oil filter YAMAHA WR 450F 2007 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: WR 450F, Model: YAMAHA WR 450F 2007Pages: 794, PDF Size: 21.82 MB

Page 224 of 794

3 - 13

INSP

ADJ

CAUTION:

Do not twist the element when squeezing

the element.

Leaving too much of solvent in the ele-

ment may result in poor starting.

5. Inspect:

Air filter element

Damage → Replace.

6. Apply:

Foam-air-filter oil or equivalent oil to the

element.

NOTE:

Squeeze out the excess oil. Element should

be wet but not dripping.

Wipe off the oil left on the element surface

using a clean dry cloth. (Excess oil in the ele-

ment may adversely affect engine starting.)

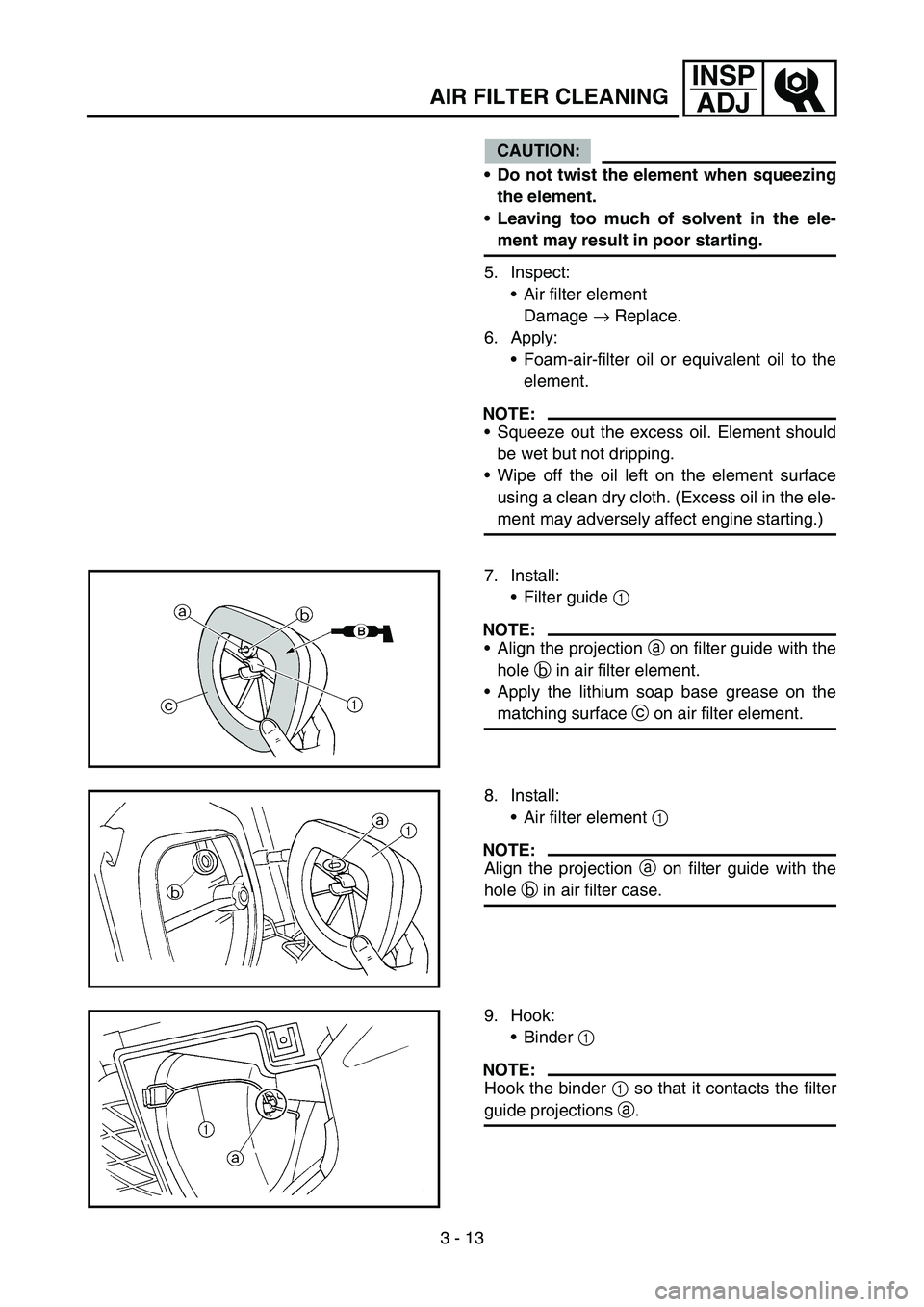

7. Install:

Filter guide 1

NOTE:

Align the projection a on filter guide with the

hole b in air filter element.

Apply the lithium soap base grease on the

matching surface c on air filter element.

8. Install:

Air filter element 1

NOTE:

Align the projection a on filter guide with the

hole b in air filter case.

9. Hook:

Binder 1

NOTE:

Hook the binder 1 so that it contacts the filter

guide projections a.

