engine YAMAHA WR 400F 2001 Manuale duso (in Italian)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: WR 400F, Model: YAMAHA WR 400F 2001Pages: 762, PDF Dimensioni: 62.36 MB

Page 39 of 762

1 - 8

GEN

INFO

SPECIAL TOOLS

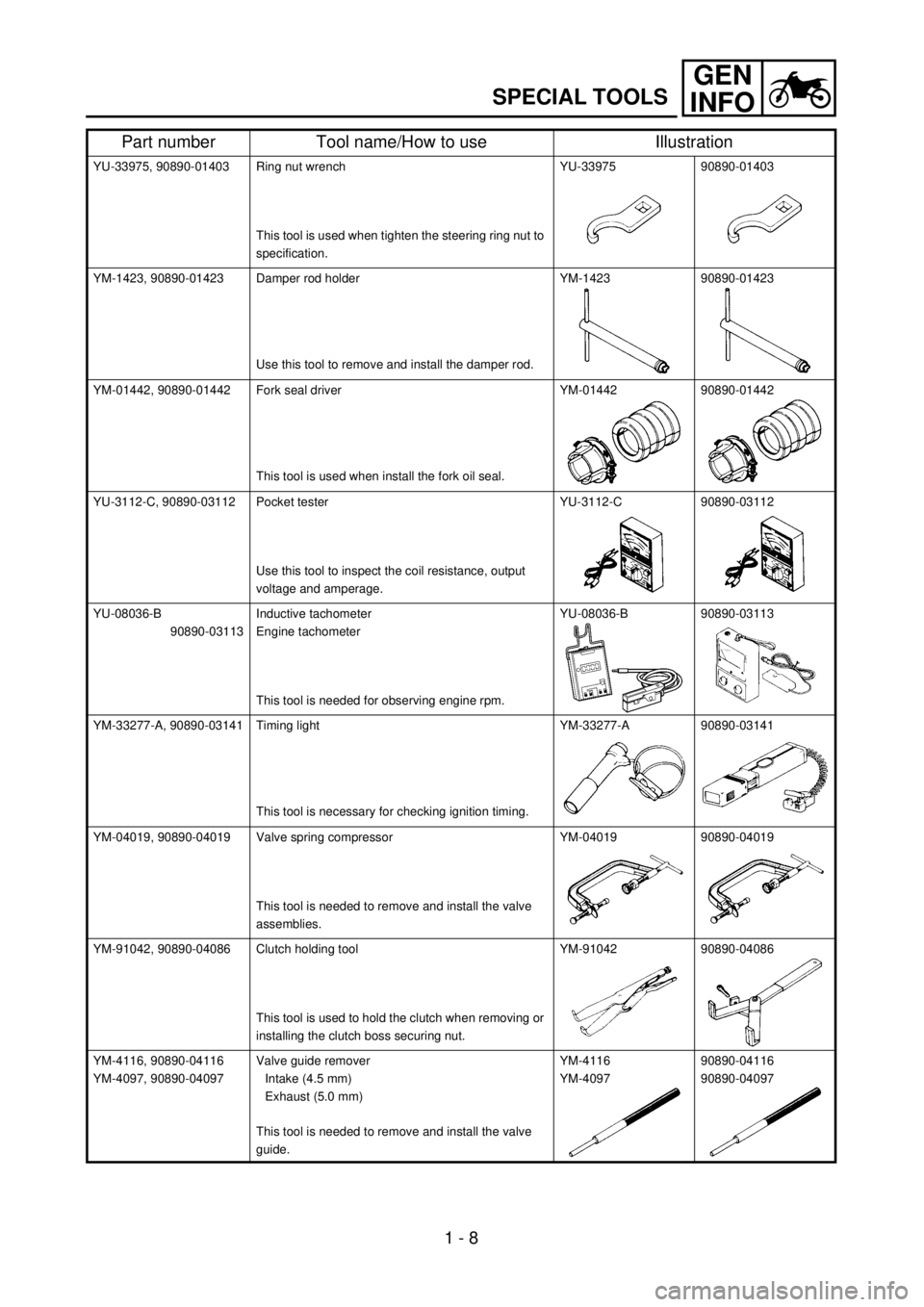

YU-33975, 90890-01403 Ring nut wrench

This tool is used when tighten the steering ring nut to

specification.YU-33975 90890-01403

YM-1423, 90890-01423 Damper rod holder

Use this tool to remove and install the damper rod.YM-1423 90890-01423

YM-01442, 90890-01442 Fork seal driver

This tool is used when install the fork oil seal.YM-01442 90890-01442

YU-3112-C, 90890-03112 Pocket tester

Use this tool to inspect the coil resistance, output

voltage and amperage.YU-3112-C 90890-03112

YU-08036-B

90890-03113Inductive tachometer

Engine tachometer

This tool is needed for observing engine rpm.YU-08036-B 90890-03113

YM-33277-A, 90890-03141 Timing light

This tool is necessary for checking ignition timing.YM-33277-A 90890-03141

YM-04019, 90890-04019 Valve spring compressor

This tool is needed to remove and install the valve

assemblies.YM-04019 90890-04019

YM-91042, 90890-04086 Clutch holding tool

This tool is used to hold the clutch when removing or

installing the clutch boss securing nut.YM-91042 90890-04086

YM-4116, 90890-04116

YM-4097, 90890-04097Valve guide remover

Intake (4.5 mm)

Exhaust (5.0 mm)

