start stop button YAMAHA WR 450F 2007 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: WR 450F, Model: YAMAHA WR 450F 2007Pages: 794, PDF Size: 21.82 MB

Page 26 of 794

GEN

INFO

1 - 1

DESCRIPTION

EC100000

GENERAL INFORMATION

EC110000

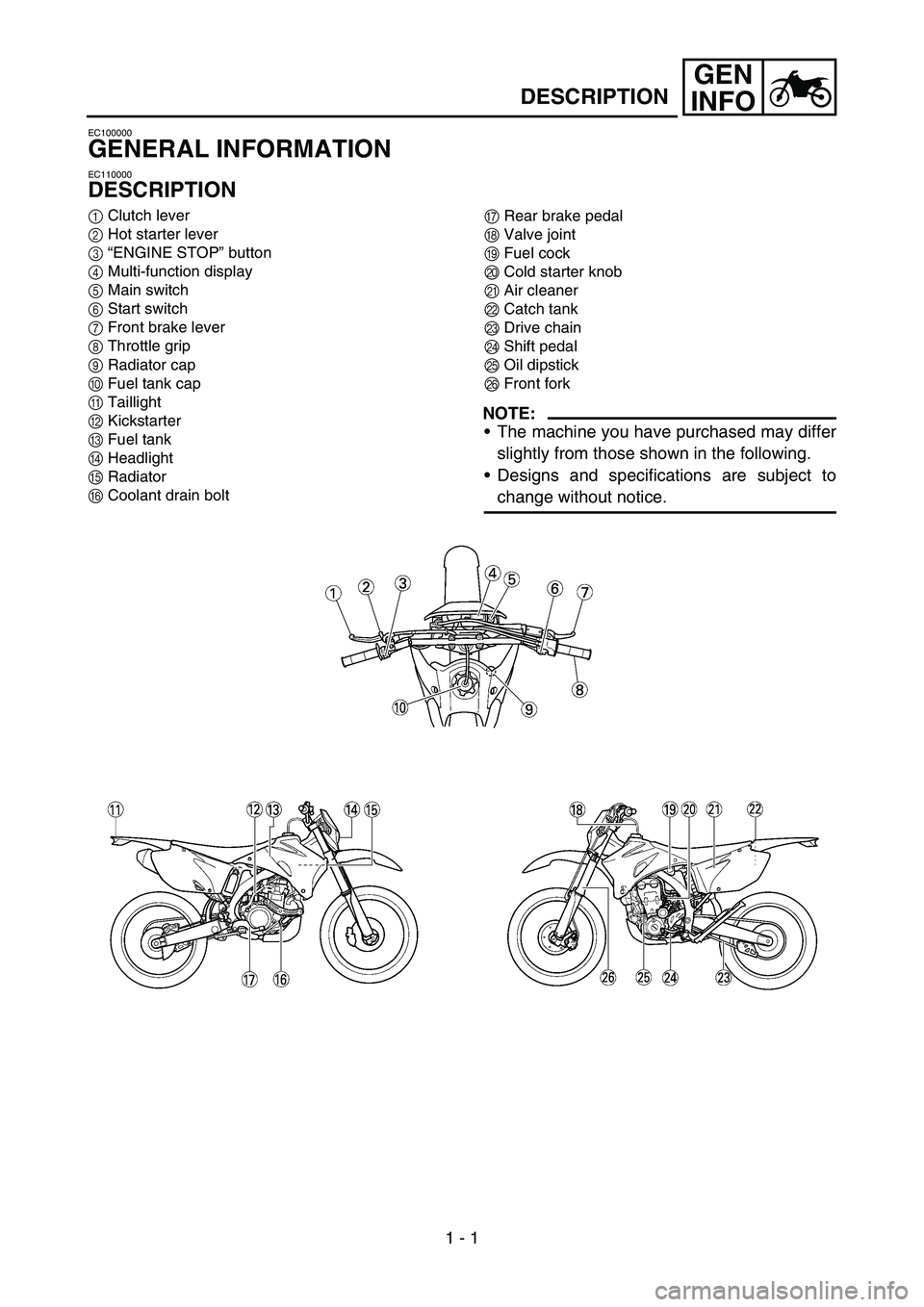

DESCRIPTION

1Clutch lever

2Hot starter lever

3“ENGINE STOP” button

4Multi-function display

5Main switch

6Start switch

7Front brake lever

8Throttle grip

9Radiator cap

0Fuel tank cap

ATaillight

BKickstarter

CFuel tank

DHeadlight

ERadiator

FCoolant drain boltGRear brake pedal

HValve joint

IFuel cock

JCold starter knob

KAir cleaner

LCatch tank

MDrive chain

NShift pedal

OOil dipstick

PFront fork

NOTE:

The machine you have purchased may differ

slightly from those shown in the following.

Designs and specifications are subject to

change without notice.