AIR FILTER CLEANING

Page 230 of 794

3 - 16

INSP

ADJ

ENGINE OIL REPLACEMENT

6. Idle the engine more than 10 seconds

while keeping the machine upright. Then

stop the engine and add the oil to the maxi-

mum level.

7. Install:

Oil tank plug

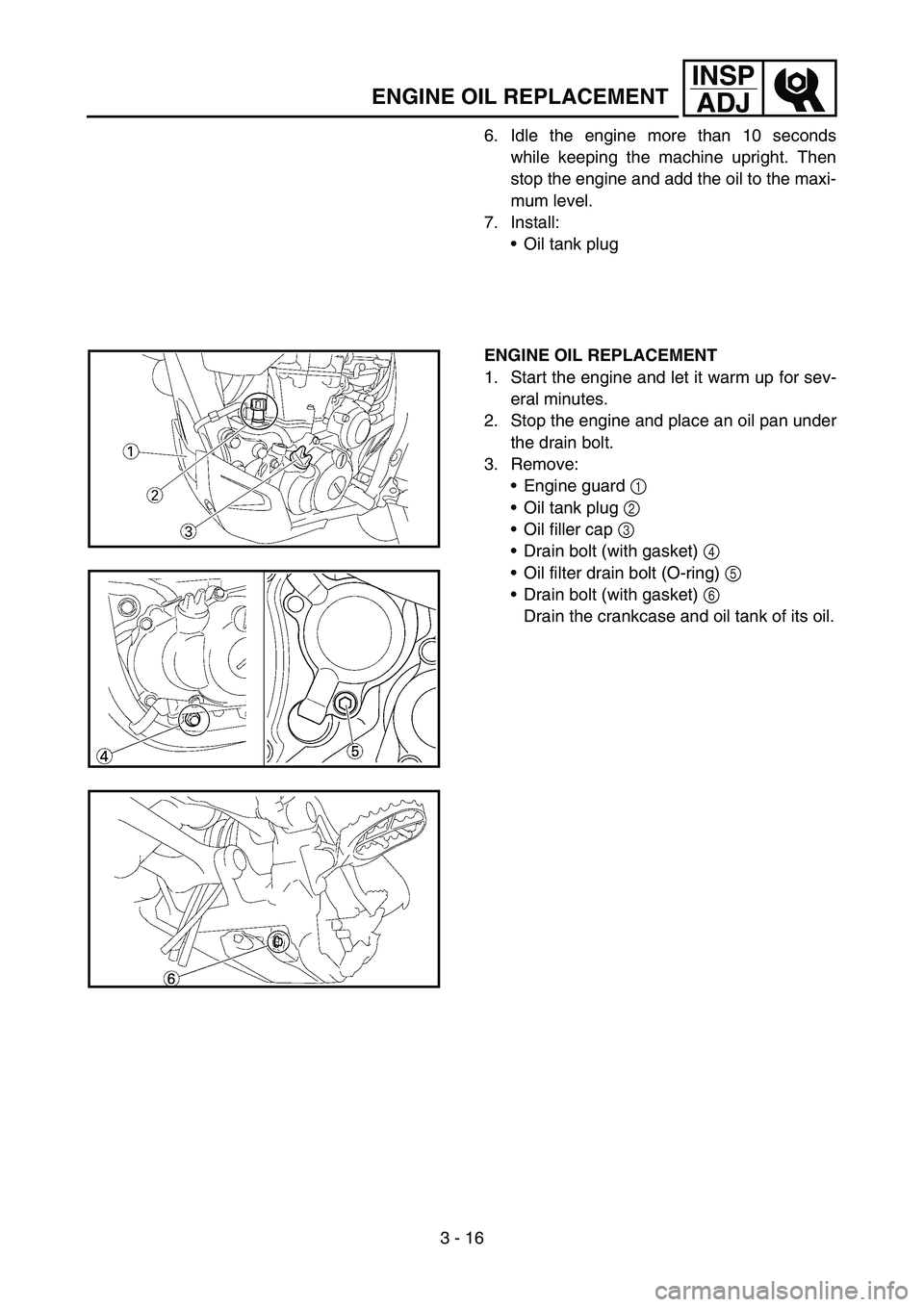

ENGINE OIL REPLACEMENT

1. Start the engine and let it warm up for sev-

eral minutes.

2. Stop the engine and place an oil pan under

the drain bolt.

3. Remove:

Engine guard 1

Oil tank plug 2

Oil filler cap 3

Drain bolt (with gasket) 4

Oil filter drain bolt (O-ring) 5

Drain bolt (with gasket) 6

Drain the crankcase and oil tank of its oil.

