battery YAMAHA WR 450F 2006 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: WR 450F, Model: YAMAHA WR 450F 2006Pages: 786, PDF Size: 22.49 MB

Page 300 of 786

3 - 52

INSP

ADJ

BATTERY INSPECTION AND CHARGING

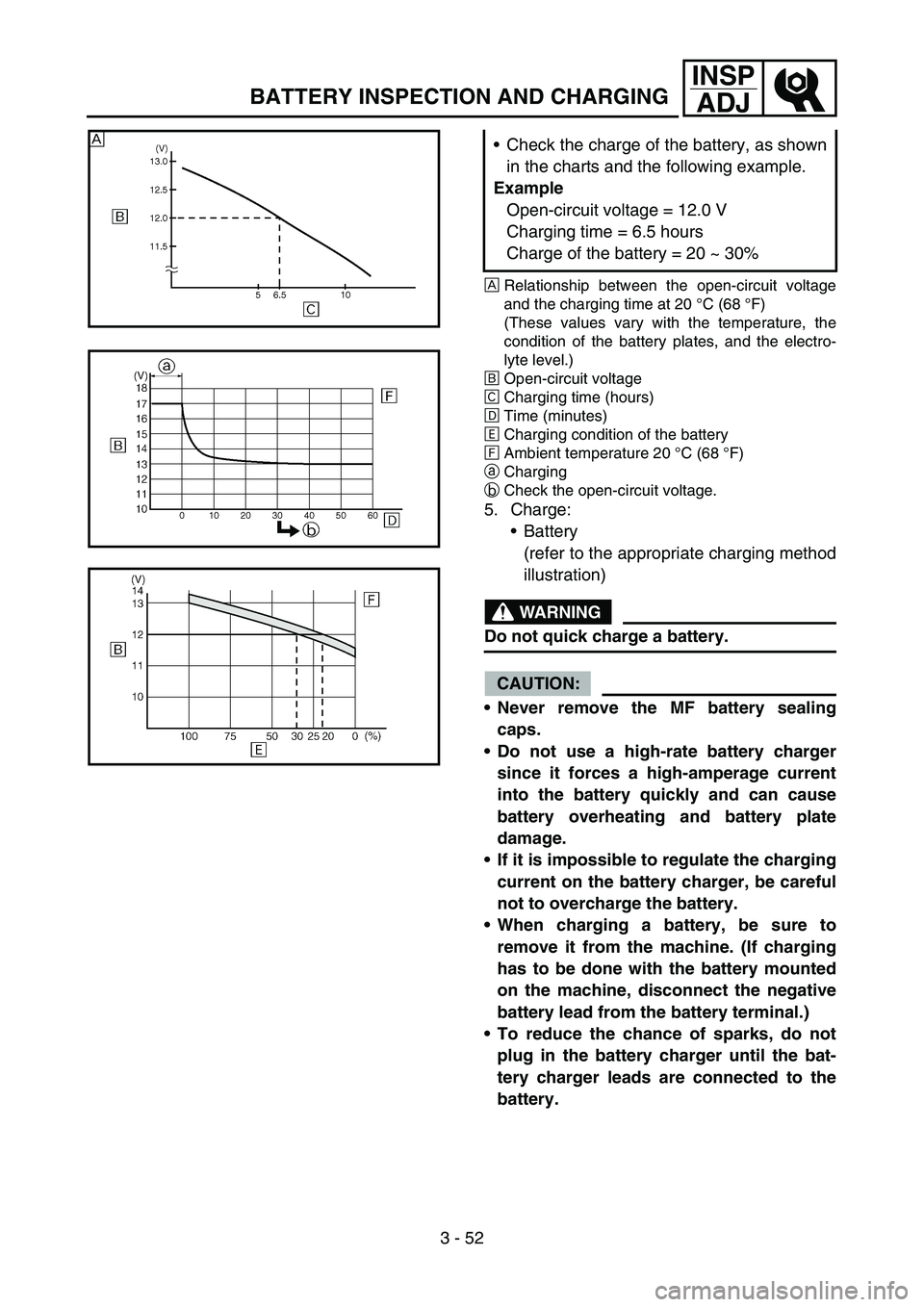

ÈRelationship between the open-circuit voltage

and the charging time at 20 °C (68 °F)

(These values vary with the temperature, the

condition of the battery plates, and the electro-

lyte level.)

ÉOpen-circuit voltage

ÊCharging time (hours)

ËTime (minutes)

ÌCharging condition of the battery

ÍAmbient temperature 20 °C (68 °F)

aCharging

bCheck the open-circuit voltage.

5. Charge:

Battery

(refer to the appropriate charging method

illustration)

WARNING

Do not quick charge a battery.

CAUTION:

Never remove the MF battery sealing

caps.

Do not use a high-rate battery charger

since it forces a high-amperage current

into the battery quickly and can cause

battery overheating and battery plate

damage.

If it is impossible to regulate the charging

current on the battery charger, be careful

not to overcharge the battery.

