light YAMAHA WR 426F 2001 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: WR 426F, Model: YAMAHA WR 426F 2001Pages: 762, PDF Size: 62.36 MB

Page 322 of 762

3 - 44

INSP

ADJ

STEERING HEAD INSPECTION AND ADJUSTMENT

2. Inspect:

lBearing free play

Exist play ® Replace.

STEERING HEAD INSPECTION AND

ADJUSTMENT

1. Elevate the front wheel by placing a suit-

able stand under the engine.

2. Check:

lSteering shaft

Grasp the bottom of the forks and gen-

tly rock the fork assembly back and

forth.

Free play ® Adjust steering head.

3. Check:

lSteering smooth action

Turn the handlebar lock to lock.

Unsmooth action ® Adjust steering ring

nut.

4. Adjust:

lSteering ring nut

Steering ring nut adjustment steps:

lRemove the headlight.

lRemove the handlebar and handle crown.

lLoosen the ring nut 1 using the ring nut

wrench 2.

Ring nut wrench:

YU-33975/90890-01403

Page 324 of 762

3 - 45

INSP

ADJ

STEERING HEAD INSPECTION AND ADJUSTMENT

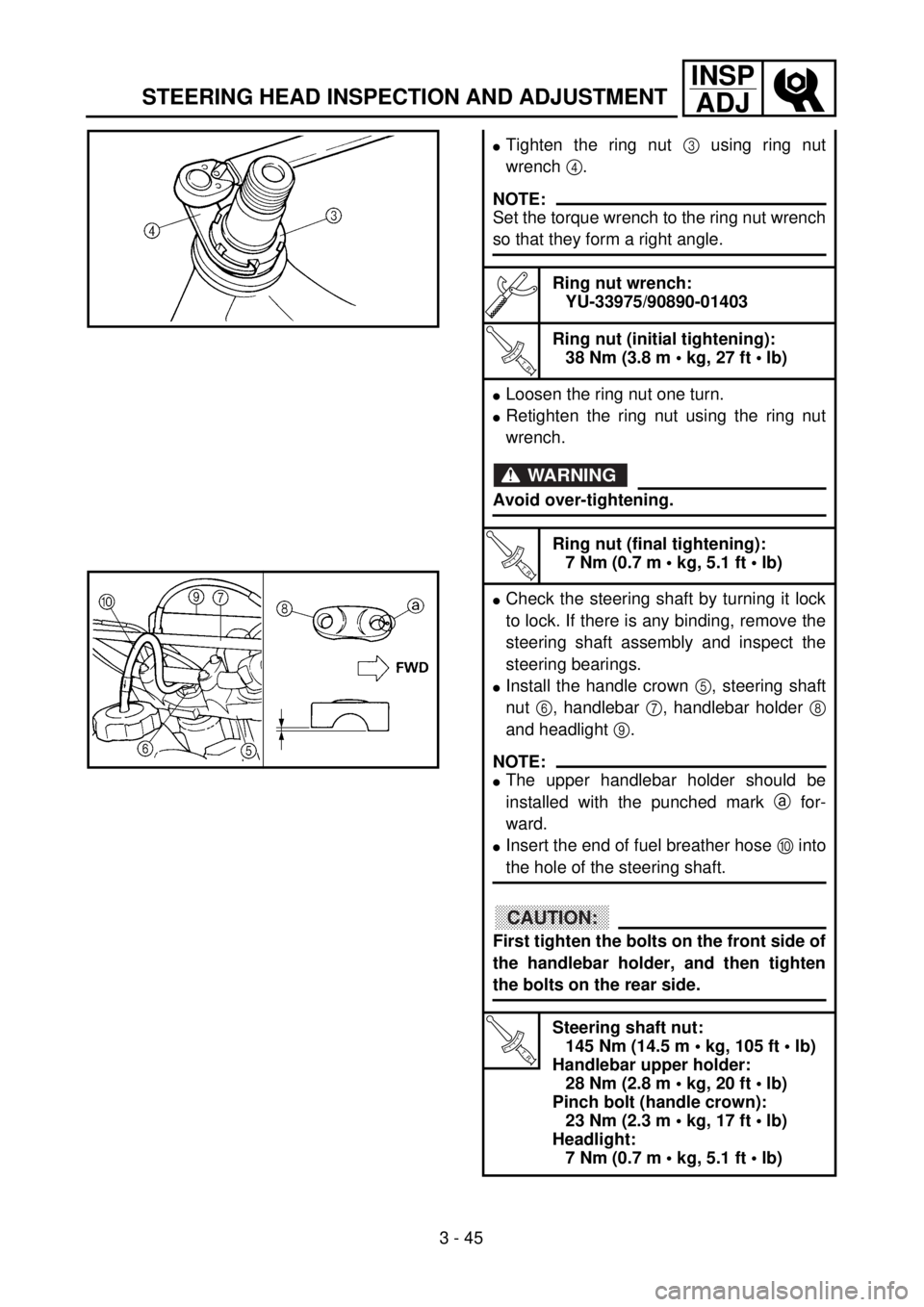

lTighten the ring nut 3 using ring nut

wrench 4.

NOTE:

Set the torque wrench to the ring nut wrench

so that they form a right angle.

Ring nut wrench:

YU-33975/90890-01403

T R..

Ring nut (initial tightening):

38 Nm (3.8 m • kg, 27 ft • lb)

lLoosen the ring nut one turn.

lRetighten the ring nut using the ring nut

wrench.

WARNING

Avoid over-tightening.

T R..

Ring nut (final tightening):

7 Nm (0.7 m • kg, 5.1 ft • lb)

lCheck the steering shaft by turning it lock

to lock. If there is any binding, remove the

steering shaft assembly and inspect the

steering bearings.

lInstall the handle crown 5, steering shaft

nut 6, handlebar 7, handlebar holder 8

and headlight 9.

NOTE:

lThe upper handlebar holder should be

installed with the punched mark a for-

ward.

lInsert the end of fuel breather hose 0 into

the hole of the steering shaft.

CAUTION:

First tighten the bolts on the front side of

the handlebar holder, and then tighten

the bolts on the rear side.

T R..

Steering shaft nut:

145 Nm (14.5 m • kg, 105 ft • lb)

Handlebar upper holder:

28 Nm (2.8 m • kg, 20 ft • lb)

Pinch bolt (handle crown):

23 Nm (2.3 m • kg, 17 ft • lb)

Headlight:

7 Nm (0.7 m • kg, 5.1 ft • lb)

Page 326 of 762

3 - 46

INSP

ADJ

LUBRICATION

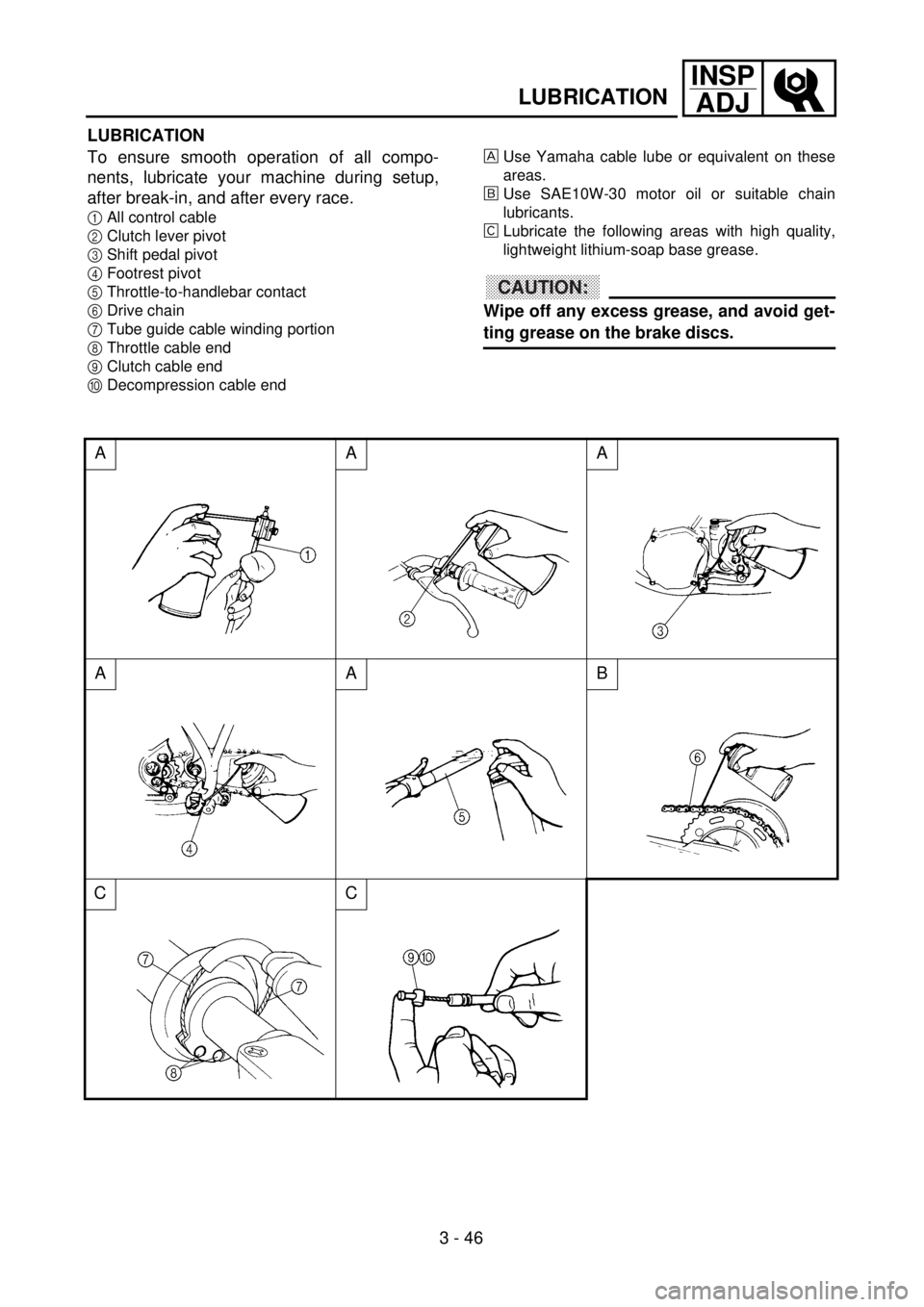

LUBRICATION

To ensure smooth operation of all compo-

nents, lubricate your machine during setup,

after break-in, and after every race.

1All control cable

2Clutch lever pivot

3Shift pedal pivot

4Footrest pivot

5Throttle-to-handlebar contact

6Drive chain

7Tube guide cable winding portion

8Throttle cable end

9Clutch cable end

0Decompression cable endUse Yamaha cable lube or equivalent on these

areas.

õUse SAE10W-30 motor oil or suitable chain

lubricants.

‚Lubricate the following areas with high quality,

lightweight lithium-soap base grease.

CAUTION:

Wipe off any excess grease, and avoid get-

ting grease on the brake discs.

AAA

AAB

CC

Page 328 of 762

3 - 47

INSP

ADJ

ELECTRICAL/SPARK PLUG INSPECTION

EC370000

ELECTRICAL

EC371001

SPARK PLUG INSPECTION

1. Remove:

lSpark plug

2. Inspect:

lElectrode 1

Wear/damage ® Replace.

lInsulator color 2

Normal condition is a medium to light

tan color.

Distinctly different color ® Check the

engine condition.

NOTE:

When the engine runs for many hours at low

speeds, the spark plug insulator will become

sooty, even if the engine and carburetor are in

good operating condition.

3. Measure:

lPlug gap a

Use a wire gauge or thickness gauge.

Out of specification ® Re-gap.

Spark plug gap:

0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

4. Clean the plug with a spark plug cleaner

if necessary.

5. Tighten:

lSpark plug

NOTE:

lBefore installing a spark plug, clean the gas-

ket surface and plug surface.

lFinger-tighten a the spark plug before

torquing to specification b.

T R..13 Nm (1.3 m · kg, 9.4 ft · lb)

Page 330 of 762

3 - 48

INSP

ADJ

IGNITION TIMING CHECK

IGNITION TIMING CHECK

1. Remove:

lTiming plug 1

2. Attach:

lTiming light

lInductive tachometer

To the spark plug lead.

