radiator YAMAHA WR 450F 2005 Manuale de Empleo (in Spanish)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: WR 450F, Model: YAMAHA WR 450F 2005Pages: 758, tamaño PDF: 17.3 MB

Page 22 of 758

CHAPTER 4

ENGINE

SEAT, FUEL TANK

AND SIDE COVERS ..................................4-1

EXHAUST PIPE AND SILENCER .............4-3

RADIATOR ................................................4-5

CARBURETOR ..........................................4-8

AIR INDUCTION SYSTEM ......................4-21

CAMSHAFTS ...........................................4-23

CYLINDER HEAD ....................................4-32

VALVES AND VALVE SPRINGS ............4-36

CYLINDER AND PISTON ........................4-45

CLUTCH ...................................................4-51

OIL FILTER, WATER PUMP

AND CRANKCASE COVER (RIGHT) .....4-58

BALANCER .............................................4-65

OIL PUMP ................................................4-68

KICK AXLE AND SHIFT SHAFT .............4-72

AC MAGNETO

AND STARTER CLUTCH ........................4-79

ENGINE REMOVAL .................................4-86

CRANKCASE AND CRANKSHAFT ........4-92

TRANSMISSION, SHIFT CAM

AND SHIFT FORK .................................4-101

CHAPTER 5

CHASSIS

FRONT WHEEL AND REAR WHEEL .......5-1

FRONT BRAKE AND REAR BRAKE .....5-10

FRONT FORK ..........................................5-26

HANDLEBAR ...........................................5-39

STEERING ...............................................5-46

SWINGARM .............................................5-52

REAR SHOCK ABSORBER ....................5-60

Page 26 of 758

GEN

INFO

1 - 1

DESCRIPTION

EC100000

GENERAL INFORMATION

EC110000

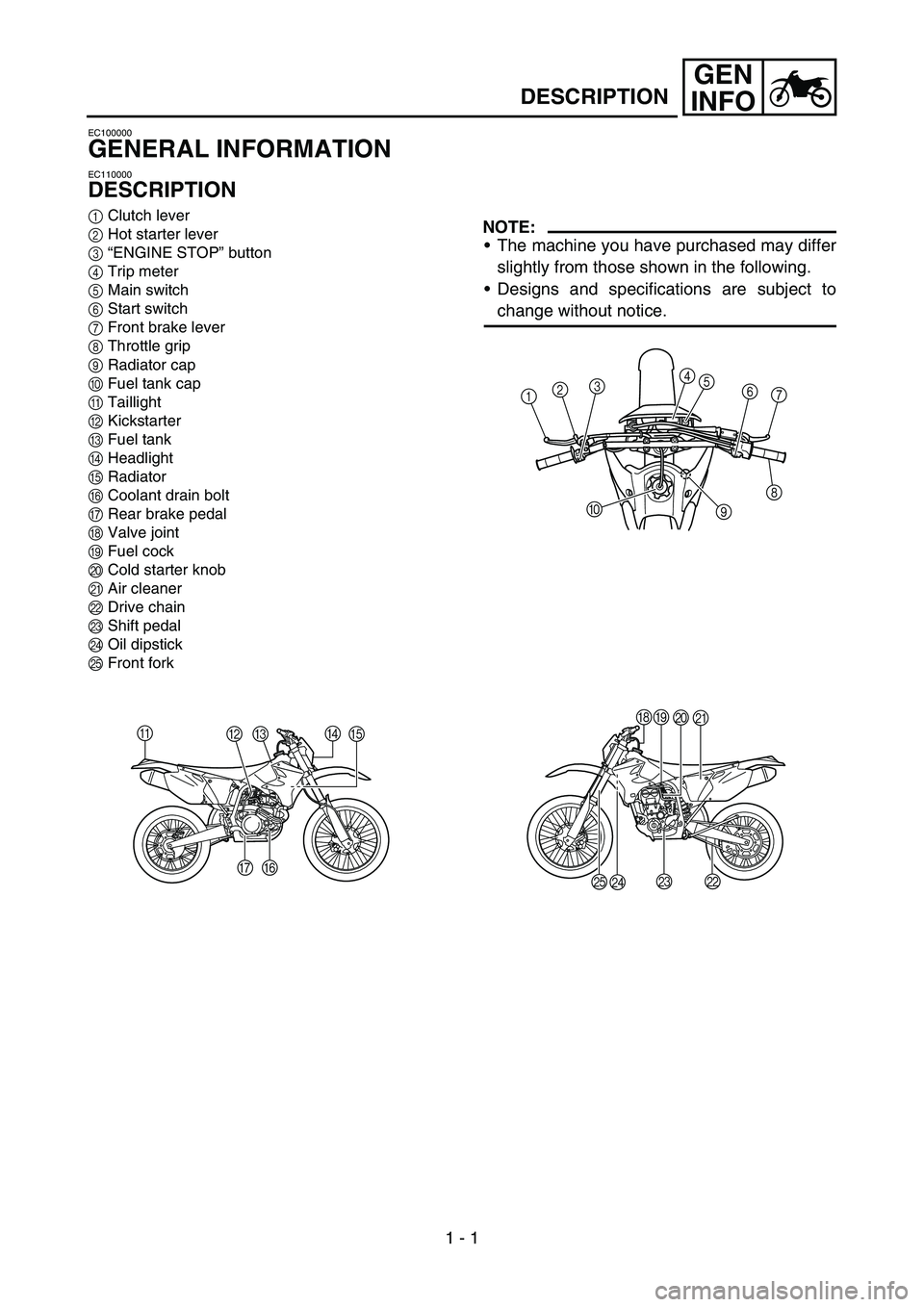