Page 232 of 794

3 - 17

INSP

ADJ

ENGINE OIL REPLACEMENT

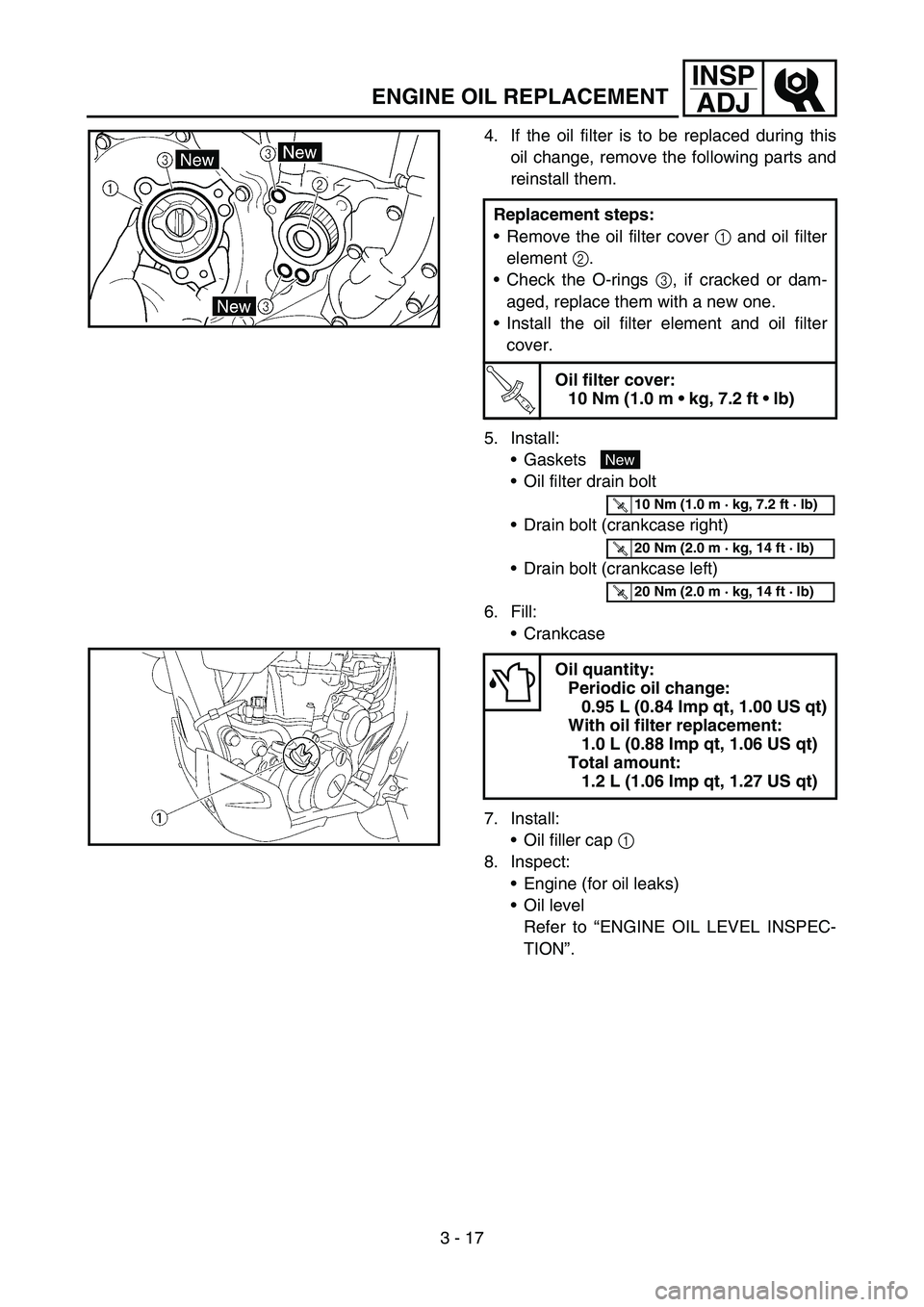

4. If the oil filter is to be replaced during this

oil change, remove the following parts and

reinstall them.

5. Install:

Gaskets

Oil filter drain bolt

Drain bolt (crankcase right)

Drain bolt (crankcase left)

6. Fill:

Crankcase

7. Install:

Oil filler cap 1

8. Inspect:

Engine (for oil leaks)

Oil level

Refer to “ENGINE OIL LEVEL INSPEC-

TION”. Replacement steps:

Remove the oil filter cover 1 and oil filter

element 2.

Check the O-rings 3, if cracked or dam-

aged, replace them with a new one.

Install the oil filter element and oil filter

cover.

T R..

Oil filter cover:

10 Nm (1.0 m kg, 7.2 ft lb)

Oil quantity:

Periodic oil change:

0.95 L (0.84 Imp qt, 1.00 US qt)

With oil filter replacement:

1.0 L (0.88 Imp qt, 1.06 US qt)

Total amount:

1.2 L (1.06 Imp qt, 1.27 US qt)

New

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..20 Nm (2.0 m · kg, 14 ft · lb)

T R..20 Nm (2.0 m · kg, 14 ft · lb)

Page 234 of 794

3 - 18

INSP

ADJ

IDLE SPEED ADJUSTMENT

9. Check:

Oil pressure

Checking steps:

Slightly loosen the oil gallery bolt 1.

Start the engine and keep it idling until oil

starts to seep from the oil gallery bolt. If no

oil comes out after one minute, turn the

engine off so it will not seize.

Check oil passages, oil filter and oil pump

for damage or leakage.

Start the engine after solving the prob-

lem(s) and recheck the oil pressure.

Tighten the oil gallery bolt to specification.

