ignition YAMAHA WR 400F 2001 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: WR 400F, Model: YAMAHA WR 400F 2001Pages: 762, PDF Size: 62.36 MB

Page 330 of 762

3 - 48

INSP

ADJ

IGNITION TIMING CHECK

IGNITION TIMING CHECK

1. Remove:

lTiming plug 1

2. Attach:

lTiming light

lInductive tachometer

To the spark plug lead.

3. Check:

lIgnition timing

Timing light:

YM-33277-A/90890-03141

Inductive tachometer:

YU-08036-B

Engine tachometer:

90890-03113

Checking steps:

lStart the engine and let it warm up. Let the

engine run at the specified speed.

Engine speed:

1,700 ~ 1,900 r/min

lVisually check the stationary pointer a is

within the firing range b on the rotor.

Incorrect firing range ® Check rotor and

pickup assembly.

4. Install:

lTiming plug

Page 678 of 762

6 - 1

–+ELEC

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC600000

ELECTRICAL

EC610000

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC611000

ELECTRICAL COMPONENTS

1

Headlight

2

“ENGINE STOP” button

3

Regulator

4

TPS (throttle position sensor)

5

Tail light

6

CDI magneto

7

Neutral switch

8

Ignition coil

9

Spark plug

0

Lights switch

A

CDI unit

COLOR CODE

B ................... Black

Br .................. Brown

G ................... Green

Gy ................. Gray

L .................... Blue

O ................... Orange

P ................... Pink

R ................... Red

EC612000

WIRING DIAGRAM

* Except for USA

B/L

R/WL/W

LY

L

Y

B

1B L

L YBLB Y

YYLB

5LB

YBLB

LB

3

7

4 8

9

W

R Br

G P

BP

B Br

G W

R

O

L B

Y B/LL/WSb

B/L B

Y O

L

A

2

Y

Br

B/WBB/W

Gy

B

PGR

WB

L YL Y

B B/L

SbW

Sb

WL/W

R/WL/WL/WR/WSb

W

O

B

0

6

B/WGyB/WGy

O

L B

Y Sb

B/L*

B/W*

Sb*

Y

BL

B

B/W

Sb .................. Sky blue

W ................... White

Y .................... Yellow

B/L ................. Black/Blue

B/W ............... Black/White

L/W ................ Blue/White

R/W ............... Red/White

6

Page 680 of 762

6 - 2

–+ELEC

MAP-CONTROLLED CDI UNIT

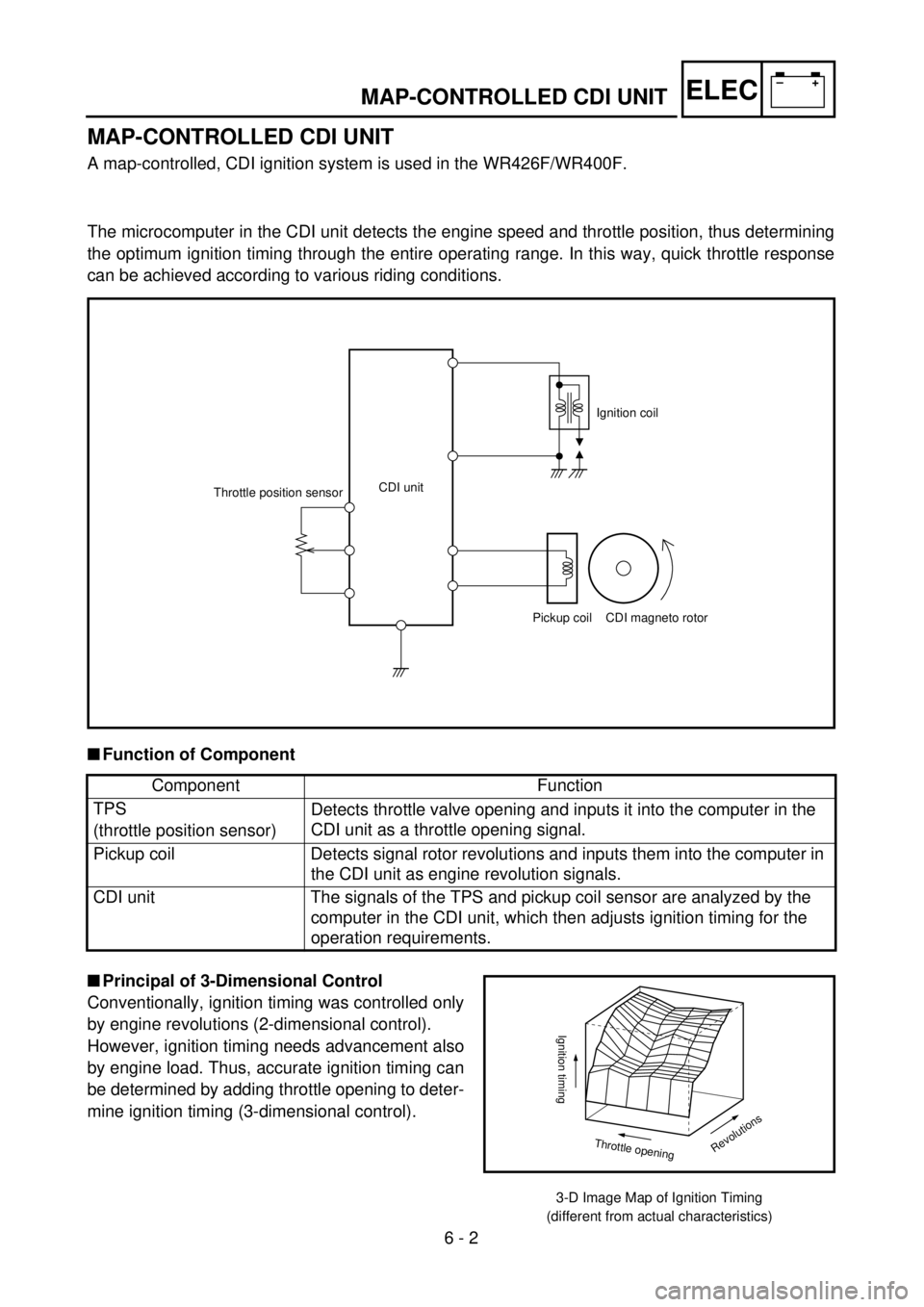

MAP-CONTROLLED CDI UNIT

