engine YAMAHA WR 400F 2001 Manuale duso (in Italian)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: WR 400F, Model: YAMAHA WR 400F 2001Pages: 762, PDF Dimensioni: 62.36 MB

Page 546 of 762

5 - 1

CHAS

EC500000

CHASSIS

EC590000

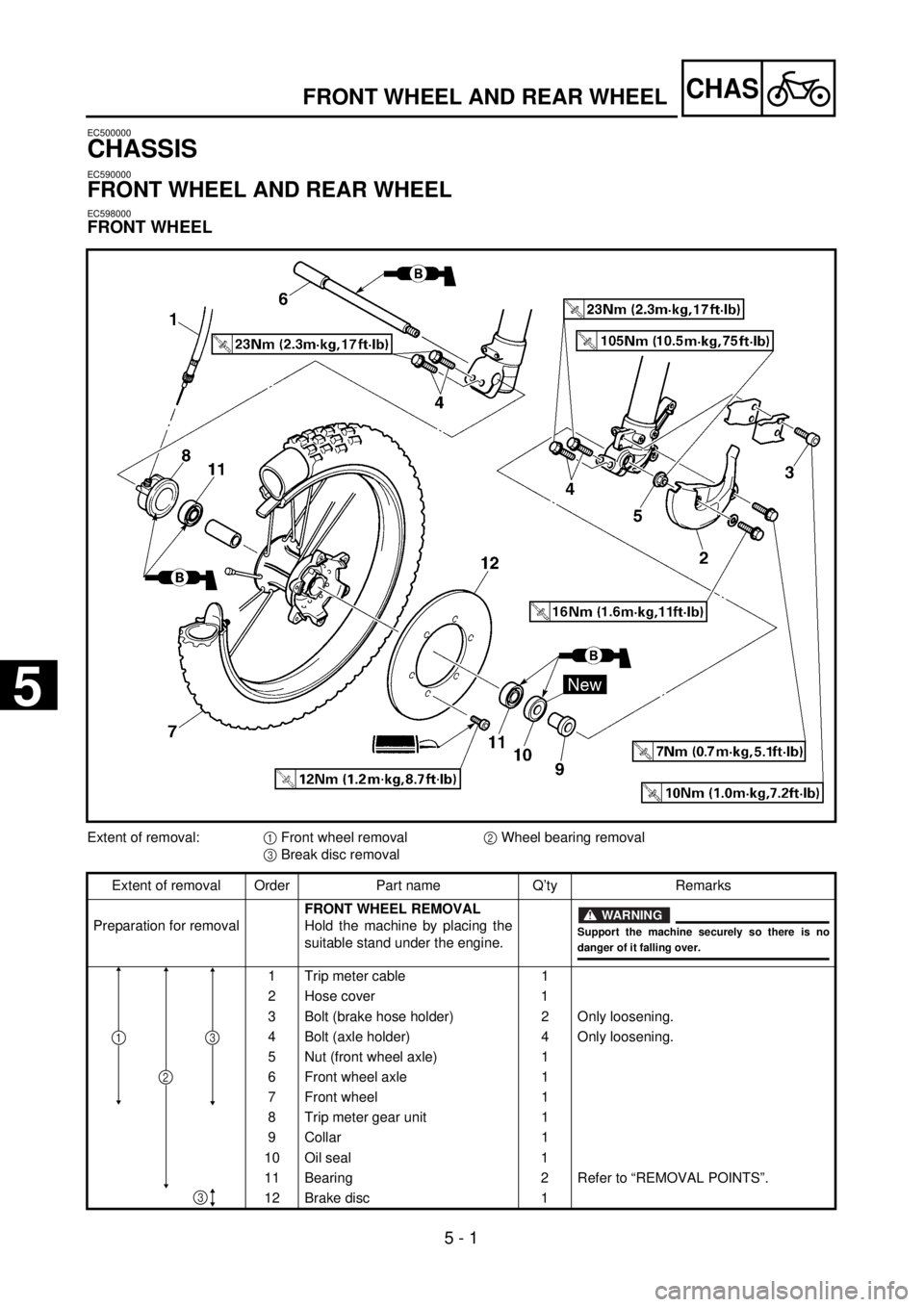

FRONT WHEEL AND REAR WHEEL

EC598000

FRONT WHEEL

Extent of removal:

1

Front wheel removal

2

Wheel bearing removal

3

Break disc removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removal

FRONT WHEEL REMOVAL

Hold the machine by placing the

suitable stand under the engine.

WARNING

Support the machine securely so there is no

danger of it falling over.

