oil YAMAHA WR 450F 2007 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: WR 450F, Model: YAMAHA WR 450F 2007Pages: 794, PDF Size: 21.82 MB

Page 276 of 794

3 - 38

INSP

ADJ

REAR SHOCK ABSORBER INSPECTION

STANDARD POSITION:

This is the position which is back by the spe-

cific number of clicks from the fully turned-in

position.

CAUTION:

Do not force the adjuster past the minimum

or maximum extent of adjustment. The

adjuster may be damaged.

WARNING

Always adjust each front fork to the same

setting. Uneven adjustment can cause poor

handling and loss of stability.

3. Install:

Rubber cap

Standard position:

9 clicks out

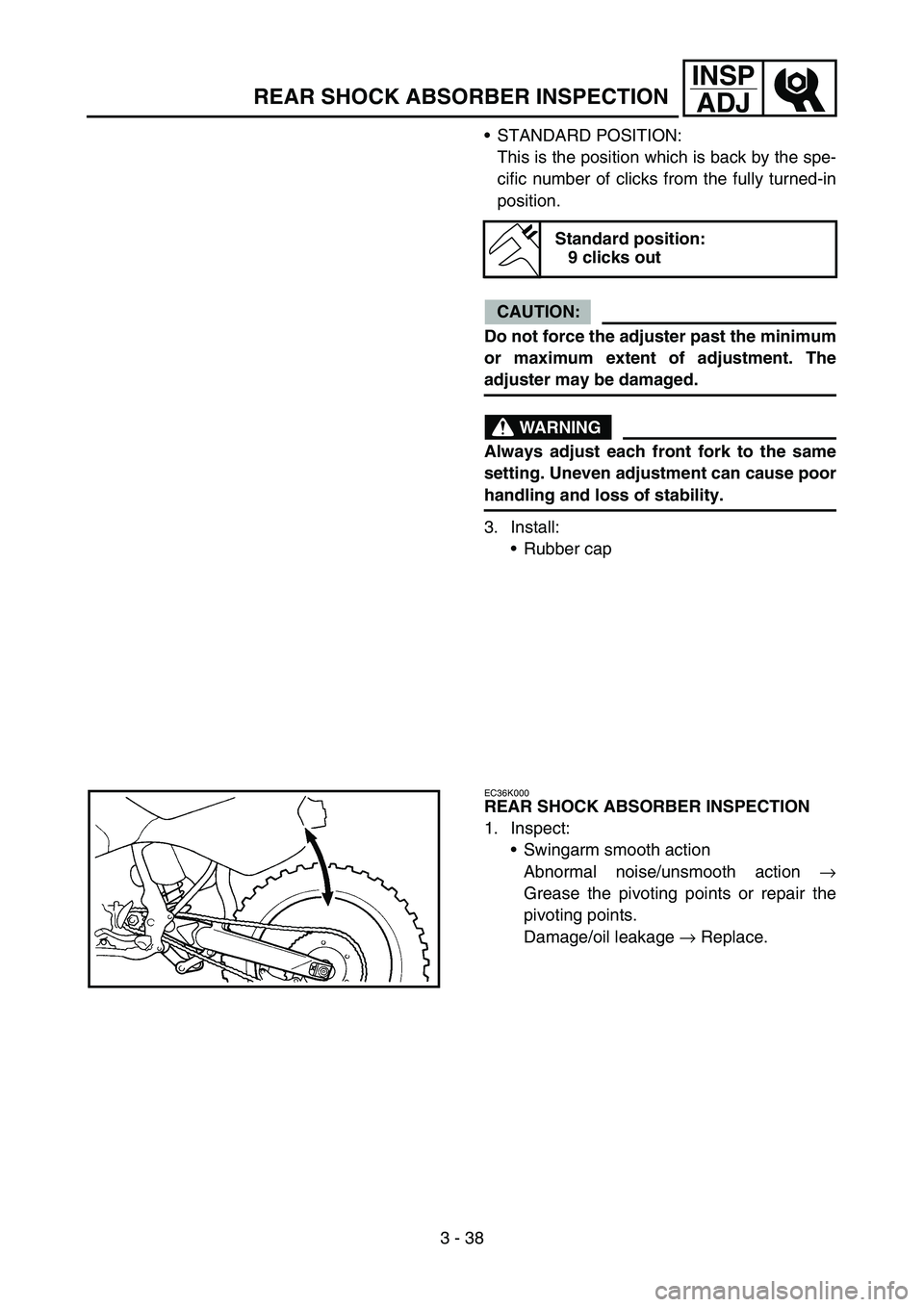

EC36K000

REAR SHOCK ABSORBER INSPECTION

1. Inspect:

Swingarm smooth action

Abnormal noise/unsmooth action →

Grease the pivoting points or repair the

pivoting points.

