check oil YAMAHA WR 450F 2007 Manuale de Empleo (in Spanish)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: WR 450F, Model: YAMAHA WR 450F 2007Pages: 794, tamaño PDF: 21.82 MB

Page 38 of 794

GEN

INFO

1 - 7

EC140001

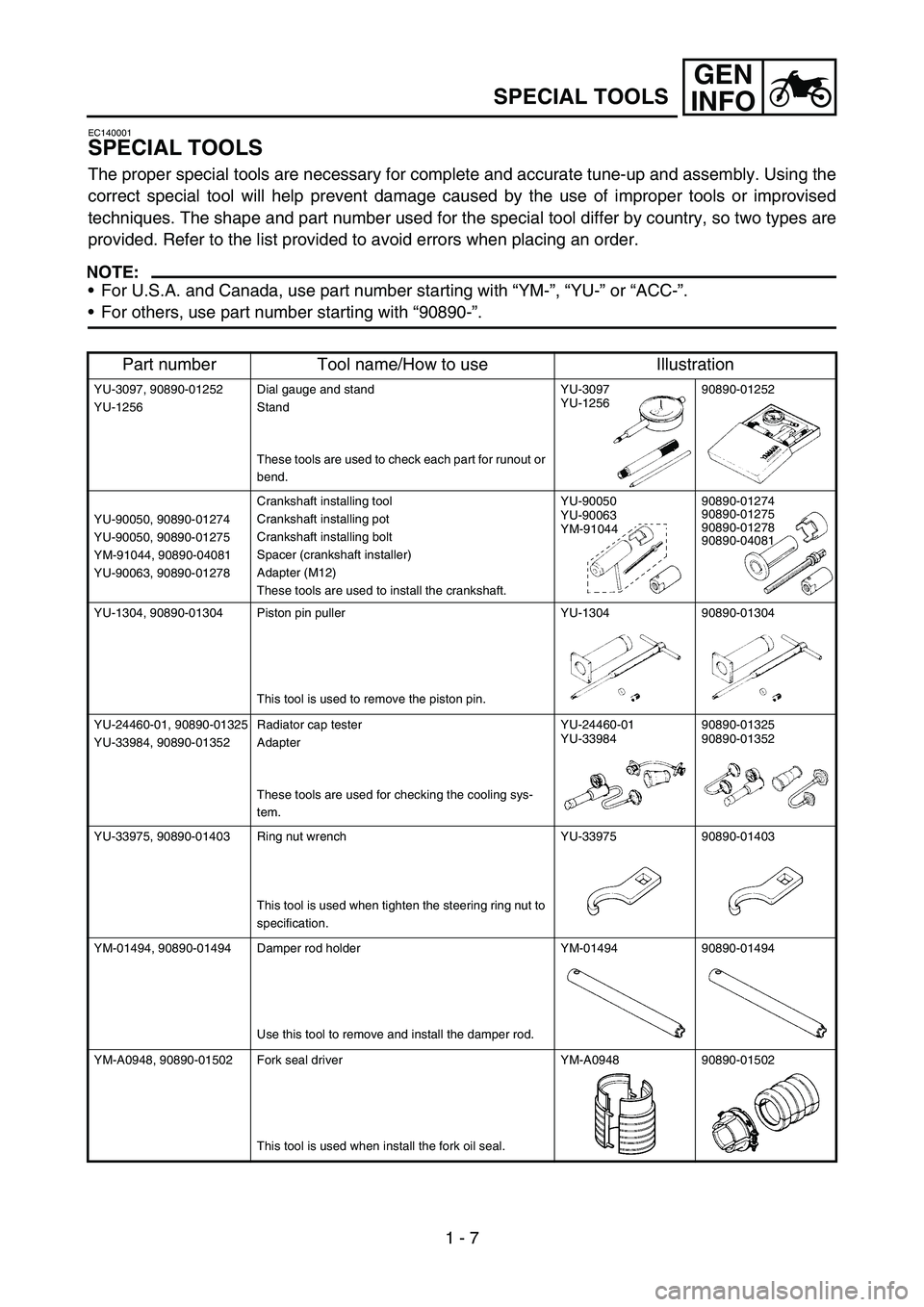

SPECIAL TOOLS

The proper special tools are necessary for complete and accurate tune-up and assembly. Using the

correct special tool will help prevent damage caused by the use of improper tools or improvised

techniques. The shape and part number used for the special tool differ by country, so two types are

provided. Refer to the list provided to avoid errors when placing an order.

NOTE:

For U.S.A. and Canada, use part number starting with “YM-”, “YU-” or “ACC-”.

For others, use part number starting with “90890-”.