A map-controlled, CDI ignition system is used in the WR426F/WR400F.

The microcomputer in the CDI unit detects the engine speed and throttle position, thus determining

the optimum ignition timing through the entire operating range. In this way, quick throttle response

can be achieved according to various riding conditions.

CDI unit

Throttle position sensor

Pickup coil CDI magneto rotorIgnition coil

n

Function of Component

Component Function

TPS

(throttle position sensor)Detects throttle valve opening and inputs it into the computer in the

CDI unit as a throttle opening signal.

Pickup coil Detects signal rotor revolutions and inputs them into the computer in

the CDI unit as engine revolution signals.

CDI unit The signals of the TPS and pickup coil sensor are analyzed by the

computer in the CDI unit, which then adjusts ignition timing for the

operation requirements.

n

Principal of 3-Dimensional Control

Conventionally, ignition timing was controlled only

by engine revolutions (2-dimensional control).

However, ignition timing needs advancement also

by engine load. Thus, accurate ignition timing can

be determined by adding throttle opening to deter-

mine ignition timing (3-dimensional control).

3-D Image Map of Ignition Timing

(different from actual characteristics)

Revolutions

Ignition timing

Throttle opening

Page 684 of 762

6 - 3

–+ELEC

IGNITION SYSTEM

EC620000

IGNITION SYSTEM

INSPECTION STEPS

Use the following steps for checking the possibility of the malfunctioning engine being attributable to

ignition system failure and for checking the spark plug which will not spark.

*: Only when the ignition checker is used.

NOTE:

l

Remove the following parts before inspection.

1) Seat

2) Fuel tank

l

Use the following special tools in this inspection.

Spark gap test*Clean or replace

spark plug.

Check entire ignition

system for connection.Repair or replace.

Check “ENGINE STOP”

button.Replace.

Check ignition coil. Primary coil Replace.

Secondary coilReplace.

Check CDI magneto. Pick-up coil Replace.

Source coil Replace.

Check neutral switch. Repair or replace.

Replace CDI unit.