3. Check:

lIgnition timing

Timing light:

YM-33277-A/90890-03141

Inductive tachometer:

YU-08036-B

Engine tachometer:

90890-03113

Checking steps:

lStart the engine and let it warm up. Let the

engine run at the specified speed.

Engine speed:

1,700 ~ 1,900 r/min

lVisually check the stationary pointer a is

within the firing range b on the rotor.

Incorrect firing range ® Check rotor and

pickup assembly.

4. Install:

lTiming plug

Page 332 of 762

3 - 49

INSP

ADJ

REPLACING THE HEADLIGHT BULBS

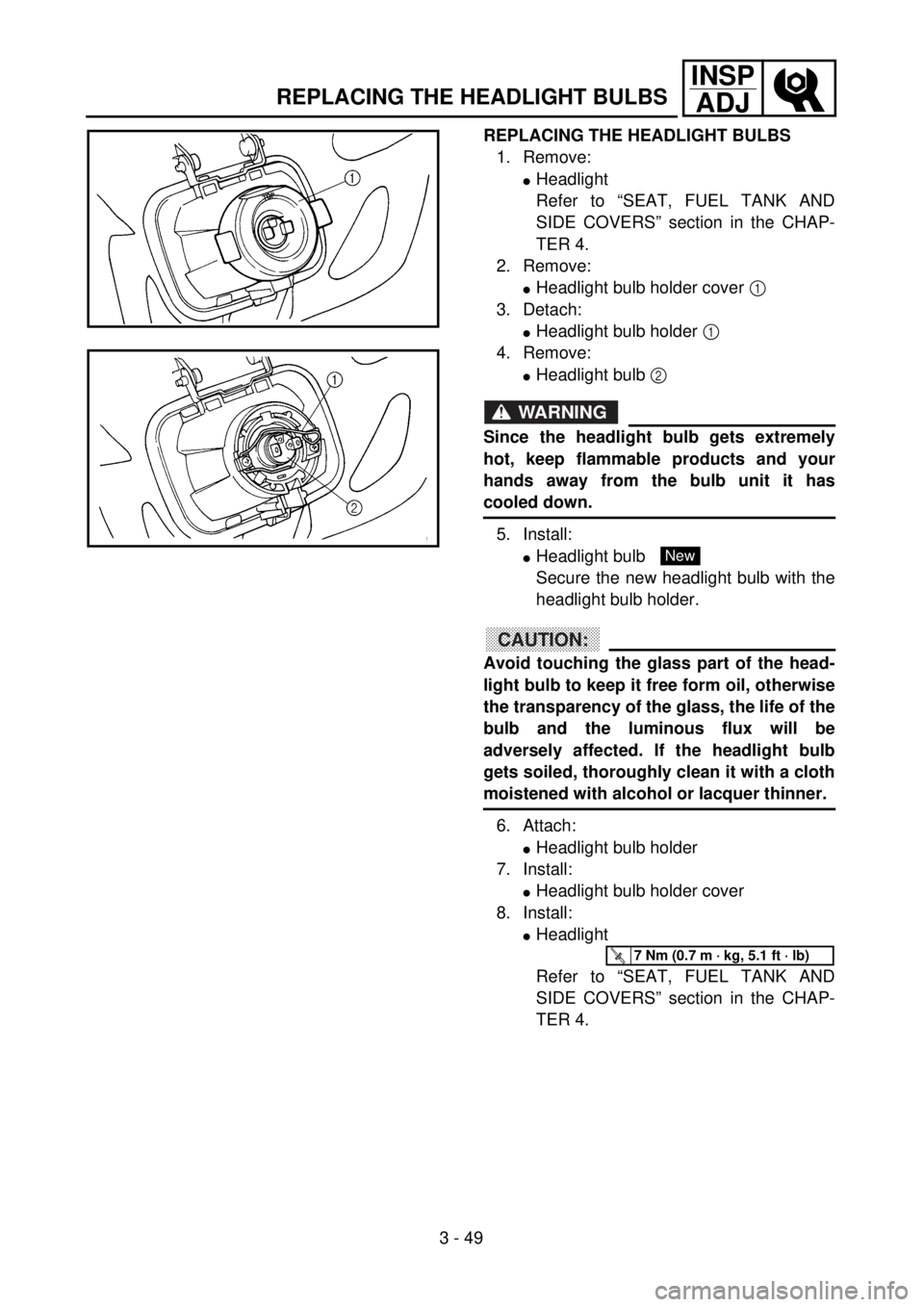

REPLACING THE HEADLIGHT BULBS

1. Remove:

lHeadlight

Refer to “SEAT, FUEL TANK AND

SIDE COVERS” section in the CHAP-

TER 4.

