ignition YAMAHA WR 450F 2006 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: WR 450F, Model: YAMAHA WR 450F 2006Pages: 786, PDF Size: 22.49 MB

Page 24 of 786

CHAPTER 6

ELECTRICAL

ELECTRICAL COMPONENTS

AND WIRING DIAGRAM ...........................6-1

MAP-CONTROLLED CDI UNIT .................6-2

IGNITION SYSTEM ....................................6-3

ELECTRIC STARTING SYSTEM ..............6-7

CHARGING SYSTEM ..............................6-17

TPS (THROTTLE POSITION SENSOR)

SYSTEM ...................................................6-19

LIGHTING SYSTEM ................................6-24

SIGNALING SYSTEM ..............................6-26

CHAPTER 7

TUNING

ENGINE ......................................................7-1

CHASSIS ...................................................7-9

Page 39 of 786

GEN

INFO

1 - 8

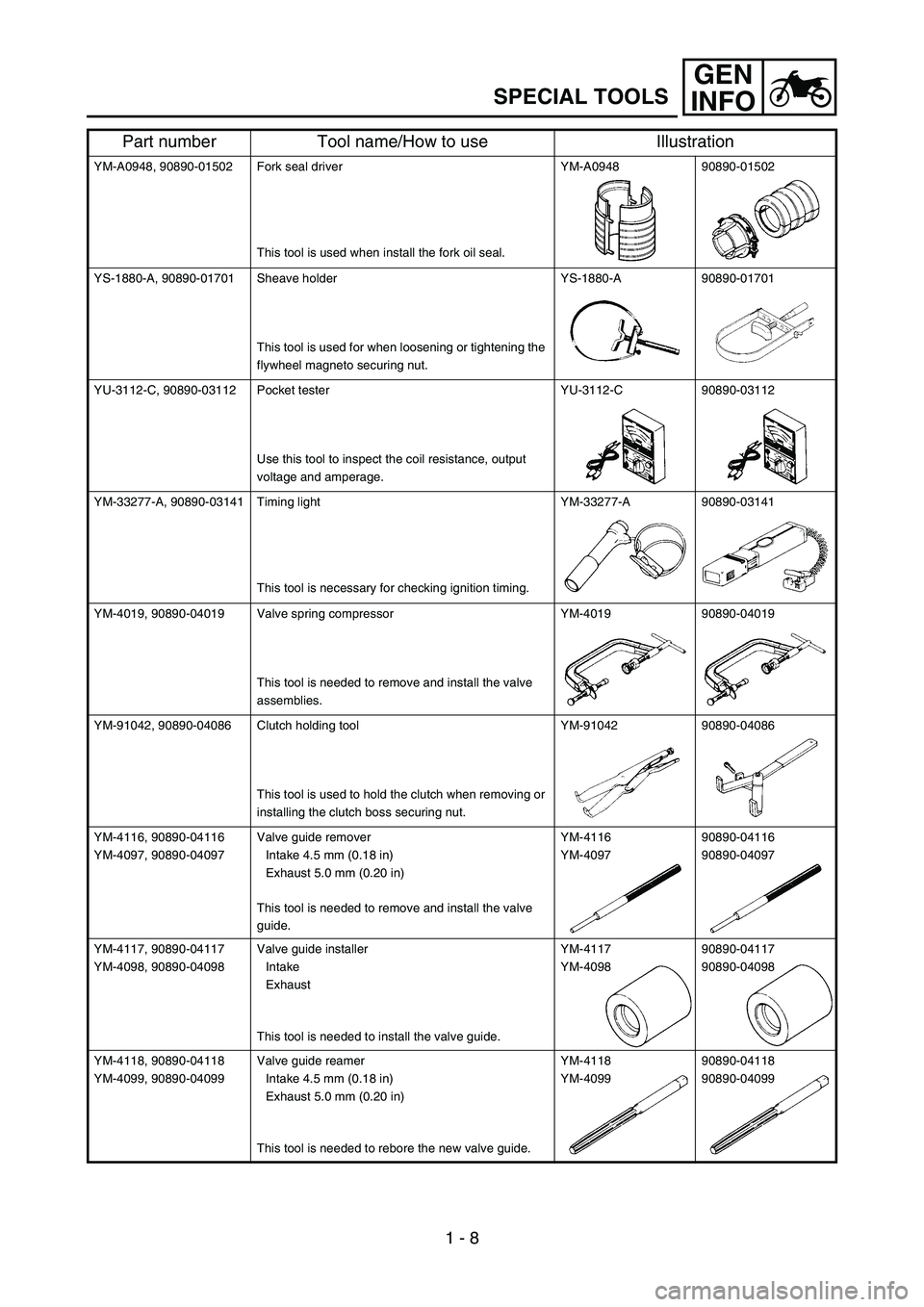

SPECIAL TOOLS

YM-A0948, 90890-01502 Fork seal driver

This tool is used when install the fork oil seal.YM-A0948 90890-01502

YS-1880-A, 90890-01701 Sheave holder

This tool is used for when loosening or tightening the

