warning YAMAHA WR 450F 2006 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: WR 450F, Model: YAMAHA WR 450F 2006Pages: 786, PDF Size: 22.49 MB

Page 222 of 786

3 - 14

INSP

ADJ

ENGINE OIL LEVEL INSPECTION

ENGINE OIL LEVEL INSPECTION

1. Stand the machine on a level surface.

NOTE:

When checking the oil level make sure that

the machine is upright.

Place the machine on a suitable stand.

WARNING

Never remove the oil tank cap just after

high speed operation. The heated oil could

spurt out. causing danger. Wait until the oil

cools down to approximately 70 °C (158 °F).

2. Idle the engine more than 3 minutes while

keeping the machine upright. Then stop the

engine and inspect the oil level.

3. Remove:

Oil tank cap 1

1

4. Inspect:

Oil level

Oil level should be between maximum a

and minimum b marks.

Oil level low → Add oil to proper level.

NOTE:

When inspecting the oil level, do not screw the

oil level gauge into the oil tank.

Insert the gauge lightly.

a

b

Page 244 of 786

3 - 24

INSP

ADJ

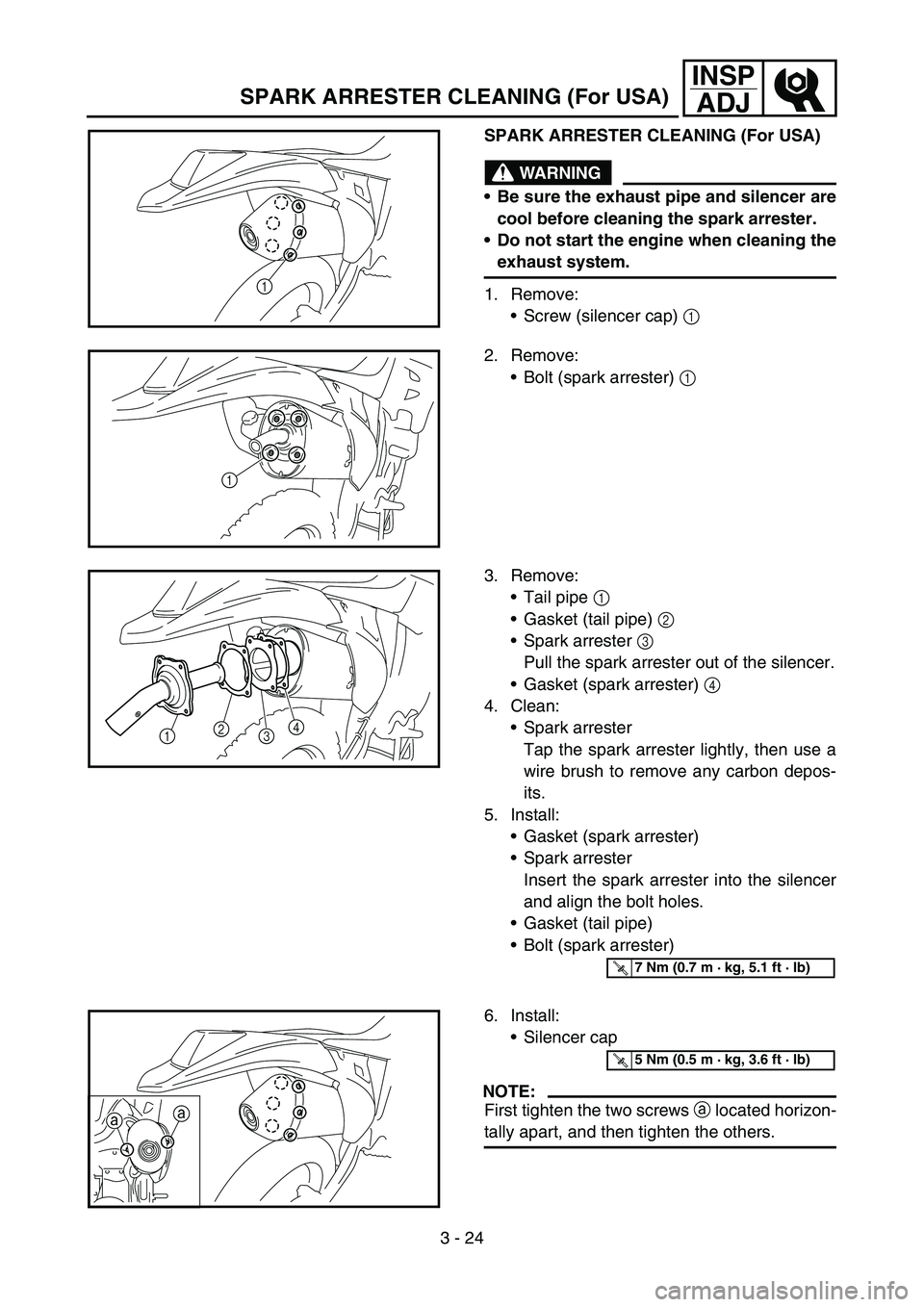

SPARK ARRESTER CLEANING (For USA)

WARNING

Be sure the exhaust pipe and silencer are

cool before cleaning the spark arrester.

Do not start the engine when cleaning the

exhaust system.

1. Remove:

Screw (silencer cap) 1

1

2. Remove:

Bolt (spark arrester) 1

1

3. Remove:

Tail pipe 1

Gasket (tail pipe) 2

Spark arrester 3

Pull the spark arrester out of the silencer.