2. Remove:

lHeadlight bulb holder cover 1

3. Detach:

lHeadlight bulb holder 1

4. Remove:

lHeadlight bulb 2

WARNING

Since the headlight bulb gets extremely

hot, keep flammable products and your

hands away from the bulb unit it has

cooled down.

5. Install:

lHeadlight bulb

Secure the new headlight bulb with the

headlight bulb holder.

CAUTION:

Avoid touching the glass part of the head-

light bulb to keep it free form oil, otherwise

the transparency of the glass, the life of the

bulb and the luminous flux will be

adversely affected. If the headlight bulb

gets soiled, thoroughly clean it with a cloth

moistened with alcohol or lacquer thinner.

6. Attach:

lHeadlight bulb holder

7. Install:

lHeadlight bulb holder cover

8. Install:

lHeadlight

Refer to “SEAT, FUEL TANK AND

SIDE COVERS” section in the CHAP-

TER 4.

New

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

Page 334 of 762

3 - 50

INSP

ADJ

ADJUSTING THE HEADLIGHT BEAMS

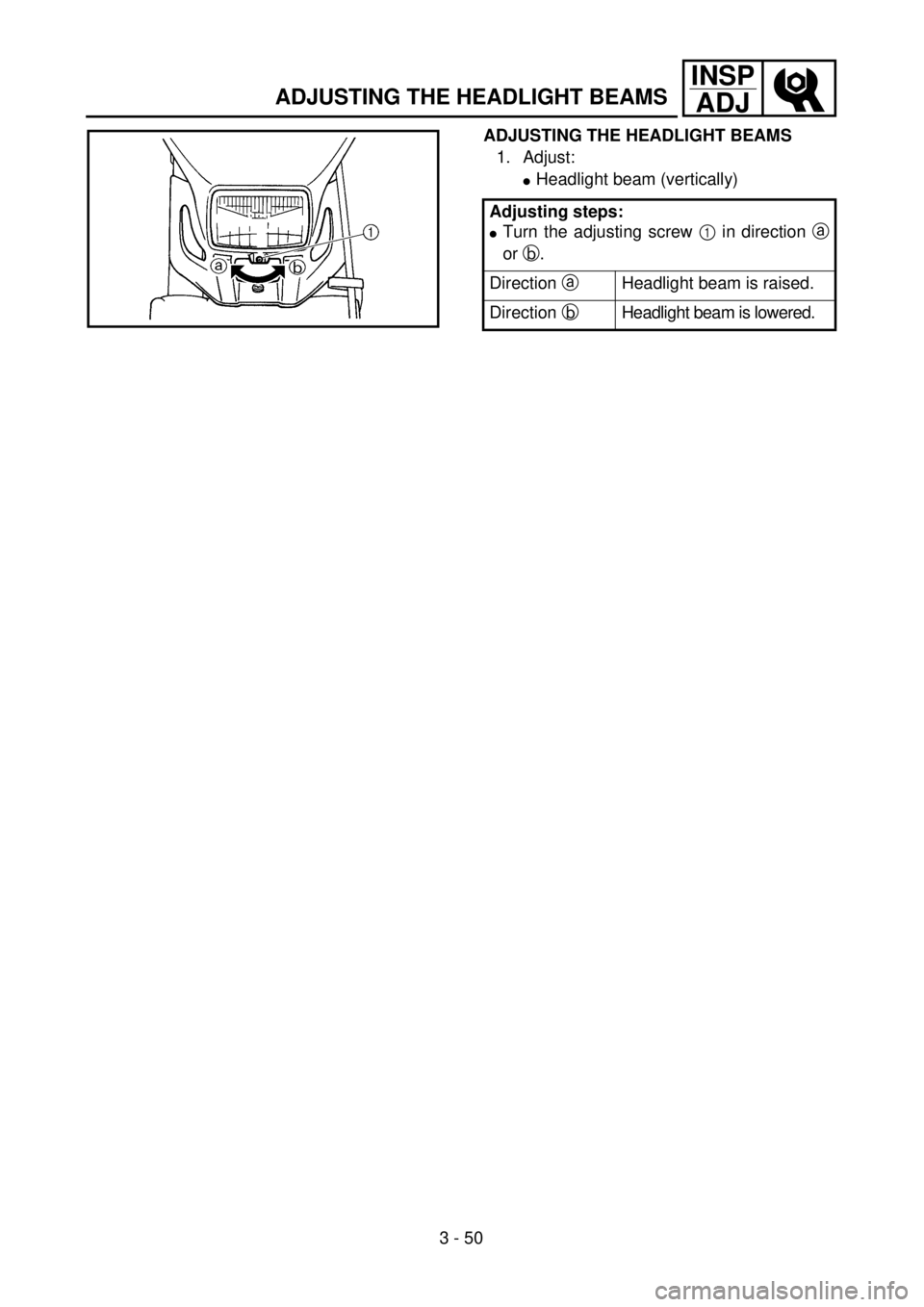

ADJUSTING THE HEADLIGHT BEAMS

1. Adjust:

lHeadlight beam (vertically)

Adjusting steps:

lTurn the adjusting screw 1 in direction a

or b.

Direction a Headlight beam is raised.

Direction b Headlight beam is lowered.