Dynamic spark tester:

YM-34487

Ignition checker:

90890-06754

Pocket tester:

YU-3112-C/90890-03112

No Spark

OK

OK

OK

OK

Spark

No good

No good

No good

No good

No good

No good

No good

OK

Page 688 of 762

6 - 4

–+ELEC

IGNITION SYSTEM

EC622001

SPARK GAP TEST

1. Disconnect the spark plug cap from spark

plug.

2. Connect the dynamic spark tester

1

(ignition checker

2

) as shown.

l

Spark plug cap

3

l

Spark plug

4

For USA and CDN

õ

Except for USA and CDN

3. Kick the kick starter.

4. Check the ignition spark gap.

5. Start engine, and increase spark gap

until misfire occurs. (for USA and CDN

only)

Minimum spark gap:

6.0 mm (0.24 in)

õ

EC624000

COUPLERS AND LEADS CONNECTION

INSPECTION

1. Check:

l

Couplers and leads connection

Rust/dust/looseness/short-circuit

®

Repair or replace.

EC625001

“ENGINE STOP” BUTTON INSPECTION

1. Inspect:

l

“ENGINE STOP” button conduct

No continuity while being pushed

®

Replace.

Continuity while being freed

®

Replace.

Tester (+) lead

®

Black/White lead

1

Tester (–) lead

®

Black lead

2

B/W

1

B

2

Tester selec-

tor position

PUSH IN

W

´

1

FREE

Page 690 of 762

6 - 5

–+ELEC

IGNITION SYSTEM

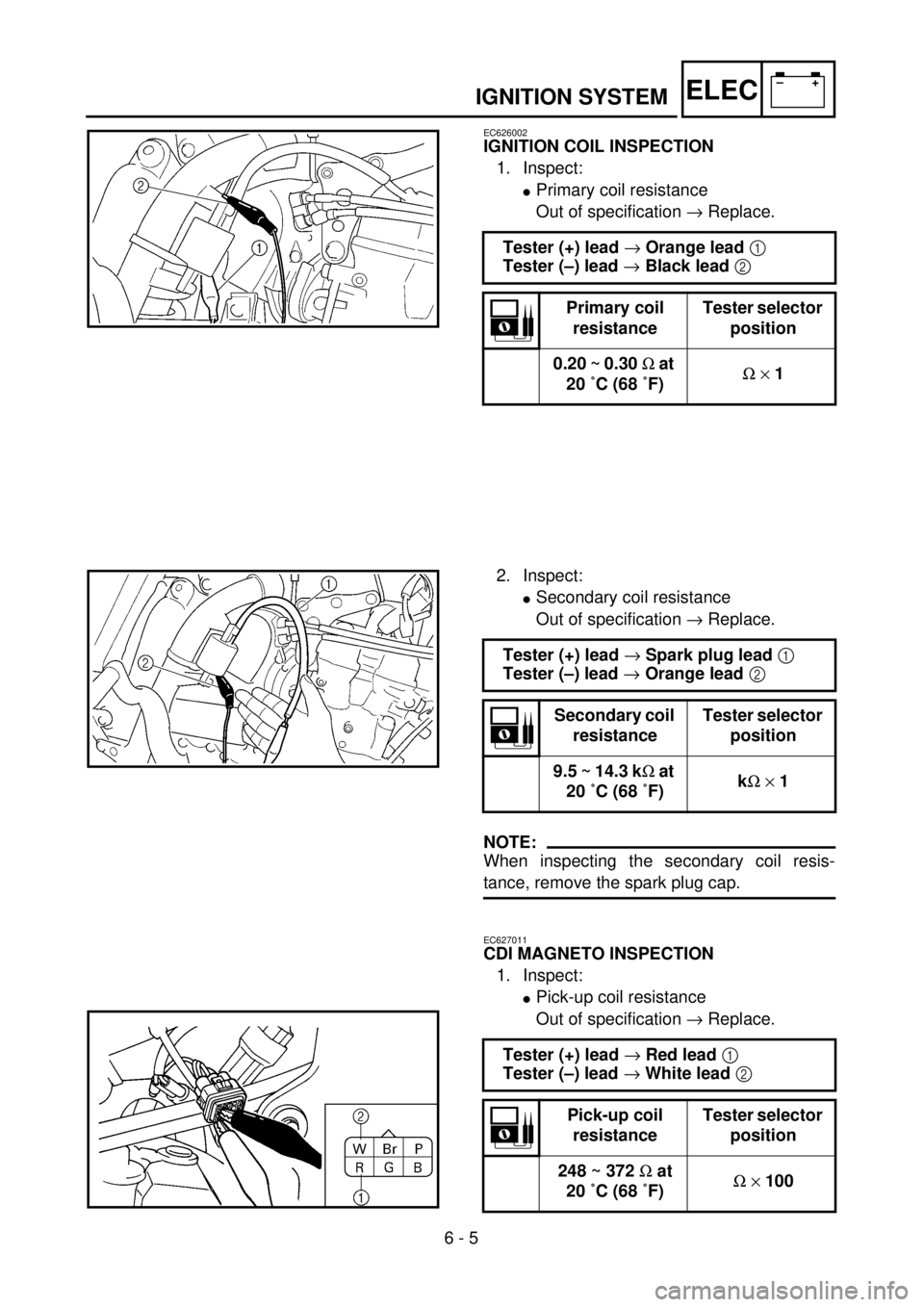

EC626002

IGNITION COIL INSPECTION

1. Inspect:

l

Primary coil resistance

Out of specification

®

Replace.

Tester (+) lead

®

Orange lead

1

Tester (–) lead ® Black lead 2

Primary coil

resistanceTester selector

position

0.20 ~ 0.30 W at

20 ˚C (68 ˚F)W ´ 1

2. Inspect:

lSecondary coil resistance

Out of specification ® Replace.

NOTE:

When inspecting the secondary coil resis-

tance, remove the spark plug cap.