flywheel magneto securing nut.YS-1880-A 90890-01701

YU-3112-C, 90890-03112 Pocket tester

Use this tool to inspect the coil resistance, output

voltage and amperage.YU-3112-C 90890-03112

YM-33277-A, 90890-03141 Timing light

This tool is necessary for checking ignition timing.YM-33277-A 90890-03141

YM-4019, 90890-04019 Valve spring compressor

This tool is needed to remove and install the valve

assemblies.YM-4019 90890-04019

YM-91042, 90890-04086 Clutch holding tool

This tool is used to hold the clutch when removing or

installing the clutch boss securing nut.YM-91042 90890-04086

YM-4116, 90890-04116

YM-4097, 90890-04097Valve guide remover

Intake 4.5 mm (0.18 in)

Exhaust 5.0 mm (0.20 in)

This tool is needed to remove and install the valve

guide.YM-4116

YM-409790890-04116

90890-04097

YM-4117, 90890-04117

YM-4098, 90890-04098Valve guide installer

Intake

Exhaust

This tool is needed to install the valve guide.YM-4117

YM-409890890-04117

90890-04098

YM-4118, 90890-04118

YM-4099, 90890-04099Valve guide reamer

Intake 4.5 mm (0.18 in)

Exhaust 5.0 mm (0.20 in)

