relay YAMAHA WR 450F 2005 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: WR 450F, Model: YAMAHA WR 450F 2005Pages: 758, PDF Size: 17.3 MB

Page 91 of 758

SPEC

2 - 16 Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Rear wheel axle and nut M20 × 1.5 1 125 12.5 90

Driven sprocket and wheel hub M8 × 1.25 6 50 5.0 36

Nipple (spoke) — 72 3 0.3 2.2

Disc cover and rear brake caliper M6 × 1.0 2 7 0.7 5.1

Protector and rear brake caliper M6 × 1.0 2 7 0.7 5.1

Chain puller adjust bolt and locknut M8 × 1.25 2 16 1.6 11

Engine mounting:

Engine upper bracket and frame M10 × 1.25 2 55 5.5 40

Engine lower bracket and frame M8 × 1.25 4 34 3.4 24

Engine and engine bracket (front) M10 × 1.25 1 69 6.9 50

Engine and engine bracket (upper) M10 × 1.25 1 52 5.2 37

Engine and frame (lower) M10 × 1.25 1 69 6.9 50

Engine guard (left and right) M8 × 1.25 2 23 2.3 17

Engine skid plate mounting (front) M6 × 1.0 3 10 1.0 7.2

Engine skid plate mounting (rear) M6 × 1.0 3 10 1.0 7.2

Regulator mounting M6 × 1.0 2 7 0.7 5.1

Pivot shaft and nut M16 × 1.5 1 85 8.5 61

Relay arm and swingarm M14 × 1.5 1 80 8.0 58

Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

Connecting rod and frame M14 × 1.5 1 80 8.0 58

Rear shock absorber and frame M10 × 1.25 1 56 5.6 40

Rear shock absorber and relay arm M10 × 1.25 1 53 5.3 38

Rear frame and frame (upper) M8 × 1.25 1 32 3.2 23

Rear frame and frame (lower) M8 × 1.25 2 29 2.9 21

Swingarm and brake hose holder M5 × 0.8 4 1 0.1 0.7

Swingarm and patch M4 × 0.7 4 2 0.2 1.4

Drive chain tensioner mounting (upper) M8 × 1.25 1 19 1.9 13

Drive chain tensioner mounting (lower) M8 × 1.25 1 20 2.0 14

Chain support and swingarm M6 × 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 × 0.8 4 6 0.6 4.3

Fuel tank mounting M6 × 1.0 2 10 1.0 7.2

Fuel tank and fuel cock M6 × 1.0 2 7 0.7 5.1

Fuel tank and seat set bracket M6 × 1.0 1 7 0.7 5.1

Fuel tank and hooking screw (fitting band) M6 × 1.0 1 7 0.7 5.1

Fuel tank and fuel tank bracket M6 × 1.0 4 7 0.7 5.1

Seat mounting M8 × 1.25 2 23 2.3 17

Side cover mounting M6 × 1.0 2 7 0.7 5.1

Air scoop and fuel tank M6 × 1.0 6 7 0.7 5.1

Air scoop and radiator panel (lower) M6 × 1.0 2 6 0.6 4.3

Front fender mounting M6 × 1.0 4 7 0.7 5.1

Rear fender mounting (front) M6 × 1.0 2 7 0.7 5.1

Rear fender mounting (rear) M6 × 1.0 2 11 1.1 8.0

Trip meter mounting M6 × 1.0 2 7 0.7 5.1

MAINTENANCE SPECIFICATIONS

Page 94 of 758

SPEC

2 - 19

NOTE:

Tighten the rotor nut to 65 Nm (6.5 m kg, 47 ft lb), loosen and retighten the rotor nut to 65 Nm

(6.5 m kg, 47 ft lb). Starter relay:

Model/manufacturer 2768090-A/JIDECO ----

Amperage rating 180 A ----

Coil winding resistance 4.2 ~ 4.6 Ω at 20 °C (68 °F) ----

Starting circuit cut-off relay:

Model/manufacturer ACM33221 M06/MATSUSHITA ----

Coil winding resistance 75.69 ~ 92.51 Ω at 20 °C (68 °F) ----

Fuse (amperage × quantity):

Main fuse 10 A × 1 ----

Reserve fuse 10 A × 1 ----

Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Stator M5 × 0.8 2 7 0.7 5.1

Holder (AC magneto lead) M5 × 0.8 2 7 0.7 5.1

Rotor M12 × 1.25 1 Refer to NOTE.