Part number Tool name/How to use Illustration

YU-3097, 90890-01252

YU-1256Dial gauge and stand

Stand

These tools are used to check each part for runout or

bend.YU-3097

YU-125690890-01252

YU-90050, 90890-01274

YU-90050, 90890-01275

YM-91044, 90890-04081

YU-90063, 90890-01278Crankshaft installing tool

Crankshaft installing pot

Crankshaft installing bolt

Spacer (crankshaft installer)

Adapter (M12)

These tools are used to install the crankshaft.YU-90050

YU-90063

YM-9104490890-01274

90890-01275

90890-01278

90890-04081

YU-1304, 90890-01304 Piston pin puller

This tool is used to remove the piston pin.YU-1304 90890-01304

YU-24460-01, 90890-01325

YU-33984, 90890-01352Radiator cap tester

Adapter

These tools are used for checking the cooling sys-

tem.YU-24460-01

YU-3398490890-01325

90890-01352

YU-33975, 90890-01403 Ring nut wrench

This tool is used when tighten the steering ring nut to

specification.YU-33975 90890-01403

YM-01494, 90890-01494 Damper rod holder

Use this tool to remove and install the damper rod.YM-01494 90890-01494

YM-A0948, 90890-01502 Fork seal driver

This tool is used when install the fork oil seal.YM-A0948 90890-01502

SPECIAL TOOLS

Page 39 of 794

GEN

INFO

1 - 8

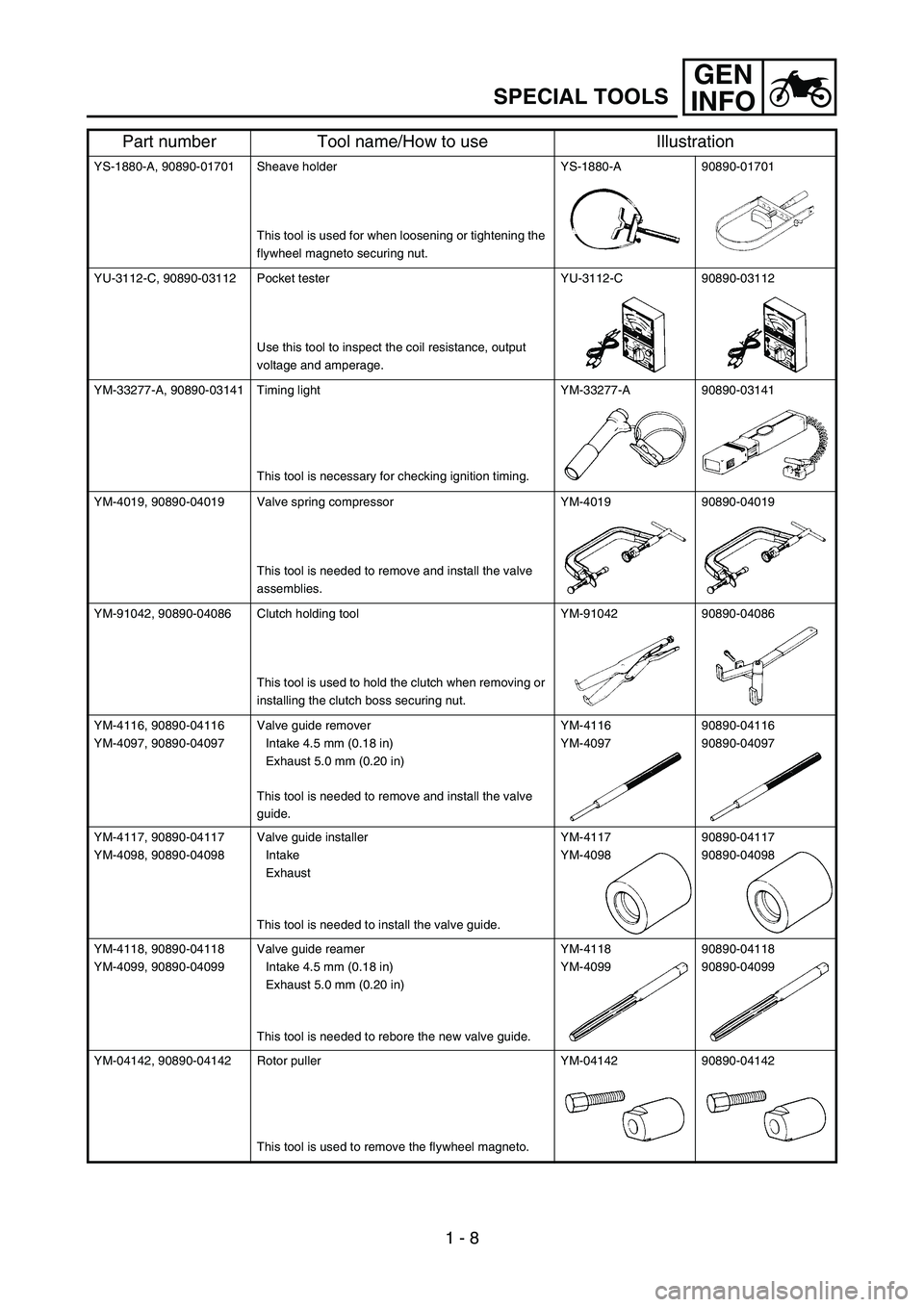

SPECIAL TOOLS

YS-1880-A, 90890-01701 Sheave holder

This tool is used for when loosening or tightening the

flywheel magneto securing nut.YS-1880-A 90890-01701

YU-3112-C, 90890-03112 Pocket tester

Use this tool to inspect the coil resistance, output

voltage and amperage.YU-3112-C 90890-03112

YM-33277-A, 90890-03141 Timing light

This tool is necessary for checking ignition timing.YM-33277-A 90890-03141

YM-4019, 90890-04019 Valve spring compressor

This tool is needed to remove and install the valve

assemblies.YM-4019 90890-04019

YM-91042, 90890-04086 Clutch holding tool

This tool is used to hold the clutch when removing or

installing the clutch boss securing nut.YM-91042 90890-04086

YM-4116, 90890-04116

YM-4097, 90890-04097Valve guide remover

Intake 4.5 mm (0.18 in)