Damage/oil leakage → Replace.

Page 287 of 794

INSP

ADJ

CONTROLE DE LA PRESSION DES

PNEUS

1. Mesurer:

Pression des pneus

Hors spécifications → Régler.

N.B.:

Contrôler les pneus à froid.

Le pneu risque de se déjanter si le

gonflage est insuffisant.

Une tige de valve de pneu inclinée

indique que le pneu est mal assis.

Une tige de valve de pneu inclinée

indique que le pneu est mal assis. Cor-

riger la position du pneu.

Pression des pneus stan-

dard:

100 kPa

(1,0 kgf/cm

2, 15 psi)

CONTROLE ET SERRAGE DES

RAYONS

1. Contrôler:

Rayons 1

Déformation/endommagement →

Remplacer.

Rayon desserré → Resserrer.

2. Serrer:

Rayons

N.B.:

Veiller à resserrer ces rayons avant et

après le rodage. Après un entraînement

ou une course, vérifier si les rayons ne

sont pas desserrés.

T R..3 Nm (0,3 m · kg, 2,2 ft · lb)

CONTROLE DES ROUES

1. Contrôler:

Voile de roue

Surélever la roue et la faire tour-

ner.

Voile excessif → Remplacer.

CONTROLE DE LA PRESSION DES PNEUS/CONTROLE ET SERRAGE DES RAYONS/CONTROLE DES ROUES

REIFENLUFTDRUCK KONTROLLIEREN/SPEICHEN KONTROLLIEREN UND SPANNEN/RÄDER KONTROLLIEREN

COMPROBACIÓN DE LA PRESIÓN DE LOS NEUMÁTICOS/COMPROBACIÓN Y APRIETE DE LOS RADIOS/

REVISIÓN DE LAS RUEDAS

3 - 43

REIFENLUFTDRUCK

KONTROLLIEREN

1. Messen:

Reifenluftdruck

Nicht nach Vorgabe

→ Einstel-

len.

HINWEIS:

Den Reifenluftdruck bei kaltem

Reifen kontrollieren.

Bei zu niedrigem Reifenluftdruck

besteht die Gefahr, dass der Rei-

fen auf der Felge rutscht.

Ein schräg stehender Ventilschaft

deutet darauf hin, dass der Reifen

sich verschoben hat.

Falls der Ventilschaft schräg steht,

sitzt der Reifen falsch auf. In die-

sem Fall die Reifenlage korrigie-

ren.

Standard-Reifenluft-

druck:

100 kPa

(1,0 kgf/cm

2, 15 psi)

SPEICHEN KONTROLLIEREN UND

SPANNEN

1. Kontrollieren:

Speichen

1

Verbogen/beschädigt

→

Erneuern.

Speiche lose

→ Spannen.

2. Festziehen:

Speichen

HINWEIS:

Die Speichen müssen vor und nach

dem Einfahren gespannt und nach

jeder Fahrt kontrolliert werden.

T R..3 Nm (0,3 m · kg, 2,2 ft · lb)

RÄDER KONTROLLIEREN

1. Kontrollieren:

Felgenschlag

Das Rad anheben und dre-

hen.

Anormaler Schlag

→ Erneu-

ern.COMPROBACIÓN DE LA

PRESIÓN DE LOS NEUMÁTICOS

1. Medir:

Presión de los neumáticos

Fuera del valor especificado →

Ajustar.

NOTA:

Compruebe la presión con los neumá-

ticos fríos.

Si los topes del talón están flojos,

cuando la presión está baja el neumá-

tico se puede salir de su posición en la

llanta.

Si la válvula del neumático está incli-

nada significa que el neumático se ha

desplazado de su posición en la llanta.

Si observa que la válvula está incli-

nada, debe considerar que el neumá-

tico se está saliendo de su posición.

Corrija la posición del neumático.

Presión estándar:

100 kPa

(1,0 kgf/cm

2, 15 psi)

COMPROBACIÓN Y APRIETE DE

LOS RADIOS

1. Comprobar:

Radios 1

Dobladura/daños → Cambiar.

Radio flojo → Apretar.

2. Apretar:

Radios

NOTA:

No olvide volver a apretar los radios

antes y después del rodaje. Después de

una práctica o una carrera, compruebe si

se han aflojado los radios.

T R..3 Nm (0,3 m · kg, 2,2 ft · lb)

REVISIÓN DE LAS RUEDAS

1. Comprobar:

Descentramiento de la rueda

Levante la rueda y gírela.