T R..

Oil gallery bolt:

10 Nm (1.0 m kg, 7.2 ft lb)

EC35M021

IDLE SPEED ADJUSTMENT

1. Start the engine and thoroughly warm it up.

2. Adjust:

Idle speed

Adjustment steps:

Turn the throttle stop screw 1 until the

specified engine idling speed.

NOTE:

Using a digital engine tachometer for idle

speed adjustment, detect the engine idling

speed by bringing the sensing element c of

the engine tachometer close to the ignition

coil 2.

To increase idle speed

→

Turn the throttle stop screw

1 in

a.

To decrease idle speed

→

Turn the throttle stop screw

1 out

b.

Engine idling speed:

1,750 ~ 1,850 r/min

c2

Page 438 of 794

4 - 59

ENG

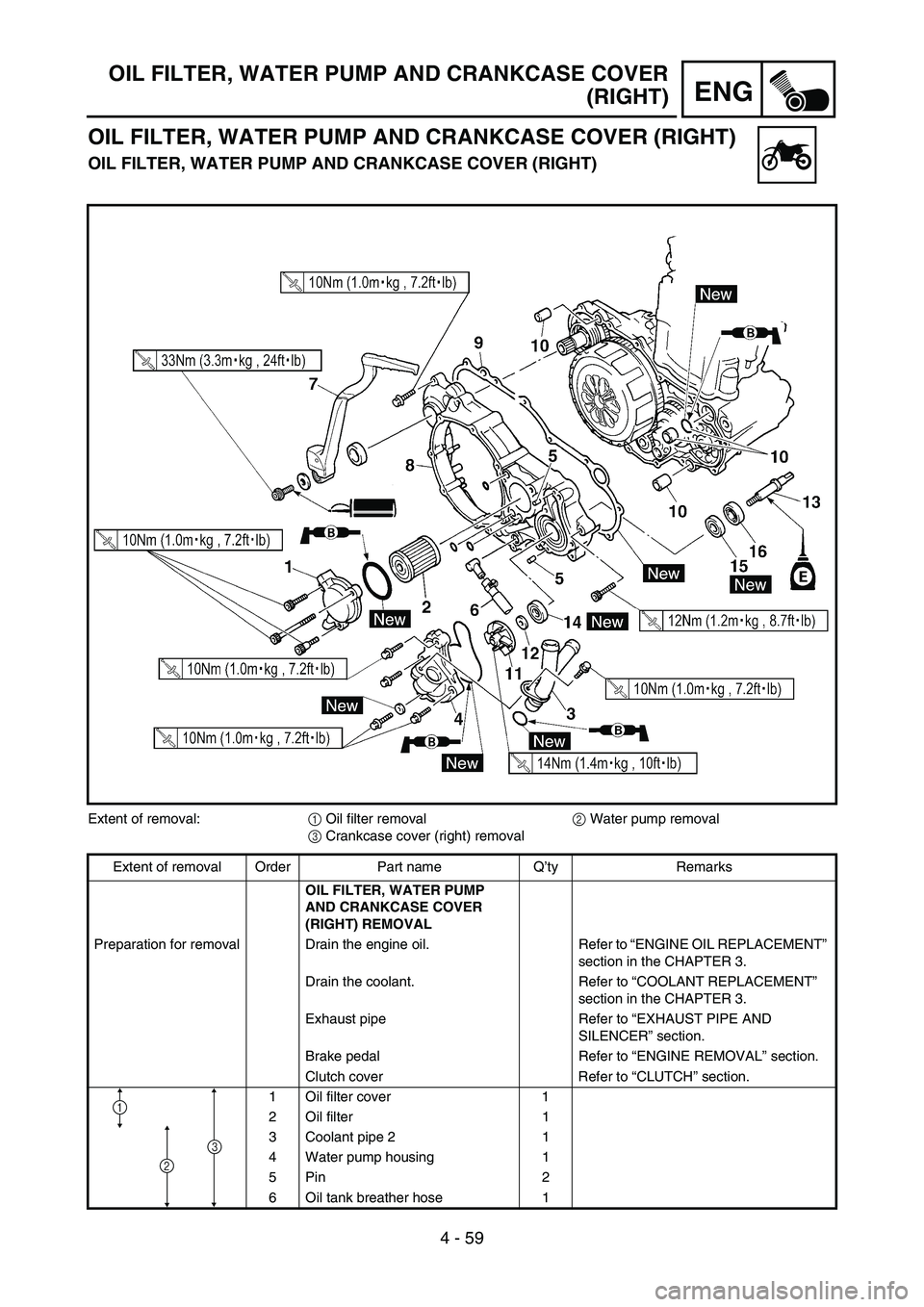

OIL FILTER, WATER PUMP AND CRANKCASE COVER

(RIGHT)