This tool is needed to remove and install the valve

guide.YM-4116

YM-409790890-04116

90890-04097

Part number Tool name/How to use Illustration

Page 50 of 762

1 - 10

GEN

INFO

CONTROL FUNCTIONS

EC150000

CONTROL FUNCTIONS

EC151000

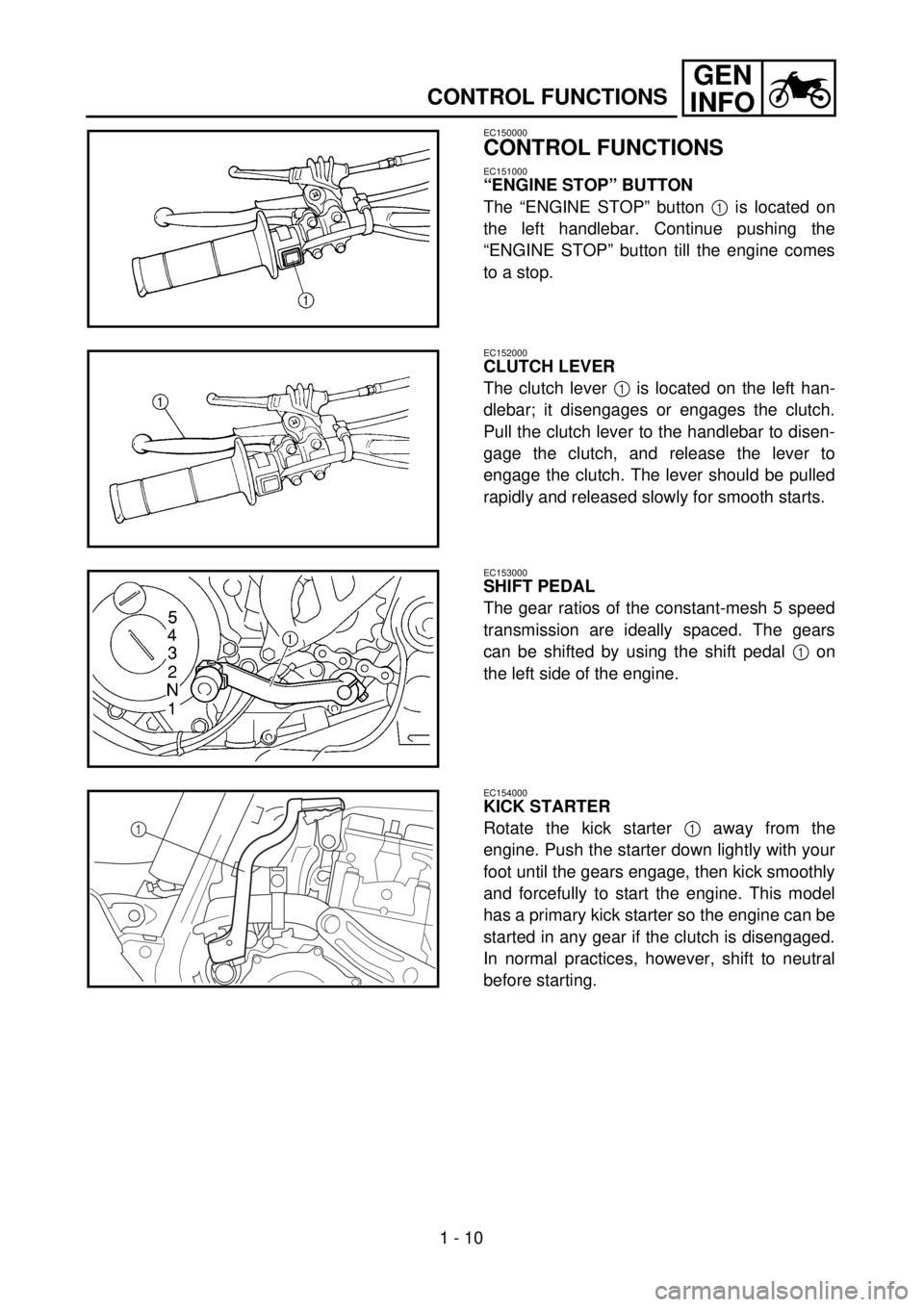

“ENGINE STOP” BUTTON

The “ENGINE STOP” button 1 is located on

the left handlebar. Continue pushing the

“ENGINE STOP” button till the engine comes

to a stop.

EC152000

CLUTCH LEVER

The clutch lever 1 is located on the left han-

dlebar; it disengages or engages the clutch.

Pull the clutch lever to the handlebar to disen-

gage the clutch, and release the lever to

engage the clutch. The lever should be pulled

rapidly and released slowly for smooth starts.

EC153000

SHIFT PEDAL

The gear ratios of the constant-mesh 5 speed

transmission are ideally spaced. The gears

can be shifted by using the shift pedal 1 on

the left side of the engine.

EC154000

KICK STARTER

Rotate the kick starter 1 away from the

engine. Push the starter down lightly with your

foot until the gears engage, then kick smoothly

and forcefully to start the engine. This model

has a primary kick starter so the engine can be

