radiator cap YAMAHA WR 400F 2001 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: WR 400F, Model: YAMAHA WR 400F 2001Pages: 762, PDF Size: 62.36 MB

Page 246 of 762

3 - 7

INSP

ADJ

COOLANT REPLACEMENT

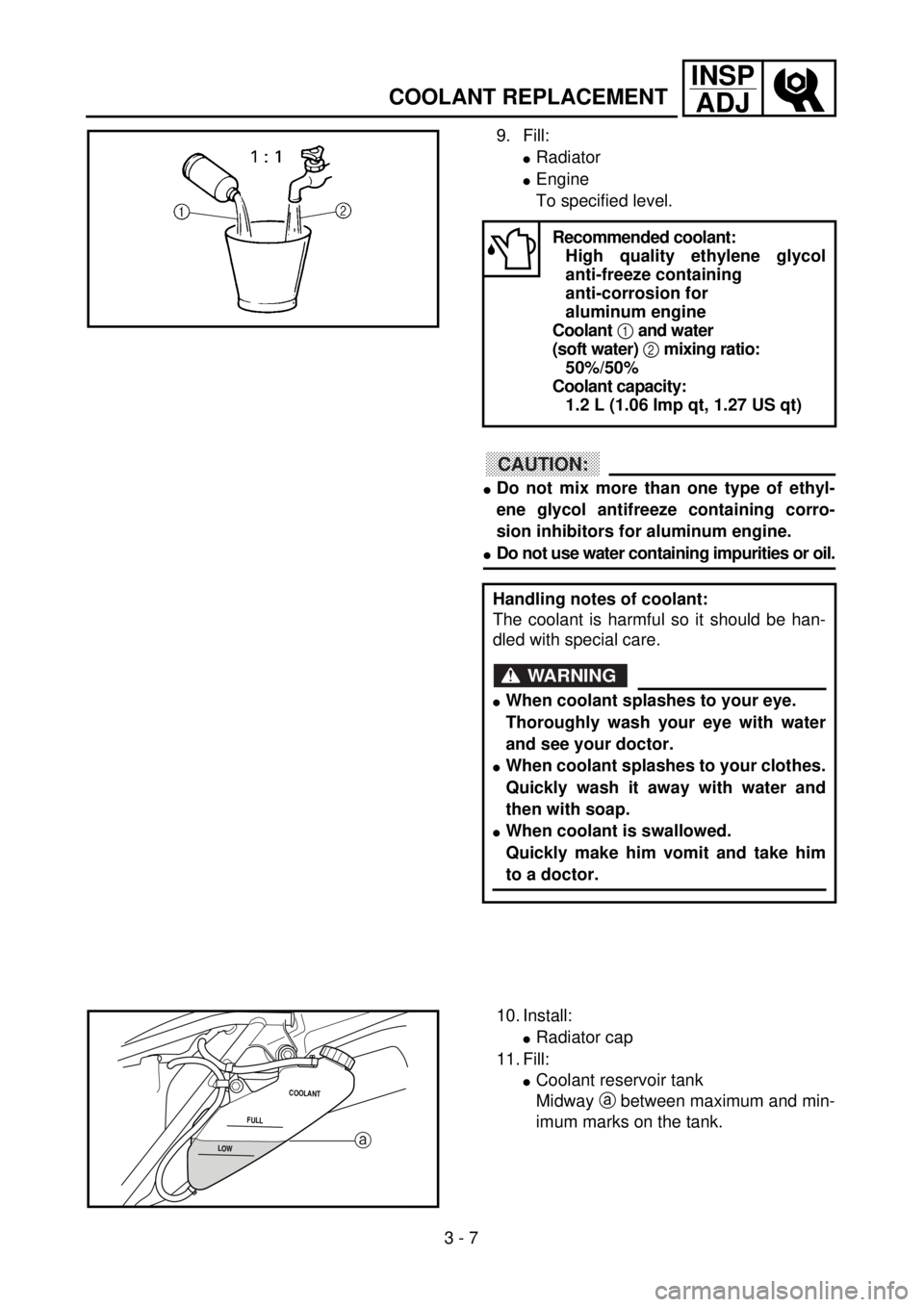

9. Fill:

lRadiator

lEngine

To specified level.

