bolt pattern YAMAHA WR 450F 2005 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: WR 450F, Model: YAMAHA WR 450F 2005Pages: 758, PDF Size: 17.3 MB

Page 218 of 758

3 - 20

INSP

ADJ

VALVE CLEARANCE ADJUSTMENT

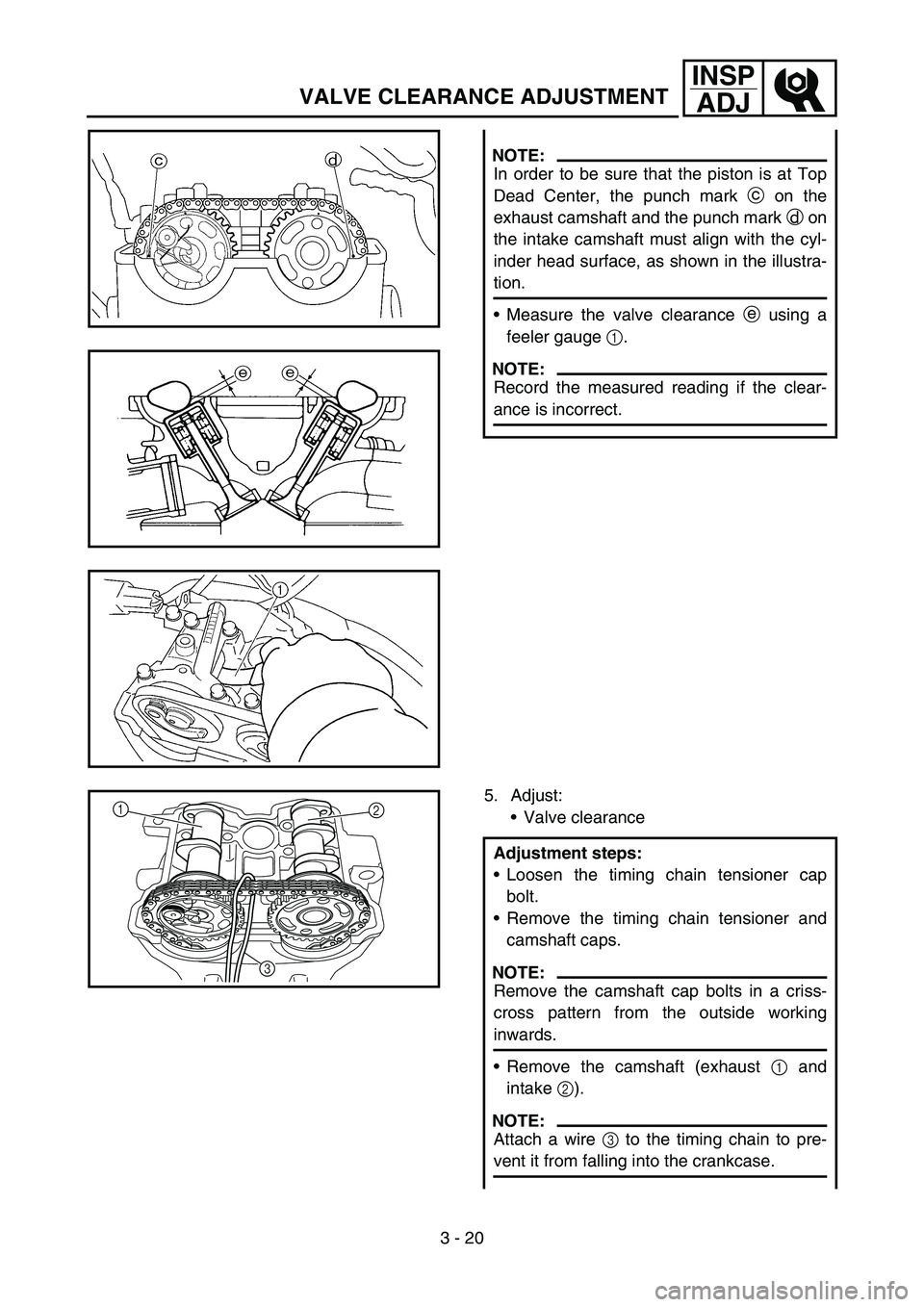

NOTE:

In order to be sure that the piston is at Top

Dead Center, the punch mark c on the

exhaust camshaft and the punch mark d on

the intake camshaft must align with the cyl-

inder head surface, as shown in the illustra-

tion.

Measure the valve clearance e using a

feeler gauge 1.

NOTE:

Record the measured reading if the clear-

ance is incorrect.

5. Adjust:

Valve clearance

Adjustment steps:

Loosen the timing chain tensioner cap

bolt.