Neutral switch M5 × 0.8 2 4 0.4 2.9

Starter motor M6 × 1.0 2 10 1.0 7.2

Starter relay terminal M6 × 1.0 2 4 0.4 2.9

Pick-up coil M6 × 1.0 2 10 1.0 7.2 Item Standard Limit

MAINTENANCE SPECIFICATIONS

Page 168 of 758

2 - 27

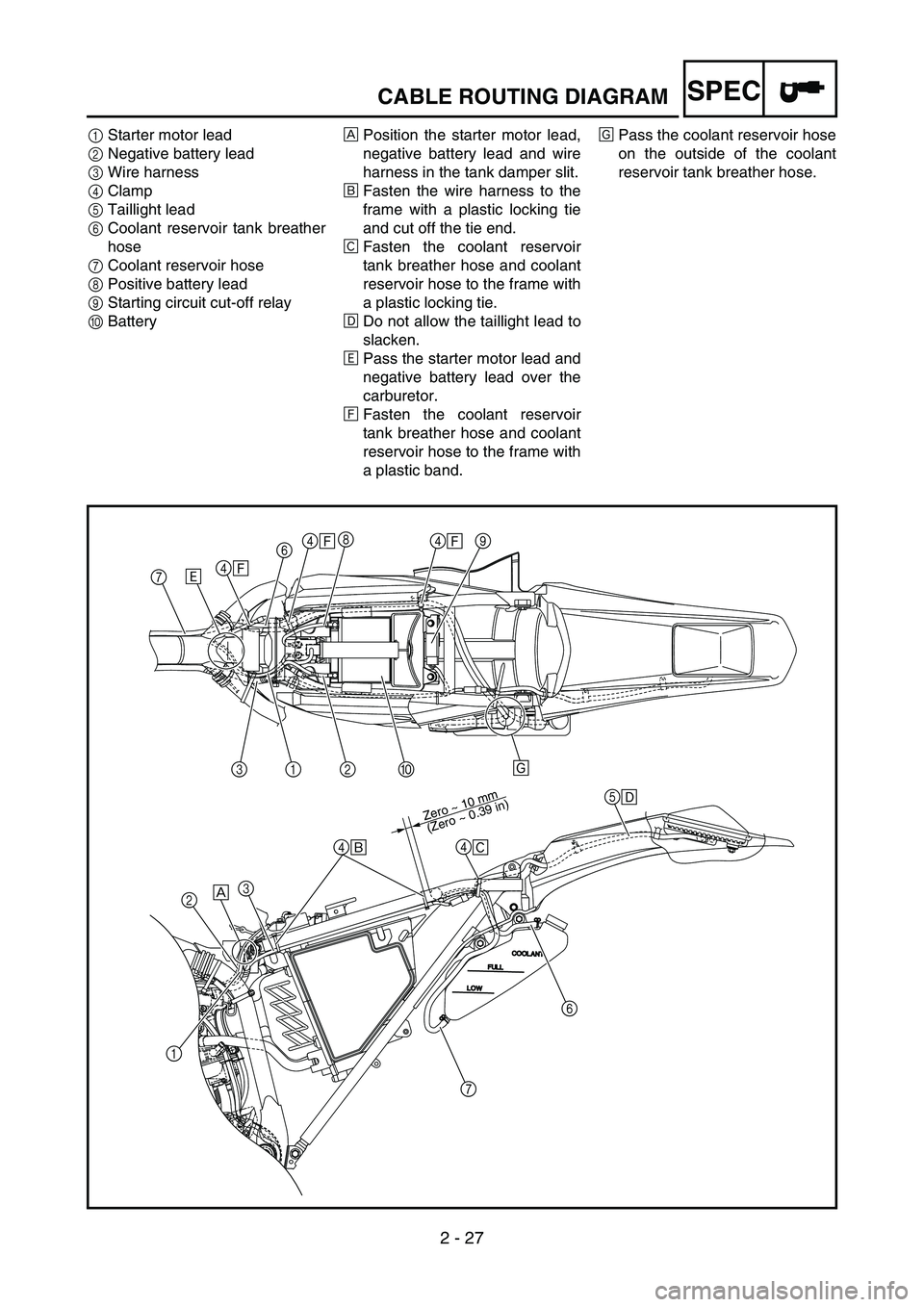

SPECCABLE ROUTING DIAGRAM

1Starter motor lead

2Negative battery lead

3Wire harness

4Clamp

5Taillight lead

6Coolant reservoir tank breather

hose

7Coolant reservoir hose

8Positive battery lead

9Starting circuit cut-off relay

0BatteryÈPosition the starter motor lead,

negative battery lead and wire

harness in the tank damper slit.

ÉFasten the wire harness to the

frame with a plastic locking tie

and cut off the tie end.

ÊFasten the coolant reservoir

tank breather hose and coolant

reservoir hose to the frame with

a plastic locking tie.

ËDo not allow the taillight lead to

slacken.

ÌPass the starter motor lead and

negative battery lead over the

carburetor.

ÍFasten the coolant reservoir

tank breather hose and coolant

reservoir hose to the frame with

a plastic band.ÎPass the coolant reservoir hose

on the outside of the coolant

reservoir tank breather hose.

7Ì4

Í

5

Ë

4

Ê

7

6

È3

2

1

4

É

4

Í4

Í

Î 0

968

213

Zero ~ 10 mm

(Zero ~ 0.39 in)