Descentramiento anómalo →

Cambiar.

Page 294 of 794

3 - 47

INSP

ADJ

LUBRICATION

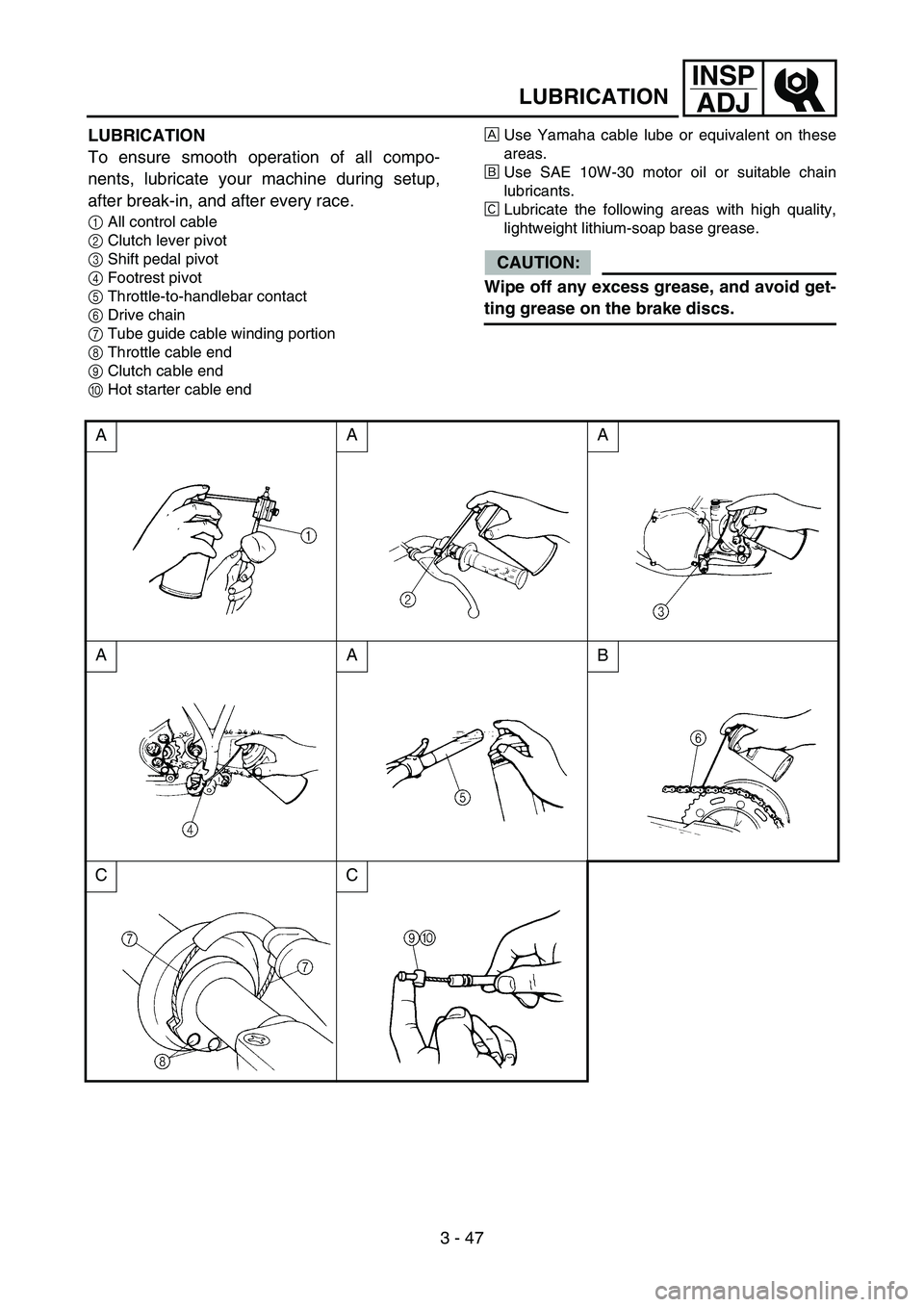

LUBRICATION

To ensure smooth operation of all compo-

nents, lubricate your machine during setup,

after break-in, and after every race.

1All control cable

2Clutch lever pivot

3Shift pedal pivot

4Footrest pivot

5Throttle-to-handlebar contact

6Drive chain

7Tube guide cable winding portion

8Throttle cable end

9Clutch cable end

0Hot starter cable endÈUse Yamaha cable lube or equivalent on these

areas.

ÉUse SAE 10W-30 motor oil or suitable chain

lubricants.

ÊLubricate the following areas with high quality,

lightweight lithium-soap base grease.