This tool is needed to rebore the new valve guide.YM-4118

YM-4099 90890-04118

90890-04099

Part number Tool name/How to use Illustration

Page 40 of 786

GEN

INFO

1 - 9

SPECIAL TOOLS

YM-04142, 90890-04142 Rotor puller

This tool is used to remove the flywheel magneto.YM-04142 90890-04142

YM-34487

90890-06754Dynamic spark tester

Ignition checker

This instrument is necessary for checking the ignition

system components.YM-34487 90890-06754

YB-35956-A, 90890-06756 Vacuum/pressure pump gauge set

This tool is used to check the air induction system.YB-35956-A 90890-06756

ACC-QUICK-GS-KT

90890-85505Quick gasket

YAMAHA Bond No. 1215

This sealant (Bond) is used for crankcase mating sur-

face, etc.ACC-QUICK-GS-KT 90890-85505

Part number Tool name/How to use Illustration

Page 74 of 786

1 - 22

GEN

INFO

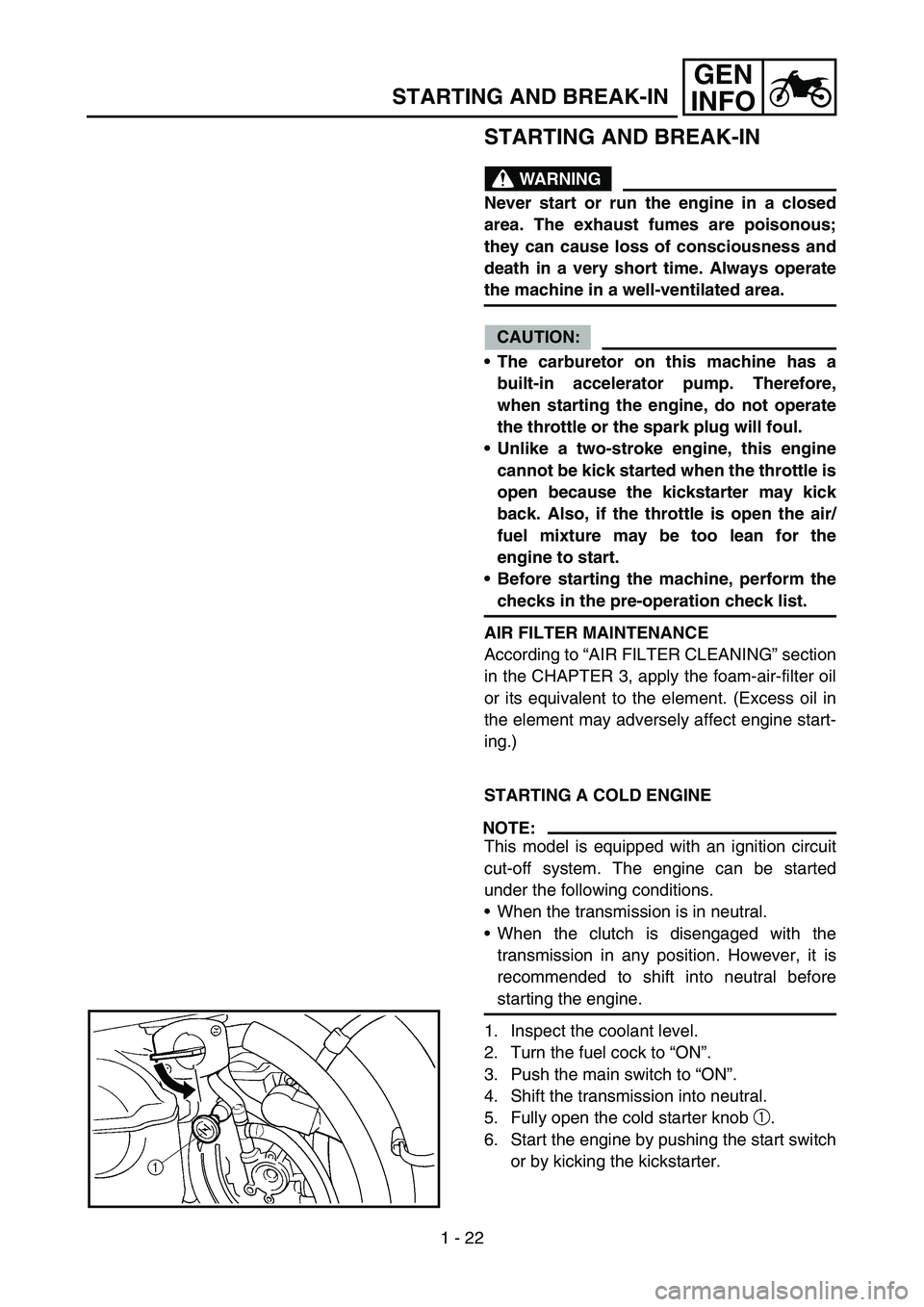

STARTING AND BREAK-IN

STARTING AND BREAK-IN

WARNING

Never start or run the engine in a closed

area. The exhaust fumes are poisonous;

they can cause loss of consciousness and

death in a very short time. Always operate

the machine in a well-ventilated area.

CAUTION:

The carburetor on this machine has a

built-in accelerator pump. Therefore,

when starting the engine, do not operate

the throttle or the spark plug will foul.

Unlike a two-stroke engine, this engine

cannot be kick started when the throttle is

open because the kickstarter may kick

back. Also, if the throttle is open the air/

fuel mixture may be too lean for the

engine to start.

Before starting the machine, perform the

checks in the pre-operation check list.

AIR FILTER MAINTENANCE

According to “AIR FILTER CLEANING” section

in the CHAPTER 3, apply the foam-air-filter oil

or its equivalent to the element. (Excess oil in

the element may adversely affect engine start-

ing.)

