ignition YAMAHA WR 450F 2007 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: WR 450F, Model: YAMAHA WR 450F 2007Pages: 794, PDF Size: 21.82 MB

Page 318 of 794

3 - 57

INSP

ADJ

REPLACING THE HEADLIGHT BULBS

3. Replace:

Blown fuse

WARNING

Never use a fuse with an amperage rating

other than that specified. Improvising or

using a fuse with the wrong amperage rat-

ing may cause extensive damage to the

electrical system, cause the starting and

ignition systems to malfunction and could

possibly cause a fire.

4. Install:

Fuse cover

Seat Replacement steps:

Set the main switch to “OFF”.

Install a new fuse of the correct amperage.

Set on the switches to verify if the electri-

cal circuit is operational.

If the fuse immediately blows again, check

the electrical circuit.

ItemsAmperage

ratingQ’ty

Main fuse 10 A 1

REPLACING THE HEADLIGHT BULBS

1. Remove:

Headlight

Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section in the CHAPTER 4.

2. Remove:

Headlight bulb holder cover 1

3. Remove:

Headlight bulb holder 1

NOTE:

Remove the headlight bulb holder by pushing

it in and turning it counterclockwise.

Page 500 of 794

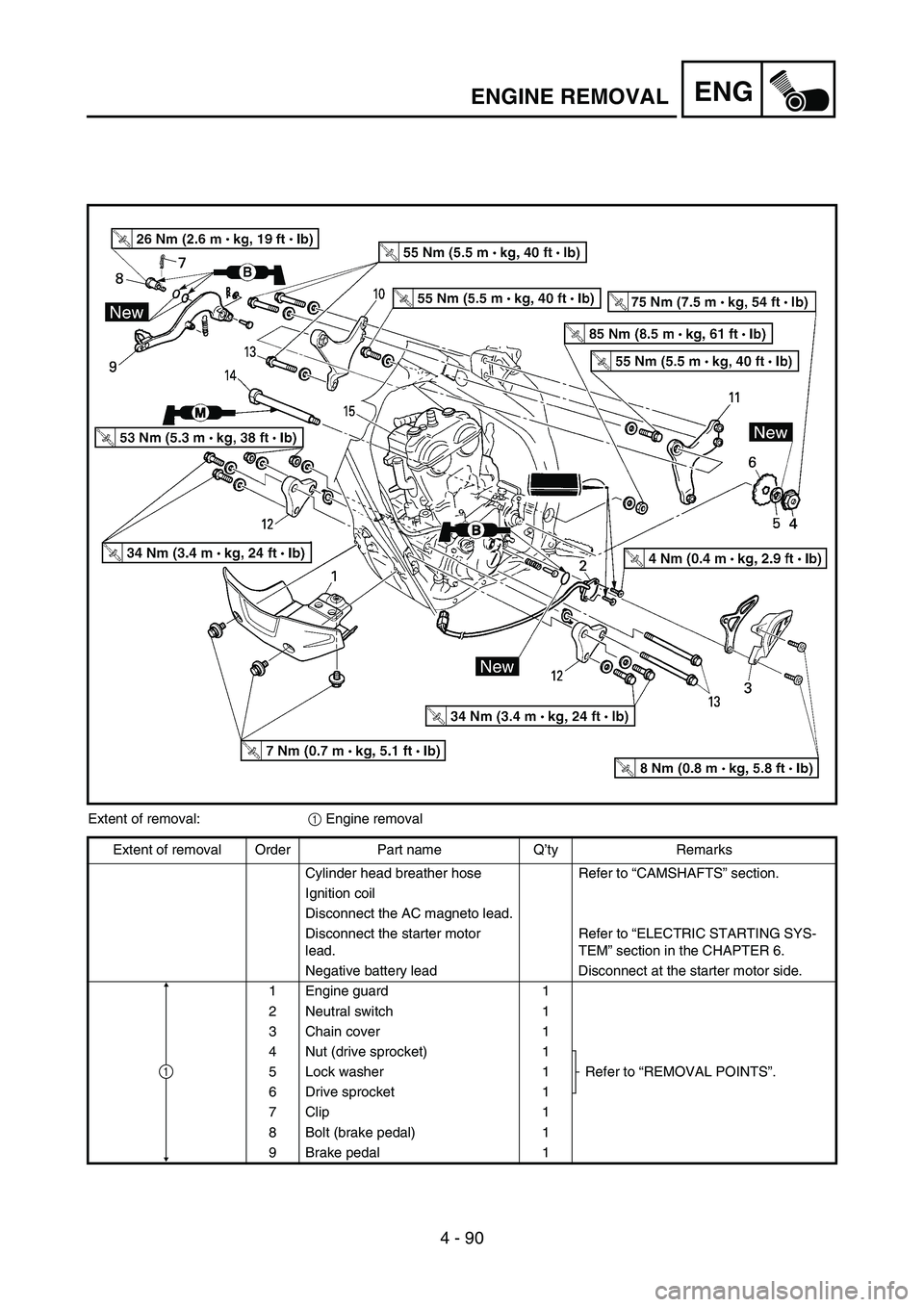

4 - 90

ENGENGINE REMOVAL

Extent of removal:

1 Engine removal

Extent of removal Order Part name Q’ty Remarks

Cylinder head breather hose Refer to “CAMSHAFTS” section.

Ignition coil

Disconnect the AC magneto lead.

Disconnect the starter motor

lead.Refer to “ELECTRIC STARTING SYS-

TEM” section in the CHAPTER 6.

Negative battery lead Disconnect at the starter motor side.

1 Engine guard 1

2 Neutral switch 1

3 Chain cover 1

4 Nut (drive sprocket) 1

Refer to “REMOVAL POINTS”. 5 Lock washer 1

6 Drive sprocket 1

7Clip 1

8 Bolt (brake pedal) 1

9 Brake pedal 1

1

Page 676 of 794

6 - 1

–+ELECELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC600000

ELECTRICAL

EC610000

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC611000

ELECTRICAL COMPONENTS

1Headlight

2Multi-function display

3“ENGINE STOP” but-

ton

4Clutch switch

5Diode

6Starter relay diode

7TPS (throttle posi-