CAUTION:

lDo not mix more than one type of ethyl-

ene glycol antifreeze containing corro-

sion inhibitors for aluminum engine.

lDo not use water containing impurities or oil.

Recommended coolant:

High quality ethylene glycol

anti-freeze containing

anti-corrosion for

aluminum engine

Coolant 1 and water

(soft water) 2 mixing ratio:

50%/50%

Coolant capacity:

1.2 L (1.06 Imp qt, 1.27 US qt)

Handling notes of coolant:

The coolant is harmful so it should be han-

dled with special care.

WARNING

lWhen coolant splashes to your eye.

Thoroughly wash your eye with water

and see your doctor.

lWhen coolant splashes to your clothes.

Quickly wash it away with water and

then with soap.

lWhen coolant is swallowed.

Quickly make him vomit and take him

to a doctor.

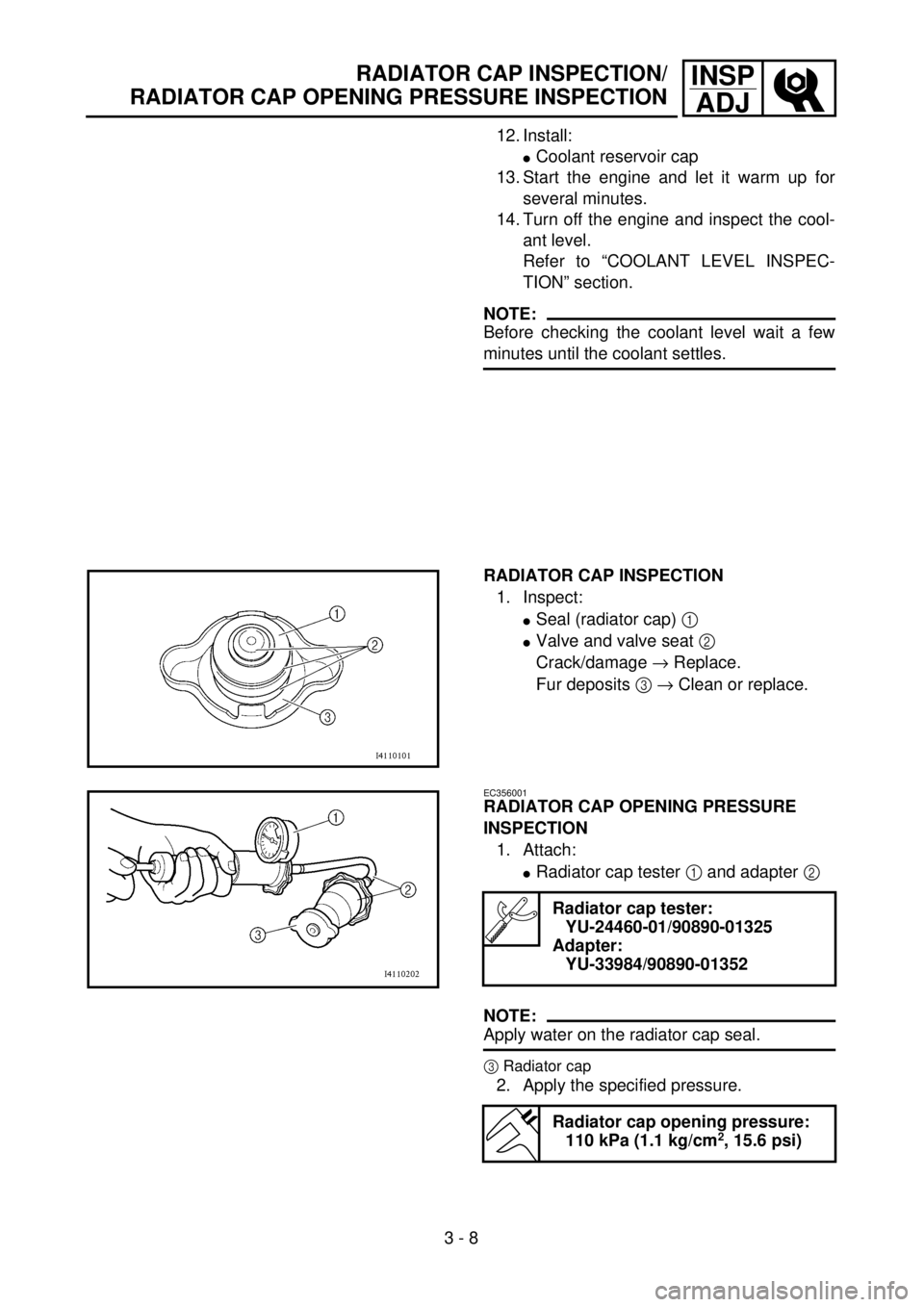

10. Install:

lRadiator cap

11. Fill:

lCoolant reservoir tank

Midway a between maximum and min-

imum marks on the tank.

LOWFULLCOOLANTa

Page 248 of 762

3 - 8

INSP