STARTING A COLD ENGINE

NOTE:

This model is equipped with an ignition circuit

cut-off system. The engine can be started

under the following conditions.

When the transmission is in neutral.

When the clutch is disengaged with the

transmission in any position. However, it is

recommended to shift into neutral before

starting the engine.

1. Inspect the coolant level.

2. Turn the fuel cock to “ON”.

3. Push the main switch to “ON”.

4. Shift the transmission into neutral.

5. Fully open the cold starter knob 1.

6. Start the engine by pushing the start switch

or by kicking the kickstarter.

Page 92 of 786

SPEC

2 - 3 Brake:

Front brake type Single disc brake

Operation Right hand operation

Rear brake type Single disc brake

Operation Right foot operation

Suspension:

Front suspension Telescopic fork

Rear suspension Swingarm (link type monocross suspension)

Shock absorber:

Front shock absorber Coil spring/oil damper

Rear shock absorber Coil spring/gas, oil damper

Wheel travel:

Front wheel travel 300 mm (11.8 in)

Rear wheel travel 305 mm (12.0 in)

Electrical:

Ignition system CDI

Generator system AC magneto

Battery type YTZ7S

Battery voltage/capacity 12 V/6 AH

Specific gravity 1.310

Headlight type: Quartz bulb (halogen)

Bulb wattage × quantity:

Headlight 12 V 60/55 W × 1

Taillight 12 V 21/5 W × 1

GENERAL SPECIFICATIONS

Page 107 of 786

SPEC

2 - 18

EC212300

ELECTRICAL

Item Standard Limit

Ignition system:

Advancer type Electrical ----

C.D.I.:

Pickup coil resistance (color) 248 ~ 372 Ω at 20 °C (68 °F)

(White – Red)----

CDI unit-model/manufacturer 5TJ-B0/YAMAHA (For USA)

5TJ-C0/YAMAHA

(Except for USA)----

----

Ignition coil:

Model/manufacturer 5TA-10/DENSO ----

Minimum spark gap 6 mm (0.24 in) ----

Primary winding resistance 0.08 ~ 0.10 Ω at 20 °C (68 °F) ----

Secondary winding resistance 4.6 ~ 6.8 kΩ at 20 °C (68 °F) ----

Charging system:

System type AC magneto ----

Model (stator)/manufacturer 5TJ 30/YAMAHA ----

Normal output 14 V/120 W at 5,000 r/min ----

Charging coil resistance (color) 0.288 ~ 0.432 Ω at 20 °C (68 °F)

(White – Ground)----

Lighting coil resistance (color) 0.224 ~ 0.336 Ω at 20 °C (68 °F)

(Yellow – Ground)----

Rectifier/regulator:

Regulator type Semiconductor short circuit ----

Model/manufacture SH712AC/SHINDENGEN ----

Regulated voltage (AC) 13.0 ~ 14.0 V ----

Regulated voltage (DC) 14.1 ~ 14.9 V ----

Rectifier capacity (AC) 12 A ----

Rectifier capacity (DC) 8 A ----

Electric starting system:

Type Constant mesh ----

Starter motor:

Model/manufacturer 5TJ10/YAMAHA ----

Operation voltage 12 V ----

Output 0.48 kW ----

Armature coil resistance 0.0117 ~ 0.0143 Ω at 20 °C

(68 °F)----

Brush overall length 7 mm (0.28 in) 3.5 mm

(0.14 in)

Brash quantity 2 pcs. ----

Spring force 3.92 ~ 5.88 N

(400 ~ 600 g, 14.1 ~ 21.2 oz)----

Commutator diameter 17.6 mm (0.69 in) 16.6 mm

(0.65 in)

Mica undercut (depth) 1.5 mm (0.06 in) ----

MAINTENANCE SPECIFICATIONS

Page 178 of 786

2 - 25

SPECCABLE ROUTING DIAGRAM

1Hot starter cable

2Clutch cable

3Throttle cable (return)

4Throttle cable (pull)

5Ignition coil

6Negative battery lead

7Starter motor lead

8Coolant reservoir tank breather

hose

9Cable holder

0Coolant reservoir hose

AClamp

BCDI unit lead

CCDI unit

DCDI unit band

ECDI unit stay (frame)

FCable bracketÈPass the throttle cables, clutch

cable and hot starter cable

through the cable guides.