tion sensor)

8Starter relay

9Fuse

0Starting circuit cut-off

relayACDI unit

BTaillight

CNeutral switch

DStarter motor

EAC magneto

FRectifier/regulator

GIgnition coil

HSpark plug

IStart switch

JMain switch

KSpeed sensor

LBatteryCOLOR CODE

B ...................... Black

Br ..................... Brown

Ch .................... Chocolate

Dg .................... Dark green

G ...................... Green

Gy .................... Gray

L....................... Blue

O ...................... Orange

R ...................... Red

Sb .................... Sky blue

EC612000

WIRING DIAGRAM

W ..................... White

Y ...................... Yellow

B/L ................... Black/Blue

B/W .................. Black/White

L/B ................... Blue/Black

L/R ................... Blue/Red

L/Y ................... Blue/Yellow

L/W .................. Blue/White

R/B................... Red/Black

R/W.................. Red/White

Page 678 of 794

–+ELEC

6 - 2

IGNITION SYSTEM

EC620000

IGNITION SYSTEM

INSPECTION STEPS

Use the following steps for checking the possibility of the malfunctioning engine being attributable to

ignition system failure and for checking the spark plug which will not spark.

*1 marked: Refer to “FUSE INSPECTION” section in the CHAPTER 3.

*2 marked: Refer to “BATTERY INSPECTION AND CHARGING” section in the CHAPTER 3.

*3 marked: Only when the ignition checker is used.

NOTE:

•Remove the following parts before inspection.

1) Seat

2) Fuel tank

•Use the following special tools in this inspection.

Dynamic spark tester:

YM-34487

Ignition checker:

90890-06754Pocket tester:

YU-3112-C/90890-03112

*1 Check fuse.Replace fuse and

check wire harness.

*2 Check battery Recharge or replace.

Spark gap test*3 Clean or replace

spark plug.

Check entire ignition

system for connection.

(couplers, leads and

ignition coil)Repair or replace.

Check “ENGINE STOP”

button.Replace.

Check main switch. Replace.

Check ignition coil. Primary coil Replace.

Secondary coil Replace.

Check AC magneto. Pick-up coil Replace.

Check neutral switch. Repair or replace.