When charging a battery, be sure to

remove it from the machine. (If charging

has to be done with the battery mounted

on the machine, disconnect the negative

battery lead from the battery terminal.)

To reduce the chance of sparks, do not

plug in the battery charger until the bat-

tery charger leads are connected to the

battery. Check the charge of the battery, as shown

in the charts and the following example.

Example

Open-circuit voltage = 12.0 V

Charging time = 6.5 hours

Charge of the battery = 20 ~ 30%

È

Page 302 of 786

3 - 53

INSP

ADJ

BATTERY INSPECTION AND CHARGING

Before removing the battery charger lead

clips from the battery terminals, be sure

to turn off the battery charger.

Make sure the battery charger lead clips

are in full contact with the battery termi-

nal and that they are not shorted. A cor-

roded battery charger lead clip may

generate heat in the contact area and a

weak clip spring may cause sparks.

If the battery becomes hot to the touch at

any time during the charging process,

disconnect the battery charger and let the

battery cool before reconnecting it. Hot

batteries can explode!

As shown in the following illustration, the

open-circuit voltage of an MF battery sta-

bilizes about 30 minutes after charging

has been completed. Therefore, wait

30 minutes after charging is completed

before measuring the open-circuit volt-

age.

Page 304 of 786

3 - 54

INSP

ADJ

BATTERY INSPECTION AND CHARGING

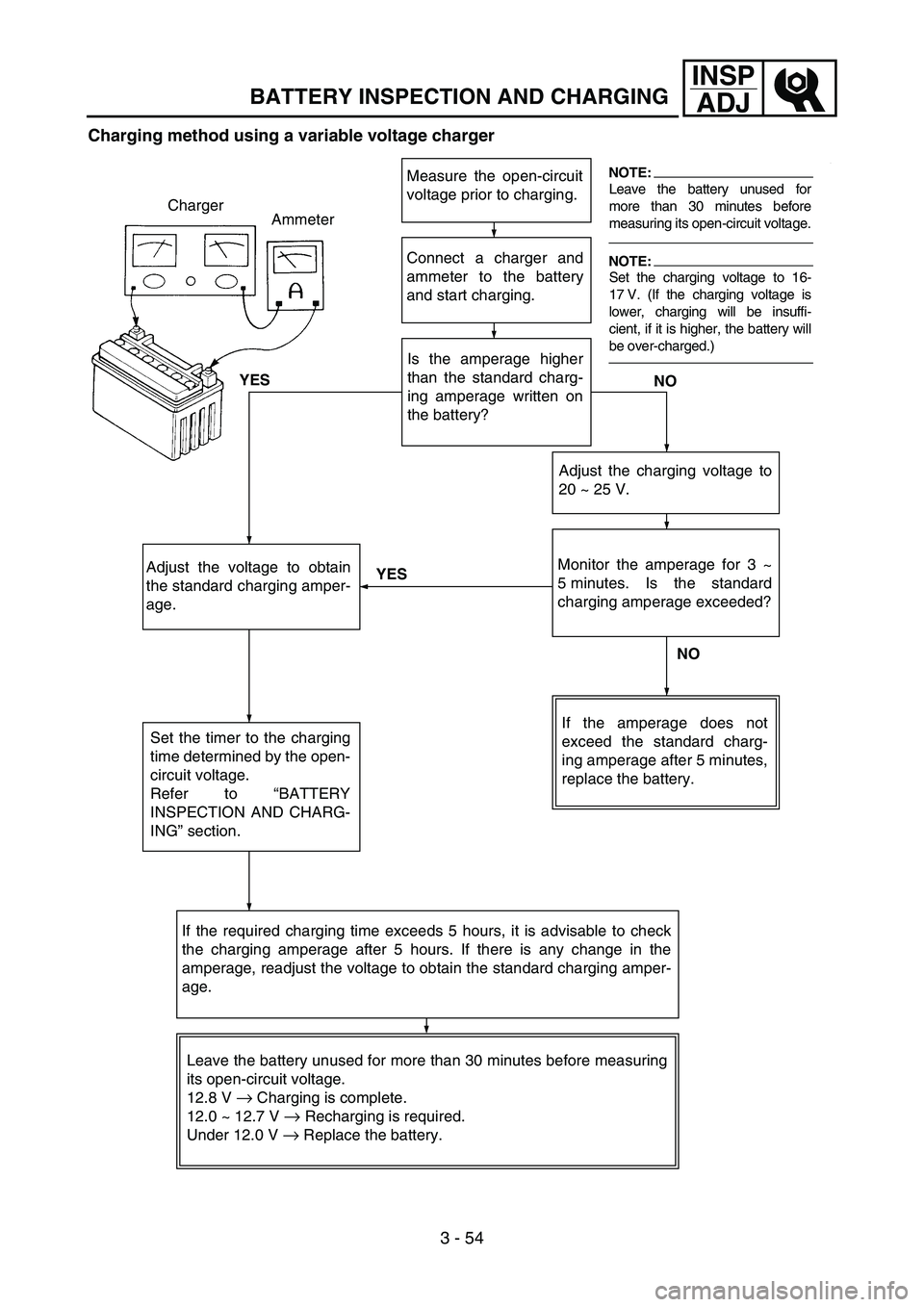

Charging method using a variable voltage charger

Connect a charger and

ammeter to the battery

and start charging.