Page 174 of 758

3 - 3

INSP

ADJ

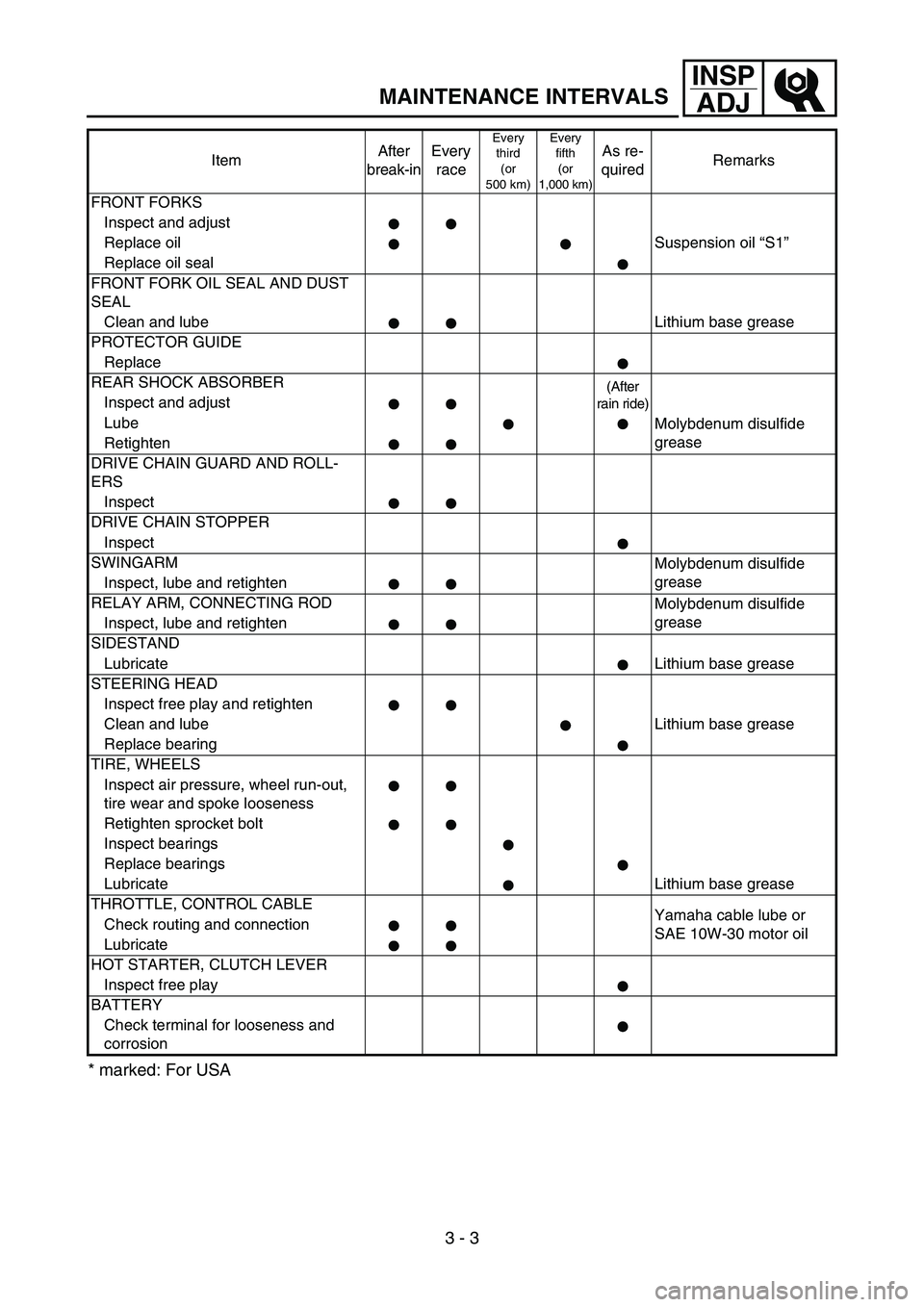

MAINTENANCE INTERVALS

* marked: For USA

FRONT FORKS

Inspect and adjust

Replace oil Suspension oil “S1”

Replace oil seal

FRONT FORK OIL SEAL AND DUST

SEAL

Clean and lube Lithium base grease

PROTECTOR GUIDE

Replace

REAR SHOCK ABSORBER

(After

rain ride)

Inspect and adjust

Lube

Molybdenum disulfide

grease

Retighten

DRIVE CHAIN GUARD AND ROLL-

ERS

Inspect

DRIVE CHAIN STOPPER

Inspect

SWINGARM

Molybdenum disulfide

grease

Inspect, lube and retighten

RELAY ARM, CONNECTING ROD

Molybdenum disulfide

grease

Inspect, lube and retighten

SIDESTAND

Lubricate Lithium base grease

STEERING HEAD

Inspect free play and retighten

Clean and lube Lithium base grease

Replace bearing

TIRE, WHEELS

Inspect air pressure, wheel run-out,

tire wear and spoke looseness

Retighten sprocket bolt

Inspect bearings

Replace bearings

Lubricate Lithium base grease

THROTTLE, CONTROL CABLE

Yamaha cable lube or

SAE 10W-30 motor oil Check routing and connection

Lubricate

HOT STARTER, CLUTCH LEVER

Inspect free play

BATTERY

Check terminal for looseness and

corrosionItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)As re-

quiredRemarks

Page 614 of 758

5 - 52

CHASSWINGARM

EC570000

SWINGARM

Extent of removal:

1 Swingarm removal

Extent of removal Order Part name Q’ty Remarks

SWINGARM REMOVAL

WARNING

Support the machine securely so there is nodanger of it falling over.

Preparation for removal Hold the machine by placing the

suitable stand under the engine.

Brake hose holder

Refer to “FRONT BRAKE AND REAR

BRAKE” section.

Rear caliper

Bolt (brake pedal) Shift the brake pedal backward.

Drive chain

1 Chain support 1

2 Chain tensioner (lower) 1

3 Bolt (rear shock absorber-relay

arm)1 Hold the swingarm.