Gasket (spark arrester) 4

4. Clean:

Spark arrester

Tap the spark arrester lightly, then use a

wire brush to remove any carbon depos-

its.

5. Install:

Gasket (spark arrester)

Spark arrester

Insert the spark arrester into the silencer

and align the bolt holes.

Gasket (tail pipe)

Bolt (spark arrester)

12

34

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

6. Install:

Silencer cap

NOTE:

First tighten the two screws a located horizon-

tally apart, and then tighten the others.aa

T R..5 Nm (0.5 m · kg, 3.6 ft · lb)

SPARK ARRESTER CLEANING (For USA)

Page 246 of 786

3 - 25

INSP

ADJ

CHASSIS/BRAKE SYSTEM AIR BLEEDING

EC360000

CHASSIS

EC361012

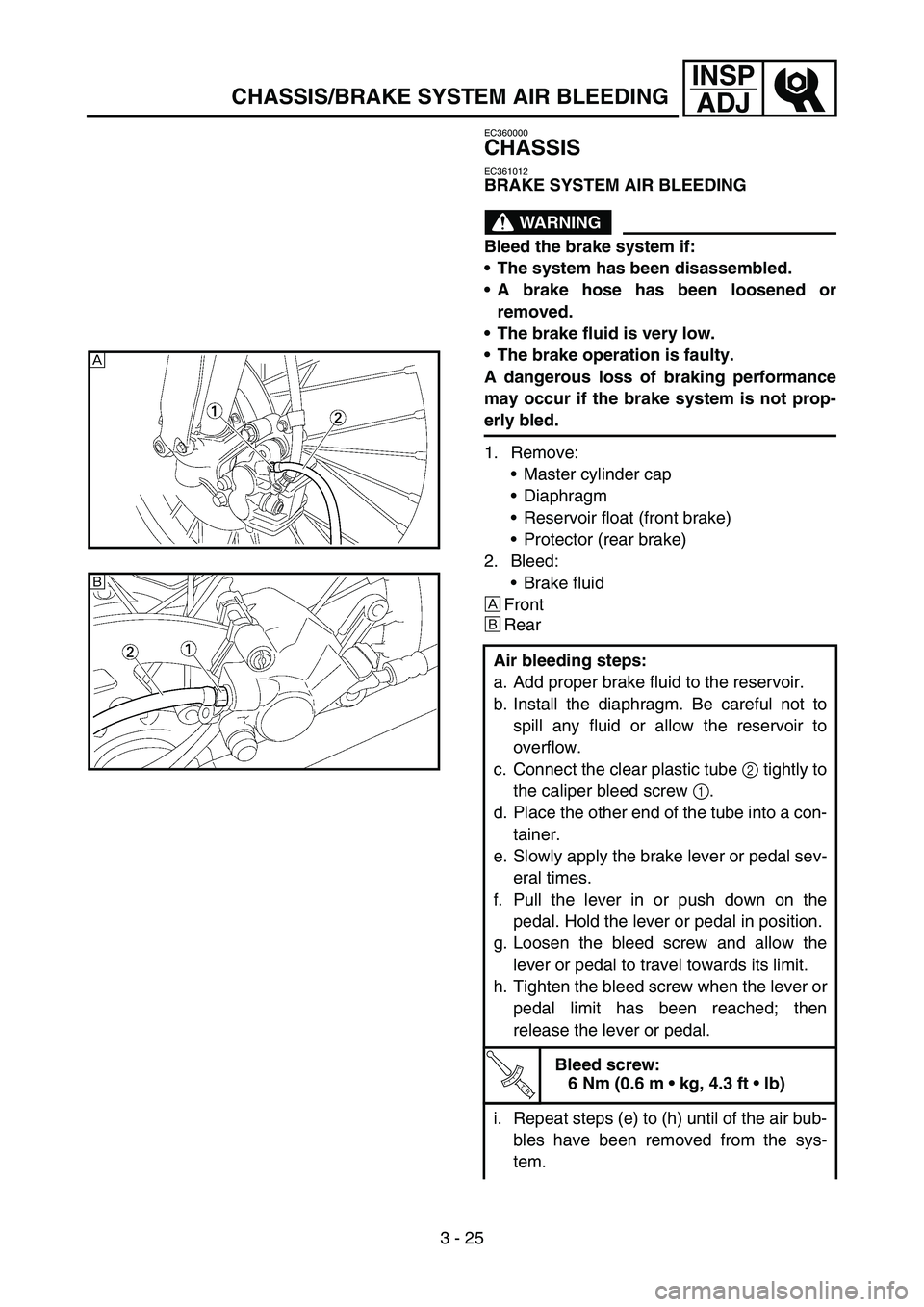

BRAKE SYSTEM AIR BLEEDING

WARNING

Bleed the brake system if:

The system has been disassembled.

A brake hose has been loosened or

removed.

The brake fluid is very low.

The brake operation is faulty.

A dangerous loss of braking performance

may occur if the brake system is not prop-

erly bled.

1. Remove:

Master cylinder cap

Diaphragm

Reservoir float (front brake)

Protector (rear brake)

2. Bleed:

Brake fluid

ÈFront

ÉRear

Air bleeding steps:

a. Add proper brake fluid to the reservoir.

b. Install the diaphragm. Be careful not to

spill any fluid or allow the reservoir to

overflow.

c. Connect the clear plastic tube 2 tightly to

the caliper bleed screw 1.

d. Place the other end of the tube into a con-

tainer.

e. Slowly apply the brake lever or pedal sev-

eral times.

f. Pull the lever in or push down on the

pedal. Hold the lever or pedal in position.

g. Loosen the bleed screw and allow the

lever or pedal to travel towards its limit.

h. Tighten the bleed screw when the lever or

pedal limit has been reached; then

release the lever or pedal.