started in any gear if the clutch is disengaged.

In normal practices, however, shift to neutral

before starting.

1

Page 51 of 762

GEN

INFO

FONCTIONS DES COMMANDES

ARMATUREN UND DEREN FUNKTION

FUNCIONES DE CONTROL

ARMATUREN UND

DEREN FUNKTION

MOTORSTOPPSCHALTER “ENGI-

NE STOP”

Der Motorstoppschalter “ENGINE

STOP” 1 befindet sich auf der linken

Seite des Lenkers.

Den Motorstoppschalter “ENGINE

STOP” gedrückt halten, bis der

Motor abstirbt.

KUPPLUNGSHEBEL

Der Kupplungshebel 1 befindet sich

auf der linken Seite des Lenkers und

dient zum Ein- und Auskuppeln. Zum

Ausrücken der Kupplung den Kupp-

lungshebel zum Lenkgriff ziehen; zum

Einrücken der Kupplung den Kupp-

lungshebel wieder freigeben. Zum

Auskuppeln den Kupplungshebel

zügig ziehen, beim Einkuppeln gefühl-

voll loslassen, um ein weiches Einrük-

ken der Kupplung zu gewährleisten.

FUSSSCHALTHEBEL

Erst das Getriebe erlaubt die Nut-

zung der Motorleistung in verschie-

denen Geschwindigkeitsbereichen,

so daß Anfahren, Bergauffahren und

schnelles Beschleunigen möglich

sind. Die Gänge dieses 5-Gang-

Getriebes werden über den Fuß-

schalthebel 1 linksseitig des Motors

bei ausgerückter Kupplung geschal-

tet.