Is the amperage higher

than the standard charg-

ing amperage written on

the battery?NO YES Charger

Ammeter

Adjust the voltage to obtain

the standard charging amper-

age.

Set the timer to the charging

time determined by the open-

circuit voltage.

Refer to “BATTERY

INSPECTION AND CHARG-

ING” section.Adjust the charging voltage to

20 ~ 25 V.

Monitor the amperage for 3 ~

5 minutes. Is the standard

charging amperage exceeded?

NO YES

If the amperage does not

exceed the standard charg-

ing amperage after 5 minutes,

replace the battery.

If the required charging time exceeds 5 hours, it is advisable to check

the charging amperage after 5 hours. If there is any change in the

amperage, readjust the voltage to obtain the standard charging amper-

age.

Leave the battery unused for more than 30 minutes before measuring

its open-circuit voltage.

12.8 V

→ Charging is complete.

12.0 ~ 12.7 V

→ Recharging is required.

Under 12.0 V

→ Replace the battery.

Leave the battery unused for

more than 30 minutes before

measuring its open-circuit voltage.

Set the charging voltage to 16-

17 V. (If the charging voltage is

lower, charging will be insuffi-

cient, if it is higher, the battery will

be over-charged.) NOTE:

NOTE:

Measure the open-circuit

voltage prior to charging.

Page 305 of 786

3 - 55

INSP

ADJ

BATTERY INSPECTION AND CHARGING

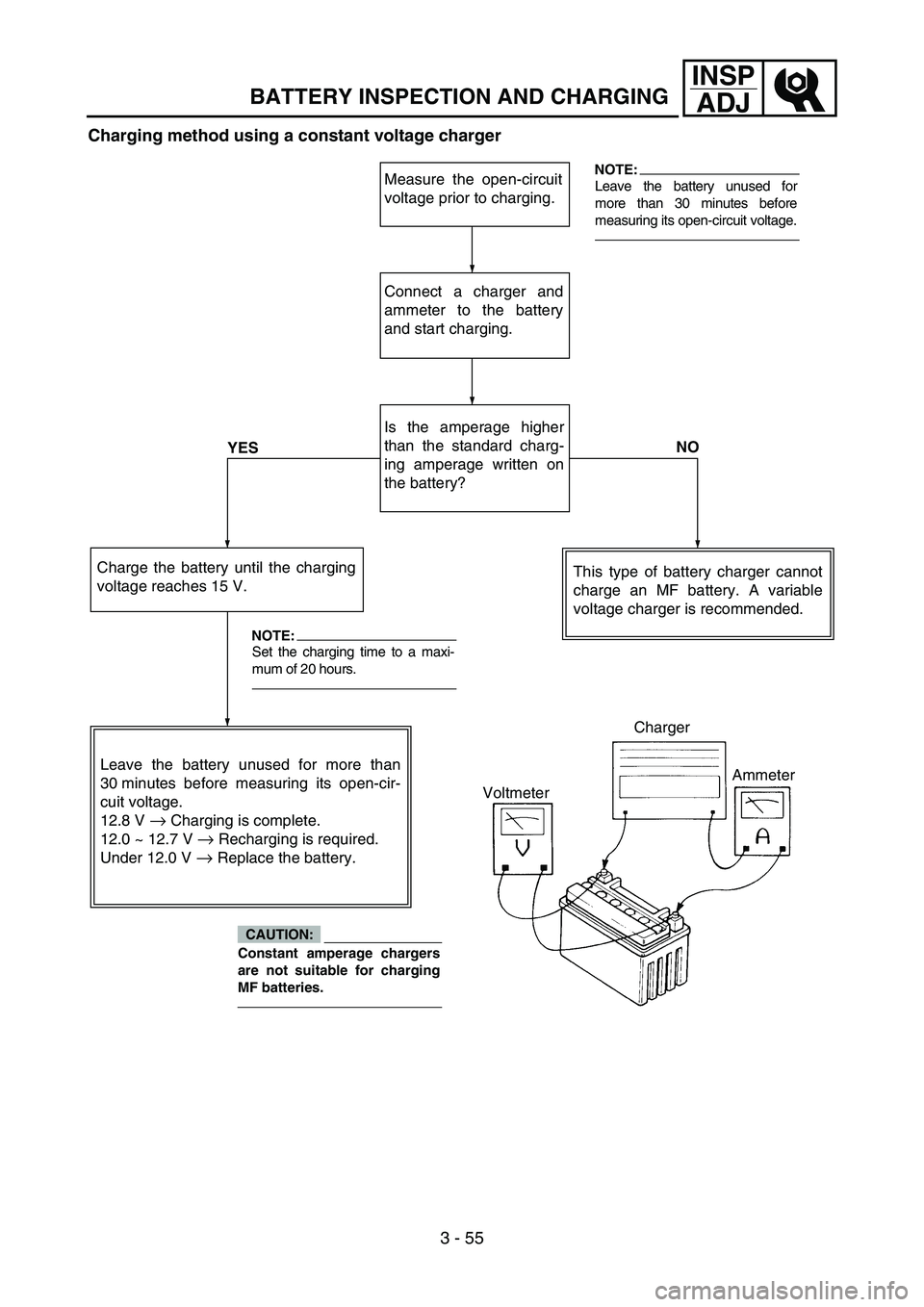

Charging method using a constant voltage charger

Measure the open-circuit

voltage prior to charging.