DESCRIPTION

1Clutch lever

2Hot starter lever

3“ENGINE STOP” button

4Trip meter

5Main switch

6Start switch

7Front brake lever

8Throttle grip

9Radiator cap

0Fuel tank cap

ATaillight

BKickstarter

CFuel tank

DHeadlight

ERadiator

FCoolant drain bolt

GRear brake pedal

HValve joint

IFuel cock

JCold starter knob

KAir cleaner

LDrive chain

MShift pedal

NOil dipstick

OFront forkNOTE:

The machine you have purchased may differ

slightly from those shown in the following.

Designs and specifications are subject to

change without notice.

A

BCD

E

F G

1234

5

6

7

8

9 0

HI

J

K

L M

N O

Page 38 of 758

GEN

INFO

1 - 7

EC140001

SPECIAL TOOLS

The proper special tools are necessary for complete and accurate tune-up and assembly. Using the

correct special tool will help prevent damage caused by the use of improper tools or improvised

techniques. The shape and part number used for the special tool differ by country, so two types are

provided. Refer to the list provided to avoid errors when placing an order.

NOTE:

For U.S.A. and Canada, use part number starting with “YM-”, “YU-” or “ACC-”.

For others, use part number starting with “90890-”.

Part number Tool name/How to use Illustration

YU-1135-A, 90890-01135 Crankcase separating tool

These tool is used to remove the crankshaft from

either case.YU-1135-A 90890-01135

YU-3097, 90890-01252

YU-1256Dial gauge and stand

Stand

These tools are used to check each part for runout or

bend.YU-3097

YU-125690890-01252

YU-90050, 90890-01274

YU-90050, 90890-01275

YM-91044, 90890-04081

YU-90063, 90890-01278Crankshaft installing tool

Crankshaft installing pot

Crankshaft installing bolt

Spacer (crankshaft installer)

Adapter (M12)