KICKSTARTER

Zum Anlassen des Motors den Kick-

starterhebel 1 ausschwenken und

langsam niedertreten, bis deutlicher

Widerstand spürbar wird; dann den

Kickstarterhebel schwungvoll durch-

treten. Dieses Modell ist mit einem

Primärkickstarter ausgerüstet, d. h.

der Motor kann auch bei eingelegtem

Gang angelassen werden – voraus-

gesetzt, daß die Kupplung ausge-

rückt ist. Normalerweise sollte

jedoch in den Leerlauf geschaltet

werden, bevor der Motor gestartet

wird.

FONCTIONS DES

COMMANDES

BOUTON D’ARRET DE MOTEUR

“ENGINE STOP”

Ce bouton d’arrêt de moteur “ENGINE

STOP” 1 est situé sur le guidon gauche.

Continuer à appuyer sur le bouton d’arrêt

de moteur “ENGINE STOP” jusqu’a que

ce le moteur s’arrête.

LEVIER D’EMBRAYAGE

Le levier d’embrayage 1 est situé sur le

guidon gauche et permet d’embrayer ou

de débrayer. Tirer le levier d’embrayage

vers le guidon pour débrayer et relâcher

le levier pour embrayer. Pour des démar-

rages doux, le levier doit être tiré rapide-

ment et relâché lentement.

PEDALE DE CHANGEMENT DE

VITESSE

Les 5 rapports de la boîte de vitesses à

prise constante sont idéalement échelon-

nés. Le changement de vitesse est com-

mandé par le sélecteur à pédale 1 situé

du côté gauche du moteur.

DEMARREUR AU PIED

Déployer la pédale de démarreur au pied

1. Appuyer légèrement sur la pédale

jusqu’à ce que les pignons se mettent en

prise puis l’actionner vigoureusement

pour démarrer le moteur. Ce modèle est

muni d’un démarreur au pied primaire,

de sorte qu’on peut démarrer sur

n’importe quelle vitesse à condition de

débrayer. Toutefois, normalement, on

remettra les vitesses au point mort avant

la mise en marche.

1 - 10

FUNCIONES DE

CONTROL

BOTÓN DE PARADA DEL MOTOR

“ENGINE STOP”

El botón de parada del motor “ENGINE

STOP” 1 está situado en el manillar

izquierdo. Pulse de forma continuada

este botón hasta que se detenga el motor.

PALANCA DEL EMBRAGUE

La palanca del embrague 1 está situada

en el manillar izquierdo; su función es la

de embragar o desembragar. Tire de la

palanca del embrague hacia el manillar

para desembragar y suelte la palanca

para embragar. Debe tirar de la palanca

rápidamente y soltarla suavemente para

obtener un arranque suave.

PEDAL DE CAMBIOS

Las relaciones de engranaje de la de la

caja de cambios de 5 velocidades de

engrane constante están óptimamente

separadas. Los engranes pueden cam-

biarse utilizando el pedal de cambios 1

en la parte izquierda del motor.

ARRANCADOR DE PEDAL

Gire el arrancador de pedal 1 hacia el

lado contrario al motor. Empuje el arran-

cador hacia abajo suavemente con el pie

hasta embragar las marchas y, a conti-

nuación, pedalee firme y uniformemente

para arrancar el motor. Este modelo

consta de un arrancador de pedal prima-

rio de forma que pueda arrancar el motor

en cualquiera de las marchas si el embra-

gue está desembragado. No obstante, en

condiciones normales, cambie a la posi-

ción de punto muerto antes de arrancar.