Remove the timing chain tensioner and

camshaft caps.

NOTE:

Remove the camshaft cap bolts in a criss-

cross pattern from the outside working

inwards.

Remove the camshaft (exhaust 1 and

intake 2).

NOTE:

Attach a wire 3 to the timing chain to pre-

vent it from falling into the crankcase.

1

2

3

Page 350 of 758

4 - 25

ENGCAMSHAFTS

REMOVAL POINTS

Camshaft

1. Remove:

Timing plug 1

Straight plug 2

2. Align:

“I” mark

With stationary pointer.

Checking steps:

Turn the crankshaft counterclockwise with

a wrench.

Align the “I” mark a on the rotor with the

stationary pointer b on the crankcase

cover. When the “I” mark is aligned with

the stationary pointer, the piston is at the

Top Dead Center (T.D.C.).

NOTE:

In order to be sure that the piston is at Top

Dead Center, the punch mark c on the

exhaust camshaft and the punch mark d

on the intake camshaft must align with the

cylinder head surface, as shown in the

illustration.

If there is no clearance, rotate the crank-

shaft counterclockwise one turn.

1

2

b

a

3. Loosen:

Tensioner cap bolt 1

4. Remove:

Timing chain tensioner 2

5. Remove:

Bolt (camshaft cap) 1

Camshaft caps 2

NOTE:

Remove the bolts (camshaft cap) in a criss-

cross pattern, working from the outside in.

CAUTION:

The bolts (camshaft cap) must be removed

evenly to prevent damage to the cylinder

head, camshafts or camshaft caps.

1

2

1

2

Page 354 of 758

4 - 27

ENGCAMSHAFTS

4. Measure:

Camshaft-to-cap clearance

Out of specification → Measure camshaft

journal diameter.

Camshaft-to-cap clearance:

0.020 ~ 0.054 mm

(0.0008 ~ 0.0021 in)

Measurement steps:

Install the camshaft onto the cylinder

head.

Position a strip of Plastigauge

® 1 onto the

camshaft.

Install the circlip, dowel pins and camshaft

caps.

T R..

Bolt (camshaft cap):

10 Nm (1.0 m kg, 7.2 ft lb)

NOTE:

Tighten the bolts (camshaft cap) in a criss-

cross pattern from innermost to outer

caps.

Do not turn the camshaft when measuring

clearance with the Plastigauge®.

Remove the camshaft caps and measure

the width of the Plastigauge

® 1.

5. Measure:

Camshaft journal diameter a

Out of specification → Replace the cam-

shaft.

Within specification → Replace camshaft

case and camshaft caps as a set.

Camshaft sprocket

1. Inspect:

Camshaft sprocket 1

Wear/damage → Replace the camshaft

assembly and timing chain as a set.

Camshaft journal diameter:

21.967 ~ 21.980 mm

(0.8648 ~ 0.8654 in)

Page 358 of 758

4 - 29

ENGCAMSHAFTS

Fit the timing chain 3 onto both camshaft

sprockets and install the camshafts on the

cylinder head.

NOTE:

The camshafts should be installed onto the

cylinder head so that the exhaust cam

sprocket punch mark c and the intake cam

sprocket punch mark d align with the sur-

face of the cylinder head.

CAUTION:

Do not turn the crankshaft during the

camshaft installation. Damage or

improper valve timing will result.

Install the clips and camshaft caps 4.

T R..

Bolt (camshaft cap):

10 Nm (1.0 m kg, 7.2 ft lb)

NOTE:

Apply the engine oil on the thread and

contact surface of the bolts (camshaft cap)

5.

Tighten the bolts (camshaft cap) in a criss-

cross pattern.

CAUTION:

The bolts (camshaft cap) must be tight-

ened evenly, or damage to the cylinder

head, camshaft caps, and camshaft will

result.

5

4

E

2. Install:

Timing chain tensioner

Installation steps:

While pressing the tensioner rod lightly

with fingers, use a thin screwdriver and

wind the tensioner rod up fully clockwise.

Page 414 of 758

4 - 57

ENGCLUTCH

7. Install:

Pressure plate 1

8. Install:

Clutch spring

Bolt (clutch spring)

NOTE:

Tighten the bolts in stage, using a crisscross

pattern.