These tools are used to install the crankshaft.YU-90050

YU-90063

YM-9104490890-01274

90890-01275

90890-01278

90890-04081

YU-1304, 90890-01304 Piston pin puller

This tool is used to remove the piston pin.YU-1304 90890-01304

YU-24460-01, 90890-01325

YU-33984, 90890-01352Radiator cap tester

Adapter

These tools are used for checking the cooling sys-

tem.YU-24460-01

YU-3398490890-01325

90890-01352

YU-33975, 90890-01403 Ring nut wrench

This tool is used when tighten the steering ring nut to

specification.YU-33975 90890-01403

YM-1423, 90890-01423 Damper rod holder

Use this tool to remove and install the damper rod.YM-1423 90890-01423

SPECIAL TOOLS

Page 84 of 758

SPEC

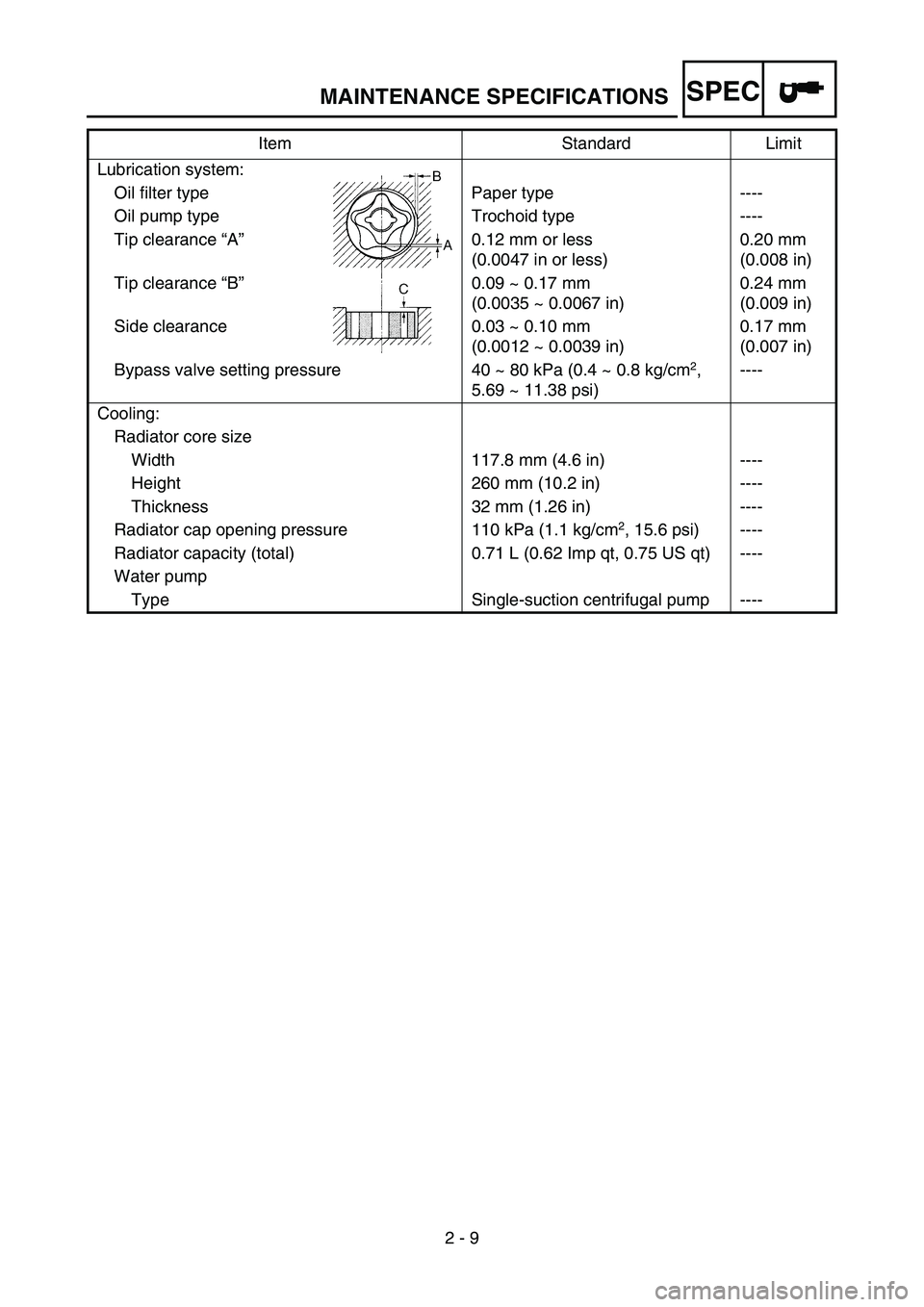

2 - 9 Lubrication system:

Oil filter type Paper type ----

Oil pump type Trochoid type ----

Tip clearance “A”0.12 mm or less

(0.0047 in or less)0.20 mm

(0.008 in)

Tip clearance “B”0.09 ~ 0.17 mm

(0.0035 ~ 0.0067 in)0.24 mm

(0.009 in)

Side clearance 0.03 ~ 0.10 mm

(0.0012 ~ 0.0039 in)0.17 mm

(0.007 in)

Bypass valve setting pressure 40 ~ 80 kPa (0.4 ~ 0.8 kg/cm

2,

5.69 ~ 11.38 psi)----

Cooling:

Radiator core size

Width 117.8 mm (4.6 in) ----

Height 260 mm (10.2 in) ----

Thickness 32 mm (1.26 in) ----

Radiator cap opening pressure 110 kPa (1.1 kg/cm

2, 15.6 psi) ----

Radiator capacity (total) 0.71 L (0.62 Imp qt, 0.75 US qt) ----

Water pump

Type Single-suction centrifugal pump ----Item Standard Limit

MAINTENANCE SPECIFICATIONS

Page 86 of 758

SPEC

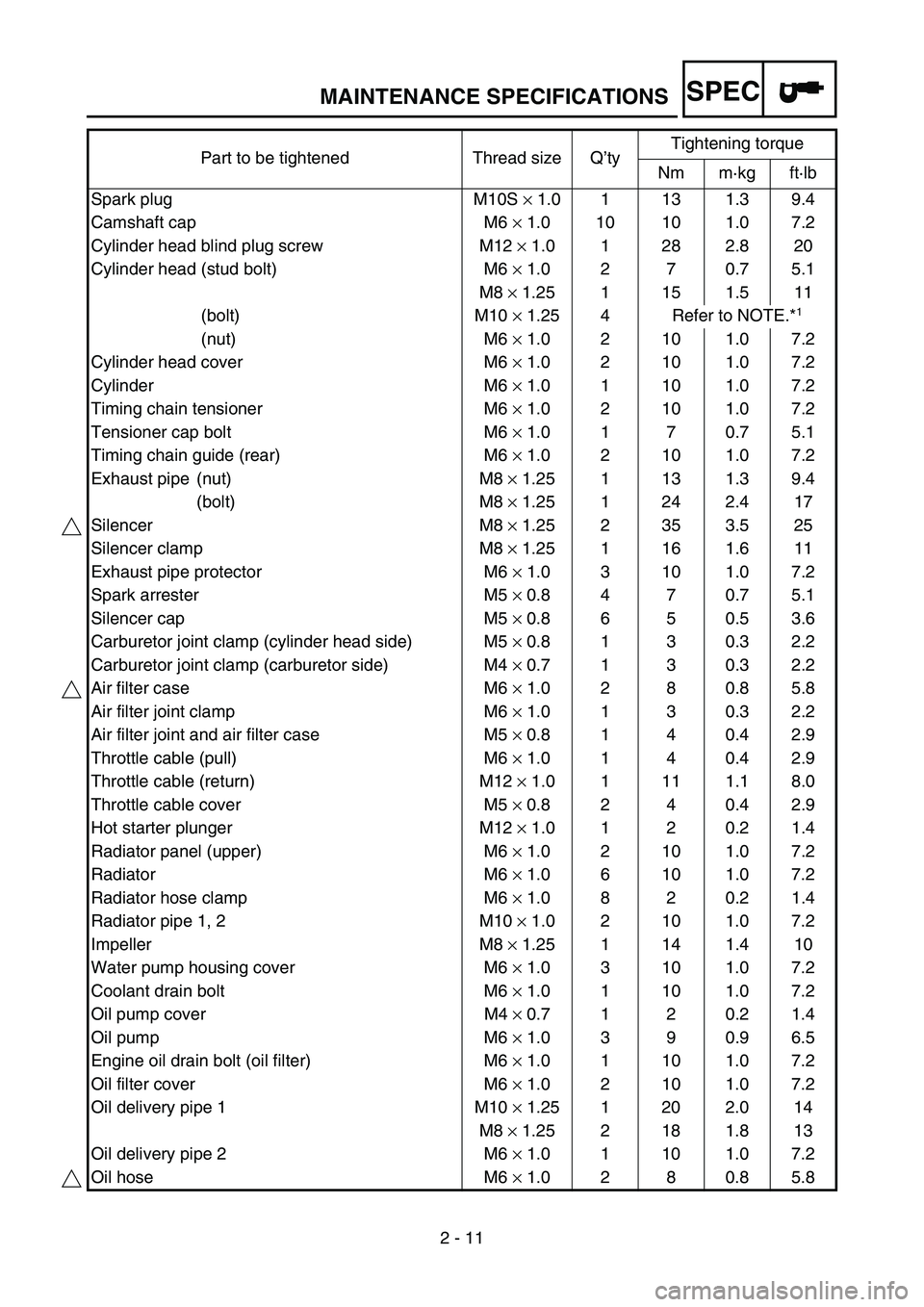

2 - 11 Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Spark plug M10S × 1.0 1 13 1.3 9.4