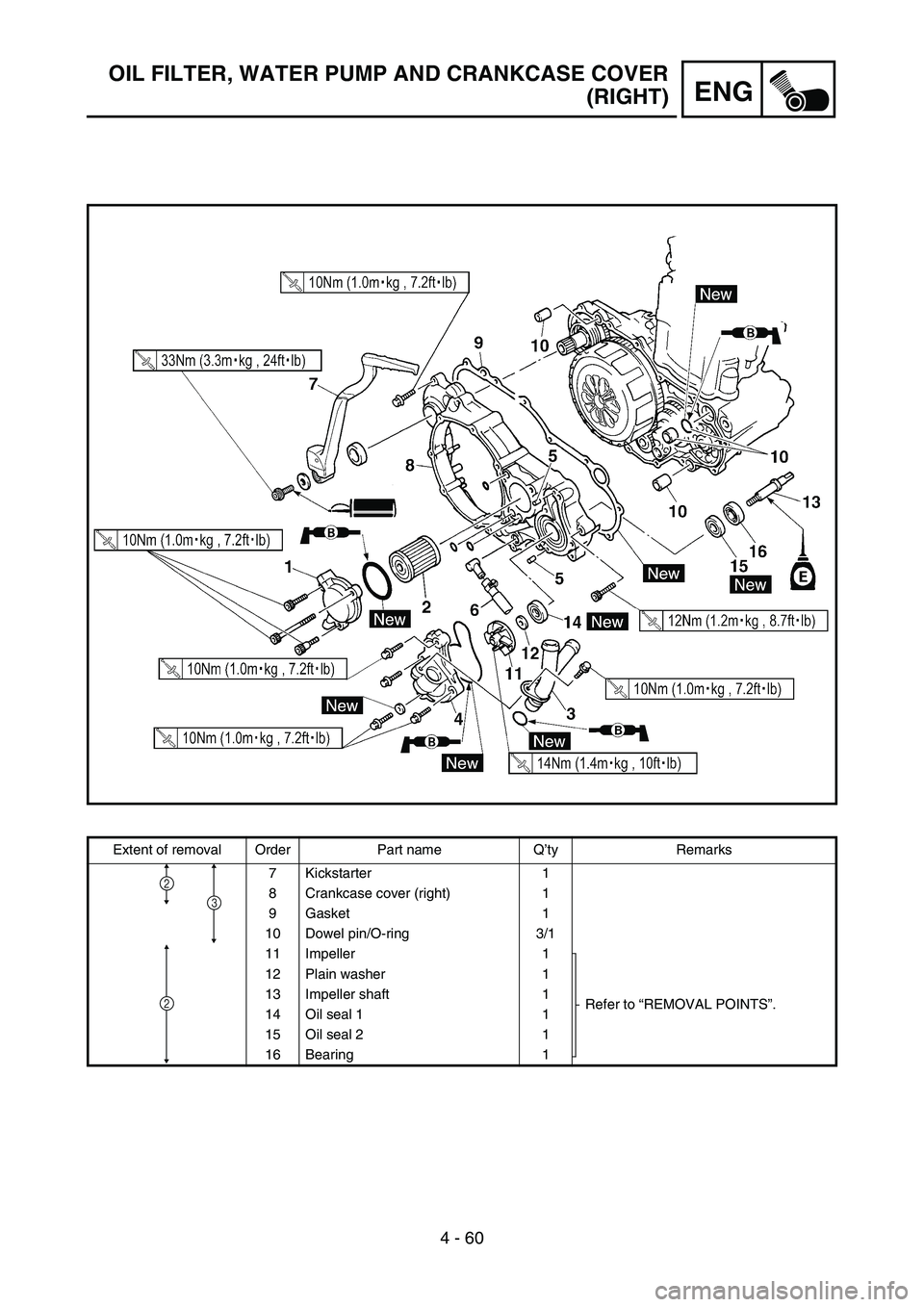

OIL FILTER, WATER PUMP AND CRANKCASE COVER (RIGHT)

OIL FILTER, WATER PUMP AND CRANKCASE COVER (RIGHT)

Extent of removal:

1 Oil filter removal

2 Water pump removal

3 Crankcase cover (right) removal

Extent of removal Order Part name Q’ty Remarks

OIL FILTER, WATER PUMP

AND CRANKCASE COVER

(RIGHT) REMOVAL

Preparation for removal Drain the engine oil. Refer to “ENGINE OIL REPLACEMENT”

section in the CHAPTER 3.

Drain the coolant. Refer to “COOLANT REPLACEMENT”

section in the CHAPTER 3.

Exhaust pipe Refer to “EXHAUST PIPE AND

SILENCER” section.

Brake pedal Refer to “ENGINE REMOVAL” section.

Clutch cover Refer to “CLUTCH” section.