Connect a charger and

ammeter to the battery

and start charging.

NO

YESIs the amperage higher

than the standard charg-

ing amperage written on

the battery?

Charge the battery until the charging

voltage reaches 15 V.

Leave the battery unused for more than

30 minutes before measuring its open-cir-

cuit voltage.

12.8 V

→ Charging is complete.

12.0 ~ 12.7 V

→ Recharging is required.

Under 12.0 V

→ Replace the battery.This type of battery charger cannot

charge an MF battery. A variable

voltage charger is recommended.

Leave the battery unused for

more than 30 minutes before

measuring its open-circuit voltage. NOTE:

Set the charging time to a maxi-

mum of 20 hours. NOTE:

Constant amperage chargers

are not suitable for charging

MF batteries.

CAUTION:

Charger

Ammeter

Voltmeter

Page 312 of 786

3 - 56

INSP

ADJ

FUSE INSPECTION

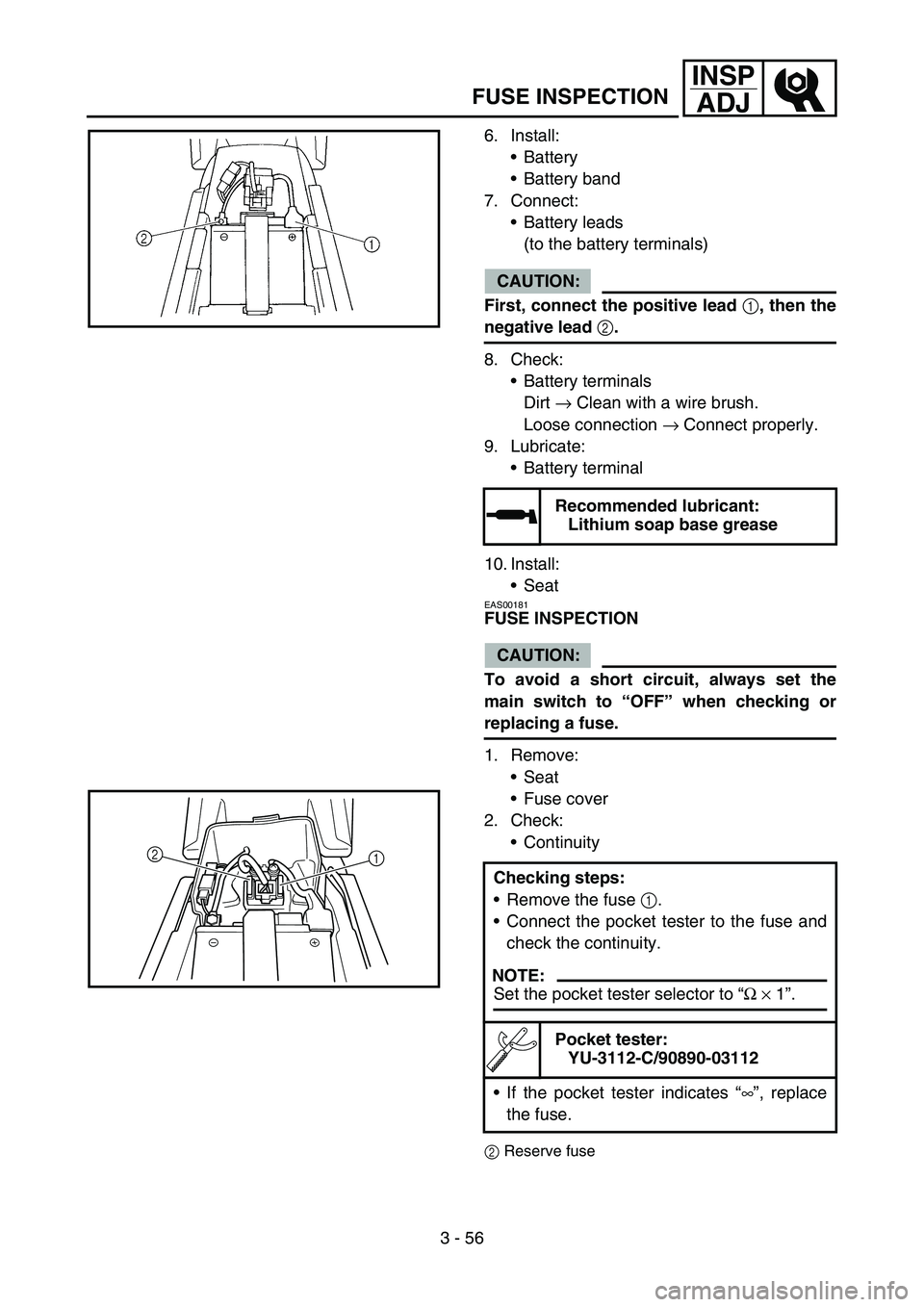

6. Install:

Battery

Battery band

7. Connect:

Battery leads

(to the battery terminals)

CAUTION:

First, connect the positive lead

1, then the

negative lead

2.