Exhaust 5.0 mm (0.20 in)

This tool is needed to remove and install the valve

guide.YM-4116

YM-409790890-04116

90890-04097

YM-4117, 90890-04117

YM-4098, 90890-04098Valve guide installer

Intake

Exhaust

This tool is needed to install the valve guide.YM-4117

YM-409890890-04117

90890-04098

YM-4118, 90890-04118

YM-4099, 90890-04099Valve guide reamer

Intake 4.5 mm (0.18 in)

Exhaust 5.0 mm (0.20 in)

This tool is needed to rebore the new valve guide.YM-4118

YM-4099 90890-04118

90890-04099

YM-04142, 90890-04142 Rotor puller

This tool is used to remove the flywheel magneto.YM-04142 90890-04142

Part number Tool name/How to use Illustration

Page 74 of 794

1 - 22

GEN

INFO

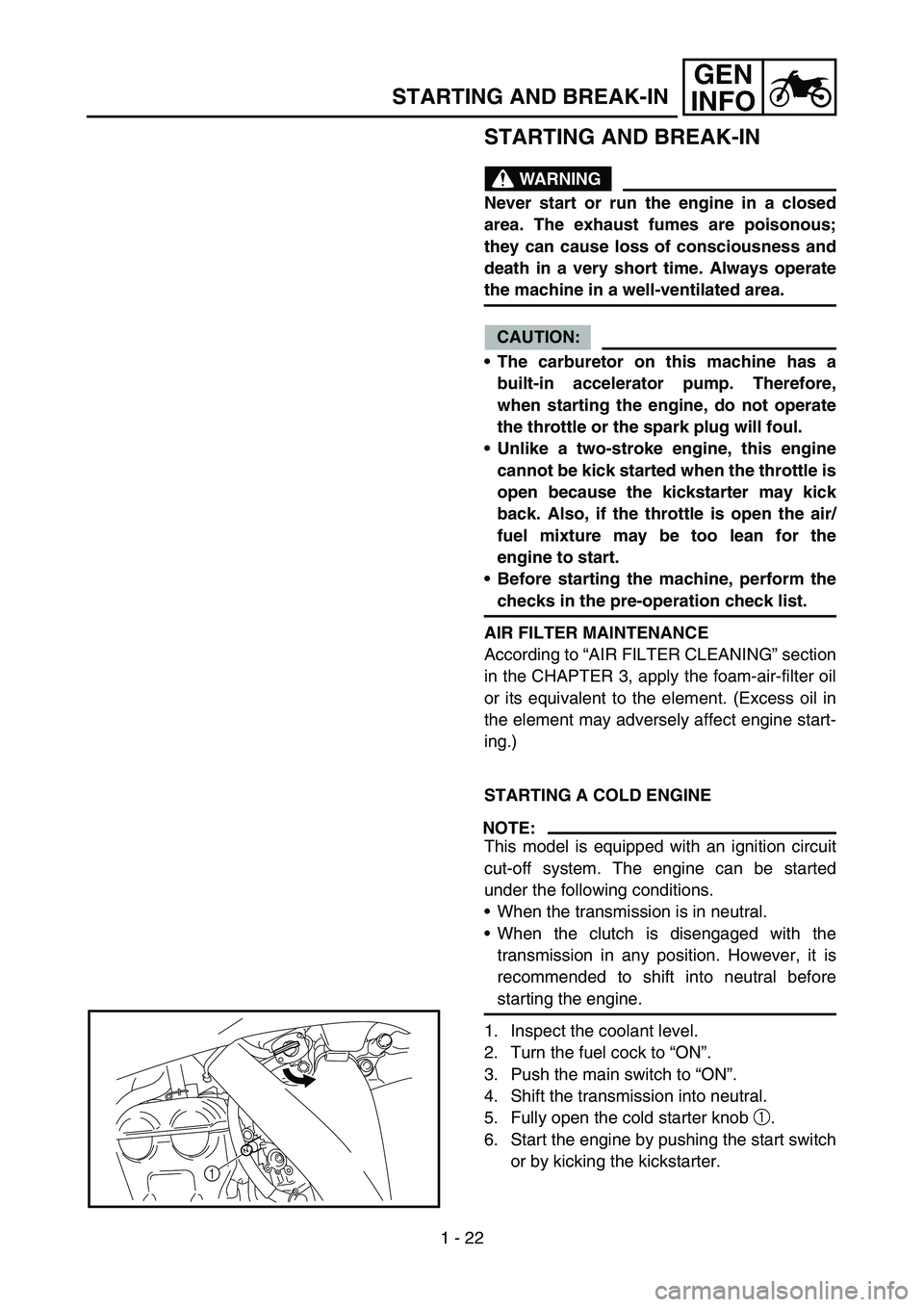

STARTING AND BREAK-IN

STARTING AND BREAK-IN

WARNING

Never start or run the engine in a closed

area. The exhaust fumes are poisonous;

they can cause loss of consciousness and

death in a very short time. Always operate

the machine in a well-ventilated area.

CAUTION:

The carburetor on this machine has a

built-in accelerator pump. Therefore,

when starting the engine, do not operate

the throttle or the spark plug will foul.