1 Trip meter cable 1

2 Hose cover 1

3 Bolt (brake hose holder) 2 Only loosening.

4 Bolt (axle holder) 4 Only loosening.

5 Nut (front wheel axle) 1

6 Front wheel axle 1

7 Front wheel 1

8 Trip meter gear unit 1

9 Collar 1

10 Oil seal 1

11 Bearing 2 Refer to “REMOVAL POINTS”.

12 Brake disc 1

2

31

3

FRONT WHEEL AND REAR WHEEL

5

Page 548 of 762

5 - 2

CHAS

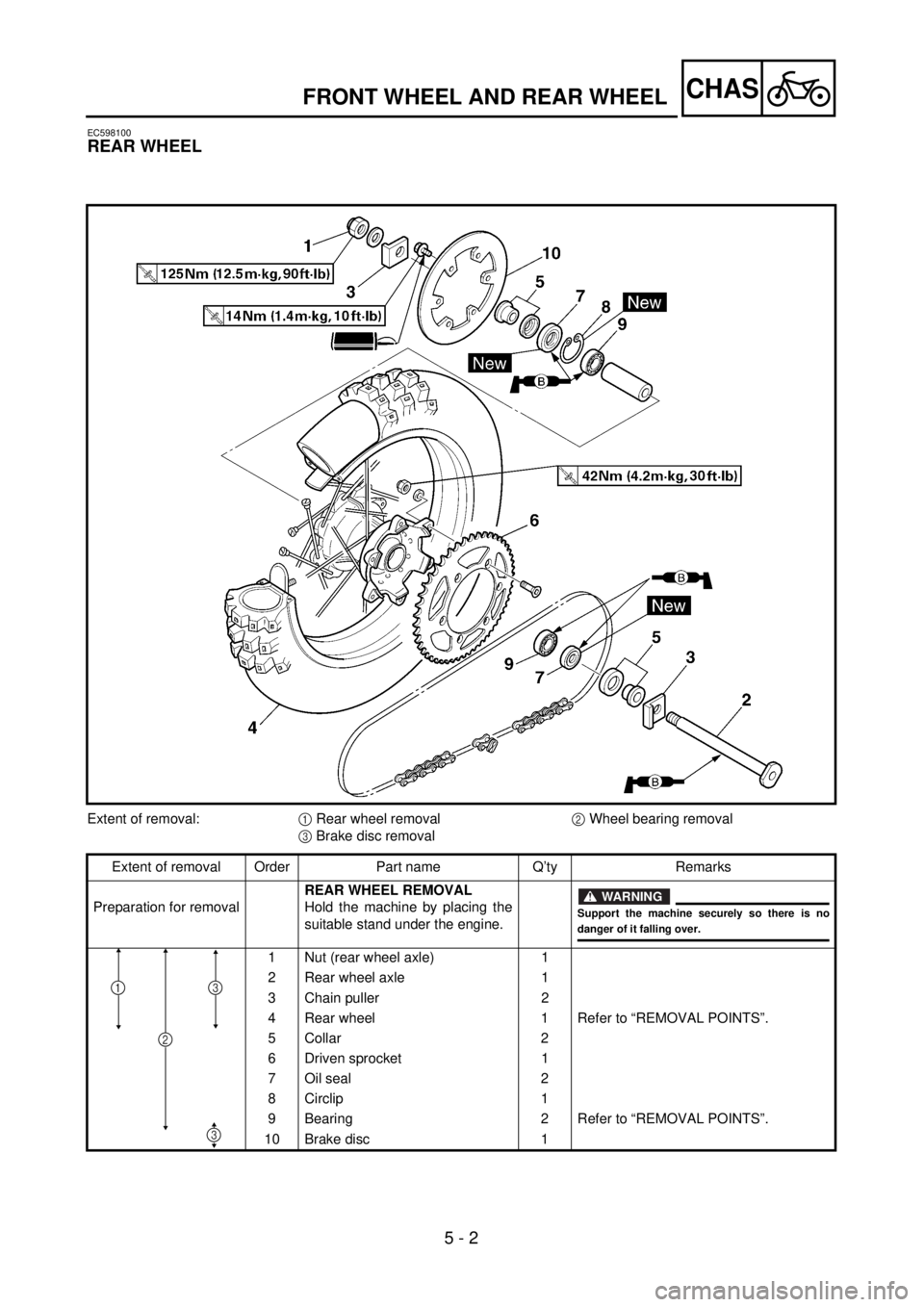

EC598100

REAR WHEEL

Extent of removal:

1

Rear wheel removal

2

Wheel bearing removal

3

Brake disc removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removal

REAR WHEEL REMOVAL

Hold the machine by placing the

suitable stand under the engine.

WARNING

Support the machine securely so there is no

danger of it falling over.