8. Check:

Battery terminals

Dirt → Clean with a wire brush.

Loose connection → Connect properly.

9. Lubricate:

Battery terminal

10. Install:

Seat

EAS00181

FUSE INSPECTION

CAUTION:

To avoid a short circuit, always set the

main switch to “OFF” when checking or

replacing a fuse.

1. Remove:

Seat

Fuse cover

2. Check:

Continuity

2Reserve fuse

Recommended lubricant:

Lithium soap base grease

Checking steps:

Remove the fuse 1.

Connect the pocket tester to the fuse and

check the continuity.

NOTE:

Set the pocket tester selector to “Ω × 1”.

Pocket tester:

YU-3112-C/90890-03112

If the pocket tester indicates “∞”, replace

the fuse.

2

1

Page 490 of 786

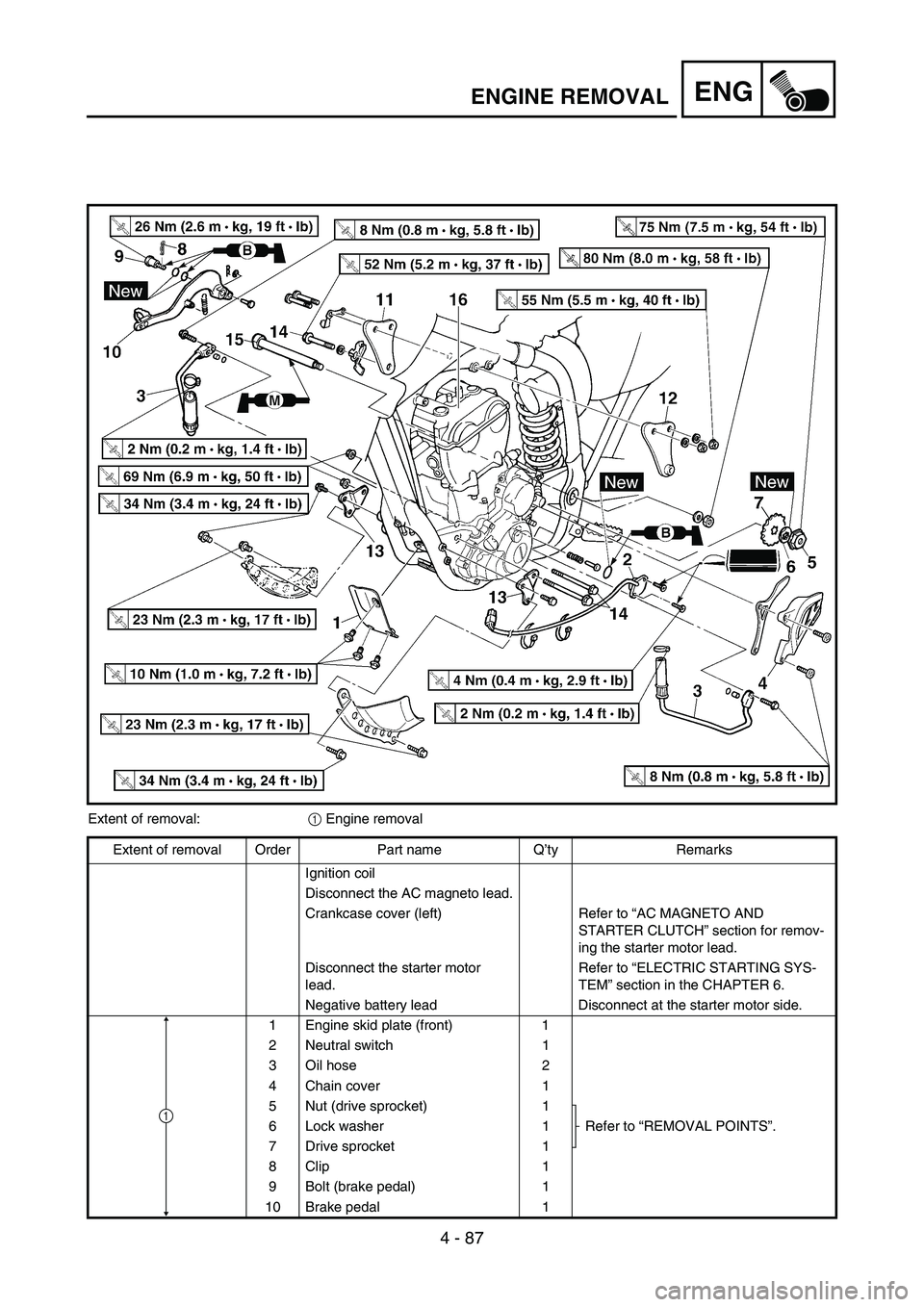

4 - 87

ENGENGINE REMOVAL

Extent of removal:

1 Engine removal

Extent of removal Order Part name Q’ty Remarks

Ignition coil

Disconnect the AC magneto lead.