ÉPass the throttle cables, clutch

cable and hot starter cable

between the radiator and frame,

then over the middle radiator

mounting boss.

ÊPass the throttle cables and

clutch cable on the outside of

the ignition coil.

ËPass the carburetor breather

hose (throttle cable cover)

through the hose holder.

ÌFasten the coolant reservoir

tank breather hose and carbure-

tor breather hoses together with

a plastic locking tie.ÍFasten the grommet of the clutch

cable with the cable holder.

ÎFasten the CDI unit lead to the

frame with a plastic locking tie

ends at the lower of the frame

and cut off the tie end.

ÏInsert the CDI unit band over the

CDI unit stay (frame) as far as

possible.

ÐFasten the starter motor lead

and negative battery lead to the

cable bracket in its slot with a

plastic locking tie and cut off the

tie end.

A

A

D

ÏE A

Ð

B

B

C

F

Í90

ÎABCD

1

2

43

È

É

Ê

5

6 7 8 Ë Ì

Page 200 of 786

3 - 4

INSP

ADJ

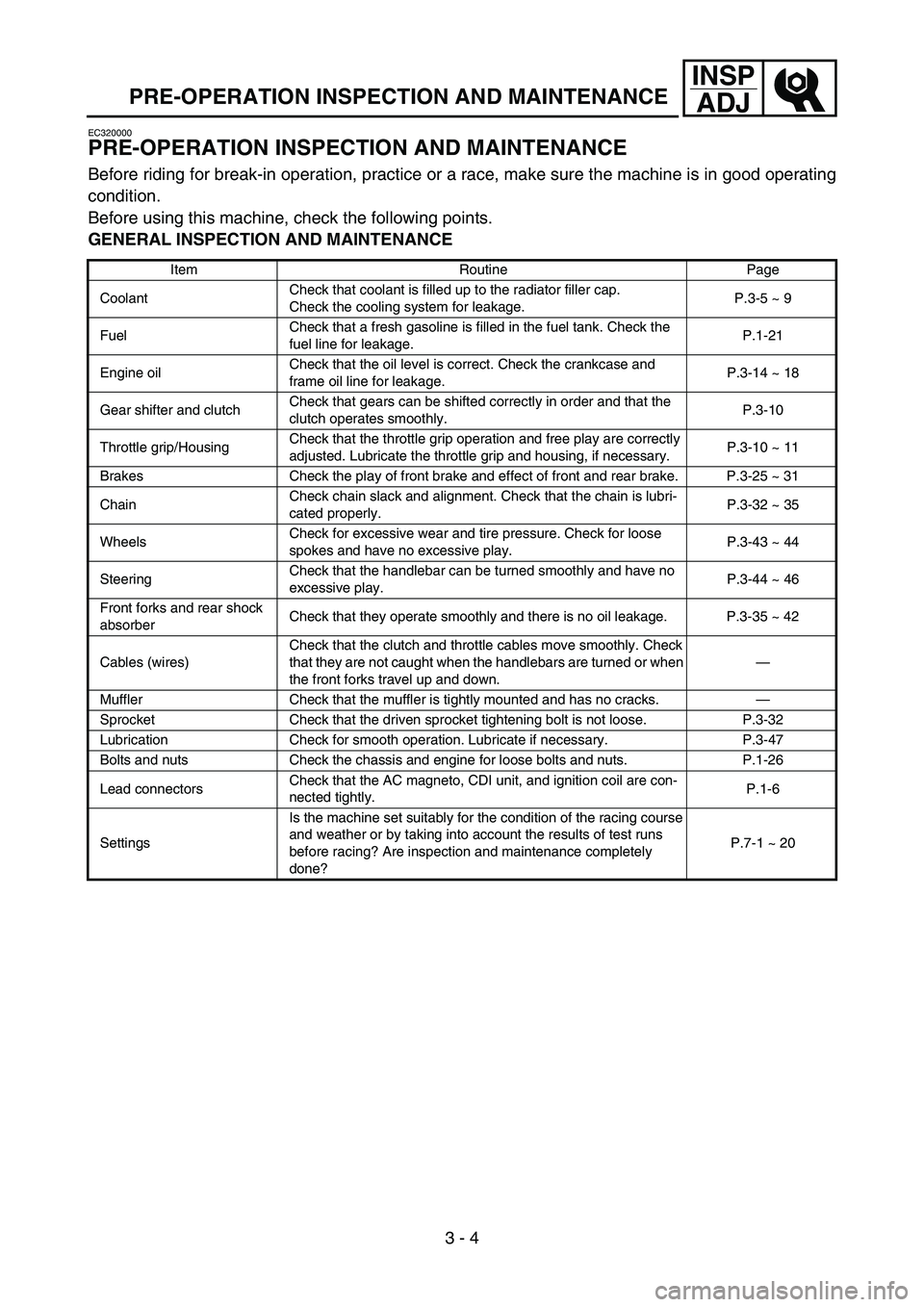

PRE-OPERATION INSPECTION AND MAINTENANCE

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator filler cap.

Check the cooling system for leakage.P.3-5 ~ 9

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-21

Engine oilCheck that the oil level is correct. Check the crankcase and

frame oil line for leakage.P.3-14 ~ 18

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-10

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-10 ~ 11

Brakes Check the play of front brake and effect of front and rear brake. P.3-25 ~ 31

ChainCheck chain slack and alignment. Check that the chain is lubri-

cated properly.P.3-32 ~ 35

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-43 ~ 44

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-44 ~ 46

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-35 ~ 42

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.—

Muffler Check that the muffler is tightly mounted and has no cracks.—

Sprocket Check that the driven sprocket tightening bolt is not loose. P.3-32