CAUTION:

Wipe off any excess grease, and avoid get-

ting grease on the brake discs.

AAA

AA

B

CC

Page 298 of 794

3 - 49

INSP

ADJ

IGNITION TIMING CHECK

IGNITION TIMING CHECK

1. Remove:

Timing plug 1

1

2. Attach:

Timing light

Inductive tachometer

To the ignition coil lead (orange lead 1).

Timing light:

YM-33277-A/90890-03141

1

3. Adjust:

Engine idling speed

Refer to “IDLE SPEED ADJUSTMENT”.

4. Check:

Ignition timing

Visually check the stationary pointer a is

within the firing range b on the rotor.

Incorrect firing range → Check rotor and

pickup assembly.

5. Install:

Timing plug

Page 300 of 794

3 - 50

INSP

ADJ

BATTERY INSPECTION AND CHARGING

WARNING

Batteries generate explosive hydrogen gas

and contain electrolyte which is made of

poisonous and highly caustic sulfuric acid.

Therefore, always follow these preventive

measures:

Wear protective eye gear when handling

or working near batteries.

Charge batteries in a well-ventilated area.

Keep batteries away from fire, sparks or

open flames (e.g., welding equipment,

lighted cigarettes).

DO NOT SMOKE when charging or han-

dling batteries.

KEEP BATTERIES AND ELECTROLYTE

OUT OF REACH OF CHILDREN.

Avoid bodily contact with electrolyte as it

can cause severe burns or permanent eye

injury.

FIRST AID IN CASE OF BODILY CONTACT:

EXTERNAL

Skin — Wash with water.

Eyes — Flush with water for 15 minutes

and get immediate medical attention.

INTERNAL

Drink large quantities of water or milk fol-

lowed with milk of magnesia, beaten egg

or vegetable oil. Get immediate medical

attention.

CAUTION:

Charging time, charging amperage and

charging voltage for an MF battery are dif-

ferent from those of conventional batteries.

The MF battery should be charged as

explained in the charging method illustra-

tions. If the battery is overcharged, the

electrolyte level will drop considerably.

Therefore, take special care when charging

the battery.

BATTERY INSPECTION AND CHARGING

Page 320 of 794

3 - 58

INSP

ADJ

ADJUSTING THE HEADLIGHT BEAMS

4. Remove:

Headlight bulb

WARNING

Since the headlight bulb gets extremely

hot, keep flammable products and your

hands away from the bulb unit it has cooled

down.

5. Install:

Headlight bulb

CAUTION:

Avoid touching the glass part of the head-

light bulb to keep it free form oil, otherwise

the transparency of the glass, the life of the

bulb and the luminous flux will be

adversely affected. If the headlight bulb

gets soiled, thoroughly clean it with a cloth

moistened with alcohol or lacquer thinner.

6. Install:

Headlight bulb holder

7. Install:

Headlight bulb holder cover

8. Install:

Headlight

Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section in the CHAPTER 4.