ADJRADIATOR CAP INSPECTION/

RADIATOR CAP OPENING PRESSURE INSPECTION

12. Install:

lCoolant reservoir cap

13. Start the engine and let it warm up for

several minutes.

14. Turn off the engine and inspect the cool-

ant level.

Refer to “COOLANT LEVEL INSPEC-

TION” section.

NOTE:

Before checking the coolant level wait a few

minutes until the coolant settles.

RADIATOR CAP INSPECTION

1. Inspect:

lSeal (radiator cap) 1

lValve and valve seat 2

Crack/damage ® Replace.

Fur deposits 3 ® Clean or replace.

EC356001

RADIATOR CAP OPENING PRESSURE

INSPECTION

1. Attach:

lRadiator cap tester 1 and adapter 2

NOTE:

Apply water on the radiator cap seal.

3Radiator cap

2. Apply the specified pressure.

Radiator cap tester:

YU-24460-01/90890-01325

Adapter:

YU-33984/90890-01352

Radiator cap opening pressure:

110 kPa (1.1 kg/cm2, 15.6 psi)

Page 250 of 762

3 - 9

INSP

ADJ

COOLING SYSTEM INSPECTION

3. Inspect:

lPressure

Impossible to maintain the specified

pressure for 10 seconds ® Replace.