Replace CDI unit.

OK

OK

No spark

OK

OK

OK

OK

OK

OK

Spark No good

No good

No good

No good

No good No good

No good

No good

No good

Page 682 of 794

6 - 3

–+ELECIGNITION SYSTEM

SPARK GAP TEST

1. Disconnect the ignition coil from spark

plug.

2. Remove the ignition coil cap.

3. Connect the dynamic spark tester 1 (igni-

tion checker 2) as shown.

•Ignition coil 3

•Spark plug 4

ÈFor USA and CDN

ÉExcept for USA and CDN

4. Kick the kickstarter.

5. Check the ignition spark gap.

6. Start engine, and increase spark gap until

misfire occurs. (for USA and CDN only)

Minimum spark gap:

6.0 mm (0.24 in)

È

É

COUPLERS, LEADS AND IGNITION COIL

CONNECTION INSPECTION

1. Check:

•Couplers and leads connection

Rust/dust/looseness/short-circuit →

Repair or replace.

•Ignition coil and spark plug as they are fit-

ted

Push in the ignition coil until it closely

contacts the spark plug hole in the cylin-

der head cover.

EC625001

“ENGINE STOP” BUTTON INSPECTION

1. Inspect:

•“ENGINE STOP” button conduct

No continuity while being pushed → Replace.

Continuity while being freed → Replace.