Crankcase cover (left) Refer to “AC MAGNETO AND

STARTER CLUTCH” section for remov-

ing the starter motor lead.

Disconnect the starter motor

lead.Refer to “ELECTRIC STARTING SYS-

TEM” section in the CHAPTER 6.

Negative battery lead Disconnect at the starter motor side.

1 Engine skid plate (front) 1

2 Neutral switch 1

3 Oil hose 2

4 Chain cover 1

5 Nut (drive sprocket) 1

Refer to “REMOVAL POINTS”. 6 Lock washer 1

7 Drive sprocket 1

8Clip 1

9 Bolt (brake pedal) 1

10 Brake pedal 1

1

Page 650 of 786

5 - 62

CHASREAR SHOCK ABSORBER

Extent of removal Order Part name Q’ty Remarks

Cylinder head breather hose Disconnect at the air filter case side.

Battery Refer to “BATTERY INSPECTION AND

CHARGING” section in the CHAPTER 3.

Disconnect the starter relay cou-

pler.

Starter motor lead Disconnect at the starter relay side.

1 Locking tie 3

2 Taillight coupler 1

3 Starting circuit cut-off relay cou-

pler1

4 Plastic band 2

5 Clamp (air filter joint) 1 Only loosening.

6Rear frame 1

7 Bolt (rear shock absorber-relay

arm)1 Hold the swingarm.

8 Bolt (rear shock absorber-frame) 1

21

Page 666 of 786

6 - 1

–+ELECELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC600000

ELECTRICAL

EC610000

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC611000

ELECTRICAL COMPONENTS

1Headlight

2Multi-function display

3“ENGINE STOP” but-

ton

4Clutch switch

5Diode

6Starter relay diode

7TPS (throttle posi-

tion sensor)