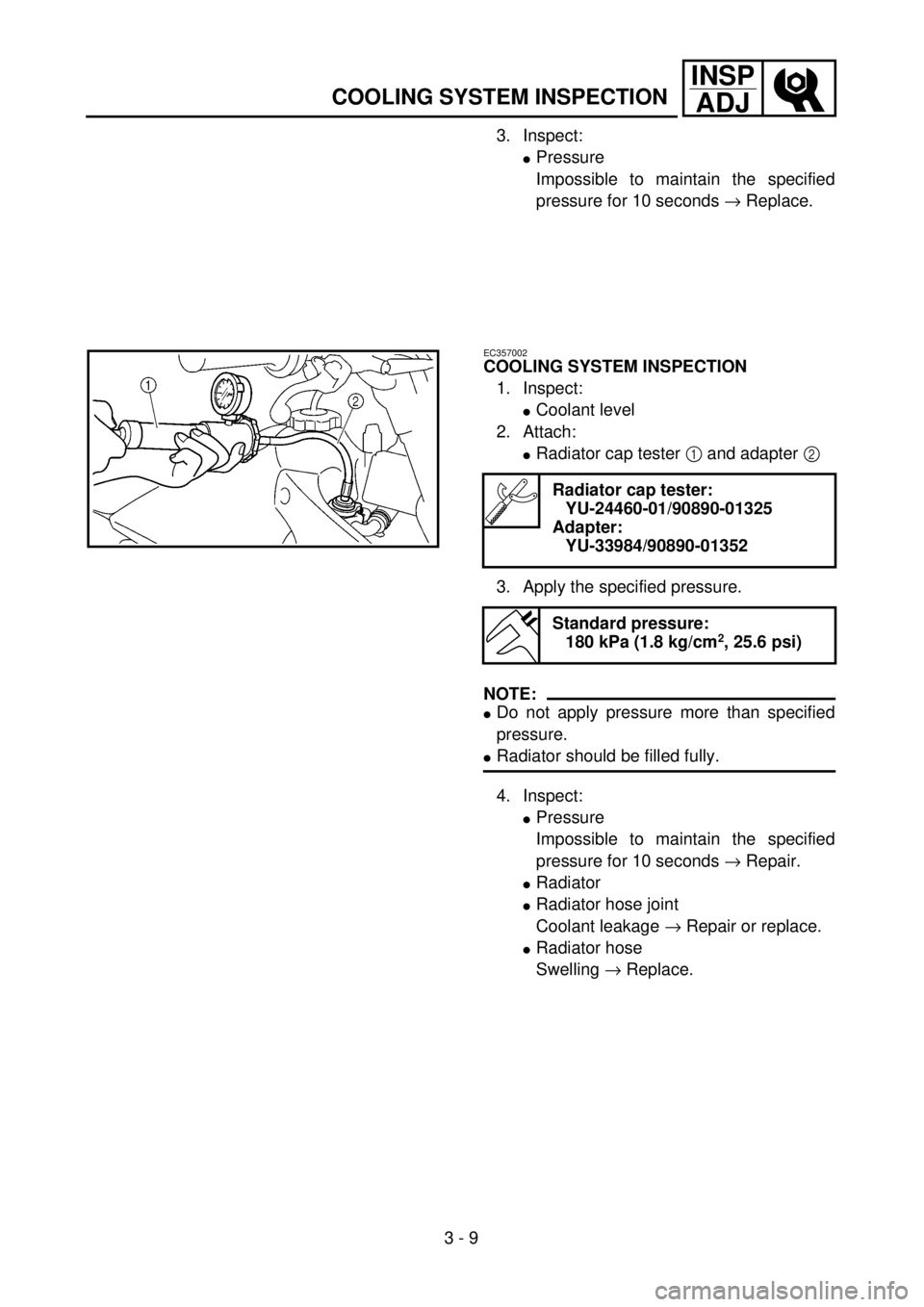

EC357002

COOLING SYSTEM INSPECTION

1. Inspect:

lCoolant level

2. Attach:

lRadiator cap tester 1 and adapter 2

3. Apply the specified pressure.

NOTE:

lDo not apply pressure more than specified

pressure.

lRadiator should be filled fully.

Radiator cap tester:

YU-24460-01/90890-01325

Adapter:

YU-33984/90890-01352

Standard pressure:

180 kPa (1.8 kg/cm2, 25.6 psi)

4. Inspect:

lPressure

Impossible to maintain the specified

pressure for 10 seconds ® Repair.

lRadiator

lRadiator hose joint

Coolant leakage ® Repair or replace.

lRadiator hose

Swelling ® Replace.

Page 346 of 762

4 - 6

ENG

RADIATOR

EC456000

HANDLING NOTE

WARNING

Do not remove the radiator cap when the

engine and radiator are hot. Scalding hot

fluid and steam may be blown out under

pressure, which could cause serious

injury.

When the engine has cooled, open the radi-

ator cap by the following procedure:

Place a thick rag, like a towel, over the radi-

ator cap, slowly rotate the cap counter-

clockwise to the detent. This procedure

allows any residual pressure to escape.

When the hissing sound has stopped,

press down on the cap while turning coun-

terclockwise and remove it.