1 Nut (rear wheel axle) 1

2 Rear wheel axle 1

3 Chain puller 2

4 Rear wheel 1 Refer to “REMOVAL POINTS”.

5 Collar 2

6 Driven sprocket 1

7 Oil seal 2

8 Circlip 1

9 Bearing 2 Refer to “REMOVAL POINTS”.

10Brake disc

1

2

31

3

FRONT WHEEL AND REAR WHEEL

Page 566 of 762

5 - 11

CHASFRONT BRAKE AND REAR BRAKE

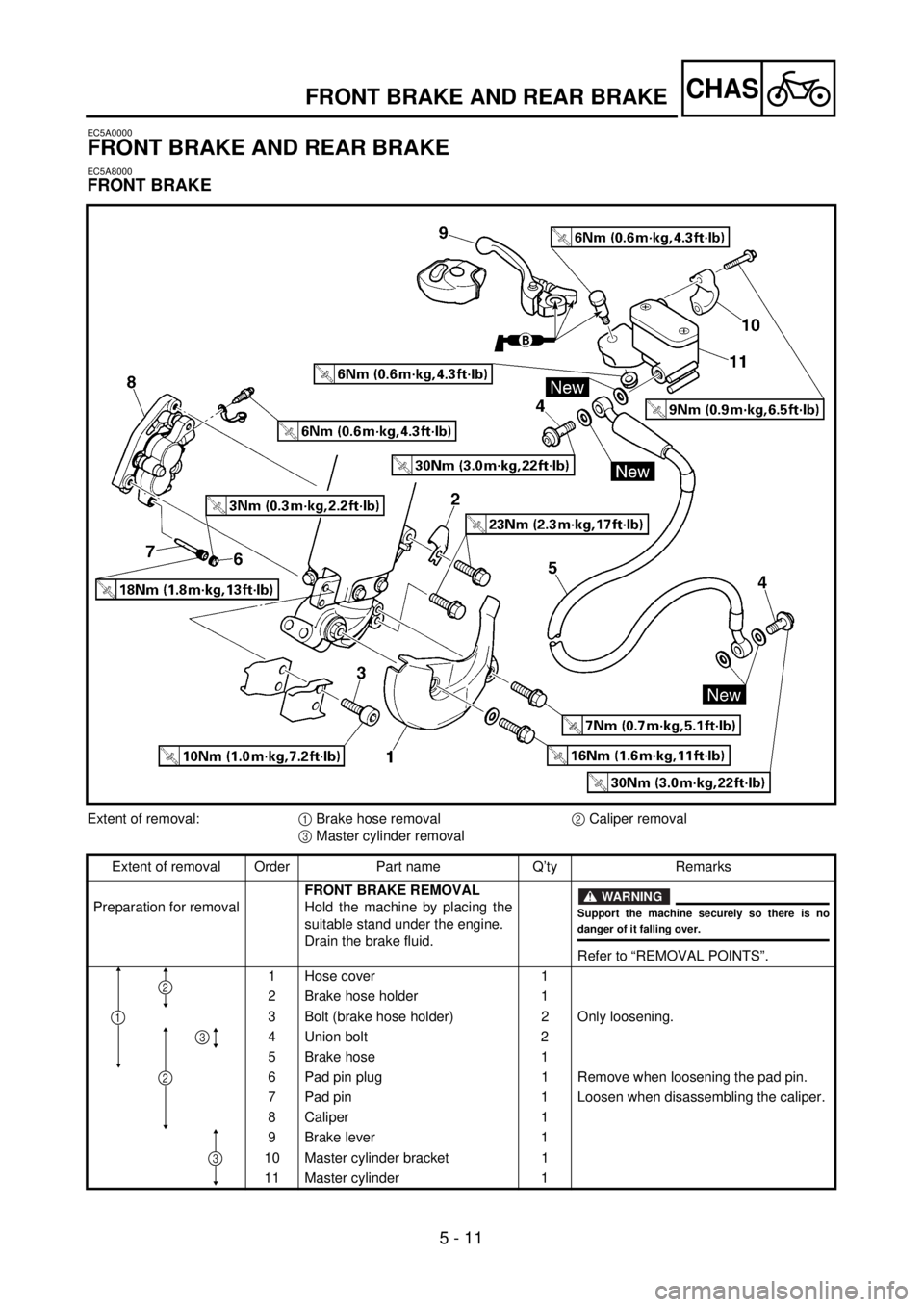

EC5A0000

FRONT BRAKE AND REAR BRAKE

EC5A8000

FRONT BRAKE

Extent of removal:1 Brake hose removal2 Caliper removal

3 Master cylinder removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalFRONT BRAKE REMOVAL

Hold the machine by placing the

suitable stand under the engine.

Drain the brake fluid.

WARNING

Support the machine securely so there is nodanger of it falling over.

Refer to “REMOVAL POINTS”.

1 Hose cover 1

2 Brake hose holder 1

3 Bolt (brake hose holder) 2 Only loosening.

4 Union bolt 2

5 Brake hose 1

6 Pad pin plug 1 Remove when loosening the pad pin.

7 Pad pin 1 Loosen when disassembling the caliper.

8 Caliper 1

9 Brake lever 1

10 Master cylinder bracket 1

11 Master cylinder 1

2

3

1

3

2

Page 568 of 762

5 - 12

CHAS

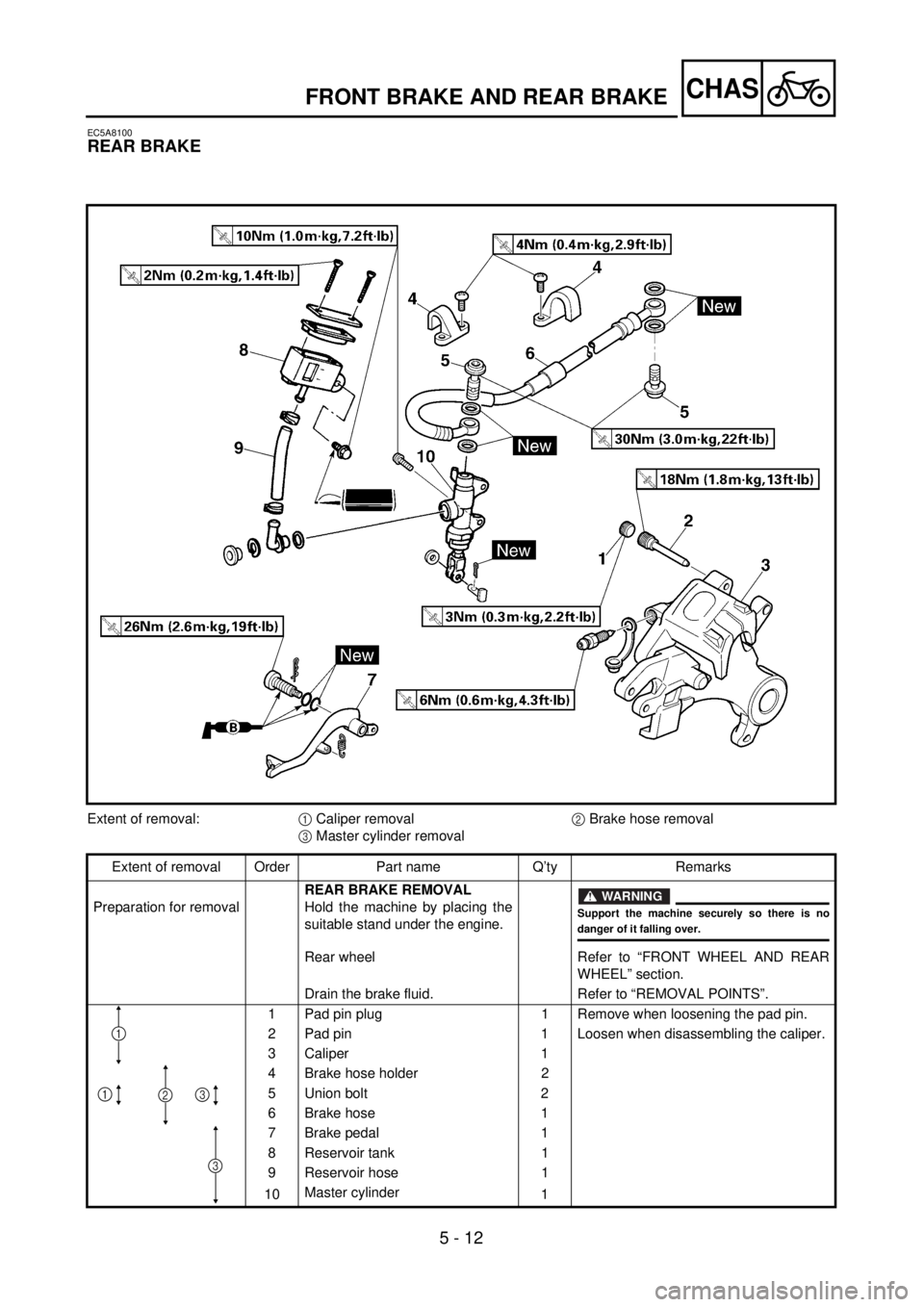

EC5A8100

REAR BRAKE

Extent of removal:1 Caliper removal2 Brake hose removal

3 Master cylinder removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalREAR BRAKE REMOVAL

Hold the machine by placing the

suitable stand under the engine.

WARNING

Support the machine securely so there is nodanger of it falling over.

Rear wheel Refer to “FRONT WHEEL AND REAR

WHEEL” section.

Drain the brake fluid. Refer to “REMOVAL POINTS”.