Page 52 of 762

1 - 11

GEN

INFO

CONTROL FUNCTIONS

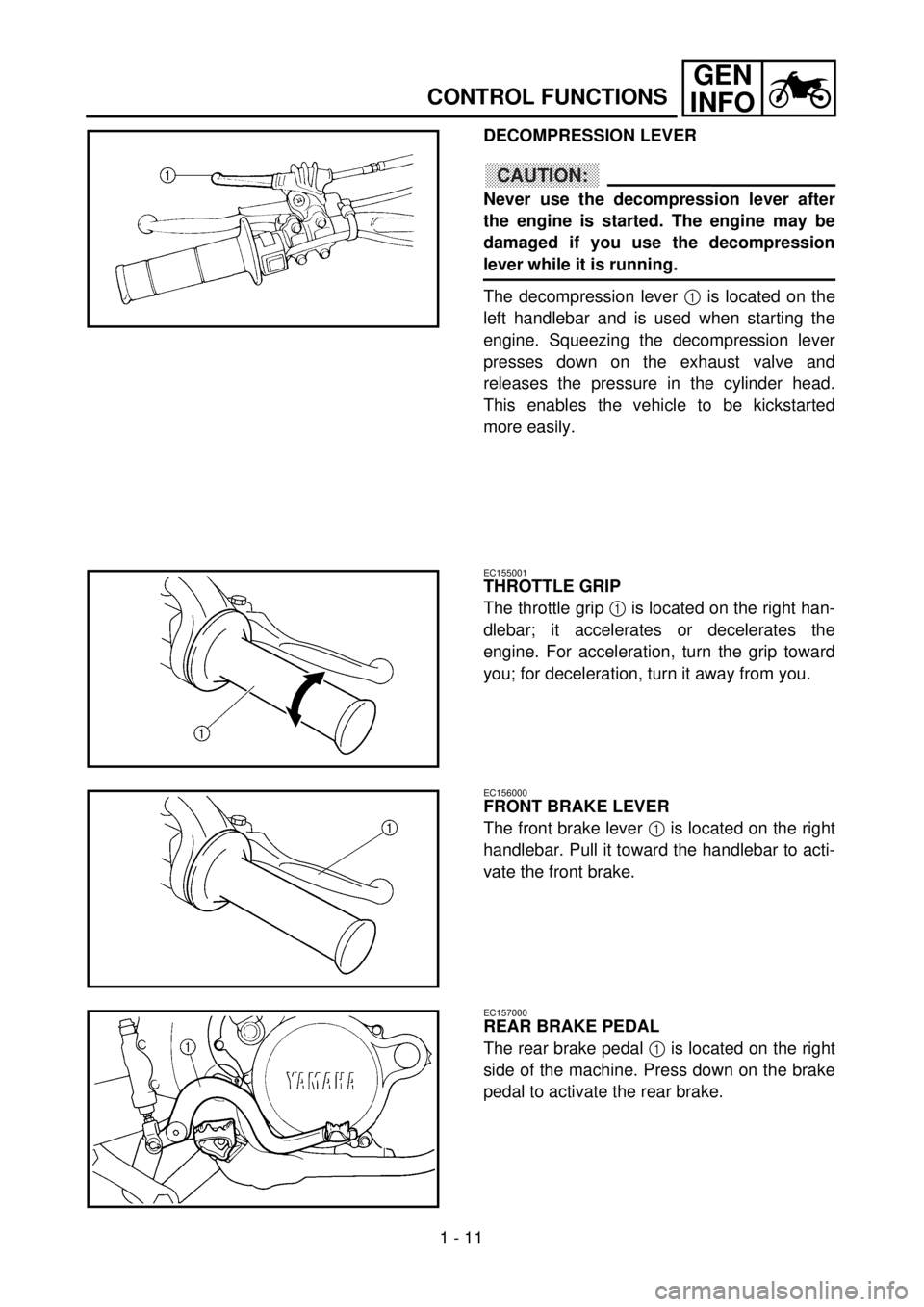

DECOMPRESSION LEVER

CAUTION:

Never use the decompression lever after

the engine is started. The engine may be

damaged if you use the decompression

lever while it is running.

The decompression lever 1 is located on the

left handlebar and is used when starting the

engine. Squeezing the decompression lever

presses down on the exhaust valve and

releases the pressure in the cylinder head.

This enables the vehicle to be kickstarted

more easily.

EC155001

THROTTLE GRIP

The throttle grip 1 is located on the right han-

dlebar; it accelerates or decelerates the

engine. For acceleration, turn the grip toward

you; for deceleration, turn it away from you.

EC156000

FRONT BRAKE LEVER

The front brake lever 1 is located on the right

handlebar. Pull it toward the handlebar to acti-

vate the front brake.

EC157000

REAR BRAKE PEDAL

The rear brake pedal 1 is located on the right

side of the machine. Press down on the brake

pedal to activate the rear brake.