Camshaft cap M6 × 1.0 10 10 1.0 7.2

Cylinder head blind plug screw M12 × 1.0 1 28 2.8 20

Cylinder head (stud bolt) M6 × 1.0 2 7 0.7 5.1

M8 × 1.25 1 15 1.5 11

(bolt) M10 × 1.25 4 Refer to NOTE.*

1

(nut) M6 × 1.0 2 10 1.0 7.2

Cylinder head cover M6 × 1.0 2 10 1.0 7.2

Cylinder M6 × 1.0 1 10 1.0 7.2

Timing chain tensioner M6 × 1.0 2 10 1.0 7.2

Tensioner cap bolt M6 × 1.0 1 7 0.7 5.1

Timing chain guide (rear) M6 × 1.0 2 10 1.0 7.2

Exhaust pipe (nut) M8 × 1.25 1 13 1.3 9.4

(bolt) M8 × 1.25 1 24 2.4 17

Silencer M8 × 1.25 2 35 3.5 25

Silencer clamp M8 × 1.25 1 16 1.6 11

Exhaust pipe protector M6 × 1.0 3 10 1.0 7.2

Spark arrester M5 × 0.8 4 7 0.7 5.1

Silencer cap M5 × 0.8 6 5 0.5 3.6

Carburetor joint clamp (cylinder head side) M5 × 0.8 1 3 0.3 2.2

Carburetor joint clamp (carburetor side) M4 × 0.7 1 3 0.3 2.2

Air filter case M6 × 1.0 2 8 0.8 5.8

Air filter joint clamp M6 × 1.0 1 3 0.3 2.2

Air filter joint and air filter case M5 × 0.8 1 4 0.4 2.9

Throttle cable (pull) M6 × 1.0 1 4 0.4 2.9

Throttle cable (return) M12 × 1.0 1 11 1.1 8.0

Throttle cable cover M5 × 0.8 2 4 0.4 2.9

Hot starter plunger M12 × 1.0 1 2 0.2 1.4

Radiator panel (upper) M6 × 1.0 2 10 1.0 7.2

Radiator M6 × 1.0 6 10 1.0 7.2

Radiator hose clamp M6 × 1.0 8 2 0.2 1.4

Radiator pipe 1, 2 M10 × 1.0 2 10 1.0 7.2

Impeller M8 × 1.25 1 14 1.4 10

Water pump housing cover M6 × 1.0 3 10 1.0 7.2

Coolant drain bolt M6 × 1.0 1 10 1.0 7.2

Oil pump cover M4 × 0.7 1 2 0.2 1.4

Oil pump M6 × 1.0 3 9 0.9 6.5

Engine oil drain bolt (oil filter) M6 × 1.0 1 10 1.0 7.2

Oil filter cover M6 × 1.0 2 10 1.0 7.2

Oil delivery pipe 1 M10 × 1.25 1 20 2.0 14

M8 × 1.25 2 18 1.8 13

Oil delivery pipe 2 M6 × 1.0 1 10 1.0 7.2

Oil hose M6 × 1.0 2 8 0.8 5.8

MAINTENANCE SPECIFICATIONS

Page 91 of 758

SPEC

2 - 16 Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Rear wheel axle and nut M20 × 1.5 1 125 12.5 90

Driven sprocket and wheel hub M8 × 1.25 6 50 5.0 36

Nipple (spoke) — 72 3 0.3 2.2

Disc cover and rear brake caliper M6 × 1.0 2 7 0.7 5.1

Protector and rear brake caliper M6 × 1.0 2 7 0.7 5.1

Chain puller adjust bolt and locknut M8 × 1.25 2 16 1.6 11

Engine mounting:

Engine upper bracket and frame M10 × 1.25 2 55 5.5 40

Engine lower bracket and frame M8 × 1.25 4 34 3.4 24

Engine and engine bracket (front) M10 × 1.25 1 69 6.9 50

Engine and engine bracket (upper) M10 × 1.25 1 52 5.2 37

Engine and frame (lower) M10 × 1.25 1 69 6.9 50

Engine guard (left and right) M8 × 1.25 2 23 2.3 17

Engine skid plate mounting (front) M6 × 1.0 3 10 1.0 7.2

Engine skid plate mounting (rear) M6 × 1.0 3 10 1.0 7.2

Regulator mounting M6 × 1.0 2 7 0.7 5.1

Pivot shaft and nut M16 × 1.5 1 85 8.5 61

Relay arm and swingarm M14 × 1.5 1 80 8.0 58

Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

Connecting rod and frame M14 × 1.5 1 80 8.0 58

Rear shock absorber and frame M10 × 1.25 1 56 5.6 40

Rear shock absorber and relay arm M10 × 1.25 1 53 5.3 38

Rear frame and frame (upper) M8 × 1.25 1 32 3.2 23

Rear frame and frame (lower) M8 × 1.25 2 29 2.9 21

Swingarm and brake hose holder M5 × 0.8 4 1 0.1 0.7

Swingarm and patch M4 × 0.7 4 2 0.2 1.4

Drive chain tensioner mounting (upper) M8 × 1.25 1 19 1.9 13

Drive chain tensioner mounting (lower) M8 × 1.25 1 20 2.0 14

Chain support and swingarm M6 × 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 × 0.8 4 6 0.6 4.3