T R..

Bleed screw:

6 Nm (0.6 m kg, 4.3 ft lb)

i. Repeat steps (e) to (h) until of the air bub-

bles have been removed from the sys-

tem.

È

É

Page 248 of 786

3 - 26

INSP

ADJ

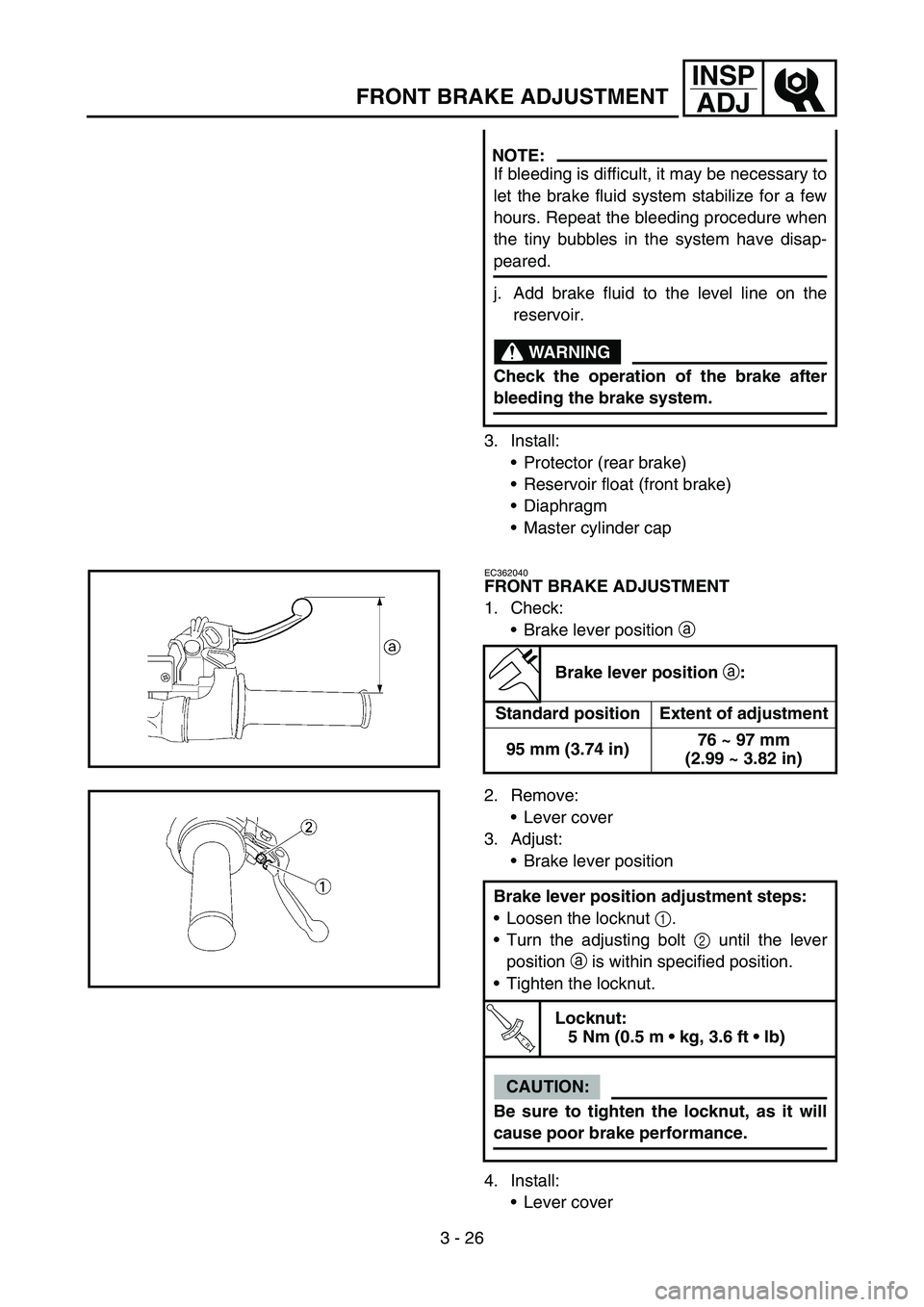

FRONT BRAKE ADJUSTMENT

3. Install:

Protector (rear brake)

Reservoir float (front brake)

Diaphragm

Master cylinder cap

NOTE:

If bleeding is difficult, it may be necessary to

let the brake fluid system stabilize for a few

hours. Repeat the bleeding procedure when

the tiny bubbles in the system have disap-

peared.

j. Add brake fluid to the level line on the

reservoir.

WARNING

Check the operation of the brake after

bleeding the brake system.

EC362040

FRONT BRAKE ADJUSTMENT

1. Check:

Brake lever position a

Brake lever position

a:

Standard position Extent of adjustment

95 mm (3.74 in)76 ~ 97 mm

(2.99 ~ 3.82 in)

2. Remove:

Lever cover

3. Adjust:

Brake lever position

4. Install:

Lever cover Brake lever position adjustment steps:

Loosen the locknut 1.