EC627011

CDI MAGNETO INSPECTION

1. Inspect:

lPick-up coil resistance

Out of specification ® Replace. Tester (+) lead ® Spark plug lead 1

Tester (–) lead ® Orange lead 2

Secondary coil

resistanceTester selector

position

9.5 ~ 14.3 kW at

20 ˚C (68 ˚F)kW ´ 1

Tester (+) lead ® Red lead 1

Tester (–) lead ® White lead 2

Pick-up coil

resistanceTester selector

position

248 ~ 372 W at

20 ˚C (68 ˚F)W ´ 100

Page 692 of 762

6 - 6

–+ELECIGNITION SYSTEM

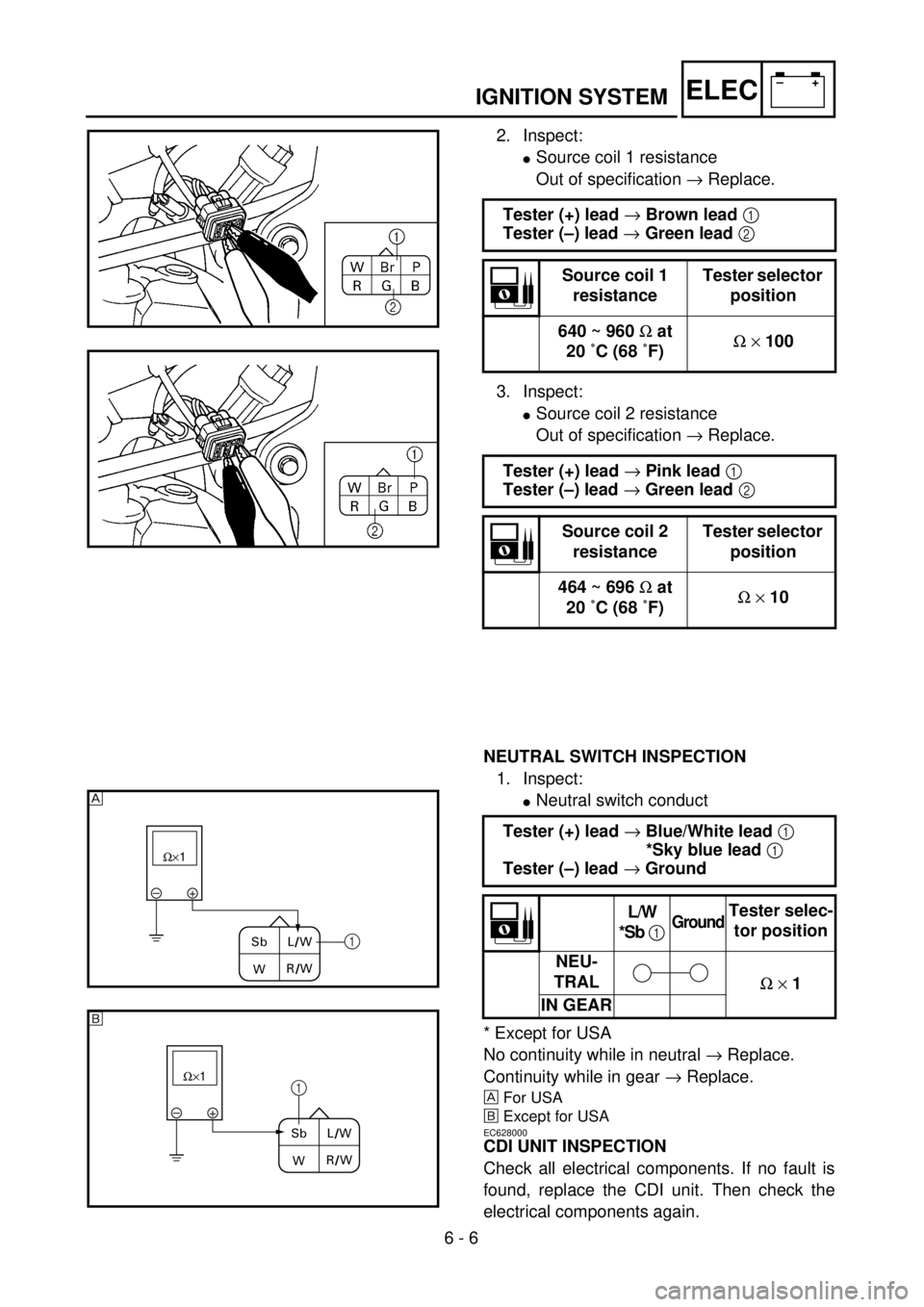

2. Inspect:

lSource coil 1 resistance

Out of specification ® Replace.

3. Inspect:

lSource coil 2 resistance

Out of specification ® Replace. Tester (+) lead ® Brown lead 1

Tester (–) lead ® Green lead 2

Source coil 1

resistanceTester selector

position

640 ~ 960 W at

20 ˚C (68 ˚F)W ´ 100

Tester (+) lead ® Pink lead 1

Tester (–) lead ® Green lead 2

Source coil 2

resistanceTester selector

position

464 ~ 696 W at

20 ˚C (68 ˚F)W ´ 10

NEUTRAL SWITCH INSPECTION

1. Inspect:

lNeutral switch conduct

* Except for USA

No continuity while in neutral ® Replace.

Continuity while in gear ® Replace.

For USA

õExcept for USA

EC628000

CDI UNIT INSPECTION

Check all electrical components. If no fault is

found, replace the CDI unit. Then check the

electrical components again.Tester (+) lead ® Blue/White lead 1

*Sky blue lead 1

Tester (–) lead ® Ground

L/W

*Sb 1GroundTester selec-

tor position

NEU-

TRAL

W ´ 1

IN GEAR

–+ W´1

R/W

W Sb L/W

1

–+ W´1

R/W

W Sb L/W

1

õ

Page 694 of 762

6 - 7

–+ELECTPS (THROTTLE POSITION SENSOR) SYSTEM

EC69000

TPS (THROTTLE POSITION SENSOR) SYSTEM

INSPECTION STEPS

If the TPS will not operate, use the following inspection steps.

*marked: Refer to “IGNITION SYSTEM” section.

NOTE:

lRemove the following parts before inspection.

1) Seat

2) Fuel tank

lUse the following special tools in this inspection.

Check entire ignition

system for connection.Repair or replace.

Check TPS. TPS coil Replace.

*Check CDI magneto. Source coil Replace.

Check CDI unit.TPS input

voltageReplace.