Fuel tank mounting M6 × 1.0 2 10 1.0 7.2

Fuel tank and fuel cock M6 × 1.0 2 7 0.7 5.1

Fuel tank and seat set bracket M6 × 1.0 1 7 0.7 5.1

Fuel tank and hooking screw (fitting band) M6 × 1.0 1 7 0.7 5.1

Fuel tank and fuel tank bracket M6 × 1.0 4 7 0.7 5.1

Seat mounting M8 × 1.25 2 23 2.3 17

Side cover mounting M6 × 1.0 2 7 0.7 5.1

Air scoop and fuel tank M6 × 1.0 6 7 0.7 5.1

Air scoop and radiator panel (lower) M6 × 1.0 2 6 0.6 4.3

Front fender mounting M6 × 1.0 4 7 0.7 5.1

Rear fender mounting (front) M6 × 1.0 2 7 0.7 5.1

Rear fender mounting (rear) M6 × 1.0 2 11 1.1 8.0

Trip meter mounting M6 × 1.0 2 7 0.7 5.1

MAINTENANCE SPECIFICATIONS

Page 164 of 758

2 - 25

SPECCABLE ROUTING DIAGRAM

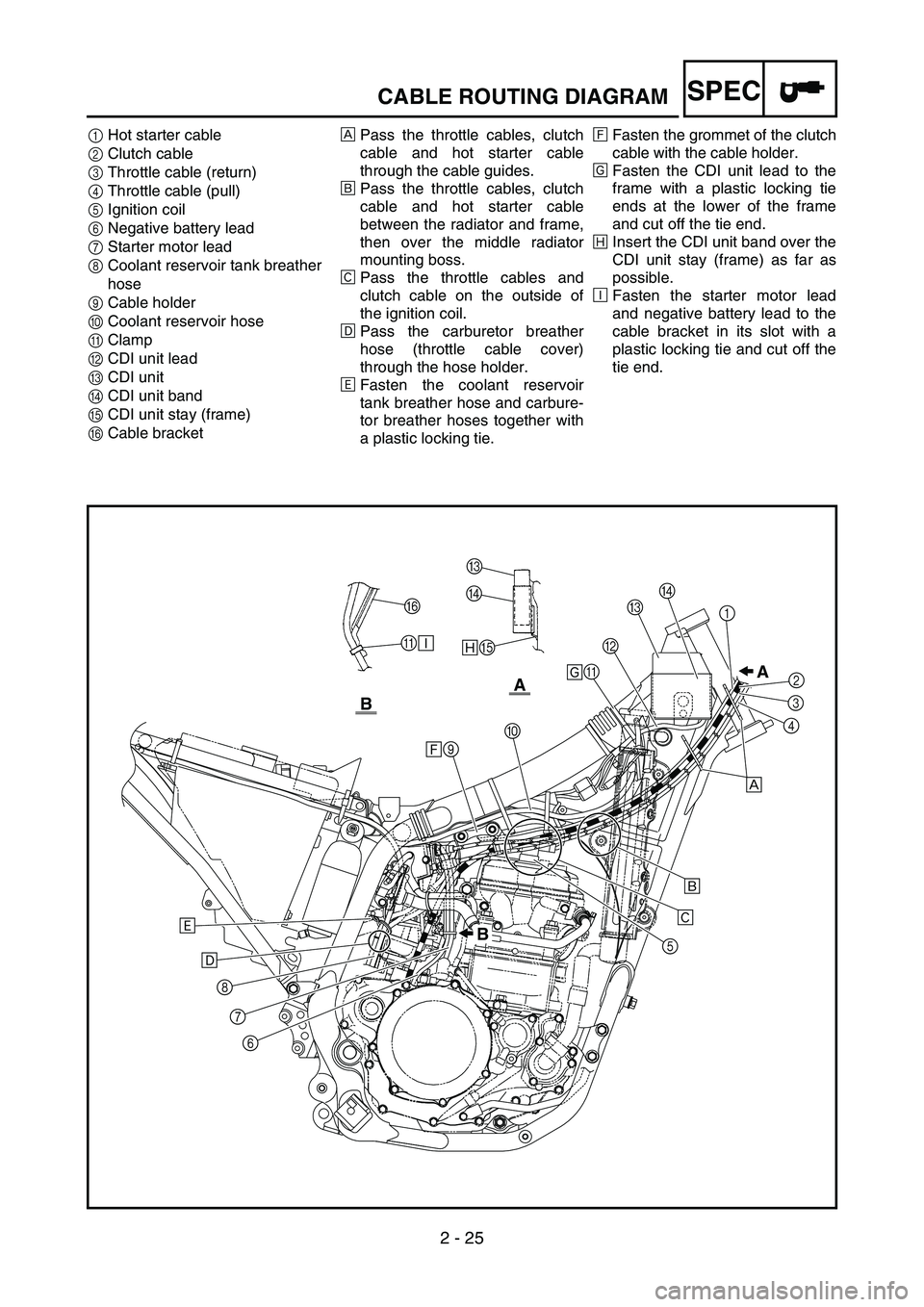

1Hot starter cable

2Clutch cable

3Throttle cable (return)

4Throttle cable (pull)

5Ignition coil

6Negative battery lead

7Starter motor lead

8Coolant reservoir tank breather

hose

9Cable holder

0Coolant reservoir hose

AClamp

BCDI unit lead

CCDI unit

DCDI unit band

ECDI unit stay (frame)

FCable bracketÈPass the throttle cables, clutch

cable and hot starter cable

through the cable guides.