Turn the adjusting bolt 2 until the lever

position a is within specified position.

Tighten the locknut.

T R..

Locknut:

5 Nm (0.5 m kg, 3.6 ft lb)

CAUTION:

Be sure to tighten the locknut, as it will

cause poor brake performance.

Page 250 of 786

3 - 27

INSP

ADJREAR BRAKE ADJUSTMENT/

FRONT BRAKE PAD INSPECTION AND REPLACEMENT

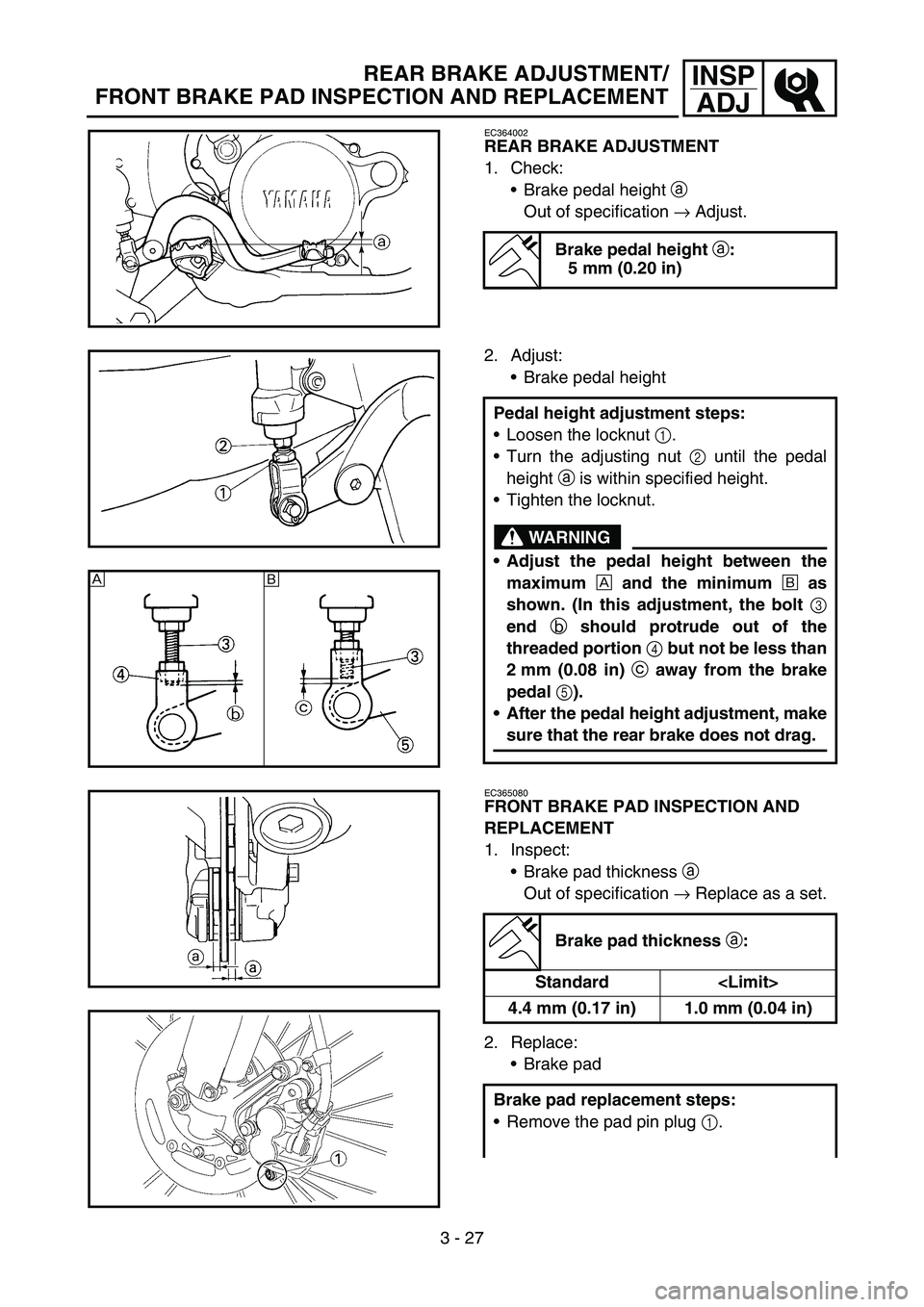

EC364002

REAR BRAKE ADJUSTMENT

1. Check:

Brake pedal height a

Out of specification → Adjust.

Brake pedal height

a:

5 mm (0.20 in)

2. Adjust:

Brake pedal height

Pedal height adjustment steps:

Loosen the locknut 1.

Turn the adjusting nut 2 until the pedal

height a is within specified height.

Tighten the locknut.

WARNING

Adjust the pedal height between the

maximum

È and the minimum

É as

shown. (In this adjustment, the bolt

3

end

b should protrude out of the

threaded portion

4 but not be less than

2 mm (0.08 in)

c away from the brake

pedal

5).

After the pedal height adjustment, make

sure that the rear brake does not drag.

È

É

EC365080

FRONT BRAKE PAD INSPECTION AND

REPLACEMENT

1. Inspect:

Brake pad thickness a

Out of specification → Replace as a set.

2. Replace:

Brake pad

Brake pad thickness

a:

Standard

4.4 mm (0.17 in) 1.0 mm (0.04 in)

Brake pad replacement steps:

Remove the pad pin plug 1.