Page 54 of 762

1 - 12

GEN

INFO

CONTROL FUNCTIONS

FUEL COCK

The fuel cock supplies fuel from the tank to

carburetor and also filters the fuel. The fuel

cock has three positions:

OFF:With the lever in this position fuel will not

flow. Always return the lever to this posi-

tion when the engine is not running.

ON: With the lever in this position fuel flows to

the carburetor. Normal riding is done with

the lever in this position.

RES:With the lever in this position fuel flows to

the carburetor from the reserve section of

the fuel tank after the main supply of the

fuel has been depleted. Normal riding is

possible with the lever is in this position,

but it is recommended to add fuel as

soon as possible.

COLD STARTER KNOB

When cold, the engine requires a richer air-fuel

mixture for starting. A separate starter circuit,

which is controlled by the cold starter knob 1,

supplies this mixture. Pull the cold starter knob

out to open the circuit for starting. When the

engine has warmed up, push it in to close the

circuit.

HOT STARTER KNOB (red)

The hot starter knob (red) 1 is used when

starting a warm engine.

Use the hot starter knob when starting the

engine again immediately after it was stopped

(the engine is still warm). Pulling out the hot

starter knob injects secondary air to thin the

air-fuel mixture temporarily, allowing the

engine to be started more easily.

CAUTION:

After the engine has started, be sure to

push the hot starter knob back in.

Page 58 of 762

1 - 14

GEN

INFO

STARTING AND BREAK-IN

STARTING AND BREAK-IN

WARNING

Never start or run the engine in a closed

area. The exhaust fumes are poisonous;

they can cause loss of consciousness and

death in a very short time. Always operate

the machine in a well-ventilated area.

CAUTION:

lThe carburetor on this motorcycle has a

built-in accelerator pump. Therefore,

when starting the engine, do not operate

the throttle or the spark plug will foul.

lUnlike a two-stroke engine, this engine

cannot be kick started when the throttle is

open because the kick starter may kick

back. Also, if the throttle is open the air/

fuel mixture may be too lean for the

engine to start.

lNever use the decompression lever after

the engine is started. The engine may be

damaged if you use the decompression

lever while it is running.

lBefore starting the machine, perform the

checks in the pre-operation check list.

STARTING A COLD ENGINE

1. Inspect the coolant level.

2. Turn the fuel cock to “ON”.

3. Shift the transmission into neutral.

4. Fully open the cold starter knob.

5. Without pulling in the decompression

lever, slowly depress the kick starter until

the compression stroke is found. When

considerable resistance of the kick starter

is felt, the engine is on the compression

stroke. If the engine is on the exhaust

stroke, resistance will only be felt when

the kick starter is initially depressed, not

through the entire range of depression

(as when the engine is on the compres-

sion stroke); therefore, depress the kick

starter a few more times.

Page 60 of 762

1 - 15

GEN

INFO

STARTING AND BREAK-IN

6. Pull the decompression lever to the han-

dlebar and depress the kick starter 10 ~

20˚.

7. Release the decompression lever and

return the kick starter to its original posi-

tion and then kick the kick starter.

WARNING

Do not open the throttle while kicking the

kick starter. Otherwise, the kick starter may

kick back.

8. Return the cold starter knob to its original

position and run the engine at 3,000 ~

5,000 r/min for 1 or 2 minutes.

NOTE:

Since this model is equipped with an accelera-

tor pump, if the engine is raced (the throttle

opened and closed), the air/fuel mixture will be

too rich and the engine may stall. Also unlike a

two-stroke engine, this model can idle.

CAUTION:

Do not warm up the engine for extended

periods of time.

Page 62 of 762

1 - 16

GEN

INFO

STARTING AND BREAK-IN

STARTING A WARM ENGINE

Do not operate the cold starter knob and throt-

tle. Open the hot starter knob (red) and start

the engine by kicking the kick starter forcefully

with a firm stroke.

As soon as the engine starts, push in the hot

starter knob to close the air passage.

Restarting an engine after a fall

Pull the hot starter knob (red) and start the

engine. As soon as the engine starts, push in

the hot starter knob to close the air passage.

The engine fails to start

Pull the hot starter knob (red) all the way out,

pull the decompression lever to the handlebar,

and while holding the lever, kick the kickstarter

10 to 20 times to clear the engine.

Then, restart the engine.