1 Oil filter cover 1

2 Oil filter 1

3 Coolant pipe 2 1

4 Water pump housing 1

5Pin 2

6 Oil tank breather hose 1

1

2

3

Page 440 of 794

4 - 60

ENG

OIL FILTER, WATER PUMP AND CRANKCASE COVER

(RIGHT)

Extent of removal Order Part name Q’ty Remarks

7 Kickstarter 1

8 Crankcase cover (right) 1

9 Gasket 1

10 Dowel pin/O-ring 3/1

11 Impeller 1

Refer to “REMOVAL POINTS”. 12 Plain washer 1

13 Impeller shaft 1

14 Oil seal 1 1

15 Oil seal 2 1

16 Bearing 1

2

2

3

Page 442 of 794

4 - 61

ENG

OIL FILTER, WATER PUMP AND CRANKCASE COVER

(RIGHT)

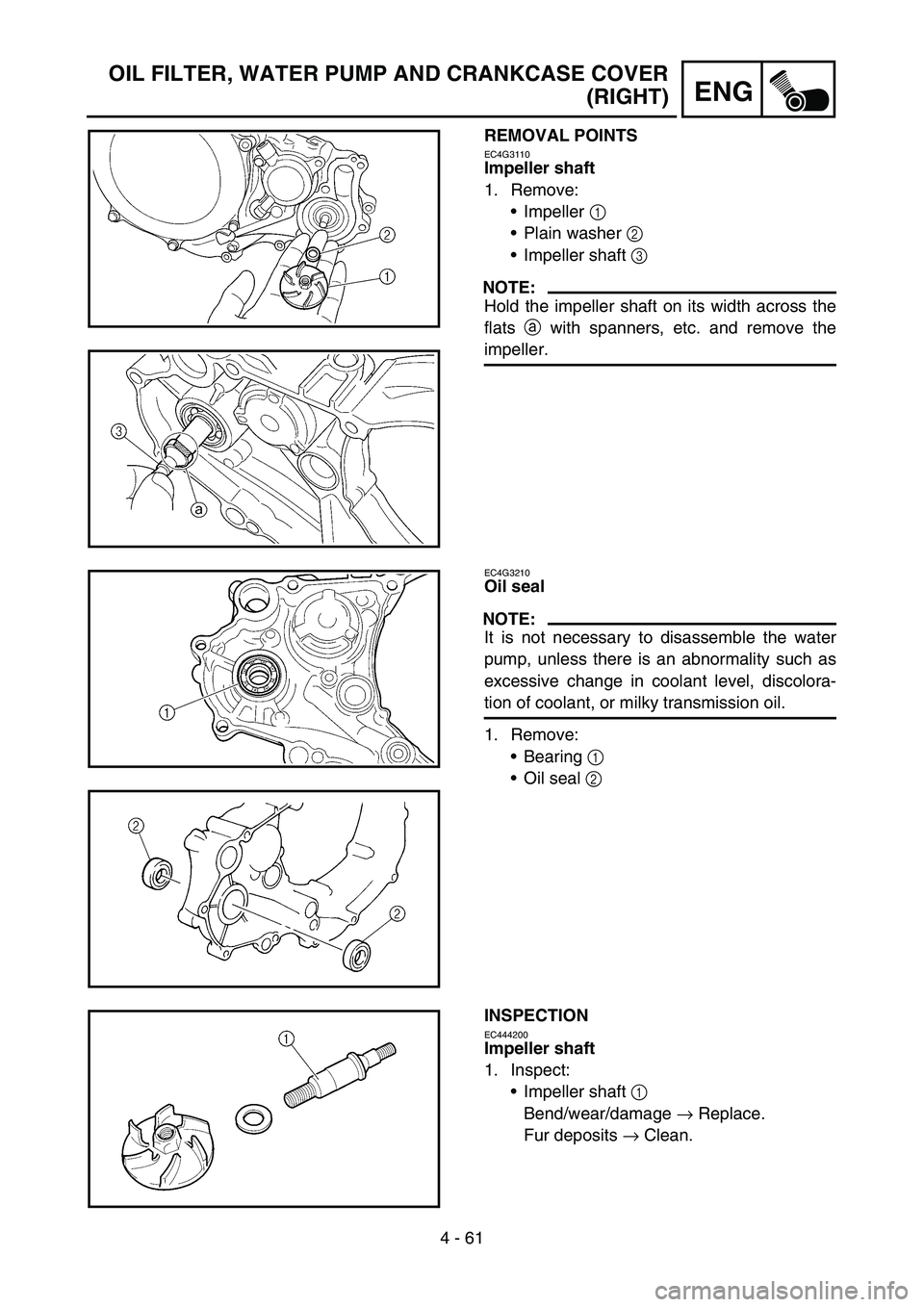

REMOVAL POINTS

EC4G3110

Impeller shaft

1. Remove:

Impeller 1

Plain washer 2

Impeller shaft 3

NOTE:

Hold the impeller shaft on its width across the

flats a with spanners, etc. and remove the

impeller.

EC4G3210

Oil seal

NOTE:

It is not necessary to disassemble the water

pump, unless there is an abnormality such as

excessive change in coolant level, discolora-

tion of coolant, or milky transmission oil.

1. Remove:

Bearing 1

Oil seal 2

INSPECTION

EC444200

Impeller shaft

1. Inspect:

Impeller shaft 1

Bend/wear/damage → Replace.

Fur deposits → Clean.