Page 258 of 786

3 - 31

INSP

ADJREAR BRAKE PAD INSULATOR INSPECTION/

BRAKE FLUID LEVEL INSPECTION

3. Inspect:

Brake fluid level

Refer to “BRAKE FLUID LEVEL INSPEC-

TION” section.

4. Check:

Brake pedal operation

A softy or spongy feeling → Bleed brake

system.

Refer to “BRAKE SYSTEM AIR BLEED-

ING” section.

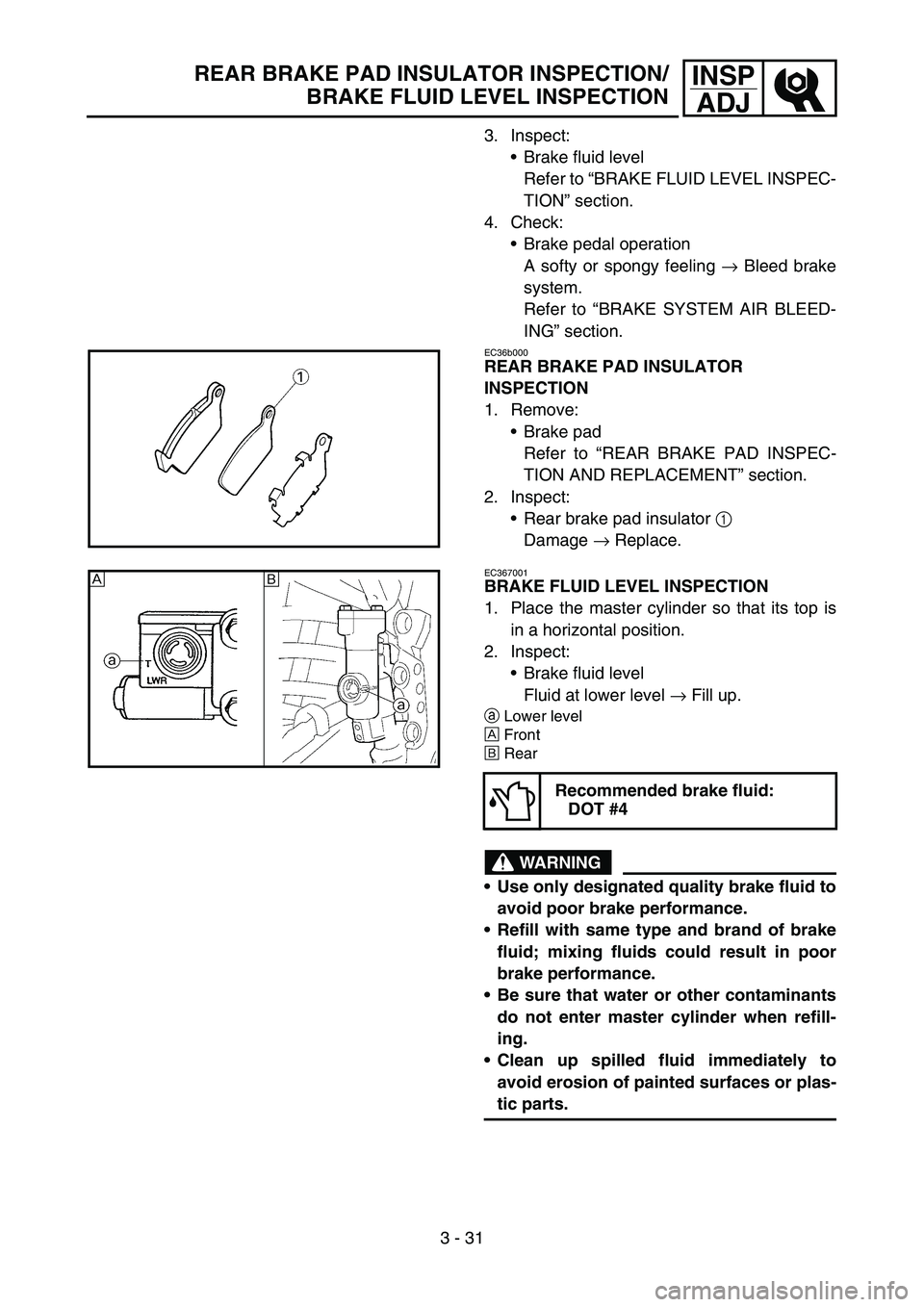

EC36b000

REAR BRAKE PAD INSULATOR

INSPECTION

1. Remove:

Brake pad

Refer to “REAR BRAKE PAD INSPEC-

TION AND REPLACEMENT” section.

2. Inspect:

Rear brake pad insulator 1

Damage → Replace.

EC367001

BRAKE FLUID LEVEL INSPECTION

1. Place the master cylinder so that its top is

in a horizontal position.

2. Inspect:

Brake fluid level

Fluid at lower level → Fill up.

aLower level

ÈFront

ÉRear

WARNING

Use only designated quality brake fluid to

avoid poor brake performance.

Refill with same type and brand of brake

fluid; mixing fluids could result in poor

brake performance.

Be sure that water or other contaminants

do not enter master cylinder when refill-

ing.

Clean up spilled fluid immediately to

avoid erosion of painted surfaces or plas-

tic parts.

Recommended brake fluid:

DOT #4

ÈÉ

Page 270 of 786

3 - 37

INSP

ADJFRONT FORK COMPRESSION DAMPING FORCE

ADJUSTMENT

STANDARD POSITION:

This is the position which is back by the spe-

cific number of clicks from the fully turned-in

position.