Unlike a two-stroke engine, this engine

cannot be kick started when the throttle is

open because the kickstarter may kick

back. Also, if the throttle is open the air/

fuel mixture may be too lean for the

engine to start.

Before starting the machine, perform the

checks in the pre-operation check list.

AIR FILTER MAINTENANCE

According to “AIR FILTER CLEANING” section

in the CHAPTER 3, apply the foam-air-filter oil

or its equivalent to the element. (Excess oil in

the element may adversely affect engine start-

ing.)

STARTING A COLD ENGINE

NOTE:

This model is equipped with an ignition circuit

cut-off system. The engine can be started

under the following conditions.

When the transmission is in neutral.

When the clutch is disengaged with the

transmission in any position. However, it is

recommended to shift into neutral before

starting the engine.

1. Inspect the coolant level.

2. Turn the fuel cock to “ON”.

3. Push the main switch to “ON”.

4. Shift the transmission into neutral.

5. Fully open the cold starter knob 1.

6. Start the engine by pushing the start switch

or by kicking the kickstarter.

1

Page 82 of 794

GEN

INFO

1 - 26

TORQUE-CHECK POINTS

TORQUE-CHECK POINTS

NOTE:

Concerning the tightening torque, refer to

“MAINTENANCE SPECIFICATIONS” section

in the CHAPTER 2.