New

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

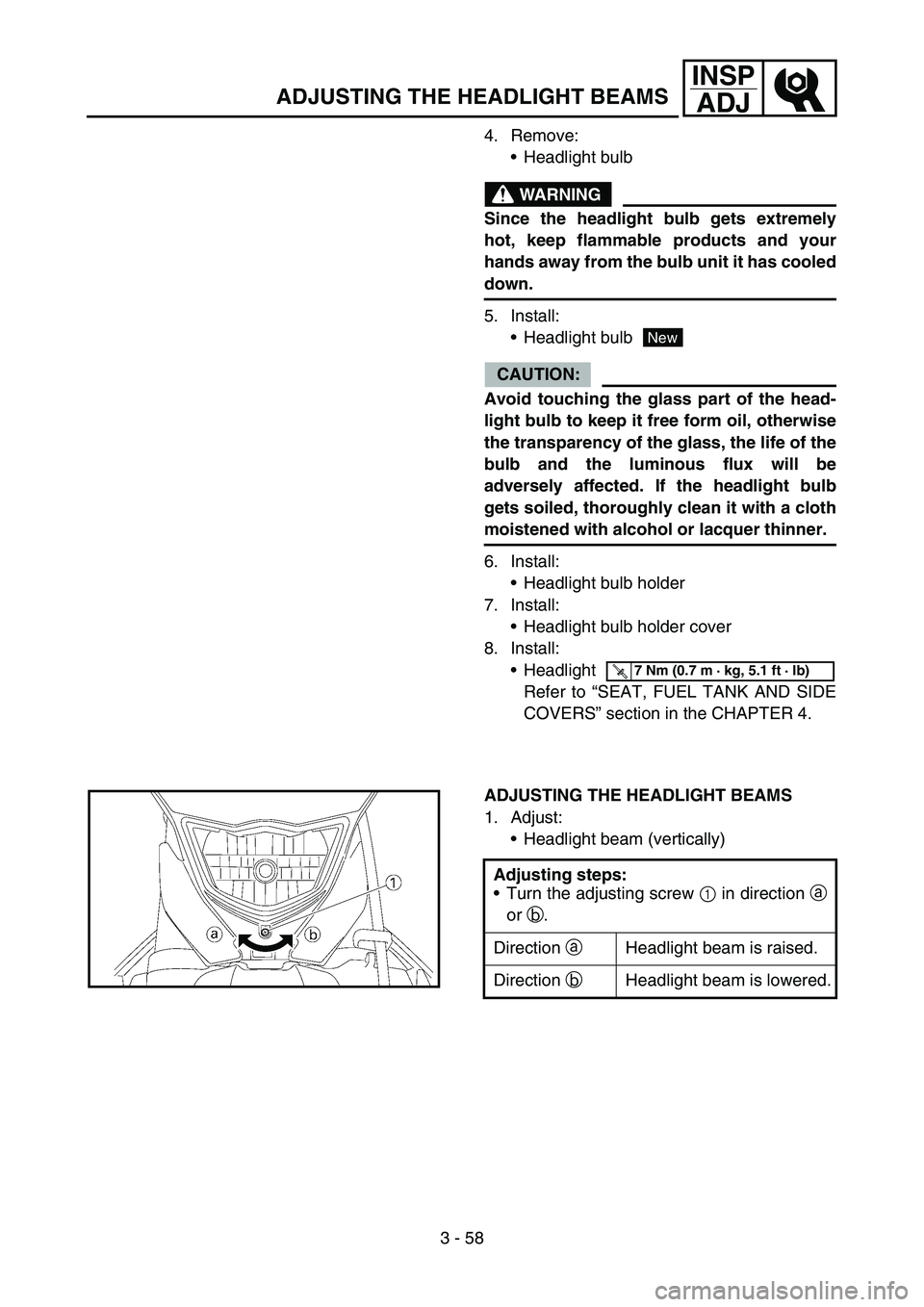

ADJUSTING THE HEADLIGHT BEAMS

1. Adjust:

Headlight beam (vertically)

Adjusting steps:

Turn the adjusting screw 1 in direction a

or b.

Direction a Headlight beam is raised.

Direction bHeadlight beam is lowered.

Page 378 of 794

4 - 29

ENGCAMSHAFTS

Decompression system

1. Check:

Decompression system

Checking steps:

Check that the decompressor cam 1

moves smoothly.

Check that the decompressor lever pin 2

projects from the camshaft.

Timing chain tensioner

1. Check:

While pressing the tensioner rod lightly

with fingers, use a thin screwdriver 1

and wind the tensioner rod up fully clock-

wise.

When releasing the screwdriver by press-

ing lightly with fingers, make sure that the

tensioner rod will come out smoothly.

If not, replace the tensioner assembly.

ASSEMBLY AND INSTALLATION

1. Install:

Exhaust camshaft 1

Intake camshaft 2

Installation steps:

Turn the crankshaft counterclockwise until

the “I” mark a on the rotor is aligned with

the stationary pointer b on the crankcase

cover.

NOTE:

Apply the molybdenum disulfide oil on the

camshafts.

Apply the engine oil on the decompression

system.