Page 444 of 794

4 - 62

ENG

OIL FILTER, WATER PUMP AND CRANKCASE COVER

(RIGHT)

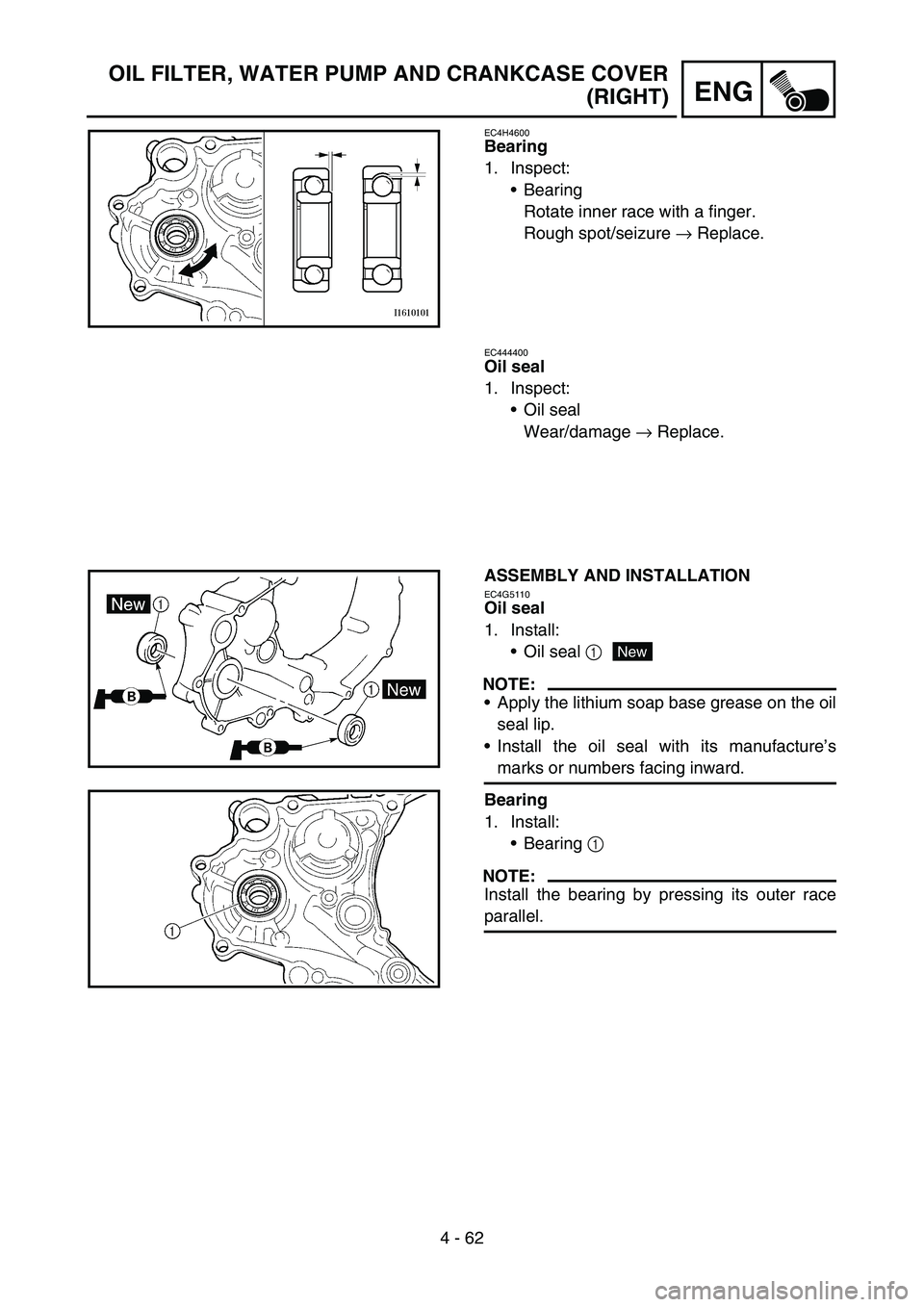

EC4H4600

Bearing

1. Inspect:

Bearing

Rotate inner race with a finger.

Rough spot/seizure → Replace.

EC444400

Oil seal

1. Inspect:

Oil seal

Wear/damage → Replace.

ASSEMBLY AND INSTALLATION

EC4G5110

Oil seal

1. Install:

Oil seal 1

NOTE:

Apply the lithium soap base grease on the oil

seal lip.

Install the oil seal with its manufacture’s

marks or numbers facing inward.

Bearing

1. Install:

Bearing 1

NOTE:

Install the bearing by pressing its outer race

parallel.

New

Page 446 of 794

4 - 63

ENG

OIL FILTER, WATER PUMP AND CRANKCASE COVER

(RIGHT)

EC4G5220

Impeller shaft

1. Install:

Impeller shaft 1

Plain washer 2

Impeller 3

NOTE:

Take care so that the oil seal lip is not dam-

aged or the spring does not slip off its posi-

tion.

When installing the impeller shaft, apply the

engine oil on the oil seal lip, bearing and

impeller shaft. And install the shaft while

turning it.

Hold the impeller shaft on its width across

the flats a with spanners, etc. and install the

impeller.

T R..14 Nm (1.4 m · kg, 10 ft · lb)

Crankcase cover (right)

1. Install:

Dowel pin 1

O-ring 2

Collar 3

Gasket 4

New

New

2. Install:

Crankcase cover (right) 1

Bolt 2

Bolt

NOTE:

Apply the engine oil on the impeller shaft

end.