Page 336 of 762

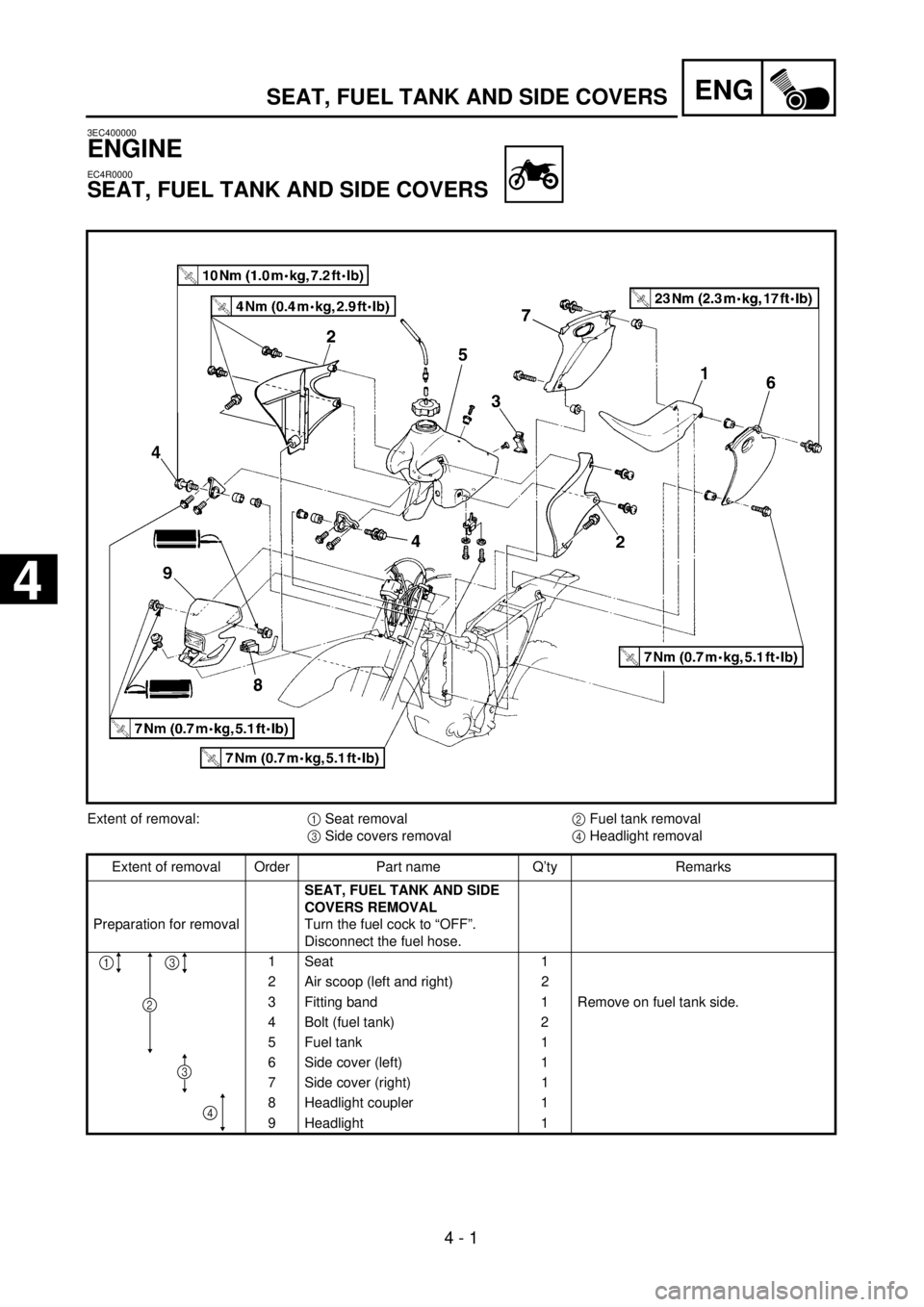

ENG

4 - 1

3EC400000

ENGINE

EC4R0000

SEAT, FUEL TANK AND SIDE COVERS

Extent of removal:

1

Seat removal

2

Fuel tank removal

3

Side covers removal

4

Headlight removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removal

SEAT, FUEL TANK AND SIDE

COVERS REMOVAL

Turn the fuel cock to “OFF”.

Disconnect the fuel hose.

1 Seat 1

2 Air scoop (left and right) 2

3 Fitting band 1 Remove on fuel tank side.

4 Bolt (fuel tank) 2

5 Fuel tank 1

6 Side cover (left) 1

7 Side cover (right) 1

8 Headlight coupler 1

9 Headlight 1

13

4

2

3

SEAT, FUEL TANK AND SIDE COVERS

4

Page 368 of 762

4 - 17

ENGCARBURETOR

10. Install:

lStarter jet 1

lPilot jet 2

lSpacer 3

lNeedle jet 4

lMain jet 5

11. Install:

lValve seat

lScrew (valve seat) 1

lNeedle valve 2

lFloat 3

lFloat pin 4

NOTE:

lAfter installing the needle valve to the float,

install them to the carburetor.

lCheck the float for smooth movement.

12. Install:

lPilot screw 1

lSpring 2

lWasher 3

lO-ring 4

* Except for USANote the following installation points:

lTurn in the pilot screw until it is lightly

seated.

lTurn out the pilot screw by the number of

turns recorded before removing.

Pilot screw:

WR426F: 1-5/8 turns out

*7/8 turns out

WR400F: 1-1/2 turns out

(example)

13. Install:

lO-ring

lFloat chamber 1

lScrew (float chamber) 2

lCable holder (throttle stop screw cable)

3

lHose holder (carburetor breather hose)