Frame to rear frame

Fuel tank to frame

Silencer to rear frame

Frame to engine

Engine bracket to engine

Engine bracket to frame

Steering shaft to frame

Steering shaft to handle crown

Handle crown to handlebar

Front fork to handle crown

Front fork to under bracket

Assembly of links

Link to frame

Link to shock absorber

Link to swingarm

Shock absorber to frame

Tightening of pivot shaft

Tightening of front axle

Tightening of axle holder

Tightening of rear axle

Wheel to sprocket

Caliper to front fork

Brake disc to wheel

Tightening of union bolt

Master cylinder to handlebar

Tightening of air bleeder

Tightening of brake hose holder

Brake pedal to frame

Brake disc to wheel

Tightening of union bolt

Master cylinder to frame

Tightening of air bleeder

Tightening of brake hose holder

Fuel tank to fuel cock

Tightening of oil hose clamp Frame construction

Combined seat and tank

Exhaust system

Engine mounting

Steering Steering shaft to

handlebar

Suspension Front Steering shaft to front

fork

Rear For link type

Rear Installation of shock

absorber

Rear Installation of

swingarm

Wheel Installation of wheel Front

Rear

Brake Front

Rear

Fuel system

Lubrication system

Page 99 of 794

SPEC

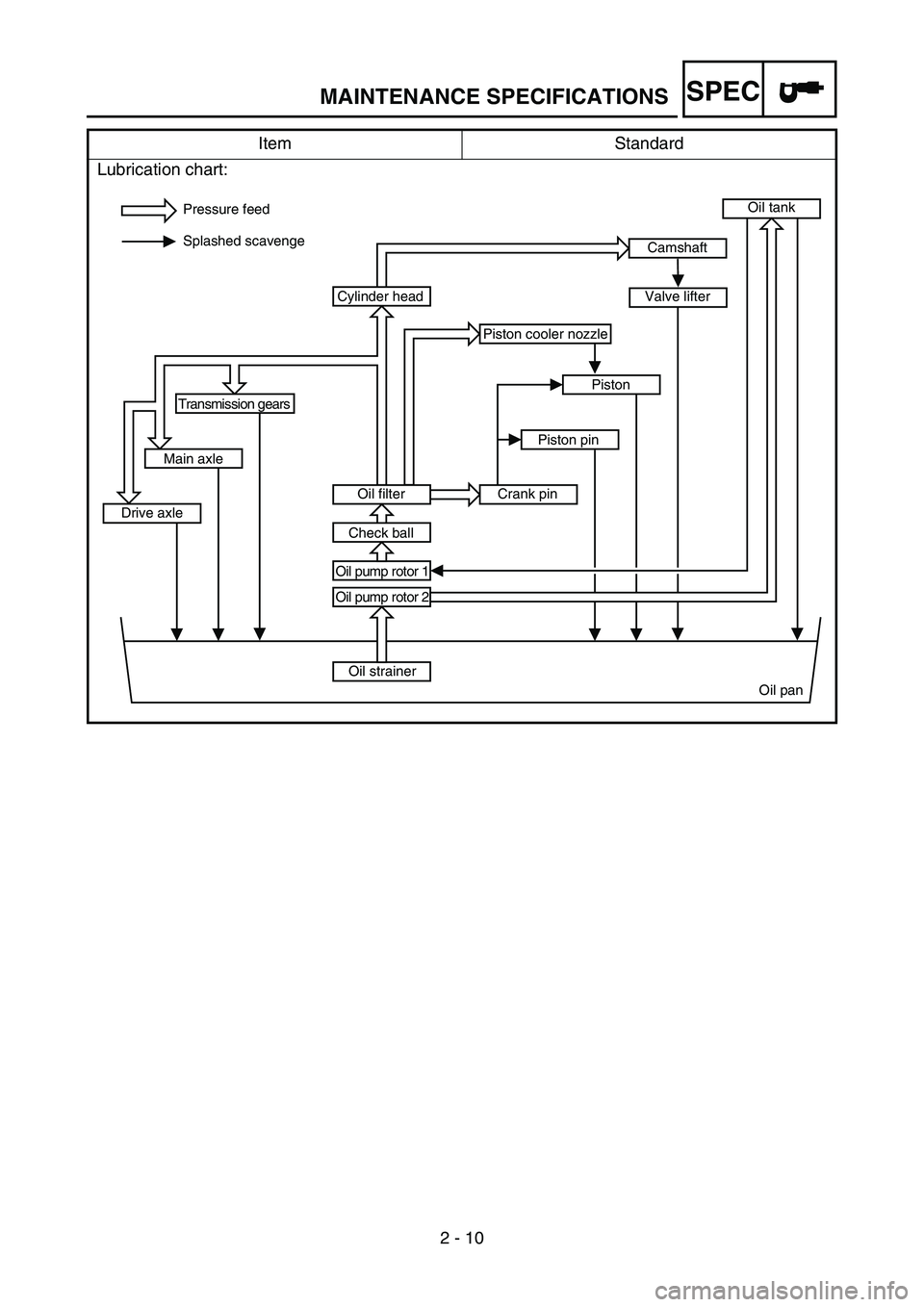

2 - 10 Item Standard

Lubrication chart:

Oil tank

Camshaft

Valve lifter Cylinder head

Piston cooler nozzle

Piston

Piston pin

Crank pin Oil filter

Check ball

Oil pump rotor 1

Oil pump rotor 2

Oil strainer Transmission gears

Main axle

Drive axlePressure feed

Splashed scavenge

Oil pan

MAINTENANCE SPECIFICATIONS

Page 101 of 794

SPEC

2 - 12

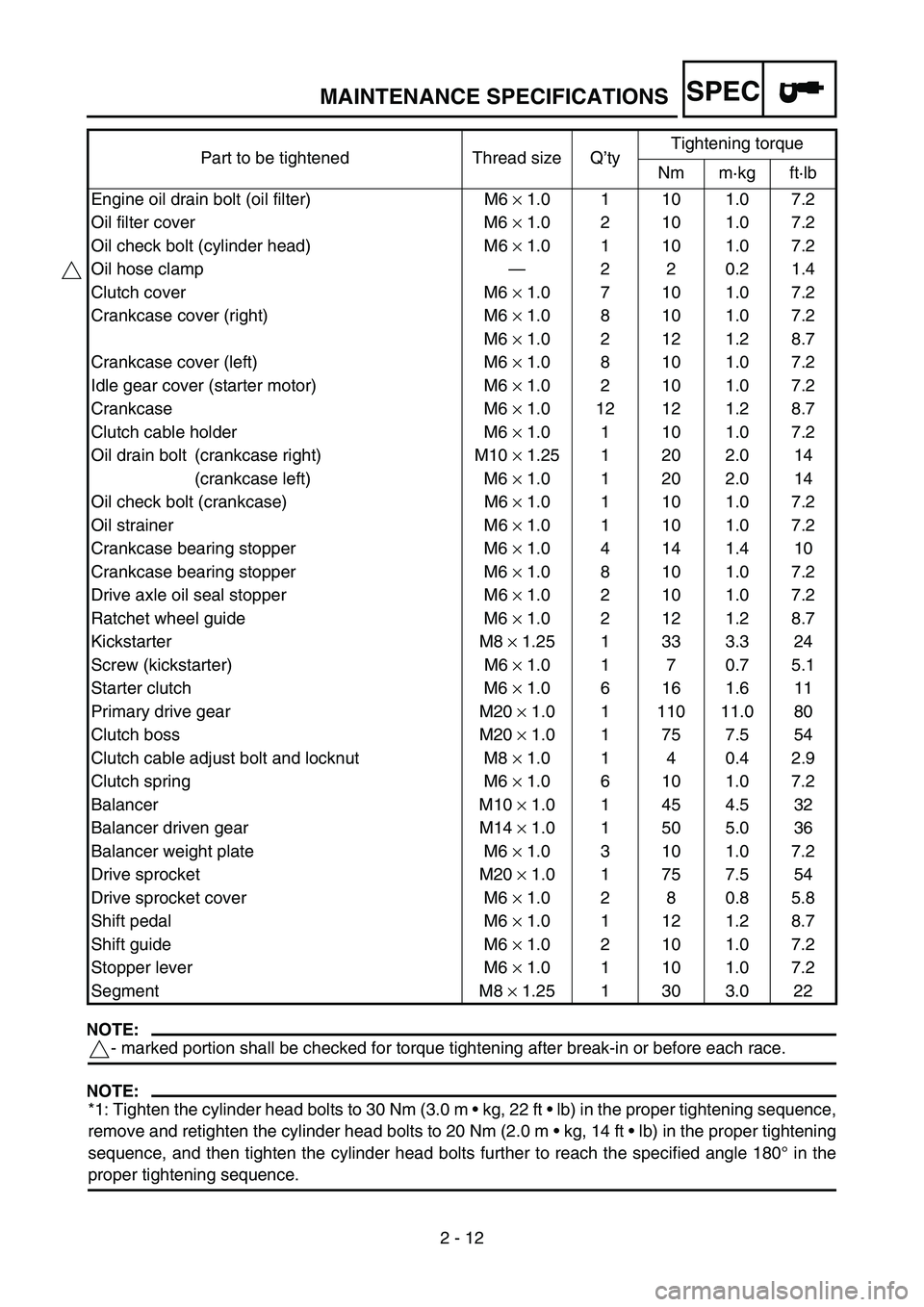

NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race.