8Starter relay

9Fuse

0Starting circuit cut-off

relayATaillight

BNeutral switch

CStarter motor

DAC magneto

ERectifier/regulator

FIgnition coil

GSpark plug

HStart switch

IMain switch

JCDI unit

KSpeed sensor

LBatteryCOLOR CODE

B ...................... Black

Br ..................... Brown

Ch .................... Chocolate

Dg .................... Dark green

Gy .................... Gray

L....................... Blue

O ...................... Orange

R ...................... Red

Sb .................... Sky blue

W ..................... White

EC612000

WIRING DIAGRAM

FGH

I

J

K

L

1 234

56

789

0A

B C

D E

B/L

W

W

R

BR/BBr

R

BR/BBr

R

Y

Y

L/R/BBB

SbL/W

L/YBBB

WY

RY

R

LY

B

YLB/L

B

B

ON

OFF

10A

BB

OFF

START

R-BrL/W

B

BrL/W

BrL/W

L/B

-Y

Y

B

LY

B

L/WSb

B/WBBB

W/R/W

R/

BGyBrL/W

ON

STOP

O

LSbB/L

W RBrB/W

L

/

BGyWR

/B

B O

L/YSbL/R

R W

Y W

Y W

Y

L B

B

B

RRR/B

B Br B

B B B B

L/W

R

R

R R B

R

BrBr

L/W L/

W

Br B

L/B

L/B

L/R

Br

R/B

L/B L

/W

B/W

WW

/RW

RO

L

Y

ELO

B

L

Y

B/LSb*1

Sb

*2B/W

B

B

L/R L/Y L/Y

B

SbSbL/W

B

Gy

SbBB/LYO

L

*2

O B

L YL/W

B/L

*1

D

E

CI

6

H4 5

B3J

K

2FG

7

8L9

1A

*2

*1

W

B

R/W

Ch

Dg

Y

B BrRW

WRB/W

SIGNAL

+

Backup

SLCT1

SLCT2

RST

GND

BrR/WB

B

R/WBr

WRB/W

R B

W

ChDgYB

B/WWRB/WWR

0

R

W

W W

L/WB/L

Y B

RB

B

L

L

*1: For USA

*2: Except for USA

Y ...................... Yellow

B/L ................... Black/Blue

B/W .................. Black/White

L/B ................... Blue/Black

L/R ................... Blue/Red

L/Y ................... Blue/Yellow

L/W .................. Blue/White

R/B................... Red/Black

R/W.................. Red/White

Page 672 of 786

–+ELEC

6 - 3

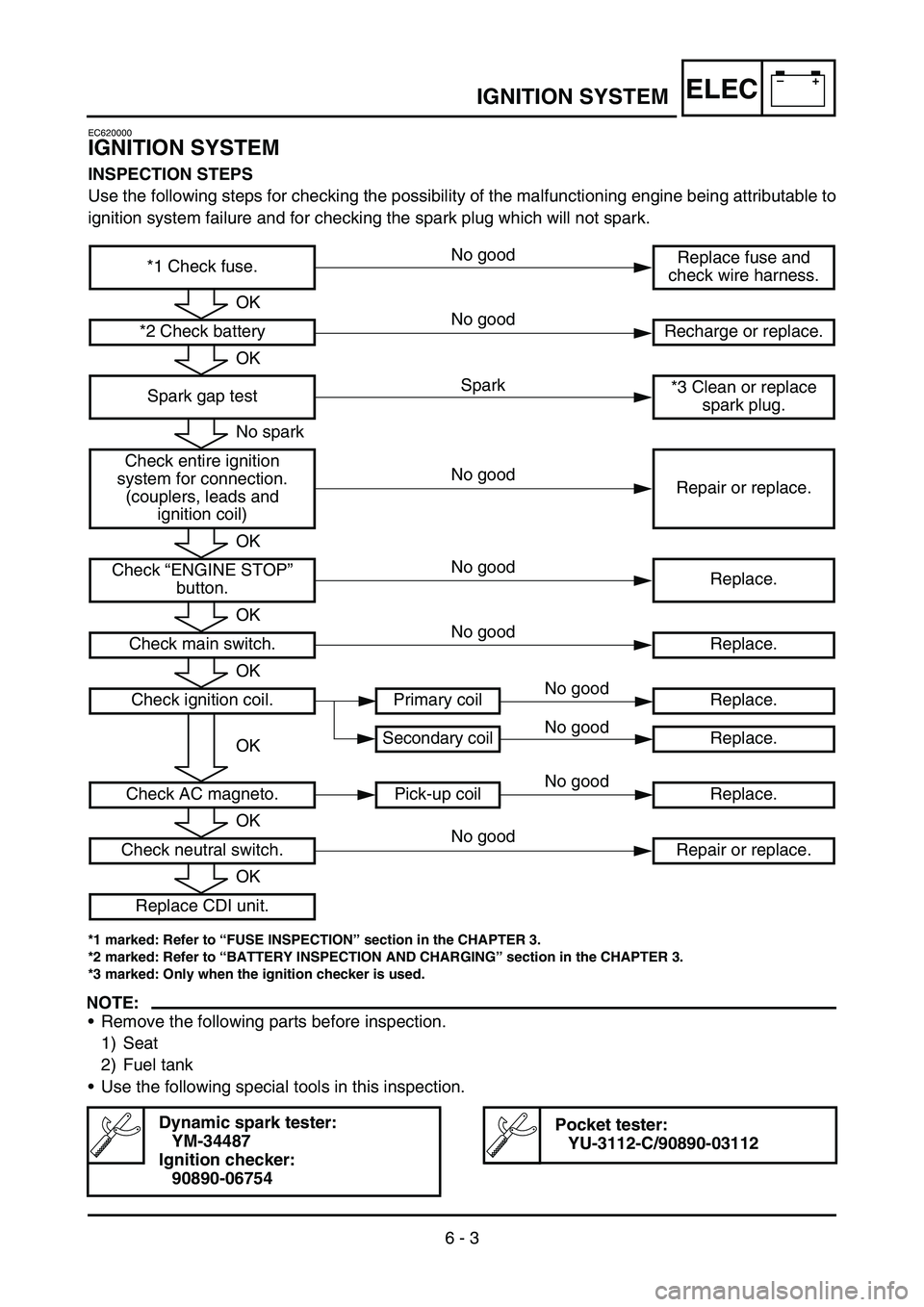

IGNITION SYSTEM

EC620000

IGNITION SYSTEM

INSPECTION STEPS

Use the following steps for checking the possibility of the malfunctioning engine being attributable to

ignition system failure and for checking the spark plug which will not spark.

*1 marked: Refer to “FUSE INSPECTION” section in the CHAPTER 3.

*2 marked: Refer to “BATTERY INSPECTION AND CHARGING” section in the CHAPTER 3.

*3 marked: Only when the ignition checker is used.

NOTE:

•Remove the following parts before inspection.

1) Seat

2) Fuel tank

•Use the following special tools in this inspection.

Dynamic spark tester:

YM-34487

Ignition checker:

90890-06754Pocket tester:

YU-3112-C/90890-03112

*1 Check fuse.Replace fuse and

check wire harness.

*2 Check battery Recharge or replace.

Spark gap test*3 Clean or replace

spark plug.

Check entire ignition

system for connection.

(couplers, leads and

ignition coil)Repair or replace.

Check “ENGINE STOP”

button.Replace.

Check main switch. Replace.

Check ignition coil. Primary coil Replace.

Secondary coil Replace.

Check AC magneto. Pick-up coil Replace.

Check neutral switch. Repair or replace.

Replace CDI unit.