1 Pad pin plug 1 Remove when loosening the pad pin.

2 Pad pin 1 Loosen when disassembling the caliper.

3 Caliper 1

4 Brake hose holder 2

5 Union bolt 2

6 Brake hose 1

7 Brake pedal 1

8 Reservoir tank 1

9 Reservoir hose 1

10Master cylinder

1

3

1

321

FRONT BRAKE AND REAR BRAKE

Page 600 of 762

5 - 28

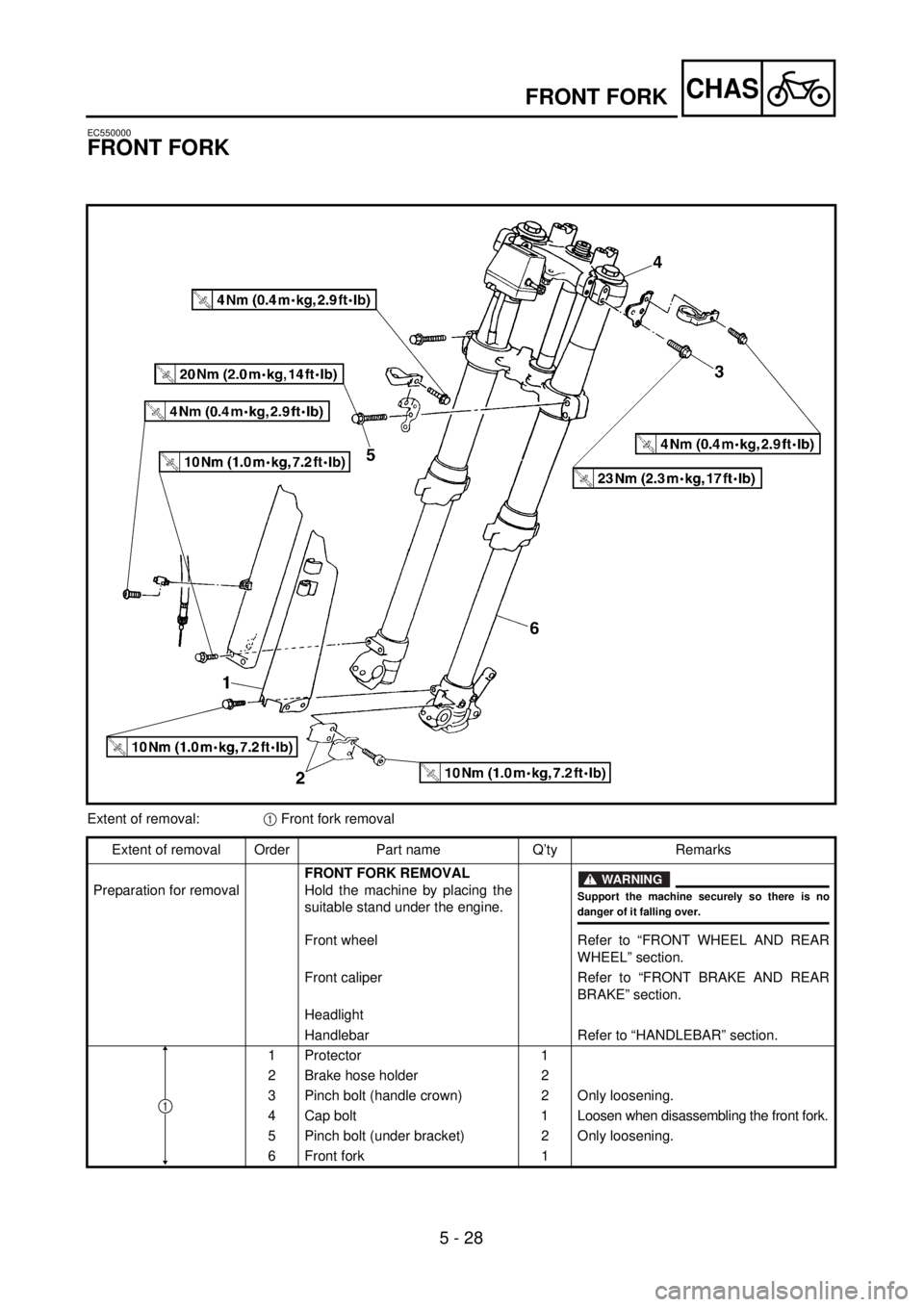

CHASFRONT FORK

EC550000

FRONT FORK

Extent of removal:1 Front fork removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalFRONT FORK REMOVAL

Hold the machine by placing the

suitable stand under the engine.

WARNING

Support the machine securely so there is nodanger of it falling over.

Front wheel Refer to “FRONT WHEEL AND REAR

WHEEL” section.

Front caliper Refer to “FRONT BRAKE AND REAR

BRAKE” section.

Headlight

Handlebar Refer to “HANDLEBAR” section.