* For EUROPE

** For AUS, NZ and ZA

CAUTION:

Do not force the adjuster past the minimum

or maximum extent of adjustment. The

adjuster may be damaged.

WARNING

Always adjust each front fork to the same

setting. Uneven adjustment can cause poor

handling and loss of stability.

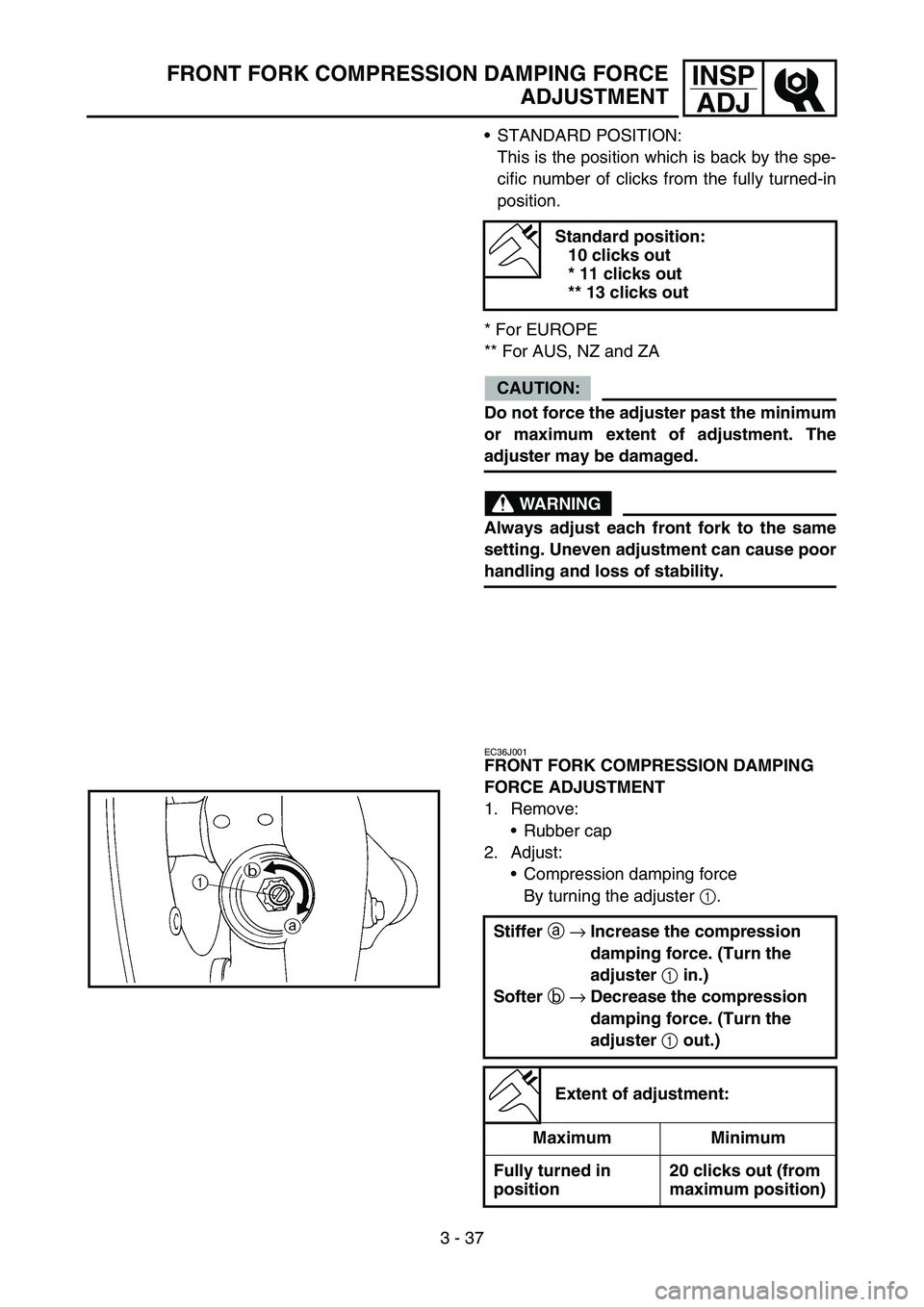

EC36J001

FRONT FORK COMPRESSION DAMPING

FORCE ADJUSTMENT

1. Remove:

Rubber cap

2. Adjust:

Compression damping force

By turning the adjuster 1.

Standard position:

10 clicks out

* 11 clicks out

** 13 clicks out

Stiffer

a

→Increase the compression

damping force. (Turn the

adjuster

1 in.)