Refer to “Restarting an engine after a fall”.

* Operate the throttle grip before kick starting.

CAUTION:

Observe the following break-in procedures

during initial operation to ensure optimum

performance and avoid engine damage.

Throttle

grip oper-

ation*Cold

starter

knobHot

starter

knob (red)

Air temperature = less than

5 ˚C (41 ˚F)Open 3

or 4 timesON OFF

Air temperature = more

than 5 ˚C (41 ˚F)None ON OFF

Air temperature (normal

temperature) = between

5 ˚C (41 ˚F) and 25 ˚C

(77 ˚F)None ON/OFF OFF

Air temperature = more

than 25 ˚C (77 ˚F)None OFF OFF

Starting an engine after a long

period of timeNone ON OFF

Restarting a warm engine None OFF ON

Restarting an engine after a fall None OFF ON

Starting a cold engine

Page 64 of 762

1 - 17

GEN

INFO

BREAK-IN PROCEDURES

1. Before starting the engine, fill the fuel

tank with the fuel.

2. Perform the pre-operation checks on the

machine.

3. Start and warm up the engine. Check the

idle speed, and check the operation of

the controls and the “ENGINE STOP”

button. Then, restart the engine and

check its operation within no more than 5

minutes after it is restarted.

4. Operate the machine in the lower gears

at moderate throttle openings for five to

eight minutes.

5. Check how the engine runs when the

motorcycle is ridden with the throttle 1/4

to 1/2 open (low to medium speed) for

about one hour.

6. Restart the engine and check the opera-

tion of the machine throughout its entire

operating range. Restart the machine

and operate it for about 10 to 15 more

minutes. The machine will now be ready

to race.

CAUTION:

l

After the break-in or before each race,

you must check the entire machine for

loose fittings and fasteners as per

“TORQUE-CHECK POINTS”.

Tighten all such fasteners as required.

l

When any of the following parts have

been replaced, they must be broken in.

CYLINDER AND CRANKSHAFT:

About one hour of break-in operation is

necessary.

PISTON, RING, VALVES, CAMSHAFTS

AND GEARS:

These parts require about 30 minutes of

break-in operation at half-throttle or less.

Observe the condition of the engine care-

fully during operation.

STARTING AND BREAK-IN

Page 65 of 762

GEN

INFO

EINFAHRVORSCHRIFTEN

1. Vor dem Anlassen des Motors

volltanken.

2. Die “ROUTINEKONTROLLE

VOR FAHRTBEGINN” ausfüh-

ren.

3. Den Motor anlassen und

warmlaufen lassen. Dabei die

Leerlaufdrehzahl überwachen

und die Funktion der Bedie-

nungselemente sowie des Mo-

torstoppschalters “ENGINE

STOP” prüfen. Innerhalb der

nächsten fünf Minuten den

Motor wieder anlassen und die

folgenden Schritte ausführen.

4. Die Maschine fünf bis acht Mi-

nuten lang bei mäßiger Gas-

drehgrifföffnung in den unte-

ren Gängen fahren.

5. Den Motorbetrieb etwa eine

Stunde lang bei 1/4 bis 1/2 ge-

öffnetem Gasdrehgriff (niedri-

ge bis mittlere Geschwindig-

keit) überprüfen.

6. Den Motor erneut anlassen

und den Motorbetrieb im ge-

samten Betriebsbereich über-

prüfen. Den Motor abschalten

und noch einmal anlassen und

die Maschine 10 bis 15 Minu-

ten betreiben. Danach ist die

Maschine für Rennen einsatz-

bereit.

ACHTUNG:

lNach dem Einfahren und vor

jedem Rennen die Schraubver-

bindungen gemäß der Tabelle

“ANZUGSMOMENTE KONTROL-

LIEREN” auf festen Sitz prüfen

und vorschriftsmäßig anziehen.

lNach der Erneuerung eines der

folgenden Teile muß die

Maschine erneut eingefahren

werden.

- ZYLINDER UND KURBEL-

WELLE

Etwa eine Stunde Einfahrzeit

- KOLBEN, KOLBENRINGE, VEN-

TILE, NOKKENWELLEN UND -

RÄDER:

Etwa 30 Minuten Einfahrzeit bei

oder unter Halbgas (Sorgfältig

den Motorbetriebüberprüfen.)