Pocket tester:

YU-3112-C/90890-03112Inductive tachometer:

YU-08036-B

Engine tachometer:

90890-03113

No good

No good

No good

No good

OK

OK

OK

Page 704 of 762

6 - 11

–+ELECLIGHTING SYSTEM

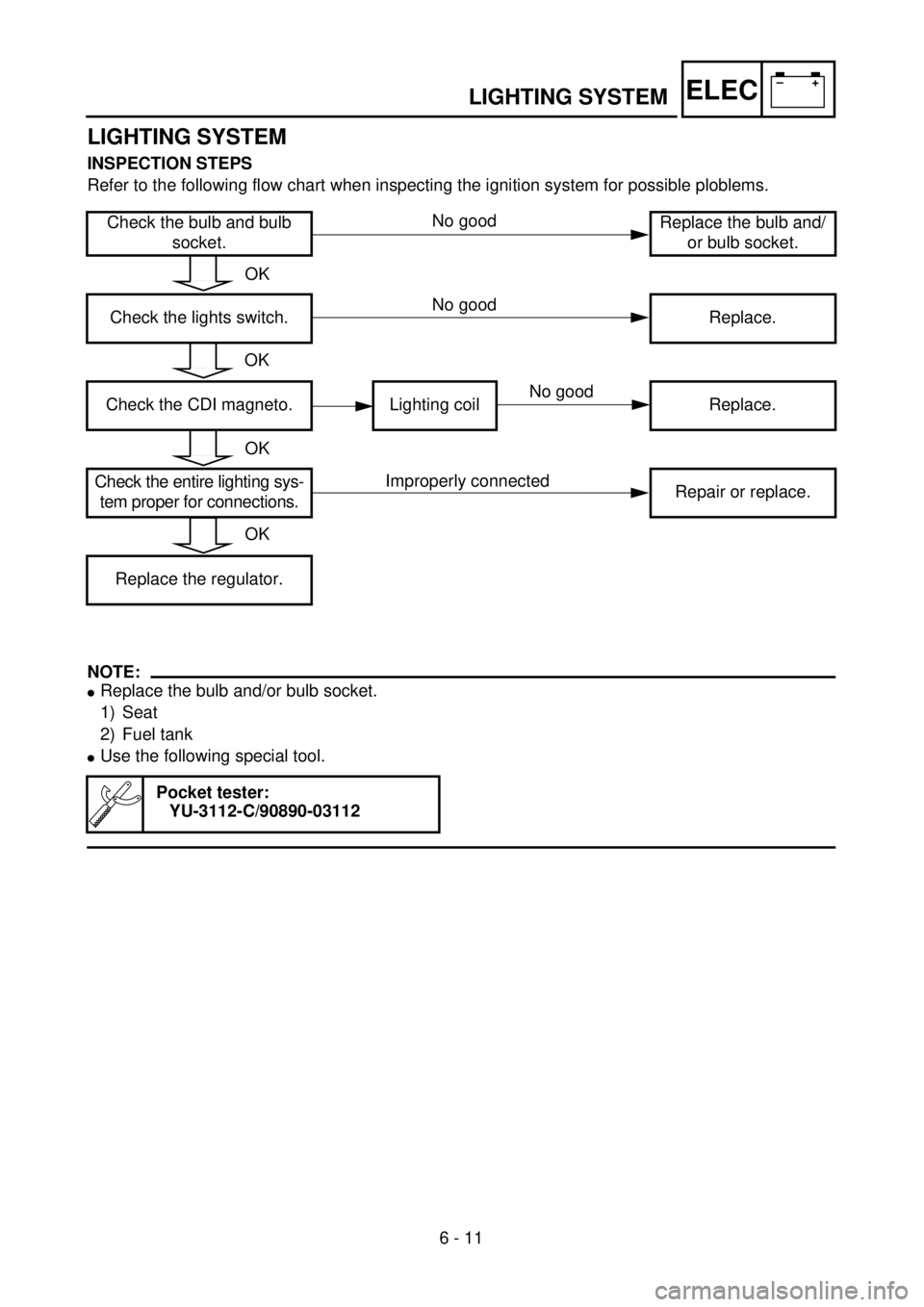

LIGHTING SYSTEM

INSPECTION STEPS

Refer to the following flow chart when inspecting the ignition system for possible ploblems.

NOTE:

lReplace the bulb and/or bulb socket.

1) Seat

2) Fuel tank

lUse the following special tool.

Check the bulb and bulb

socket.Replace the bulb and/

or bulb socket.

Check the lights switch. Replace.

Check the CDI magneto. Lighting coil Replace.

Check the entire lighting sys-

tem proper for connections.Repair or replace.

Replace the regulator.

Pocket tester:

YU-3112-C/90890-03112

OK

OK

OK

OK

No good

No good

Improperly connected

No good