T R..8 Nm (0.8 m · kg, 5.8 ft · lb)

9. Install:

Gasket (clutch cover) 1

Dowel pin 2

New

10. Install:

Clutch cover 1

Bolt (clutch cover)

NOTE:

Tighten the bolts in stage, using a crisscross

pattern.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 424 of 758

4 - 62

ENG

OIL FILTER, WATER PUMP AND CRANKCASE COVER

(RIGHT)

EC4G5220

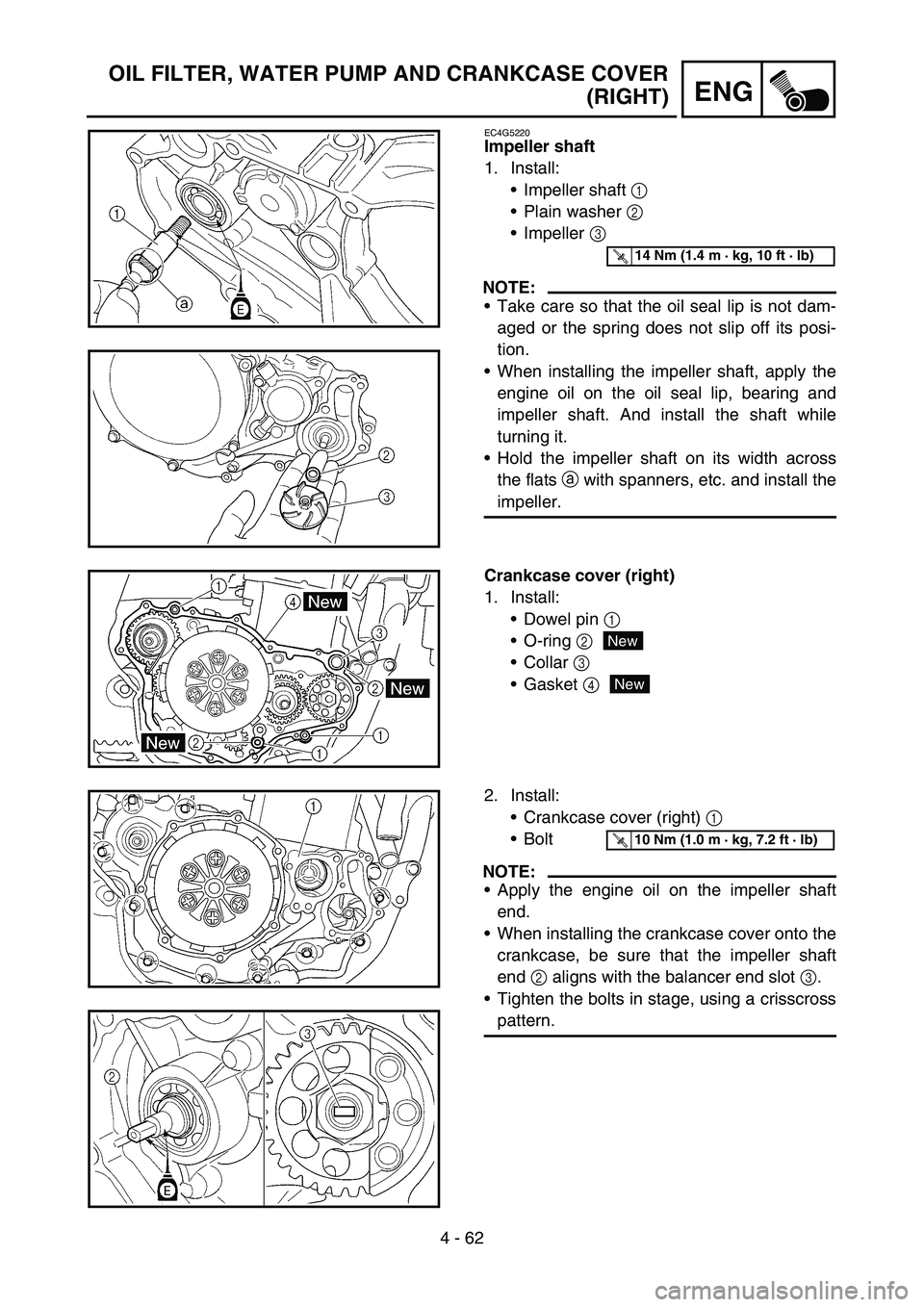

Impeller shaft

1. Install:

Impeller shaft 1

Plain washer 2

Impeller 3

NOTE:

Take care so that the oil seal lip is not dam-

aged or the spring does not slip off its posi-

tion.

When installing the impeller shaft, apply the

engine oil on the oil seal lip, bearing and

impeller shaft. And install the shaft while

turning it.

Hold the impeller shaft on its width across

the flats a with spanners, etc. and install the

impeller.

T R..14 Nm (1.4 m · kg, 10 ft · lb)

Crankcase cover (right)

1. Install:

Dowel pin 1

O-ring 2

Collar 3

Gasket 4

New

New

2. Install:

Crankcase cover (right) 1

Bolt

NOTE:

Apply the engine oil on the impeller shaft

end.