1 Protector 1

2 Brake hose holder 2

3 Pinch bolt (handle crown) 2 Only loosening.

4 Cap bolt 1Loosen when disassembling the front fork.

5 Pinch bolt (under bracket) 2 Only loosening.

6 Front fork 1

1

Page 626 of 762

5 - 41

CHAS

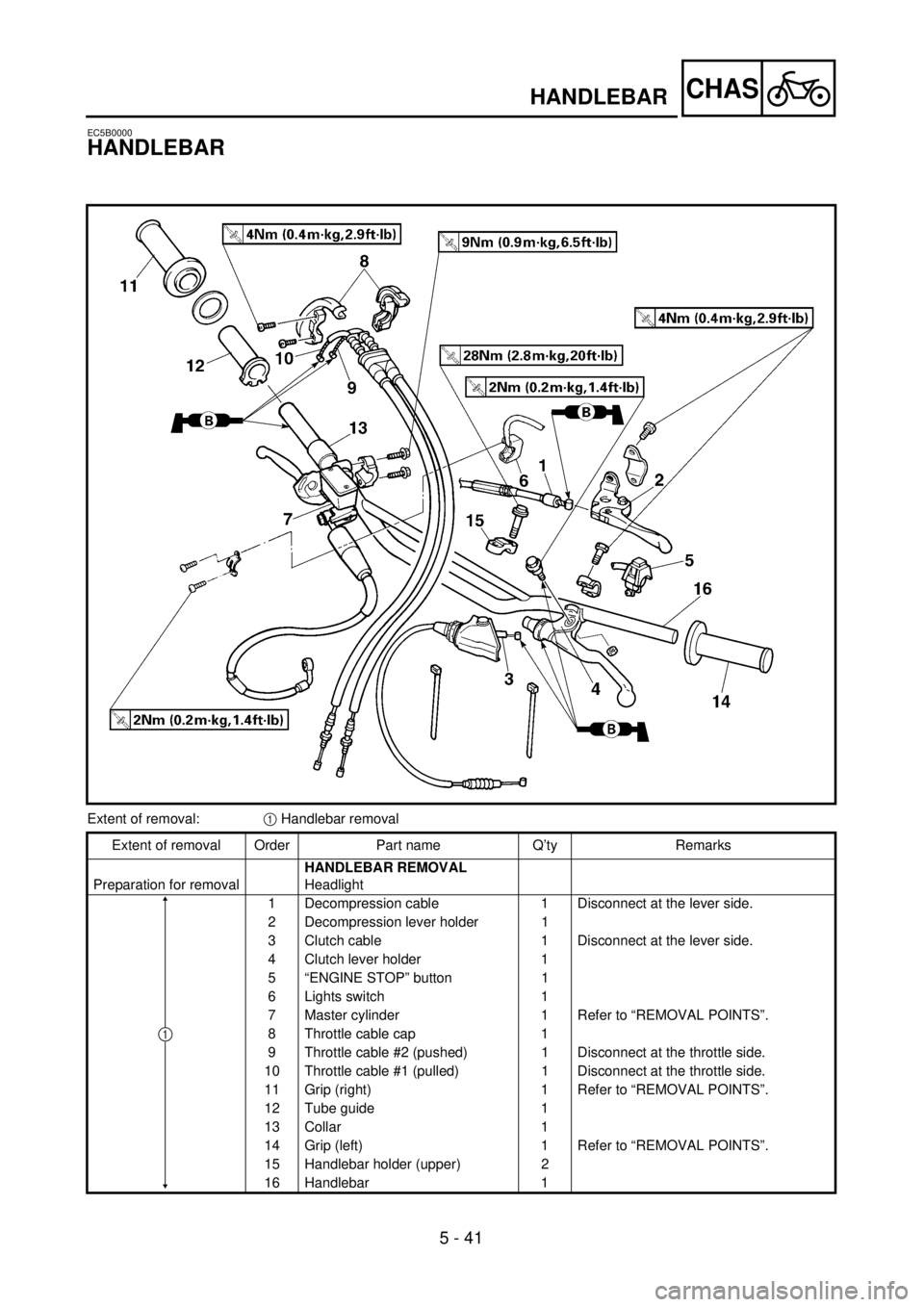

EC5B0000

HANDLEBAR

Extent of removal:1 Handlebar removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalHANDLEBAR REMOVAL