Page 380 of 794

4 - 30

ENGCAMSHAFTS

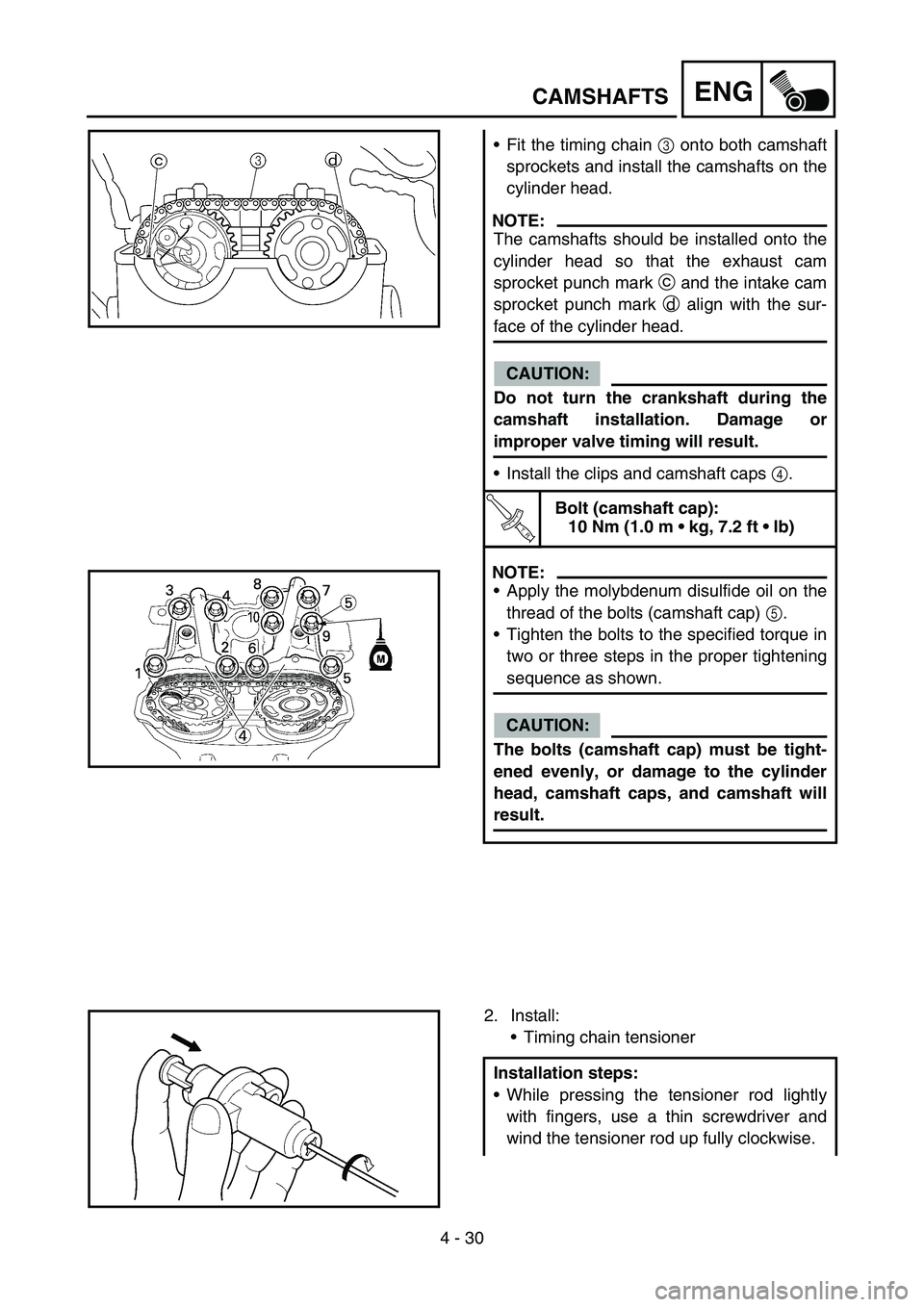

Fit the timing chain 3 onto both camshaft

sprockets and install the camshafts on the

cylinder head.

NOTE:

The camshafts should be installed onto the

cylinder head so that the exhaust cam

sprocket punch mark c and the intake cam

sprocket punch mark d align with the sur-

face of the cylinder head.

CAUTION:

Do not turn the crankshaft during the

camshaft installation. Damage or

improper valve timing will result.

Install the clips and camshaft caps 4.

T R..

Bolt (camshaft cap):

10 Nm (1.0 m kg, 7.2 ft lb)

NOTE:

Apply the molybdenum disulfide oil on the

thread of the bolts (camshaft cap) 5.

Tighten the bolts to the specified torque in

two or three steps in the proper tightening

sequence as shown.

CAUTION:

The bolts (camshaft cap) must be tight-

ened evenly, or damage to the cylinder

head, camshaft caps, and camshaft will

result.

2. Install:

Timing chain tensioner

Installation steps:

While pressing the tensioner rod lightly

with fingers, use a thin screwdriver and

wind the tensioner rod up fully clockwise.

Page 402 of 794

4 - 41

ENGVALVES AND VALVE SPRINGS

5. Measure:

Runout (valve stem)

Out of specification → Replace.

NOTE:

When installing a new valve always replace

the guide.

If the valve is removed or replaced always

replace the oil seal.

6. Eliminate:

Carbon deposits

(from the valve face and valve seat)

7. Inspect:

Valve seats

Pitting/wear → Reface the valve seat.