Softer

b

→Decrease the compression

damping force. (Turn the

adjuster

1 out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position20 clicks out (from

maximum position)

Page 272 of 786

3 - 38

INSP

ADJ

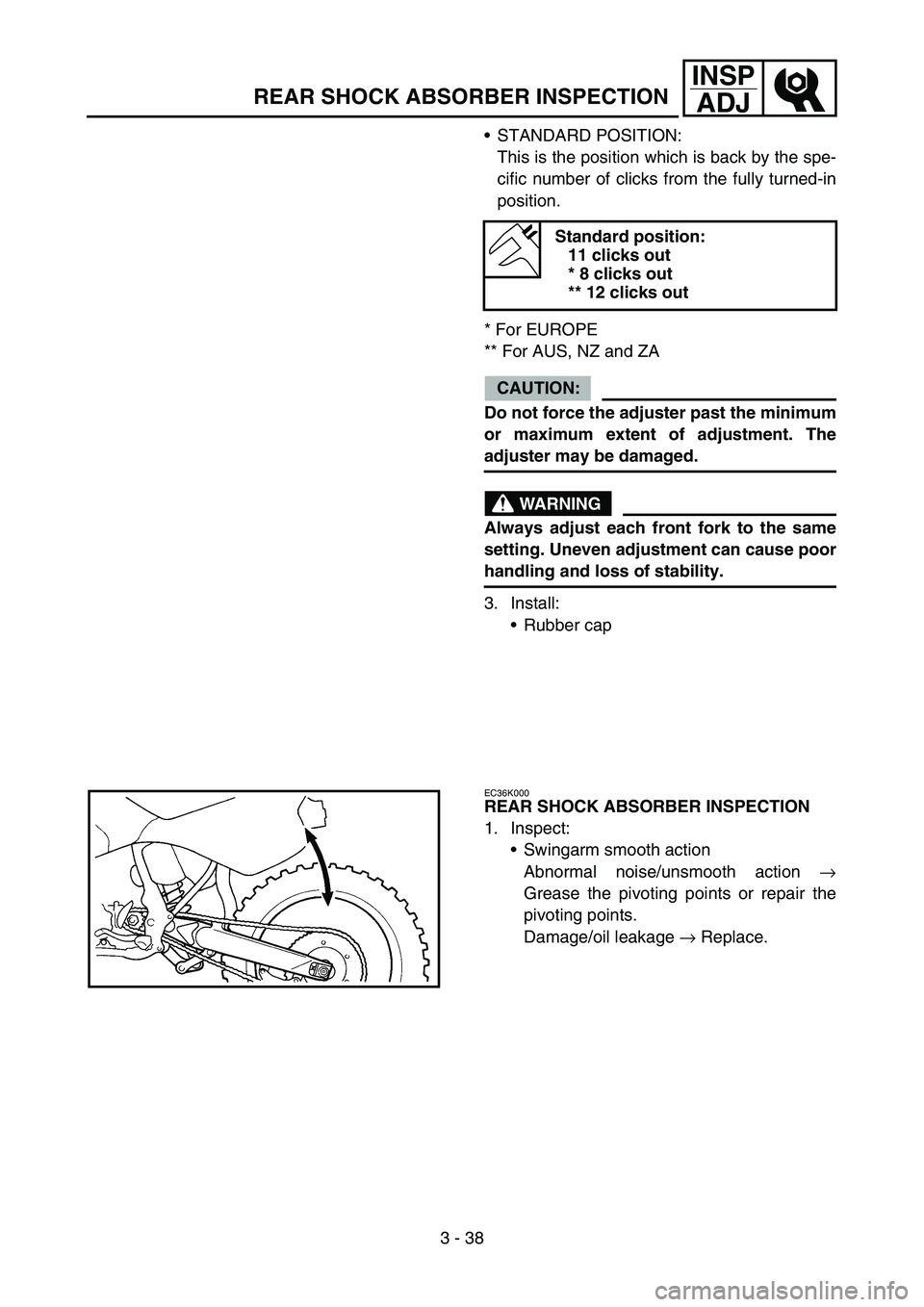

REAR SHOCK ABSORBER INSPECTION

STANDARD POSITION:

This is the position which is back by the spe-

cific number of clicks from the fully turned-in

position.

* For EUROPE

** For AUS, NZ and ZA

CAUTION:

Do not force the adjuster past the minimum

or maximum extent of adjustment. The

adjuster may be damaged.

WARNING

Always adjust each front fork to the same

setting. Uneven adjustment can cause poor

handling and loss of stability.

3. Install:

Rubber cap

Standard position:

11 clicks out

* 8 clicks out

** 12 clicks out

EC36K000

REAR SHOCK ABSORBER INSPECTION

1. Inspect:

Swingarm smooth action

Abnormal noise/unsmooth action →

Grease the pivoting points or repair the

pivoting points.

Damage/oil leakage → Replace.