OK

OK

No spark

OK

OK

OK

OK

OK

OK

Spark No good

No good

No good

No good

No good No good

No good

No good

No good

Page 678 of 786

6 - 5

–+ELECIGNITION SYSTEM

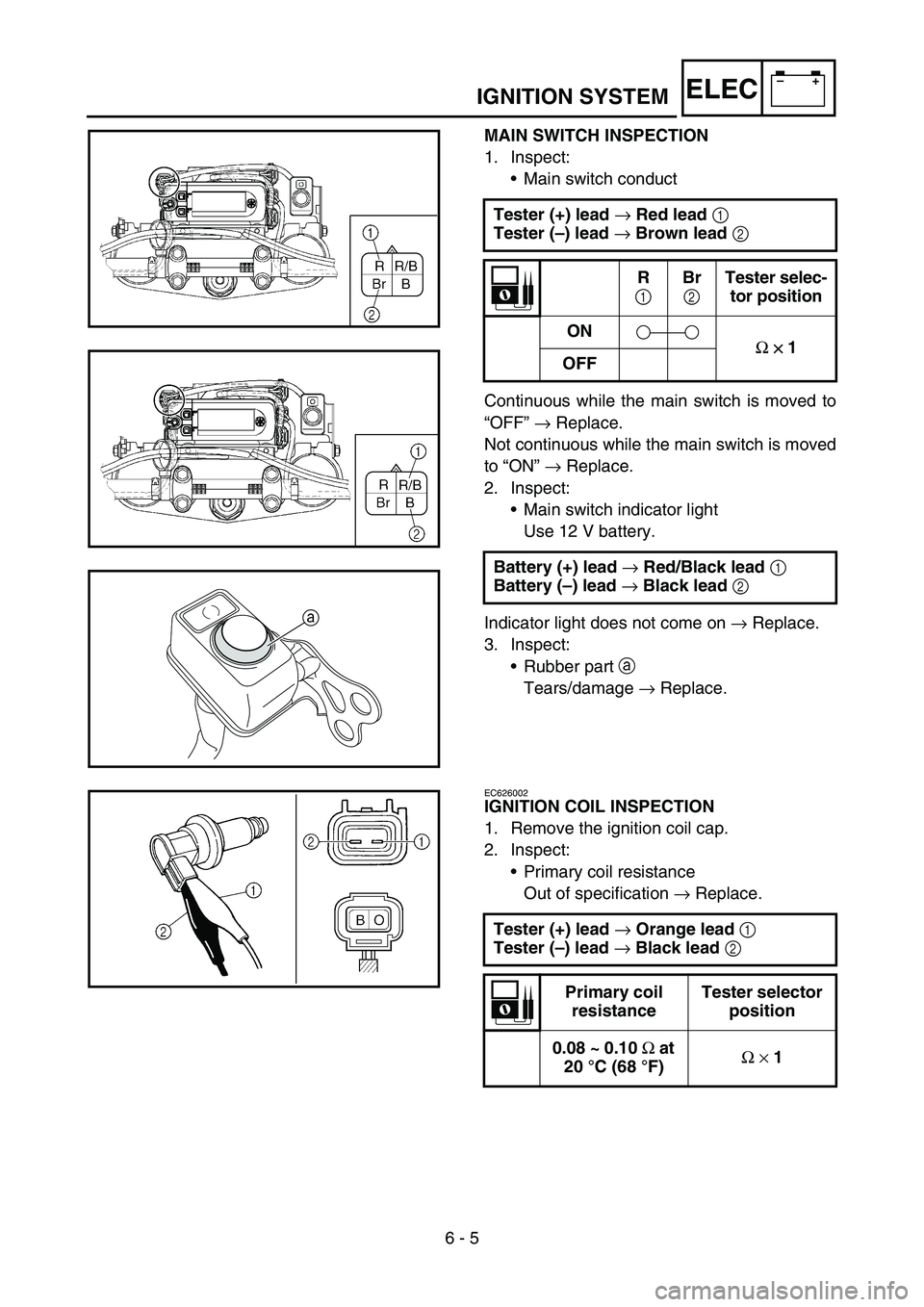

MAIN SWITCH INSPECTION

1. Inspect:

•Main switch conduct

Continuous while the main switch is moved to

“OFF” → Replace.

Not continuous while the main switch is moved

to “ON” → Replace.

2. Inspect:

•Main switch indicator light

Use 12 V battery.

Indicator light does not come on → Replace.

3. Inspect:

•Rubber part a

Tears/damage → Replace. Tester (+) lead

→ Red lead

1

Tester (–) lead

→ Brown lead

2

R

1 Br

2 Tester selec-

tor position

ON

Ω

×

×× × 1

OFF

Battery (+) lead

→ Red/Black lead

1

Battery (–) lead

→ Black lead

2

a

EC626002

IGNITION COIL INSPECTION

1. Remove the ignition coil cap.

2. Inspect:

•Primary coil resistance

Out of specification → Replace.

Tester (+) lead

→ Orange lead

1

Tester (–) lead

→ Black lead

2

Primary coil

resistanceTester selector

position

0.08 ~ 0.10

Ω at

20 °C (68 °F)Ω

× 1