MISE EN MARCHE ET RODAGE

ANLASSEN UND EINFAHREN

ARRANQUE Y RODAJE

PROCEDURE DE RODAGE

1. Avant de mettre le moteur en

marche, faire le plein d’essence.

2. Effectuer les contrôles avant utili-

sation de la machine.

3. Lancer le moteur et le laisser se

réchauffer. Vérifier le régime de

ralenti, le fonctionnement des

commandes et l’efficacité du bou-

ton d’arrêt du moteur “ENGINE

STOP”. Remettre ensuite le

moteur en marche et vérifier son

fonctionnement dans les 5 minutes

maximum.

4. Piloter la machine sur les rapports

inférieurs et à régime modéré

durant les cinq à huit premières

minutes. S’arrêter et vérifier l’état

de la bougie; elle devrait donner

des indices de richesse durant le

rodage.

5. Vérifier le fonctionnement du

moteur à une ouverture des gaz de

1/4 à 1/2 (petite à moyenne

vitesse) pendant environ 1 heure.

6. Remettre le moteur en marche et

vérifier son fonctionnement à

tous les régimes. Arrêter et véri-

fier la bougie. Relancer le moteur

et piloter la machine pendant 10 à

15 minutes supplémentaires. Elle

sera alors prête pour la course.

ATTENTION:

lAprès le rodage ou avant chaque

course, il faut vérifier toutes les fixa-

tions et serrages comme indiqué

dans “POINTS DE VERIFICA-

TION DE COUPLE DE SER-

RAGE”.

Serrer toutes ces fixations comme

requis.

lAprès avoir remplacé les pièces sui-

vantes, un nouveau rodage est

nécessaire.

CYLINDRE ET VILEBREQUIN:

Une heure environ de rodage est

nécessaire.

PISTONS, SEGMENTS, SOUPAPES,

ARBRES A CAMES

Ces pièces nécessitent un rodage de

30 minutes environ à une ouverture

des gaz de maximum 1/2. Surveiller

attentivement l’état du moteur pen-

dant la marche.PROCEDIMIENTOS DE RODAJE

1. Antes de arrancar el motor, llene

el depósito de combustible.

2. Realice las comprobaciones en el

vehículo previas a la conducción.

3. Arranque y deje que se caliente el

motor. Compruebe la velocidad

de ralentí, el funcionamiento de

los controles y el botón de parada

del motor “ENGINE STOP”. A

continuación, arranque nueva-

mente el motor y compruebe su

funcionamiento durante 5 minu-

tos como máximo después de

haberlo arrancado.

4. Maneje el vehículo en las mar-

chas inferiores y modere las aber-

turas del acelerador durante cinco

u ocho minutos.

5. Compruebe cómo funciona el

motor cuando maneje la motoci-

cleta con el acelerador 1/4 a 1/2

abierto (velocidad baja a mode-

rada) durante una hora aproxima-

damente.

6. Arranque el motor otra vez y

compruebe el funcionamiento del

vehículo en toda su gama de fun-

cionamiento. Arranque el motor y

maneje el vehículo durante otros

10 a 15 minutos. El vehículo ya

está preparado para la carrera.

PRECAUCION:

lDespués del rodaje o antes de cada

carrera, debe comprobar en todo el

vehículo la existencia de acopla-

mientos y remaches flojos así como

“TORSIONES-PUNTOS DE COM-

PROBACIÓN”.

En caso necesario, apriete todos los

remaches.

lCuando haya sustituido cualquiera

de las siguientes piezas, éstas deben

ser sometidas al rodaje.

CILINDRO Y CIGÜEÑAL:

Es necesario realizar aproximada-

mente una hora de conducción de

rodaje.

PISTÓN, ANILLO, VÁLVULAS,

ÁRBOLES DE LEVAS Y ENGRA-

NAJES:

Estas piezas requieren alrededor de

30 minutos de funcionamiento de

rodaje con el acelerador a la mitad o

inferior. Observe el estado del

motor cuidadosamente durante el

funcionamiento del mismo.

1 - 17