NOTE:

*1: Tighten the cylinder head bolts to 30 Nm (3.0 m kg, 22 ft lb) in the proper tightening sequence,

remove and retighten the cylinder head bolts to 20 Nm (2.0 m kg, 14 ft lb) in the proper tightening

sequence, and then tighten the cylinder head bolts further to reach the specified angle 180° in the

proper tightening sequence.Engine oil drain bolt (oil filter) M6 × 1.0 1 10 1.0 7.2

Oil filter cover M6 × 1.0 2 10 1.0 7.2

Oil check bolt (cylinder head) M6 × 1.0 1 10 1.0 7.2

Oil hose clamp—220.21.4

Clutch cover M6 × 1.0 7 10 1.0 7.2

Crankcase cover (right) M6 × 1.0 8 10 1.0 7.2

M6 × 1.0 2 12 1.2 8.7

Crankcase cover (left) M6 × 1.0 8 10 1.0 7.2

Idle gear cover (starter motor) M6 × 1.0 2 10 1.0 7.2

Crankcase M6 × 1.0 12 12 1.2 8.7

Clutch cable holder M6 × 1.0 1 10 1.0 7.2

Oil drain bolt (crankcase right) M10 × 1.25 1 20 2.0 14

(crankcase left) M6 × 1.0 1 20 2.0 14

Oil check bolt (crankcase) M6 × 1.0 1 10 1.0 7.2

Oil strainer M6 × 1.0 1 10 1.0 7.2

Crankcase bearing stopper M6 × 1.0 4 14 1.4 10

Crankcase bearing stopper M6 × 1.0 8 10 1.0 7.2

Drive axle oil seal stopper M6 × 1.0 2 10 1.0 7.2

Ratchet wheel guide M6 × 1.0 2 12 1.2 8.7

Kickstarter M8 × 1.25 1 33 3.3 24

Screw (kickstarter) M6 × 1.0 1 7 0.7 5.1

Starter clutch M6 × 1.0 6 16 1.6 11

Primary drive gear M20 × 1.0 1 110 11.0 80

Clutch boss M20 × 1.0 1 75 7.5 54

Clutch cable adjust bolt and locknut M8 × 1.0 1 4 0.4 2.9

Clutch spring M6 × 1.0 6 10 1.0 7.2

Balancer M10 × 1.0 1 45 4.5 32

Balancer driven gear M14 × 1.0 1 50 5.0 36

Balancer weight plate M6 × 1.0 3 10 1.0 7.2

Drive sprocket M20 × 1.0 1 75 7.5 54

Drive sprocket cover M6 × 1.0 2 8 0.8 5.8

Shift pedal M6 × 1.0 1 12 1.2 8.7

Shift guide M6 × 1.0 2 10 1.0 7.2

Stopper lever M6 × 1.0 1 10 1.0 7.2

Segment M8 × 1.25 1 30 3.0 22 Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