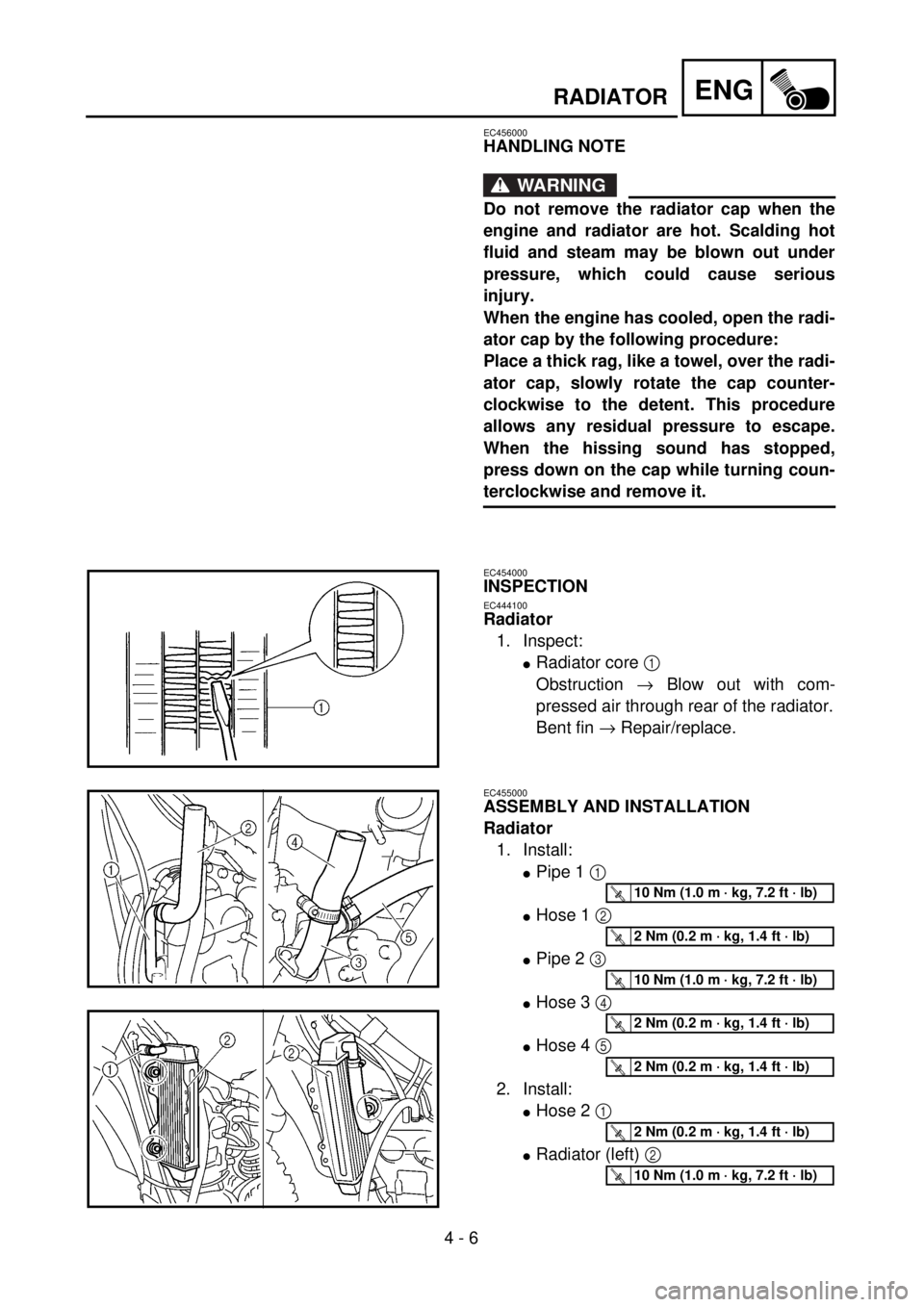

EC454000

INSPECTION

EC444100

Radiator

1. Inspect:

l

Radiator core

1

Obstruction

®

Blow out with com-

pressed air through rear of the radiator.

Bent fin

®

Repair/replace.

EC455000

ASSEMBLY AND INSTALLATION

Radiator

1. Install:

l

Pipe 1

1

lHose 1 2

lPipe 2 3

lHose 3 4

lHose 4 5

2. Install:

lHose 2 1

lRadiator (left) 2

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..2 Nm (0.2 m · kg, 1.4 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..2 Nm (0.2 m · kg, 1.4 ft · lb)

T R..2 Nm (0.2 m · kg, 1.4 ft · lb)

T R..2 Nm (0.2 m · kg, 1.4 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 508 of 762