When installing the crankcase cover onto the

crankcase, be sure that the impeller shaft

end 2 aligns with the balancer end slot 3.

Tighten the bolts in stage, using a crisscross

pattern.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 468 of 758

4 - 84

ENG

5. Install:

Bolt (starter clutch) 1

Plain washer (rotor)

Nut (rotor) 2

Use the sheave holder 3.

NOTE:

Tighten the rotor nut to 65 Nm (6.5 m kg,

47 ftlb), loosen and retighten the rotor nut to

65 Nm (6.5 m kg, 47 ft lb).

Sheave holder:

YS-1880-A/90890-01701

1

1

3

2

T R..16 Nm (1.6 m · kg, 11 ft · lb)

T R..65 Nm (6.5 m · kg, 47 ft · lb)

6. Install:

Shaft 1

Bearing 2

Idle gear 2 3

NOTE:

Apply the engine oil on the shaft, bearing and

idle gear inner circumference.

7. Install:

Dowel pin

Gasket [crankcase cover (left)]

Crankcase cover (left) 1

Bolt [crankcase cover (left)]

NOTE:

Tighten the bolts in stage, using a crisscross

pattern.

New

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

8. Install:

Plain washer

Torque limiter 1

Plain washer

NOTE:

Apply the engine oil to the shaft and plain

washers.1

AC MAGNETO AND STARTER CLUTCH

Page 500 of 758

4 - 100

ENGCRANKCASE AND CRANKSHAFT

5. Install:

Dowel pin 1

O-ring 2

Crankcase (right)

To crankcase (left).

NOTE:

Fit the crankcase (right) onto the crankcase

(left). Tap lightly on the case with soft ham-

mer.

When installing the crankcase, the connect-

ing rod should be positioned at TDC (top

dead center).

New

6. Tighten:

Hose guide 1

Clutch cable holder 2

Bolt (clutch cable holder)

Bolt (crankcase)

NOTE:

Tighten the crankcase tightening bolts in

stage, using a crisscross pattern.

7. Install:

Oil delivery pipe

O-ring

Bolt (oil delivery pipe 2)

8. Install:

Timing chain

Timing chain guide (rear)

Bolt (timing chain guide)

9. Remove:

Sealant

Forced out on the cylinder mating surface.

10. Apply:

Engine oil

To the crank pin, bearing and oil delivery

hole.

11. Check:

Crankshaft and transmission operation.

Unsmooth operation → Repair.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..12 Nm (1.2 m · kg, 8.7 ft · lb)

New

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 520 of 758

5 - 5

CHASFRONT WHEEL AND REAR WHEEL

EC595000

ASSEMBLY AND INSTALLATION

Front wheel

1. Install:

Bearing (left) 1

Spacer 2

Bearing (right) 3

Oil seal 4

NOTE:

Apply the lithium soap base grease on the

bearing and oil seal lip when installing.

Use a socket that matches the outside diam-

eter of the race of the bearing.

Left side of bearing shall be installed first.

Install the oil seal with its manufacture’s

marks or numbers facing outward.

CAUTION:

Do not strike the inner race of the bearing.

Contact should be made only with the outer

race.

2. Install:

Brake disc 1

Bolt (brake disc) 2

NOTE:

Tighten the bolts in stage, using a crisscross

pattern.

New

T R..12 Nm (1.2 m · kg, 8.7 ft · lb)

3. Install:

Collar 1

NOTE:

Apply the lithium soap base grease on the oil

seal lip.

4. Install:

Trip meter gear unit 1

NOTE:

Apply the lithium soap base grease on the oil

seal lip of the trip meter gear unit.

Make sure the two projections a in the

wheel hub are meshed with the two slots b

in the trip meter gear unit.

b a1

B

Page 526 of 758

5 - 8

CHAS

2. Install:

•Brake disc 1

Bolt (brake disc) 2

NOTE:

Tighten the bolts in stage, using a crisscross

pattern.

T R..14 Nm (1.4 m · kg, 10 ft · lb)

3. Install:

Driven sprocket 1

Bolt (driven sprocket) 2

Plain washer (driven sprocket) 3

Nut (driven sprocket) 4

NOTE:

Tighten the nuts in stage, using a crisscross

pattern.

T R..50 Nm (5.0 m · kg, 36 ft · lb)

4. Install:

Collar 1

NOTE:

Apply the lithium soap base grease on the oil

seal lip.

5. Install:

Wheel

NOTE:

Install the brake disc 1 between the brake

pads 2 correctly.

6. Install:

Drive chain 1

NOTE:

Push the wheel 2 forward and install the drive

chain.

FRONT WHEEL AND REAR WHEEL