Runout limit:

0.01 mm (0.0004 in)

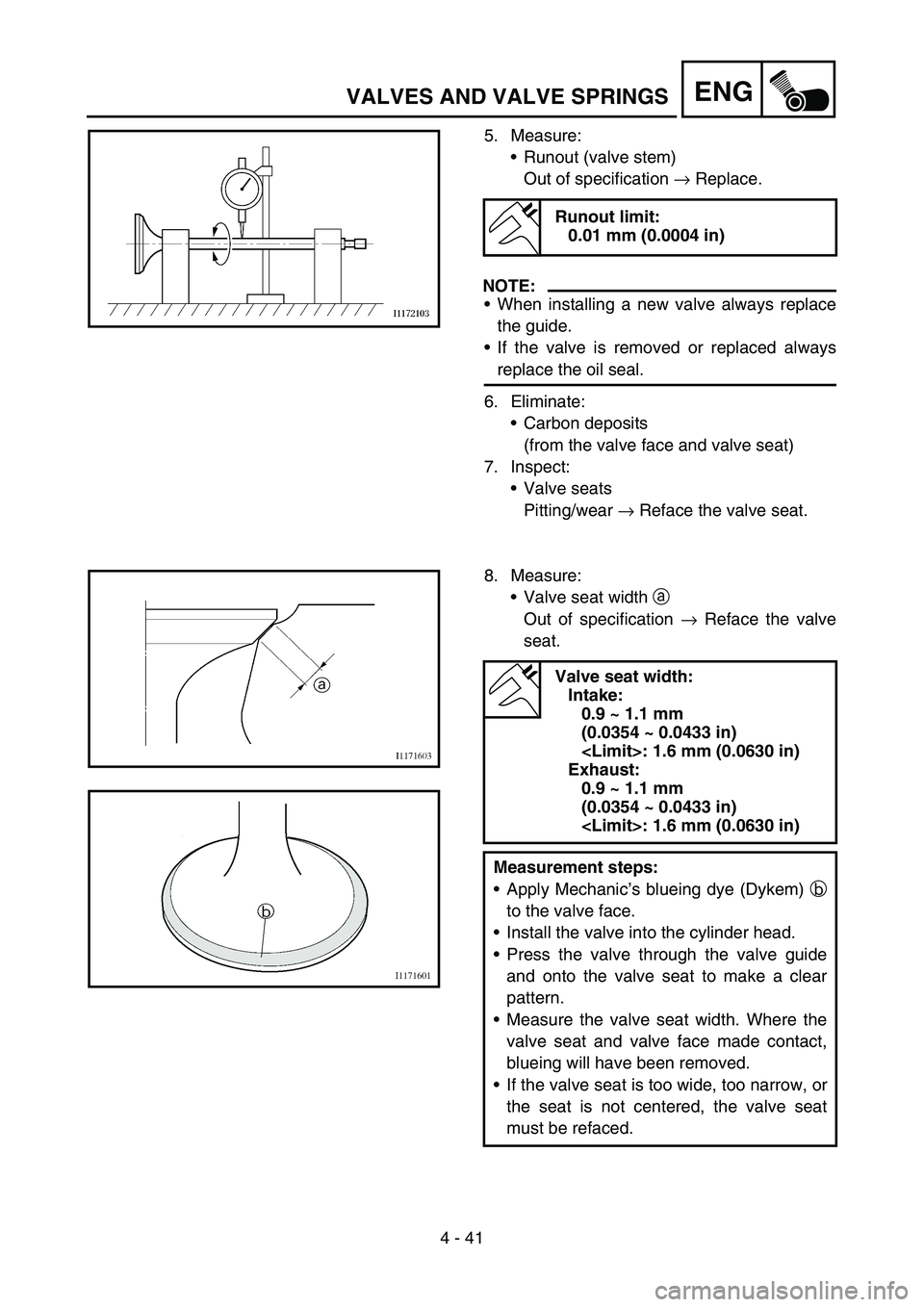

8. Measure:

Valve seat width a

Out of specification → Reface the valve

seat.

Valve seat width:

Intake:

0.9 ~ 1.1 mm

(0.0354 ~ 0.0433 in)

Exhaust:

0.9 ~ 1.1 mm

(0.0354 ~ 0.0433 in)

Measurement steps:

Apply Mechanic’s blueing dye (Dykem) b

to the valve face.

Install the valve into the cylinder head.

Press the valve through the valve guide

and onto the valve seat to make a clear

pattern.

Measure the valve seat width. Where the

valve seat and valve face made contact,

blueing will have been removed.

If the valve seat is too wide, too narrow, or

the seat is not centered, the valve seat

must be refaced.