When installing the crankcase cover onto the

crankcase, be sure that the impeller shaft

end 2 aligns with the balancer end slot 3.

Tighten the bolts in stage, using a crisscross

pattern.

T R..12 Nm (1.2 m · kg, 8.7 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 448 of 794

4 - 64

ENG

OIL FILTER, WATER PUMP AND CRANKCASE COVER

(RIGHT)

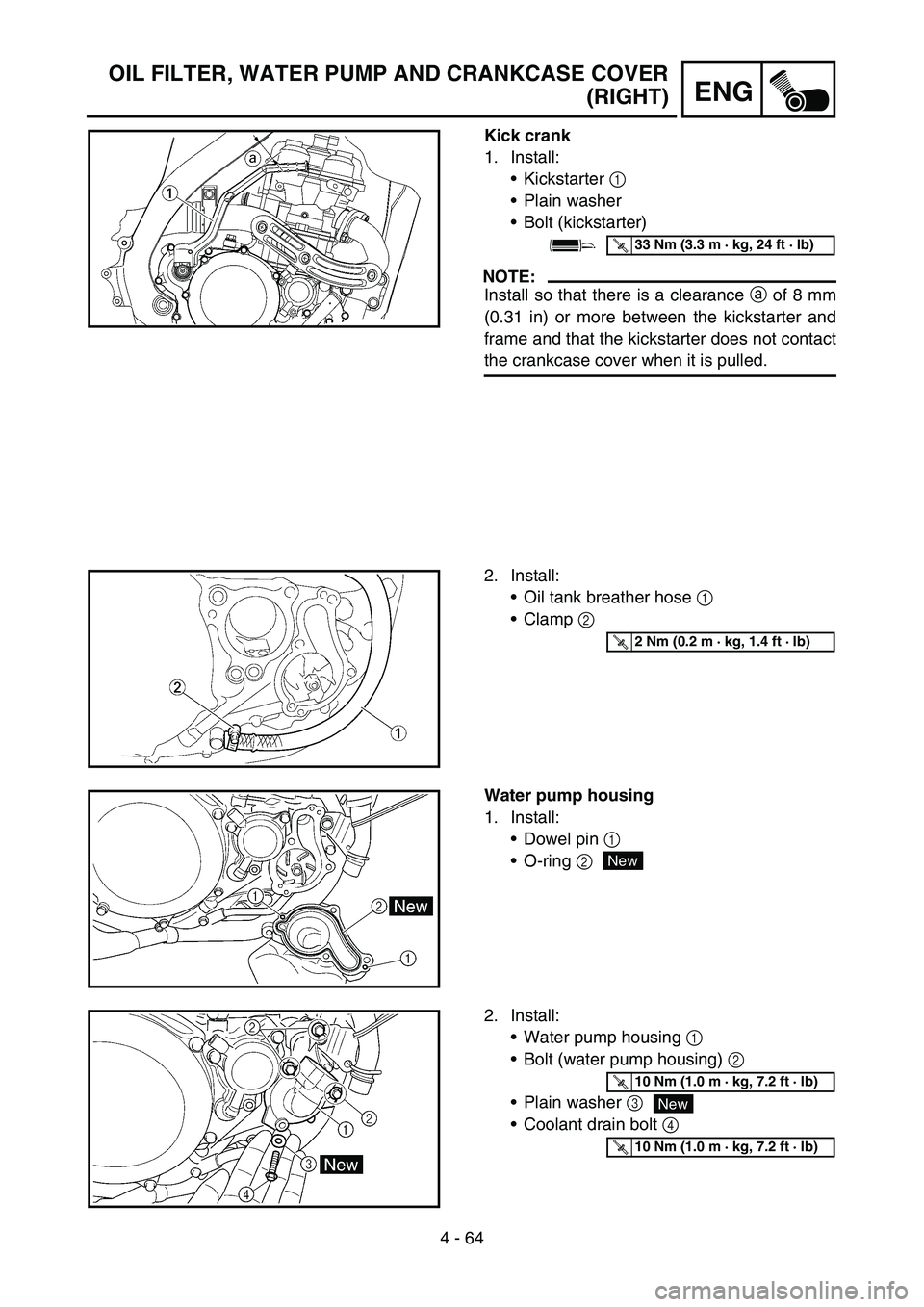

Kick crank

1. Install:

Kickstarter 1

Plain washer

Bolt (kickstarter)

NOTE:

Install so that there is a clearance a of 8 mm

(0.31 in) or more between the kickstarter and

frame and that the kickstarter does not contact

the crankcase cover when it is pulled.

T R..33 Nm (3.3 m · kg, 24 ft · lb)

2. Install:

Oil tank breather hose 1

Clamp 2

T R..2 Nm (0.2 m · kg, 1.4 ft · lb)

Water pump housing

1. Install:

Dowel pin 1

O-ring 2

New

2. Install:

Water pump housing 1

Bolt (water pump housing) 2

Plain washer 3

Coolant drain bolt 4

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

New

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)