Headlight

1 Decompression cable 1 Disconnect at the lever side.

2 Decompression lever holder 1

3 Clutch cable 1 Disconnect at the lever side.

4 Clutch lever holder 1

5 “ENGINE STOP” button 1

6 Lights switch 1

7 Master cylinder 1 Refer to “REMOVAL POINTS”.

8 Throttle cable cap 1

9 Throttle cable #2 (pushed) 1 Disconnect at the throttle side.

10 Throttle cable #1 (pulled) 1 Disconnect at the throttle side.

11 Grip (right) 1 Refer to “REMOVAL POINTS”.

12 Tube guide 1

13 Collar 1

14 Grip (left) 1 Refer to “REMOVAL POINTS”.

15 Handlebar holder (upper) 2

16 Handlebar 1

1

HANDLEBAR

Page 627 of 762

5 - 41

CHAS

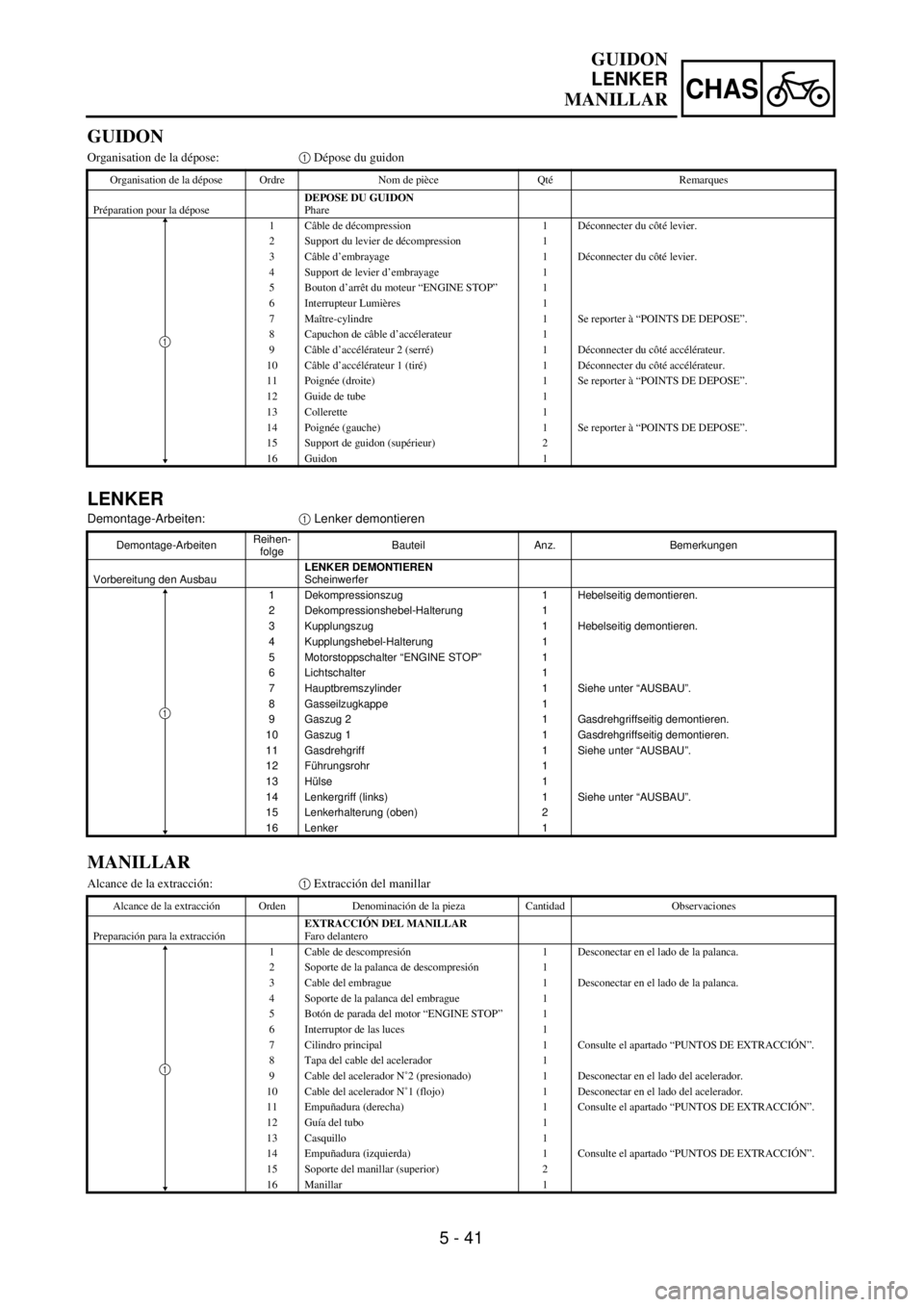

LENKER

Demontage-Arbeiten:

1

Lenker demontieren

Demontage-ArbeitenReihen-

folgeBauteil Anz. Bemerkungen

Vorbereitung den Ausbau

LENKER DEMONTIEREN

Scheinwerfer

1 Dekompressionszug 1 Hebelseitig demontieren.

2 Dekompressionshebel-Halterung 1

3 Kupplungszug 1 Hebelseitig demontieren.

4 Kupplungshebel-Halterung 1

5 Motorstoppschalter “ENGINE STOP” 1

6 Lichtschalter 1

7 Hauptbremszylinder 1 Siehe unter “AUSBAU”.

8 Gasseilzugkappe 1

9 Gaszug 2 1 Gasdrehgriffseitig demontieren.

10 Gaszug 1 1 Gasdrehgriffseitig demontieren.

11 Gasdrehgriff 1 Siehe unter “AUSBAU”.

12 Führungsrohr 1

13 Hülse 1

14 Lenkergriff (links) 1 Siehe unter “AUSBAU”.

15 Lenkerhalterung (oben) 2

16Lenker

1

1

GUIDON

LENKER

MANILLAR

GUIDON

Organisation de la dépose:

1

Dépose du guidon

Organisation de la dépose Ordre Nom de pièce Qté Remarques

Préparation pour la dépose

DEPOSE DU GUIDON

Phare

1 Câble de décompression 1 Déconnecter du côté levier.

2 Support du levier de décompression 1

3 Câble d’embrayage 1 Déconnecter du côté levier.

4 Support de levier d’embrayage 1

5 Bouton d’arrêt du moteur “ENGINE STOP” 1

6 Interrupteur Lumières 1

7 Maître-cylindre 1 Se reporter à “POINTS DE DEPOSE”.

8 Capuchon de câble d’accélerateur 1

9 Câble d’accélérateur 2 (serré) 1 Déconnecter du côté accélérateur.

10 Câble d’accélérateur 1 (tiré) 1 Déconnecter du côté accélérateur.

11 Poignée (droite) 1 Se reporter à “POINTS DE DEPOSE”.

12 Guide de tube 1

13 Collerette 1

14 Poignée (gauche) 1 Se reporter à “POINTS DE DEPOSE”.

15 Support de guidon (supérieur) 2

16 Guidon 1

1

MANILLAR

Alcance de la extracción:

1

Extracción del manillar

Alcance de la extracción Orden Denominación de la pieza Cantidad Observaciones

Preparación para la extracción

EXTRACCIÓN DEL MANILLAR

Faro delantero

1 Cable de descompresión 1 Desconectar en el lado de la palanca.

2 Soporte de la palanca de descompresión 1

3 Cable del embrague 1 Desconectar en el lado de la palanca.

4 Soporte de la palanca del embrague 1

5 Botón de parada del motor “ENGINE STOP” 1

6 Interruptor de las luces 1

7 Cilindro principal 1 Consulte el apartado “PUNTOS DE EXTRACCIÓN”.

8 Tapa del cable del acelerador 1

9 Cable del acelerador N˚2 (presionado) 1 Desconectar en el lado del acelerador.

10 Cable del acelerador N˚1 (flojo) 1 Desconectar en el lado del acelerador.

11 Empuñadura (derecha) 1 Consulte el apartado “PUNTOS DE EXTRACCIÓN”.

12 Guía del tubo 1

13 Casquillo 1

14 Empuñadura (izquierda) 1 Consulte el apartado “PUNTOS DE EXTRACCIÓN”.

15 Soporte del manillar (superior) 2

16Manillar

1

1

Page 632 of 762

5 - 44

CHASHANDLEBAR

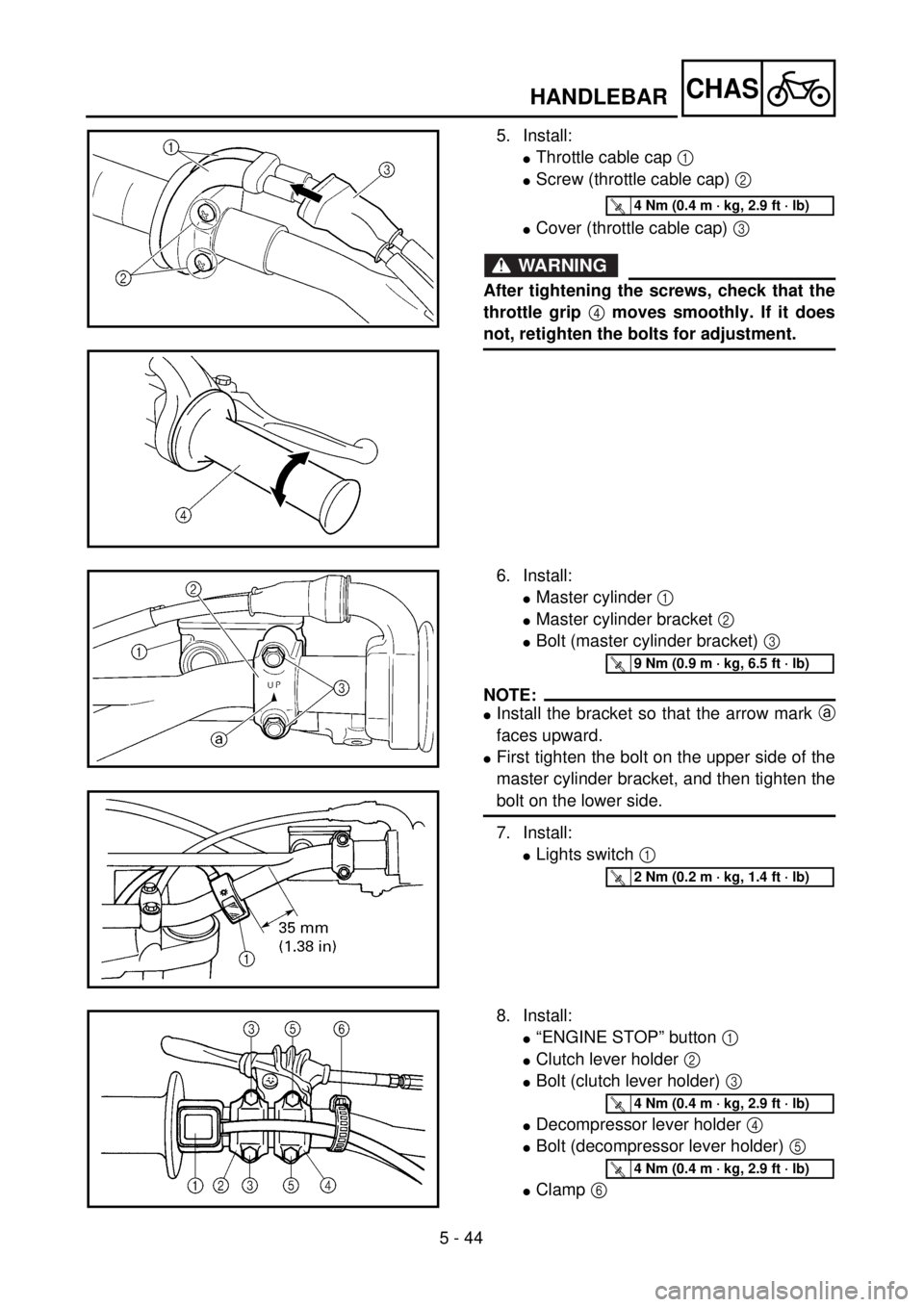

5. Install:

lThrottle cable cap 1

lScrew (throttle cable cap) 2

lCover (throttle cable cap) 3

WARNING

After tightening the screws, check that the

throttle grip 4 moves smoothly. If it does

not, retighten the bolts for adjustment.

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

6. Install:

lMaster cylinder 1

lMaster cylinder bracket 2

lBolt (master cylinder bracket) 3

NOTE:

lInstall the bracket so that the arrow mark a

faces upward.

lFirst tighten the bolt on the upper side of the

master cylinder bracket, and then tighten the

bolt on the lower side.

7. Install:

lLights switch 1

T R..9 Nm (0.9 m · kg, 6.5 ft · lb)

T R..2 Nm (0.2 m · kg, 1.4 ft · lb)

8. Install:

l“ENGINE STOP” button 1

lClutch lever holder 2

lBolt (clutch lever holder) 3

lDecompressor lever holder 4

lBolt (decompressor lever holder) 5

lClamp 6

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

Page 633 of 762

5 - 44

CHAS

GUIDON

LENKER

MANILLAR

5. Montieren:

lGasseilzugkappe 1

lSchrauben (Gasseilzugkap-

pe) 2

lAnlaufscheibe (Gasseilzug-

kappe) 3

WARNUNG

Nach dem Festziehen der Schrau-

ben den Gasdrehgriff 4 auf

Leichtgängigkeit prüfen. Gegebe-

nenfalls das Gasdrehgriffgehäuse

erneut ausrichten und befestigen.

T R..4 Nm (0,4 m · kg)

6. Montieren:

lHauptbremszylinder 1

lHauptbremszylinder-Halte-

rung 2

lSchraube (Hauptbremszy-

linder-Halterung) 3

HINWEIS:

lDie Halterung mit nach oben ge-

richteter Pfeilmarkierung a ein-

bauen.

lZuerst die oberen, dann die unte-

ren Halterungsschrauben festzie-

hen.

7. Einbauen:

lLichtschalter 1

T R..9 Nm (0,9 m · kg)

T R..2 Nm (0,2 m · kg)

8. Montieren:

lMotorstoppschalter “ENGI-

NE STOP” 1

lKupplungshebel-Halterung

2

lSchraube (Halterung) 3

lDekompressionshebel-Hal-

terung 4

lSchraube (Dekompressi-

onshebel-Halterung) 5

lKabelbinder 6

T R..4 Nm (0,4 m · kg)

T R..4 Nm (0,4 m · kg)

5. Monter:

lCapuchon de câble d’accéléra-

teur 1

lVis (capuchon de câble d’accé-

lérateur) 2

lCache (capuchon de câble

d’accélérateur) 3

AVERTISSEMENT

Après avoir serré les vis, vérifier que

la poignée des gaz 4 tourne sans pro-

blème. Sinon resserrer les boulons

pour la régler.

T R..4 Nm (0,4 m · kg, 2,9 ft · lb)

6. Monter:

lMaître-cylindre 1

lDemi-palier de fixation de maî-

tre-cylindre 2

lBoulon (demi-palier de fixation)

3

N.B.:

lReposer la support pour que la flèche

a soit dirigée vers le haut.

lSerrer d’abord le boulon sur le côté

supérieur du demi-palier de fixation de

maître-cylindre, puis serrer le boulon

sur le côté inférieur.