Page 286 of 786

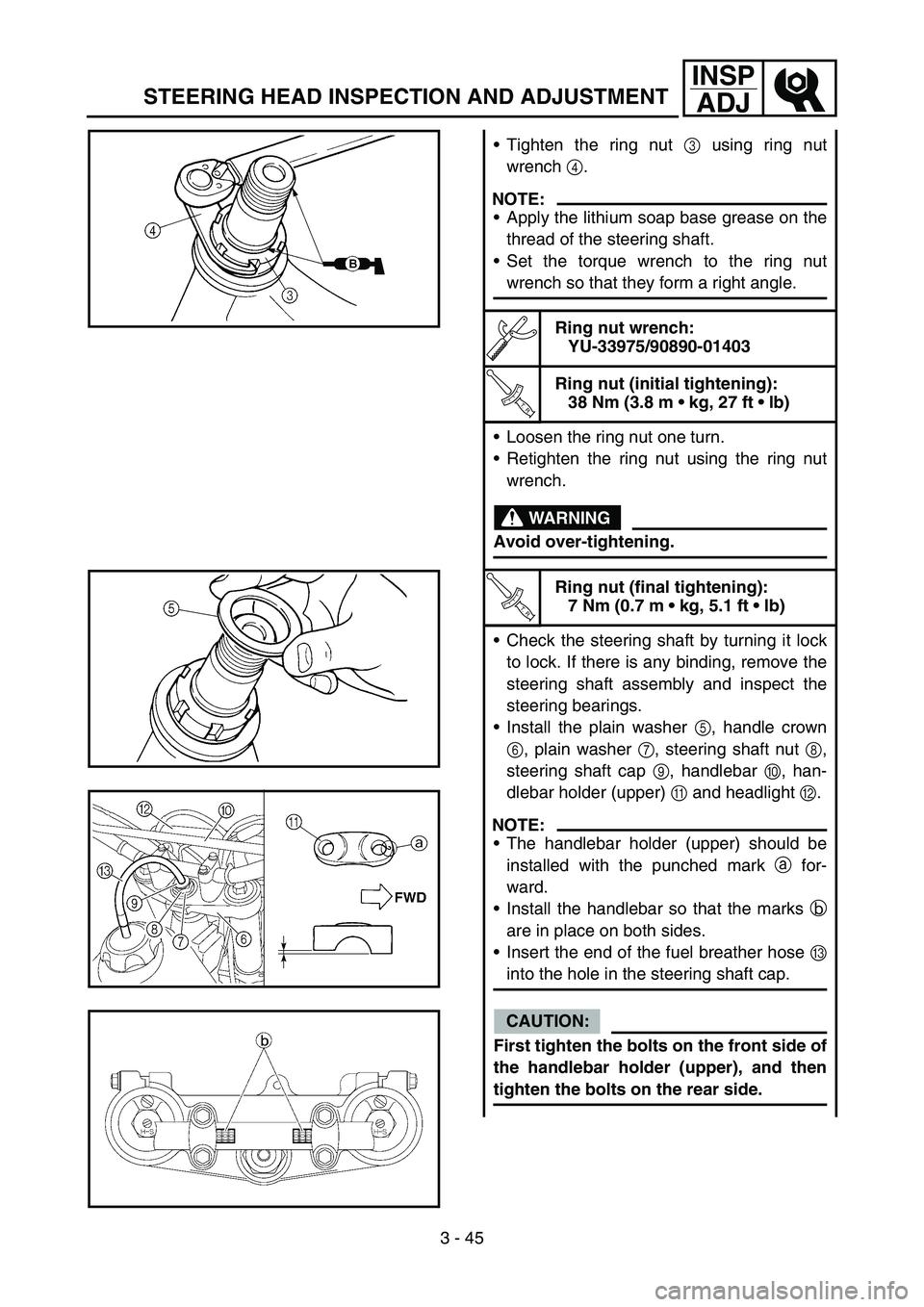

3 - 45

INSP

ADJ

STEERING HEAD INSPECTION AND ADJUSTMENT

Tighten the ring nut 3 using ring nut

wrench 4.

NOTE:

Apply the lithium soap base grease on the

thread of the steering shaft.

Set the torque wrench to the ring nut

wrench so that they form a right angle.

Ring nut wrench:

YU-33975/90890-01403

T R..

Ring nut (initial tightening):

38 Nm (3.8 m kg, 27 ft lb)

Loosen the ring nut one turn.

Retighten the ring nut using the ring nut

wrench.

WARNING

Avoid over-tightening.

T R..

Ring nut (final tightening):

7 Nm (0.7 m kg, 5.1 ft lb)

Check the steering shaft by turning it lock

to lock. If there is any binding, remove the

steering shaft assembly and inspect the

steering bearings.

Install the plain washer 5, handle crown

6, plain washer 7, steering shaft nut 8,

steering shaft cap 9, handlebar 0, han-

dlebar holder (upper) A and headlight B.

NOTE:

The handlebar holder (upper) should be

installed with the punched mark a for-

ward.

Install the handlebar so that the marks b

are in place on both sides.

Insert the end of the fuel breather hose C

into the hole in the steering shaft cap.

CAUTION:

First tighten the bolts on the front side of

the handlebar holder (upper), and then

tighten the bolts on the rear side.

Page 296 of 786

3 - 50

INSP

ADJ

BATTERY INSPECTION AND CHARGING

WARNING

Batteries generate explosive hydrogen gas

and contain electrolyte which is made of

poisonous and highly caustic sulfuric acid.

Therefore, always follow these preventive

measures:

Wear protective eye gear when handling

or working near batteries.

Charge batteries in a well-ventilated area.

Keep batteries away from fire, sparks or

open flames (e.g., welding equipment,

lighted cigarettes).

DO NOT SMOKE when charging or han-

dling batteries.

KEEP BATTERIES AND ELECTROLYTE

OUT OF REACH OF CHILDREN.

Avoid bodily contact with electrolyte as it

can cause severe burns or permanent eye

injury.

FIRST AID IN CASE OF BODILY CONTACT:

EXTERNAL

Skin — Wash with water.

Eyes — Flush with water for 15 minutes

and get immediate medical attention.

INTERNAL

Drink large quantities of water or milk fol-

lowed with milk of magnesia, beaten egg

or vegetable oil. Get immediate medical

attention.

CAUTION:

Charging time, charging amperage and

charging voltage for an MF battery are dif-

ferent from those of conventional batteries.

The MF battery should be charged as

explained in the charging method illustra-

tions. If the battery is overcharged, the

electrolyte level will drop considerably.

Therefore, take special care when charging

the battery.

BATTERY INSPECTION AND CHARGING