt, 1.14 Imp.qt)

With oil filter removal: 1.40 L (1.48 US qt, 1.23 Imp.qt)

BN3-9-E0.book 13 ページ 2015年6月25日 木曜日 午前10時46分

Page 56 of 100

Periodic maintenance and adjustment

6-14

1

2

3

4

56

7

8

9

10

11

12

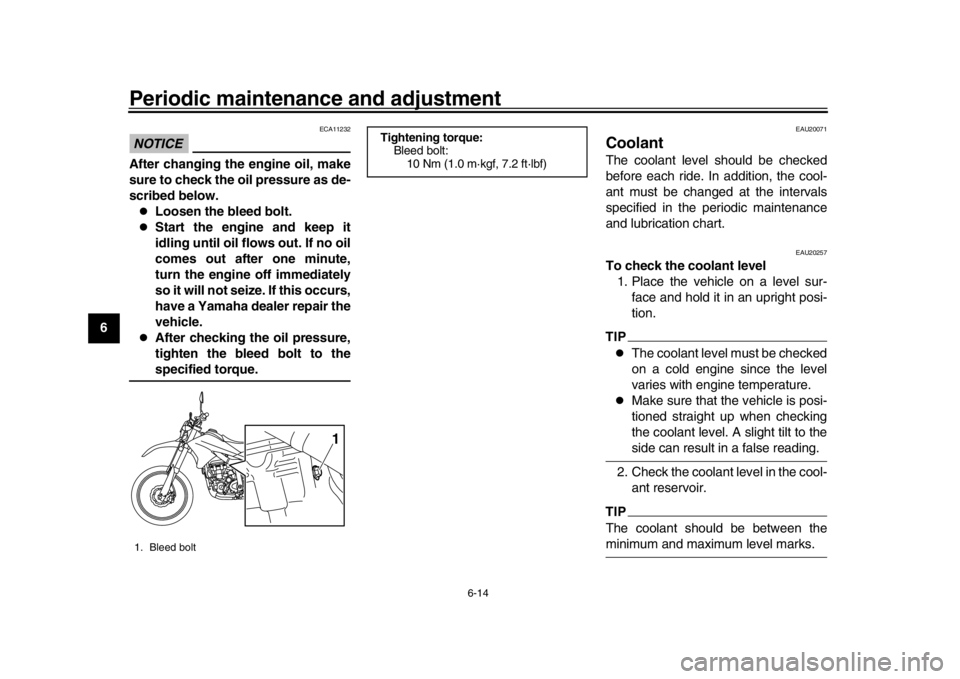

NOTICE

ECA11232

After changing the engine oil, make

sure to check the oil pressure as de-

scribed below.

Loosen the bleed bolt.

Start the engine and keep it

idling until oil flows out. If no oil

comes out after one minute,

turn the engine off immediately

so it will not seize. If this occurs,

have a Yamaha dealer repair the

vehicle.

After checking the oil pressure,

tighten the bleed bolt to thespecified torque.

EAU20071

CoolantThe coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU20257

To check the coolant level 1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion.TIP

The coolant level must be checked

on a cold engine since the level

varies with engine temperature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to theside can result in a false reading.

2. Check the coolant level in the cool- ant reservoir.

TIPThe coolant should be between theminimum and maximum level marks.

1. Bleed bolt

1

Tightening torque:Bleed bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

BN3-9-E0.book 14 ページ 2015年6月25日 木曜日 午前10時46分

Page 60 of 100

Periodic maintenance and adjustment

6-18

1

2

3

4

56

7

8

9

10

11

12 with solvent, and then squeeze the

remaining solvent out.

WARNING!

Use only a dedicated parts

cleaning solvent. To avoid the

risk of fire or explosion, do not

use gasoline or solvents with a

low flash point.

[EWA10432]

NOTICE:

To avoid damaging the foam

material, handle it gently and

carefully, and do not twist or

wring it.

[ECA10512]

5. Apply oil of the recommended type to the entire surface of the sponge

material, and then squeeze the ex-

cess oil out.TIPThe sponge material should be wet butnot dripping.

6. Pull the sponge material over the air filter element frame.

7. Insert the air filter element into the air filter case. NOTICE: Make sure

that the air filter element is prop-

erly seated in the air filter case.

The engine should never be op- erated without the air filter ele-

ment installed, otherwise the

piston(s) and/or cylinder(s) may

become excessively worn.

[ECA10482]

8. Place the holding clip in the origi-

nal position.

9. Close the air filter case cover, and then install the screw.

10. Install the panel.

To clean the air filter check hose 1. Check the hose at the bottom of the air filter case for accumulated

dirt or water.

2. If dirt or water is visible, remove the hose, clean it, and then install

it.

1. Sponge material

2. Air filter element frame

1

2

Recommended oil: Yamaha foam air filter oil or other

quality foam air filter oil

1. Air filter check hose

1

BN3-9-E0.book 18 ページ 2015年6月25日 木曜日 午前10時46分