Page 404 of 794

4 - 42

ENGVALVES AND VALVE SPRINGS

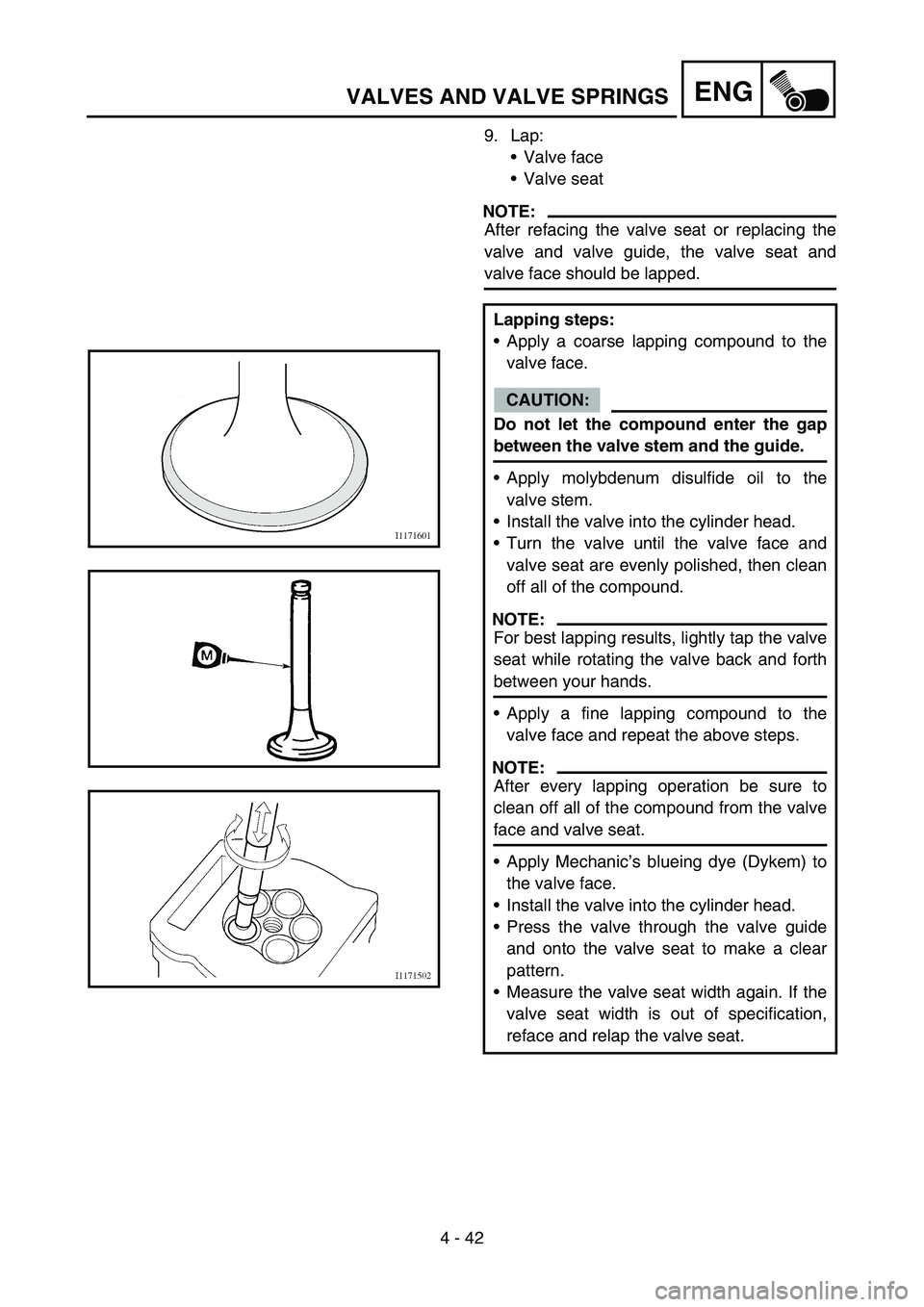

9. Lap:

Valve face

Valve seat

NOTE:

After refacing the valve seat or replacing the

valve and valve guide, the valve seat and

valve face should be lapped.

Lapping steps:

Apply a coarse lapping compound to the

valve face.

CAUTION:

Do not let the compound enter the gap

between the valve stem and the guide.

Apply molybdenum disulfide oil to the

valve stem.

Install the valve into the cylinder head.

Turn the valve until the valve face and

valve seat are evenly polished, then clean

off all of the compound.

NOTE:

For best lapping results, lightly tap the valve

seat while rotating the valve back and forth

between your hands.

Apply a fine lapping compound to the

valve face and repeat the above steps.

NOTE:

After every lapping operation be sure to

clean off all of the compound from the valve

face and valve seat.

Apply Mechanic’s blueing dye (Dykem) to

the valve face.

Install the valve into the cylinder head.

Press the valve through the valve guide

and onto the valve seat to make a clear

pattern.

Measure the valve seat width again. If the

valve seat width is out of specification,

reface and relap the valve seat.