Lubrication Check for smooth operation. Lubricate if necessary. P.3-47

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-26

Lead connectorsCheck that the AC magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-6

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 20

Page 230 of 786

3 - 18

INSP

ADJ

IDLE SPEED ADJUSTMENT

10. Install:

Oil filler plug

11. Inspect:

Engine (for oil leaks)

Oil level

Refer to “ENGINE OIL LEVEL INSPEC-

TION”.

12. Check:

Oil pressure

EC35M021

IDLE SPEED ADJUSTMENT

1. Start the engine and thoroughly warm it up.

2. Adjust:

Idle speed Checking steps:

Slightly loosen the oil gallery bolt 1.

Start the engine and keep it idling until oil

starts to seep from the oil gallery bolt. If no

oil comes out after one minute, turn the

engine off so it will not seize.

Check oil passages, oil filter and oil pump

for damage or leakage.

Start the engine after solving the prob-

lem(s) and recheck the oil pressure.

Tighten the oil gallery bolt to specification.

T R..

Oil gallery bolt:

10 Nm (1.0 m kg, 7.2 ft lb)

Adjustment steps:

Turn the throttle stop screw 1 until the

specified engine idling speed.

NOTE:

Using a digital engine tachometer for idle

speed adjustment, detect the engine idling

speed by bringing the sensing element c of

the engine tachometer close to the ignition

coil 2.

To increase idle speed

→

Turn the throttle stop screw

1 in

a.

To decrease idle speed

→

Turn the throttle stop screw

1 out

b.

Engine idling speed:

1,700 ~ 1,900 r/min

c2

Page 294 of 786

3 - 49

INSP

ADJ

IGNITION TIMING CHECK

IGNITION TIMING CHECK

1. Remove:

Timing plug 1

1

2. Attach:

Timing light

Inductive tachometer

To the ignition coil lead (orange lead 1).

Timing light:

YM-33277-A/90890-03141

1

3. Adjust:

Engine idling speed

Refer to “IDLE SPEED ADJUSTMENT”.

4. Check:

Ignition timing

Visually check the stationary pointer a is

within the firing range b on the rotor.

Incorrect firing range → Check rotor and

pickup assembly.

5. Install:

Timing plug