2. Inspect:

•Rubber part

a

Tears/damage → Replace. Tester (+) lead

→ Black lead

1

Tester (–) lead

→ Black lead

2

B

1 B

2 Tester selec-

tor position

PUSH IN

Ω

×

×× × 1

FREE

a

Page 684 of 794

6 - 4

–+ELECIGNITION SYSTEM

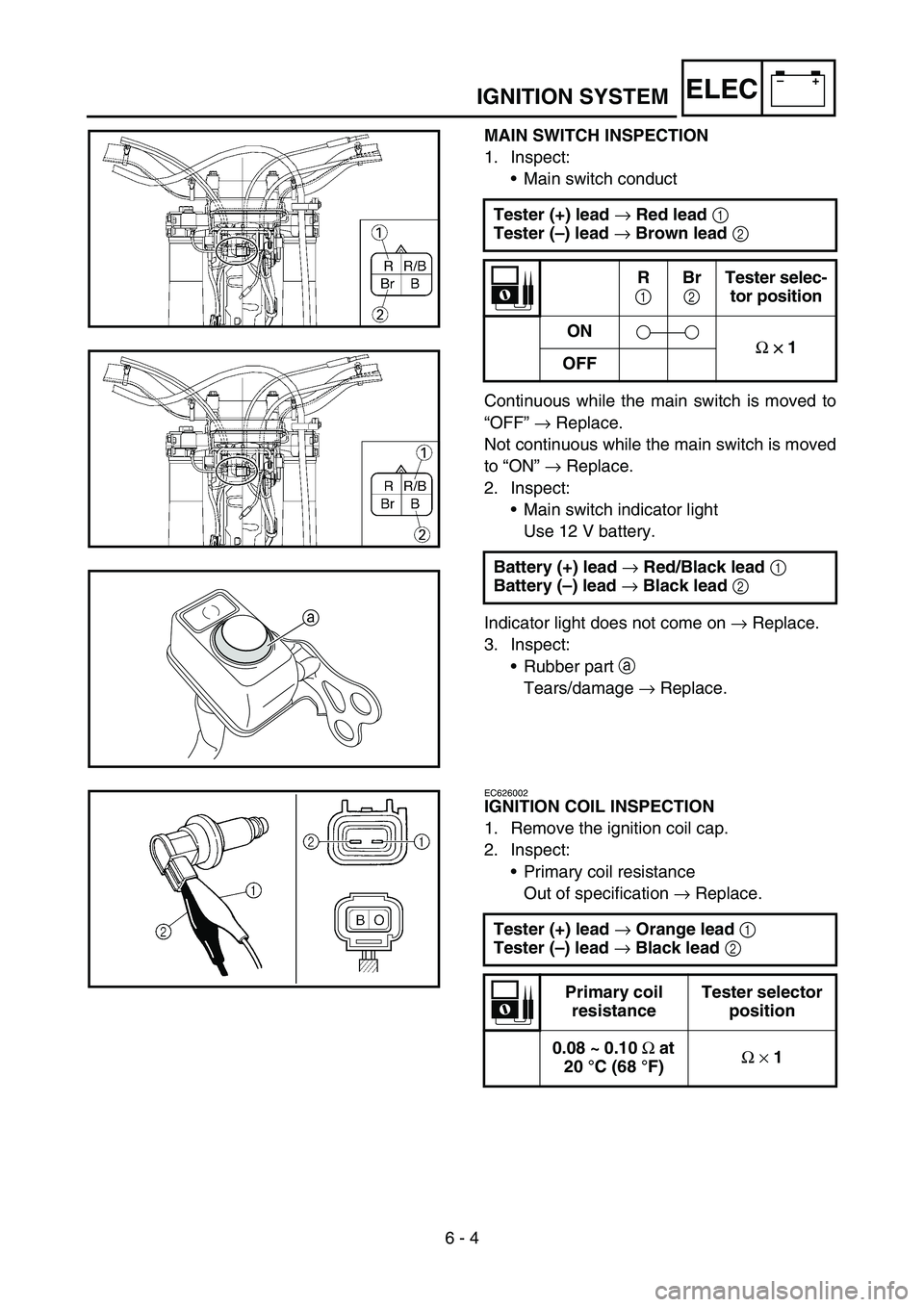

MAIN SWITCH INSPECTION

1. Inspect:

•Main switch conduct

Continuous while the main switch is moved to

“OFF” → Replace.

Not continuous while the main switch is moved

to “ON” → Replace.

2. Inspect:

•Main switch indicator light

Use 12 V battery.

Indicator light does not come on → Replace.

3. Inspect:

•Rubber part a

Tears/damage → Replace. Tester (+) lead

→ Red lead

1

Tester (–) lead

→ Brown lead

2

R

1 Br

2 Tester selec-

tor position

ON

Ω

×

×× × 1

OFF

Battery (+) lead

→ Red/Black lead

1

Battery (–) lead

→ Black lead

2

a

EC626002

IGNITION COIL INSPECTION

1. Remove the ignition coil cap.

2. Inspect:

•Primary coil resistance

Out of specification → Replace.