ÉPass the throttle cables, clutch

cable and hot starter cable

between the radiator and frame,

then over the middle radiator

mounting boss.

ÊPass the throttle cables and

clutch cable on the outside of

the ignition coil.

ËPass the carburetor breather

hose (throttle cable cover)

through the hose holder.

ÌFasten the coolant reservoir

tank breather hose and carbure-

tor breather hoses together with

a plastic locking tie.ÍFasten the grommet of the clutch

cable with the cable holder.

ÎFasten the CDI unit lead to the

frame with a plastic locking tie

ends at the lower of the frame

and cut off the tie end.

ÏInsert the CDI unit band over the

CDI unit stay (frame) as far as

possible.

ÐFasten the starter motor lead

and negative battery lead to the

cable bracket in its slot with a

plastic locking tie and cut off the

tie end.

A

A

D

ÏE A

Ð

B

B

C

F

Í90

ÎABCD

1

2

43

È

É

Ê

5

6 7 8 Ë Ì

Page 173 of 758

3 - 2

INSP

ADJ

MAINTENANCE INTERVALS

ROTOR NUT

Retighten

MUFFLER

Inspect and retighten

Clean

Replace * Whichever comes first

*SPARK ARRESTER

(Every six

months)

Clean

CRANK

Inspect and clean

CARBURETOR

Inspect, adjust and clean

AIR INDUCTION SYSTEM

Inspect and clean

SPARK PLUG

Inspect and clean

Replace

DRIVE CHAIN

Use chain lube

Chain slack: 48 ~ 58 mm

(1.9 ~ 2.3 in) Lubricate, slack, alignment

Replace

COOLING SYSTEM

Check coolant level and leakage

Check radiator cap operation

Replace coolant Every two years

Inspect hoses

OUTSIDE NUTS AND BOLTS Refer to “STARTING

AND BREAK-IN” section

in the CHAPTER 1. Retighten

AIR FILTER

Use foam air-filter oil or

equivalent oil Clean and lubricate

Replace

OIL FILTER

Replace

OIL STRAINER (frame)

Clean

FRAME

Clean and inspect

FUEL TANK, COCK

Clean and inspect

BRAKES

Adjust lever position and pedal height

Lubricate pivot point

Check brake disc surface

Check fluid level and leakage

Retighten brake disc bolts, caliper

bolts, master cylinder bolts and union

bolts

Replace pads

Replace brake fluid Every one yearItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)As re-

quiredRemarks

3

Page 184 of 758

3 - 4

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator filler cap.

Check the cooling system for leakage.P.3-5 ~ 9

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-14

Engine oilCheck that the oil level is correct. Check the crankcase and

frame oil line for leakage.P.3-14 ~ 18

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-10

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-10 ~ 11

Brakes Check the play of front brake and effect of front and rear brake. P.3-25 ~ 31

ChainCheck chain slack and alignment. Check that the chain is lubri-

cated properly.P.3-32 ~ 35

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-43 ~ 44

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-44 ~ 46

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-35 ~ 42

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.—

Muffler Check that the muffler is tightly mounted and has no cracks.—

Sprocket Check that the driven sprocket tightening bolt is not loose. P.3-32

Lubrication Check for smooth operation. Lubricate if necessary. P.3-47

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-19

Lead connectorsCheck that the AC magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-6