7. Posér:

lL’interrupteur lumières 1

T R..9 Nm (0,9 m · kg, 6,5 ft · lb)

T R..2 Nm (0,2 m · kg, 1,4 ft · lb)

8. Monter:

lBouton d’arrêt du moteur

“ENGINE STOP” 1

lSupport de levier d’embrayage

2

lBoulon (support de levier

d’embrayage) 3

lSupport du levier de décom-

presseur

4

lBoulon (support du levier de

décompresseur) 5

lBride 6

T R..4 Nm (0,4 m · kg, 2,9 ft · lb)

T R..4 Nm (0,4 m · kg, 2,9 ft · lb)

5. Instalar:

lTapa del cable del acelerador

1

lTornillo (tapa del cable del ace-

lerador) 2

lCubierta (tapa del cable del

acelerador) 3

ADVERTENCIA

Después de apretar los tornillos, com-

pruebe que la empuñadura del acele-

rador 4 se mueva suavemente. Si no

es así, vuelva a apretar los pernos para

realizar el ajuste.

T R..4 Nm (0,4 m · kg, 2,9 ft · lb)

6. Instalar:

lCilindro principal 1

lMénsula del cilindro principal

2

lPerno (ménsula del cilindro

principal) 3

NOTA:

lInstale la ménsula de form a que la

flecha esté hacia arriba.

lApriete en primer lugar el perno de la

parte superior de la ménsula del cilin-

dro principal y después apriete el

perno de la parte inferior.

7. Instalar:

lInterruptor de las luces 1

T R..9 Nm (0,9 m · kg, 6,5 ft · lb)

T R..2 Nm (0,2 m · kg, 1,4 ft · lb)

8. Instalar:

lBotón de parada del motor

“ENGINE STOP” 1

lSoporte de la palanca del

embrague 2

lPerno (soporte de la palanca

del embrague) 3

lSoporte de la palanca del des-

compresor 4

lPerno (soporte de la palanca

del descompresor) 5

lAbrazadera 6

T R..4 Nm (0,4 m · kg, 2,9 ft · lb)

T R..4 Nm (0,4 m · kg, 2,9 ft · lb)

Page 634 of 762

5 - 45

CHASHANDLEBAR

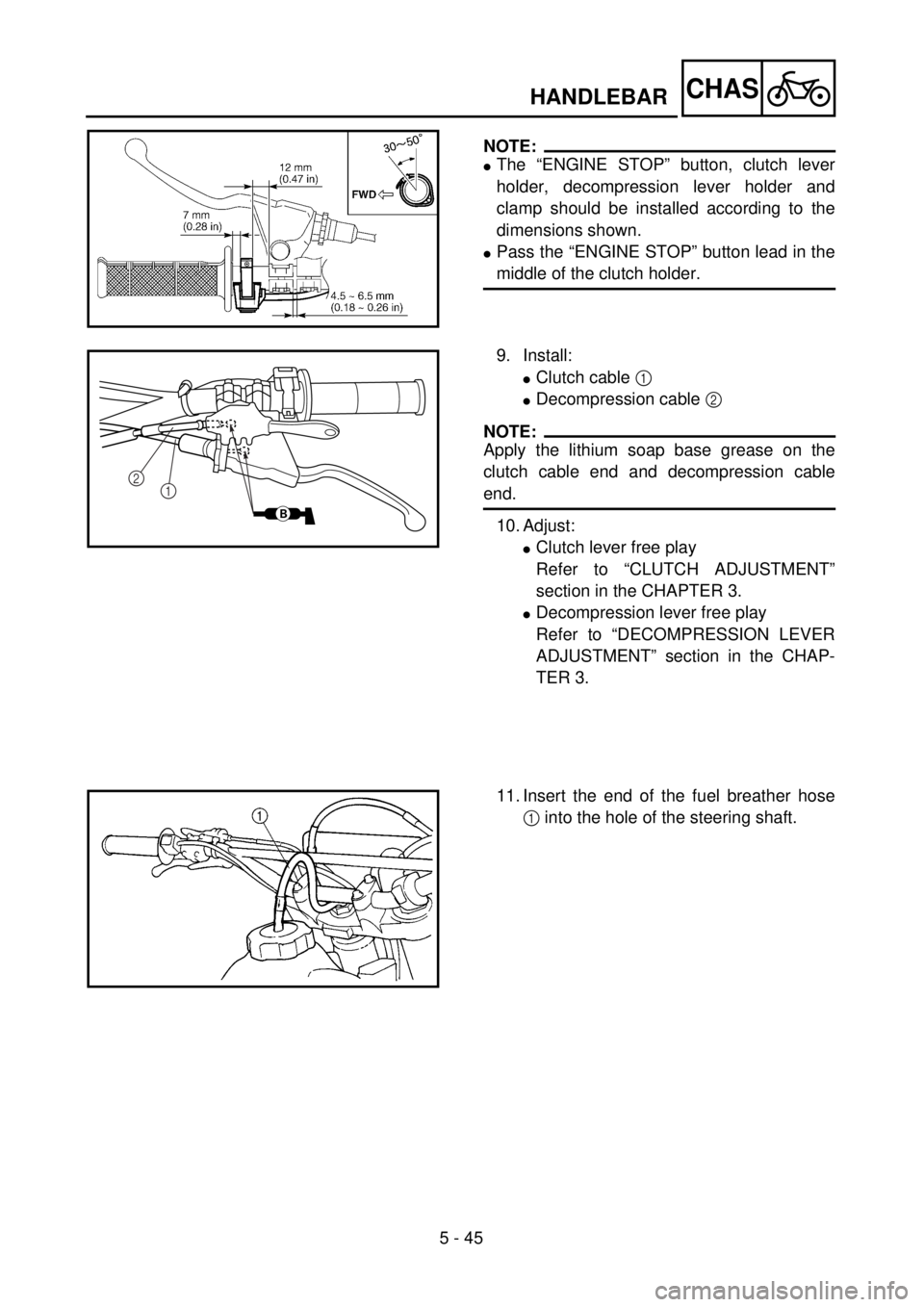

NOTE:

lThe “ENGINE STOP” button, clutch lever

holder, decompression lever holder and

clamp should be installed according to the

dimensions shown.

lPass the “ENGINE STOP” button lead in the

middle of the clutch holder.

9. Install:

lClutch cable 1

lDecompression cable 2

NOTE:

Apply the lithium soap base grease on the

clutch cable end and decompression cable

end.

10. Adjust:

lClutch lever free play

Refer to “CLUTCH ADJUSTMENT”

section in the CHAPTER 3.

lDecompression lever free play

Refer to “DECOMPRESSION LEVER

ADJUSTMENT” section in the CHAP-

TER 3.

B

2

1

11. Insert the end of the fuel breather hose

1 into the hole of the steering shaft.