Tester (+) lead

→ Orange lead

1

Tester (–) lead

→ Black lead

2

Primary coil

resistanceTester selector

position

0.08 ~ 0.10

Ω at

20 °C (68 °F)Ω

× 1

Page 686 of 794

6 - 5

–+ELECIGNITION SYSTEM

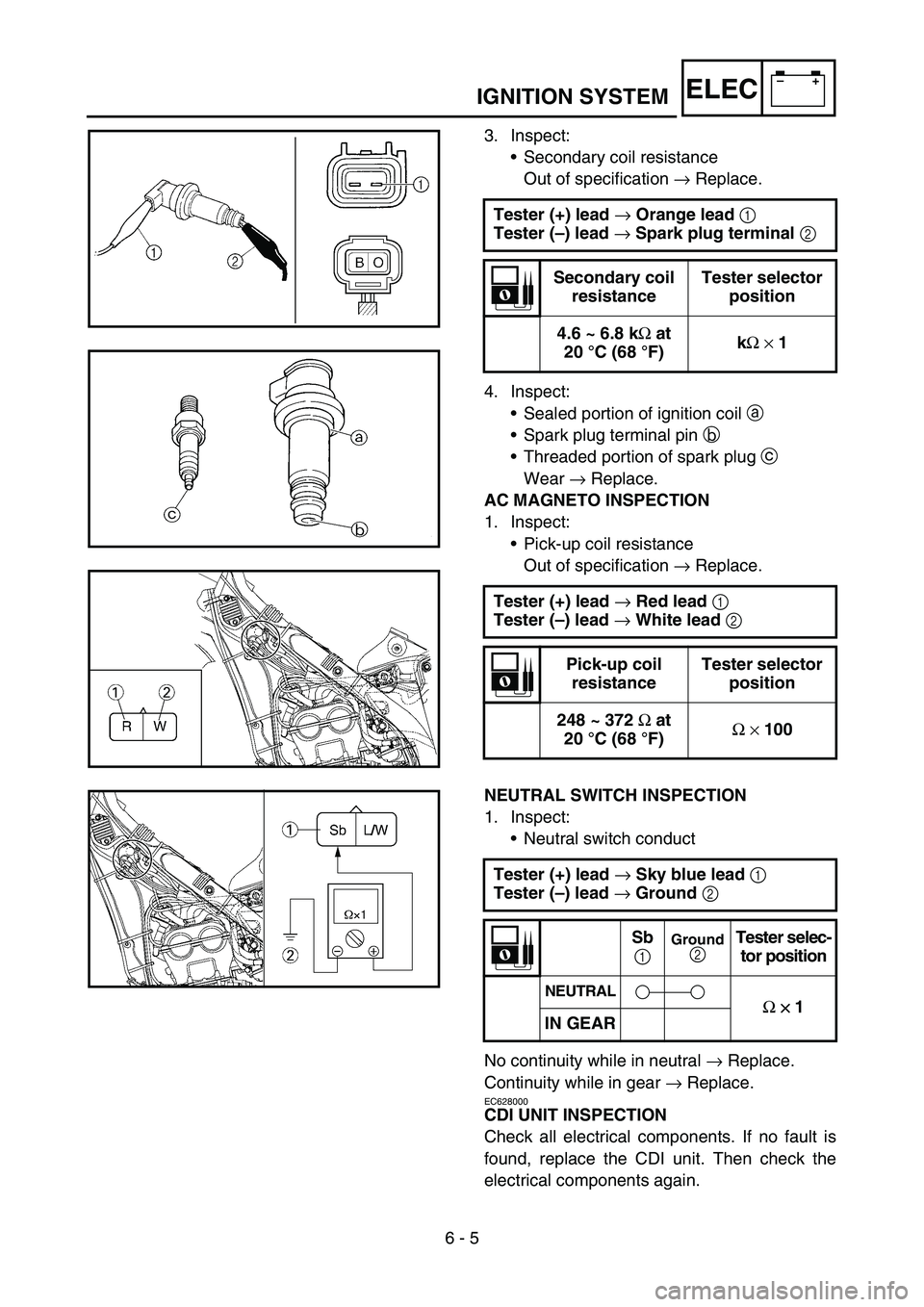

3. Inspect:

•Secondary coil resistance

Out of specification → Replace.

4. Inspect:

•Sealed portion of ignition coil a

•Spark plug terminal pin b

•Threaded portion of spark plug c

Wear → Replace.

AC MAGNETO INSPECTION

1. Inspect:

•Pick-up coil resistance

Out of specification → Replace.

NEUTRAL SWITCH INSPECTION

1. Inspect:

•Neutral switch conduct

No continuity while in neutral → Replace.

Continuity while in gear → Replace.

EC628000

CDI UNIT INSPECTION

Check all electrical components. If no fault is

found, replace the CDI unit. Then check the

electrical components again.Tester (+) lead

→ Orange lead

1

Tester (–) lead

→ Spark plug terminal

2

Secondary coil

resistanceTester selector

position

4.6 ~ 6.8 k

Ω at

20 °C (68 °F)k

Ω

× 1

Tester (+) lead

→ Red lead

1

Tester (–) lead

→ White lead

2

Pick-up coil

resistanceTester selector

position

248 ~ 372

Ω at

20 °C (68 °F)Ω

× 100

Tester (+) lead

→ Sky blue lead

1

Tester (–) lead

→ Ground

2

Sb

1 Ground 2

Tester selec-

tor position

NEUTRAL

Ω

×

×× × 1

IN GEAR

Page 716 of 794

–+ELEC

6 - 18

TPS (THROTTLE POSITION SENSOR) SYSTEM

EC690000

TPS (THROTTLE POSITION SENSOR) SYSTEM

INSPECTION STEPS

If the TPS will not operate, use the following inspection steps.

NOTE:

Use the following special tools in this inspection.

Pocket tester:

YU-3112-C/90890-03112

Check entire ignition

system for connection.Repair or replace.

Check TPS. TPS coil Replace.

Check CDI unit.TPS input

voltageReplace.

OK

OK

No good

No good

No good