ENG

4 - 87

ENGINE REMOVAL

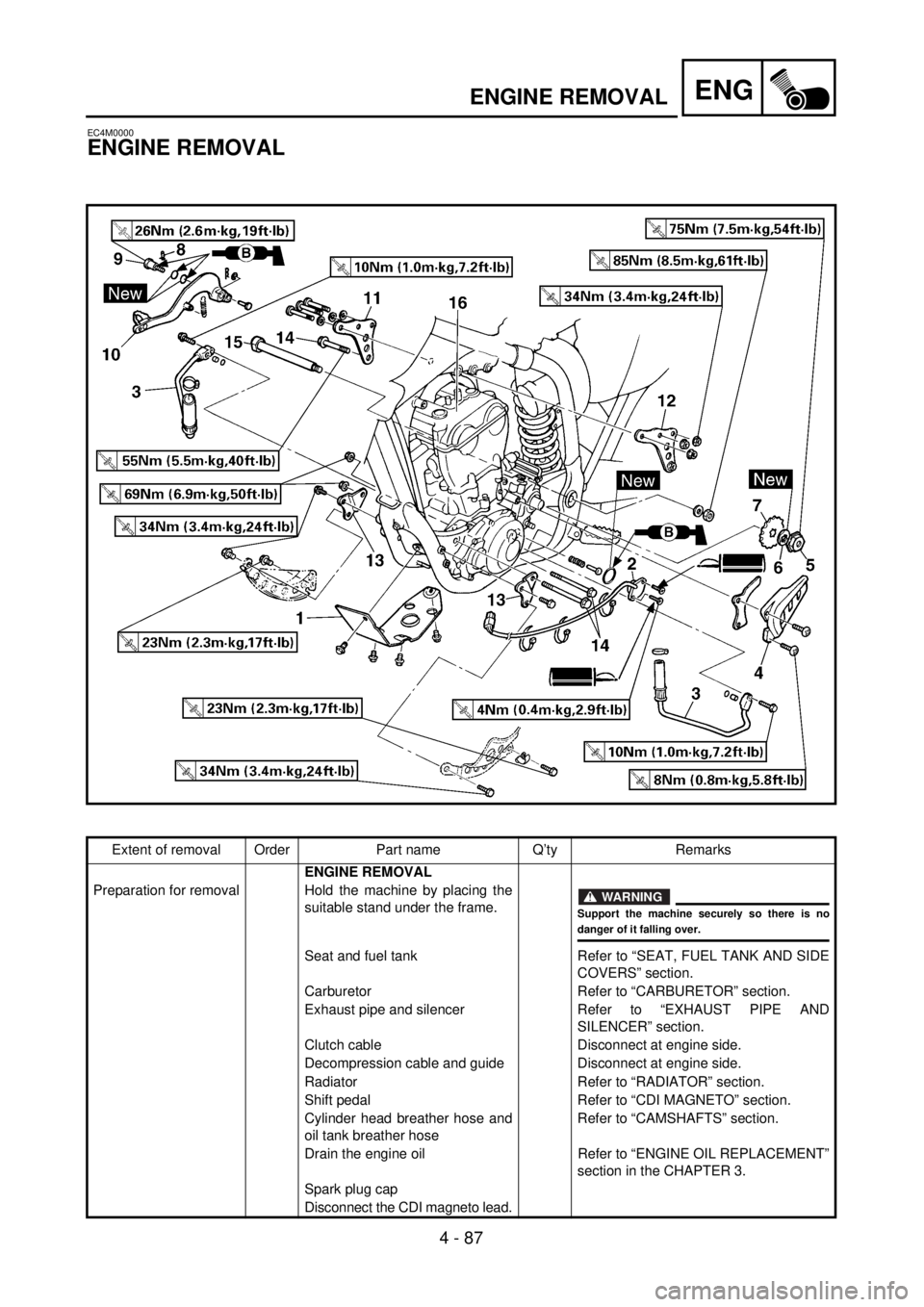

EC4M0000

ENGINE REMOVAL

Extent of removal Order Part name Q’ty Remarks

ENGINE REMOVAL

Preparation for removal Hold the machine by placing the

suitable stand under the frame.

WARNING

Support the machine securely so there is nodanger of it falling over.

Seat and fuel tank Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

Carburetor Refer to “CARBURETOR” section.

Exhaust pipe and silencer Refer to “EXHAUST PIPE AND

SILENCER” section.

Clutch cable Disconnect at engine side.

Decompression cable and guide Disconnect at engine side.

Radiator Refer to “RADIATOR” section.

Shift pedal Refer to “CDI MAGNETO” section.

Cylinder head breather hose and

oil tank breather hoseRefer to “CAMSHAFTS” section.

Drain the engine oil Refer to “ENGINE OIL REPLACEMENT”

section in the CHAPTER 3.

Spark plug cap

Disconnect the CDI magneto lead.