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 20

Page 188 of 758

3 - 5

INSP

ADJ

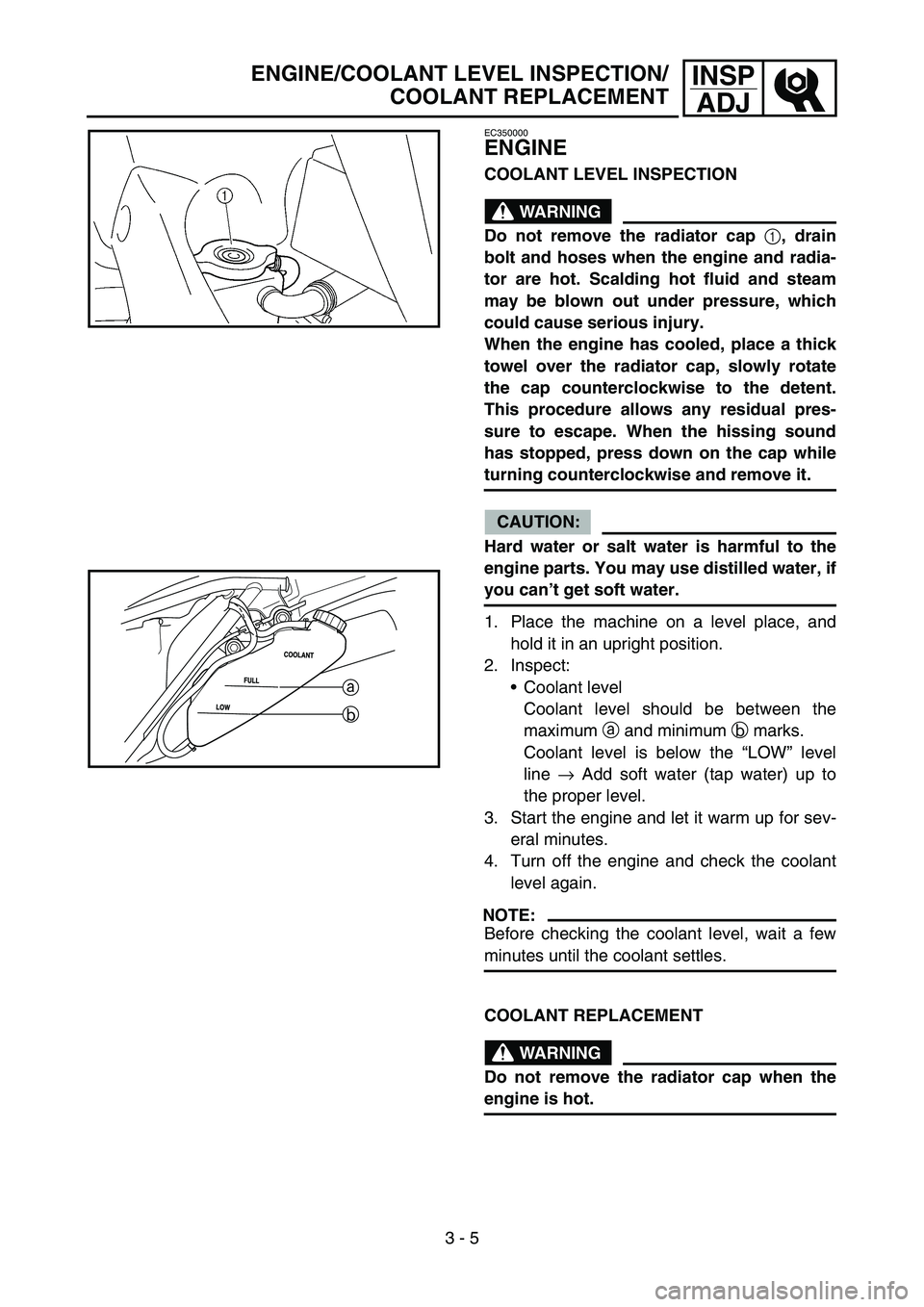

EC350000

ENGINE

COOLANT LEVEL INSPECTION

WARNING

Do not remove the radiator cap

1, drain

bolt and hoses when the engine and radia-

tor are hot. Scalding hot fluid and steam

may be blown out under pressure, which

could cause serious injury.

When the engine has cooled, place a thick

towel over the radiator cap, slowly rotate

the cap counterclockwise to the detent.

This procedure allows any residual pres-

sure to escape. When the hissing sound

has stopped, press down on the cap while

turning counterclockwise and remove it.

CAUTION:

Hard water or salt water is harmful to the

engine parts. You may use distilled water, if

you can’t get soft water.

1. Place the machine on a level place, and

hold it in an upright position.

2. Inspect:

Coolant level

Coolant level should be between the

maximum a and minimum b marks.

Coolant level is below the “LOW” level

line → Add soft water (tap water) up to

the proper level.

3. Start the engine and let it warm up for sev-

eral minutes.

4. Turn off the engine and check the coolant

level again.

NOTE:

Before checking the coolant level, wait a few

minutes until the coolant settles.

a

b

COOLANT REPLACEMENT

WARNING

Do not remove the radiator cap when the

engine is hot.

ENGINE/COOLANT LEVEL INSPECTION/

COOLANT REPLACEMENT