4

WR426F

õWR400F421 3

44õ

Page 386 of 762

4 - 26

ENGCAMSHAFTS

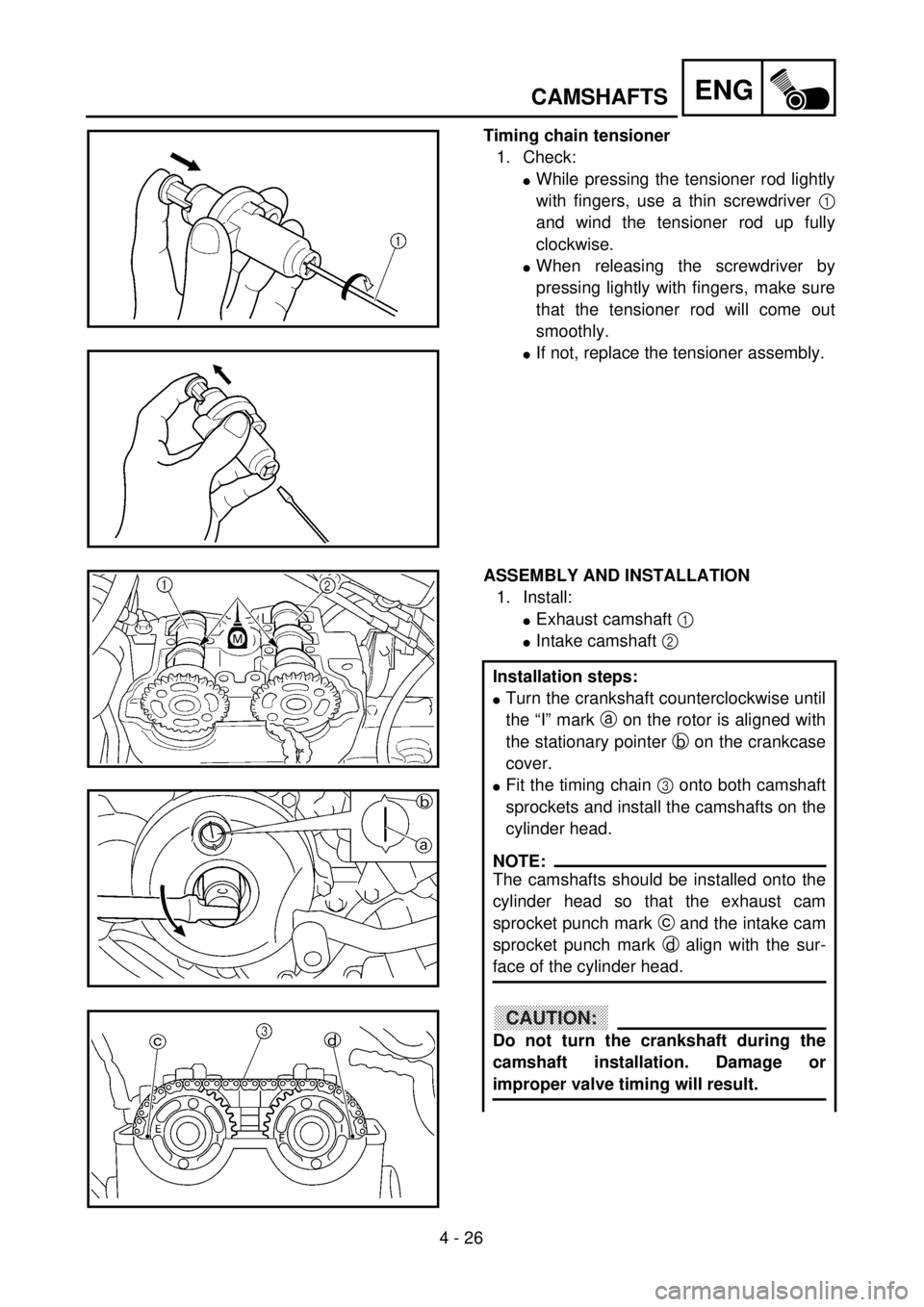

Timing chain tensioner

1. Check:

lWhile pressing the tensioner rod lightly

with fingers, use a thin screwdriver 1

and wind the tensioner rod up fully

clockwise.

lWhen releasing the screwdriver by

pressing lightly with fingers, make sure

that the tensioner rod will come out

smoothly.

lIf not, replace the tensioner assembly.

ASSEMBLY AND INSTALLATION

1. Install:

lExhaust camshaft 1

lIntake camshaft 2

Installation steps:

lTurn the crankshaft counterclockwise until

the “I” mark a on the rotor is aligned with

the stationary pointer b on the crankcase

cover.

lFit the timing chain 3 onto both camshaft

sprockets and install the camshafts on the

cylinder head.

NOTE:

The camshafts should be installed onto the

cylinder head so that the exhaust cam

sprocket punch mark c and the intake cam

sprocket punch mark d align with the sur-

face of the cylinder head.

CAUTION:

Do not turn the crankshaft during the

camshaft installation. Damage or

improper valve timing will result.