MAINTENANCE SPECIFICATIONS

Page 192 of 794

3 - 1

INSP

ADJ

MAINTENANCE INTERVALS

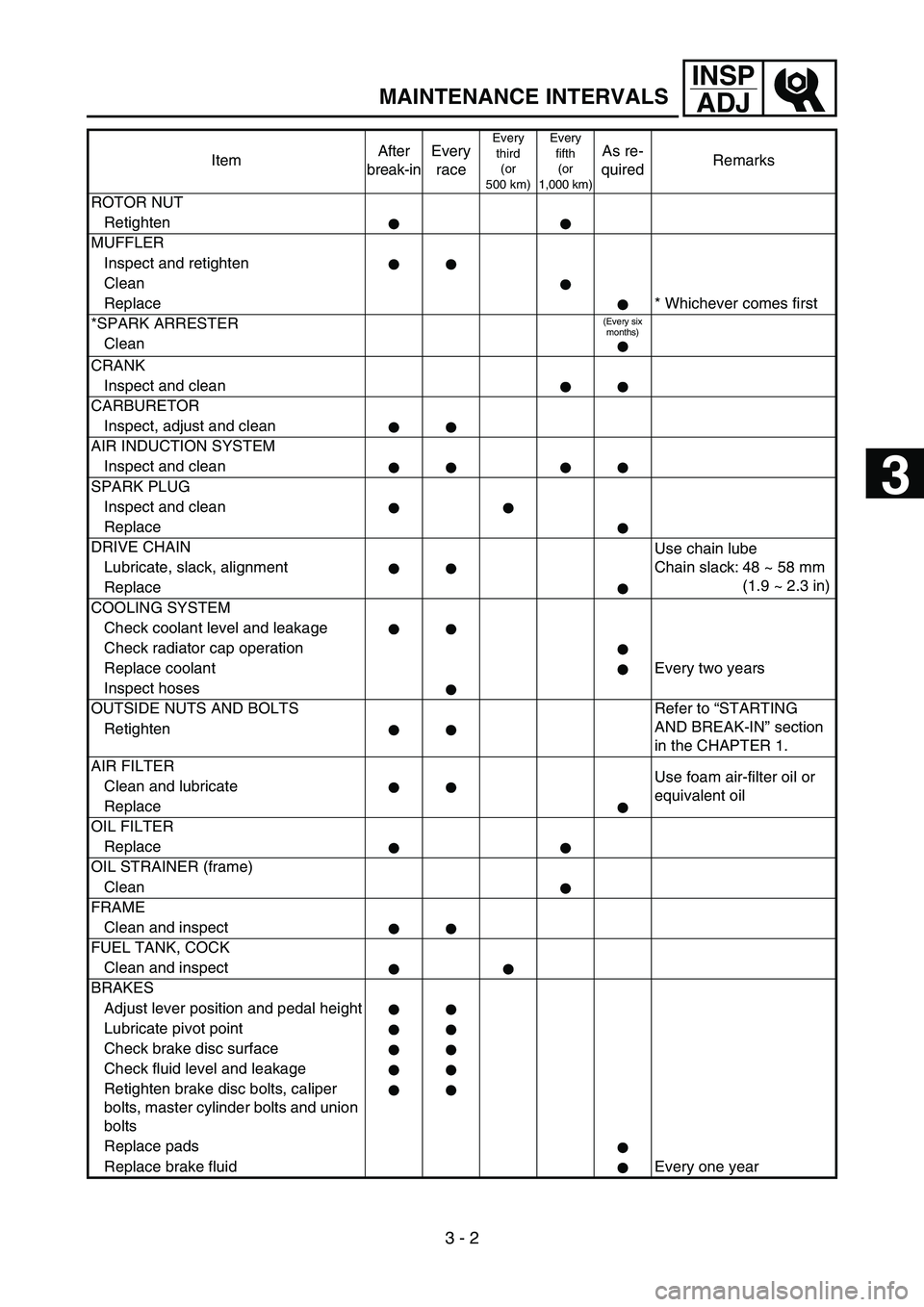

EC300000

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind

that such factors as weather, terrain, geographical location, and individual usage will alter the

required maintenance and lubrication intervals. If you are a doubt as to what intervals to follow in

maintaining and lubricating your machine, consult your Yamaha dealer.

ItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)As re-

quiredRemarks

ENGINE OIL

Replace

VALVES

The engine must be cold.

Check the valve seats

and valve stems for wear. Check the valve clearances

Inspect

Replace

VALVE SPRINGS

Check the free length and

the tilt. Inspect

Replace

VALVE LIFTERS

Check for scratches and

wear. Inspect

Replace

CAMSHAFTS Inspect the camshaft sur-

face.

Inspect the decompres-

sion system Inspect

Replace

CAMSHAFT SPROCKETS

Check for wear on the

teeth and for damage. Inspect

Replace

PISTON

Inspect crack

Inspect carbon deposits

and eliminate them. Inspect

Clean

Replace

PISTON RING

Check ring end gap Inspect

Replace

PISTON PIN

Inspect

Replace

CYLINDER HEAD Inspect carbon deposits

and eliminate them.

Change gasket Inspect and clean

CYLINDER

Inspect and clean

Inspect score marks

Inspect wear

Replace

CLUTCH

Inspect housing, friction

plate, clutch plate and

spring Inspect and adjust

Replace

TRANSMISSION

Inspect

Replace bearing

SHIFT FORK, SHIFT CAM, GUIDE BAR

InspectInspect wear

Page 193 of 794

3 - 2

INSP

ADJ

MAINTENANCE INTERVALS

ROTOR NUT

Retighten

MUFFLER

Inspect and retighten

Clean

Replace * Whichever comes first

*SPARK ARRESTER

(Every six

months)

Clean

CRANK

Inspect and clean

CARBURETOR

Inspect, adjust and clean

AIR INDUCTION SYSTEM

Inspect and clean

SPARK PLUG

Inspect and clean

Replace

DRIVE CHAIN

Use chain lube

Chain slack: 48 ~ 58 mm

(1.9 ~ 2.3 in) Lubricate, slack, alignment

Replace

COOLING SYSTEM

Check coolant level and leakage

Check radiator cap operation

Replace coolant Every two years

Inspect hoses

OUTSIDE NUTS AND BOLTS Refer to “STARTING

AND BREAK-IN” section

in the CHAPTER 1. Retighten

AIR FILTER

Use foam air-filter oil or

equivalent oil Clean and lubricate

Replace

OIL FILTER

Replace

OIL STRAINER (frame)

Clean

FRAME

Clean and inspect

FUEL TANK, COCK

Clean and inspect

BRAKES

Adjust lever position and pedal height

Lubricate pivot point

Check brake disc surface

Check fluid level and leakage

Retighten brake disc bolts, caliper

bolts, master cylinder bolts and union

bolts

Replace pads

Replace brake fluid Every one yearItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)As re-

quiredRemarks

3

Page 194 of 794

3 - 3

INSP

ADJ

MAINTENANCE INTERVALS

* marked: For USA

FRONT FORKS

Inspect and adjust

Replace oil Suspension oil “S1”

Replace oil seal

FRONT FORK OIL SEAL AND DUST

SEAL

Clean and lube Lithium base grease

PROTECTOR GUIDE

Replace

REAR SHOCK ABSORBER

(After

rain ride)