4 Bolt (connecting rod) 1

5 Pivot shaft 1

6 Swingarm 1

1

Page 616 of 758

5 - 53

CHASSWINGARM

EC578000

SWINGARM DISASSEMBLY

Extent of removal:

1 Swingarm disassembly

2 Connecting rod removal and disassembly

3 Relay arm removal and disassembly

Extent of removal Order Part name Q’ty Remarks

SWINGARM DISASSEMBLY

1 Cap 2 Refer to “REMOVAL POINTS”.

2 Relay arm 1

3 Connecting rod 1

4 Collar 2

5 Oil seal 2

6 Thrust bearing 2

7 Bush 2

8 Oil seal 8

9 Bearing 10 Refer to “REMOVAL POINTS”.

1

2

32

3

Page 618 of 758

5 - 54

CHASSWINGARM

EC573000

REMOVAL POINTS

Cap

1. Remove:

Cap (left) 1

NOTE:

Remove with a slotted-head screwdriver

inserted under the mark a on the cap (left).

EC573200

Bearing

1. Remove:

Bearing 1

NOTE:

Install the bearing by pressing its outer race.

EC574010

INSPECTION

Wash the bearings, bushes, collars, and cov-

ers in a solvent.

EC574111

Swingarm

1. Inspect:

Bearing 1

Bush 2

Free play exists/unsmooth revolution/rust

→ Replace bearing and bush as a set.

2. Inspect:

Oil seal 3

Damage → Replace.

Relay arm

1. Inspect:

Bearing 1

Collar 2

Free play exists/unsmooth revolution/rust

→ Replace bearing and collar as a set.

2. Inspect:

Oil seal 3

Damage → Replace.

Page 620 of 758

5 - 55

CHASSWINGARM

Connecting rod

1. Inspect:

Bearing 1

Collar 2

Free play exists/unsmooth revolution/rust

→ Replace bearing and collar as a set.

2. Inspect:

Oil seal 3

Damage → Replace.

EC575000

ASSEMBLY AND INSTALLATION

Bearing and oil seal

1. Install:

Bearing 1

Oil seal 2

To swingarm.

NOTE:

Apply the molybdenum disulfide grease on

the bearing when installing.

Install the bearing by pressing it on the side

having the manufacture’s marks or numbers.

First install the outer and then the inner bear-

ings to a specified depth from inside.

Installed depth of bearings:

Outer

a: Zero mm (Zero in)

Inner

b: 8.5 mm (0.33 in)

2. Install:

Bearing 1

Plain washer 2

Oil seal 3

To relay arm.

NOTE:

Apply the molybdenum disulfide grease on

the bearing when installing.

Install the bearing by pressing it on the side

having the manufacture’s marks or numbers.

Apply the molybdenum disulfide grease on

the plain washer.

Installed depth of bearings

a:

Zero mm (Zero in)

Page 622 of 758

5 - 56

CHASSWINGARM

3. Install:

Bearing 1

Oil seal 2

To connecting rod.

NOTE:

Apply the molybdenum disulfide grease on

the bearing when installing.

Install the bearing by pressing it on the side

having the manufacture’s marks or numbers.

Installed depth of bearings

a:

5 mm (0.20 in)

Swingarm

1. Install:

Bush 1

Thrust bearing 2

Oil seal 3

Collar 4

To swingarm 5.

NOTE:

Apply the molybdenum disulfide grease on the

bushes, thrust bearings, oil seal lips and con-

tact surfaces of the collar and thrust bearing.

2. Install:

Collar 1

Washer 2

To relay arm 3.

NOTE:

Apply the molybdenum disulfide grease on the

collars and oil seal lips.

Page 624 of 758

5 - 57

CHASSWINGARM

3. Install:

Collar 1

To connecting rod 2.

NOTE:

Apply the molybdenum disulfide grease on the

collar and oil seal lips.

4. Install:

Connecting rod 1

Bolt (connecting rod) 2

Plain washer 3

Nut (connecting rod) 4

To relay arm 5.

NOTE:

Apply the molybdenum disulfide grease on the

bolt.

T R..80 Nm (8.0 m · kg, 58 ft · lb)

5. Install:

Relay arm 1

Bolt (relay arm) 2

Plain washer 3

Nut (relay arm) 4

To swingarm.

NOTE:

Apply the molybdenum disulfide grease on

the bolt.

Do not tighten the nut yet.