Inspect and adjust

Lube

Molybdenum disulfide

grease

Retighten

DRIVE CHAIN GUARD AND ROLL-

ERS

Inspect

SWINGARM

Molybdenum disulfide

grease

Inspect, lube and retighten

RELAY ARM, CONNECTING ROD

Molybdenum disulfide

grease

Inspect, lube and retighten

SIDESTAND

Lubricate Lithium base grease

STEERING HEAD

Inspect free play and retighten

Clean and lube Lithium base grease

Replace bearing

TIRE, WHEELS

Inspect air pressure, wheel run-out,

tire wear and spoke looseness

Retighten sprocket bolt

Inspect bearings

Replace bearings

Lubricate Lithium base grease

THROTTLE, CONTROL CABLE

Yamaha cable lube or

SAE 10W-30 motor oil Check routing and connection

Lubricate

HOT STARTER, CLUTCH LEVER

Inspect free play

BATTERY

Check terminal for looseness and

corrosionItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)As re-

quiredRemarks

Page 204 of 794

3 - 4

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

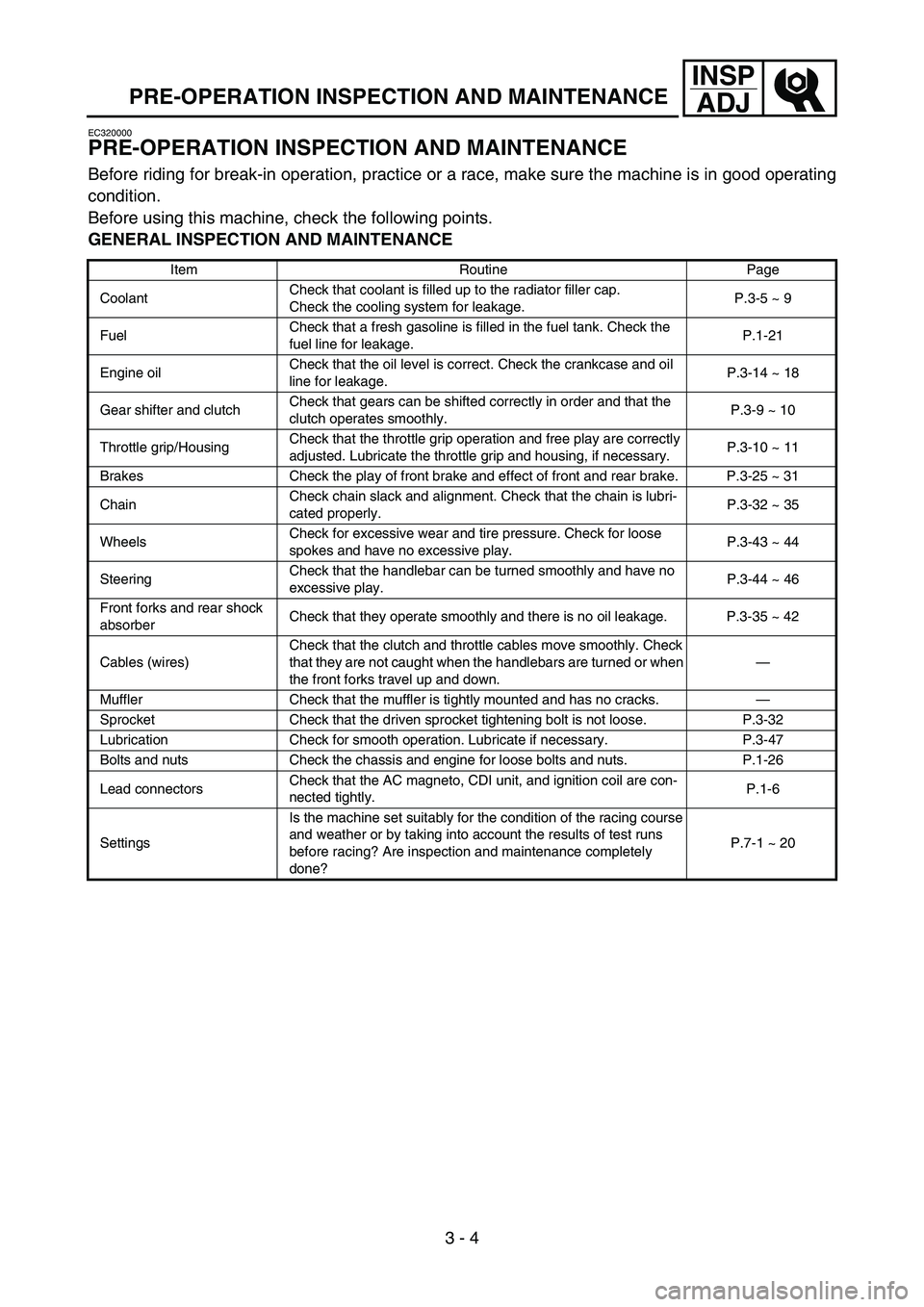

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator filler cap.

Check the cooling system for leakage.P.3-5 ~ 9

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-21

Engine oilCheck that the oil level is correct. Check the crankcase and oil

line for leakage.P.3-14 ~ 18

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-9 ~ 10

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-10 ~ 11

Brakes Check the play of front brake and effect of front and rear brake. P.3-25 ~ 31

ChainCheck chain slack and alignment. Check that the chain is lubri-

cated properly.P.3-32 ~ 35

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-43 ~ 44

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-44 ~ 46

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-35 ~ 42

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.—

Muffler Check that the muffler is tightly mounted and has no cracks.—

Sprocket Check that the driven sprocket tightening bolt is not loose. P.3-32

Lubrication Check for smooth operation. Lubricate if necessary. P.3-47

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-26

Lead connectorsCheck that the AC magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-6

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 20