Page 50 of 794

1 - 10

GEN

INFO

CONTROL FUNCTIONS

EC150000

CONTROL FUNCTIONS

MAIN SWITCH

Functions of the respective switch positions

are as follows:

ON:

The engine can be started only at this position.

OFF:

All electrical circuits are switched off.

Main switch indicator light

The main switch 1 is equipped with an indica-

tor light 2 to avoid forgetting to turn it off. This

light functions as follows.

It lights up with the main switch “ON”.

It goes out when the engine increases its

speed after being started.

It lights up again when the engine is stopped.

NOTE:

If the indicator light will not light up with the

main switch “ON”, it shows a lack of the battery

voltage. Recharge the battery.

EC151000

“ENGINE STOP” BUTTON

The “ENGINE STOP” button 1 is located on

the left handlebar. Continue pushing the

“ENGINE STOP” button till the engine comes

to a stop.

START SWITCH

The start switch 1 is located on the right han-

dlebar. Push this switch to crank the engine

with the starter.

Page 58 of 794

1 - 14

GEN

INFO

MULTI-FUNCTION DISPLAY

WARNING

Be sure to stop the machine before making

any setting changes to the multi-function

display.

The multi-function display is equipped with the

following:

BASIC MODE:

Speedometer

Clock

Two tripmeters (which shows the distance

that has been traveled since it was last set to

zero)

RACE MODE:

Timer (which shows the time that has been

accumulated since the start of timer mea-

surement)

Tripmeter (which shows the accumulated

travel distance in timer measurement)

Change tripmeter digits (capable of change

to any given ones)

DESCRIPTION

Operation buttons:

1Select button “SLCT 1”

2Select button “SLCT 2”

3Reset button “RST”

Screen display:

4Tripmeter indicator

5Tripmeter indicator

6Timer indicator

7Clock/Timer

8Speedometer

9Odometer/Tripmeter

NOTE:

The operation buttons can be pushed in the

following two manners:

Short push: Push the button. ( )

Long push: Push the button for 2 seconds or

more. ( )

MULTI-FUNCTION DISPLAY

Page 64 of 794

1 - 17

GEN

INFO

MULTI-FUNCTION DISPLAY

Returning to BASIC MODE from RACE

MODE

NOTE:

It is possible to return to BASIC MODE with

timer measurement at a stop.

1. Check that the timer is not in operation. If

the timer is in operation, stop the timer by

pushing the “SLCT1” button and “SLCT2”

button at the same time.

2. Push the “SLCT1” button and “SLCT2” but-

ton for 2 seconds or more at the same time

to change over to BASIC MODE.

RACE MODE

Putting measurement on standby

NOTE:

Starting measurement consists of the following

two starts, either of which can be selected.

Manual start

Starting measurement by the rider himself

operating the button. (A long push on “SLCT2”

button will put measurement on standby.)

Auto start

Starting timer measurement automatically on

detection of the movement of the machine. (A

long push on “SLCT1” button will put measure-

ment on standby.)

Manual start

NOTE:

Initial setting at changeover to RACE MODE

will remain for manual start.

1. Check that changeover to RACE MODE

has been made. (Refer to “Changeover

from BASIC MODE to RACE MODE”.)

NOTE:

When the machine is made ready for a run by

manual start, and will start flashing.

Page 66 of 794

1 - 18

GEN

INFO

MULTI-FUNCTION DISPLAY

2. Start timer measurement by pushing the

“RST” button.

3. When stopping timer measurement, push-

ing the “SLCT1” button and “SLCT2” button

at the same time.

NOTE:

If the machine is run while timer measurement

is not made, no change will occur to the digit in

tripmeter A (TRIP A).

4. To resume the measurement, again push

the “SLCT1” button and “SLCT2” button at

the same time.

Auto start

1. Check that changeover has been made to

RACE MODE. (Refer to “Changeover from

BASIC MODE to RACE MODE”.)

2. Make the machine ready for a run by push-

ing the “SLCT1” button for 2 seconds or

more.

NOTE:

When measurement is made ready for a run

by auto start, and will start flashing.

Timer display will turn on scrolling from left to

right.

3. Run the machine and start timer measure-

ment.

4. To stop timer measurement, pushing the

“SLCT1” button and the “SLCT2” button at

the same time.

NOTE:

If the machine is run while timer measurement

is not made, no change will occur to the digit in

tripmeter A (TRIP A).

5. To resume the measurement, again push-

ing the “SLCT1” button and “SLCT2” button

at the same time.

Page 68 of 794

1 - 19

GEN

INFO

MULTI-FUNCTION DISPLAY

Resetting measurement data

NOTE:

Resetting can be made in the following two

manners.

Resetting is possible while timer measurement

is made:

Reset tripmeter A.

Resetting is possible while timer measurement

is not made:

Reset tripmeter A and timer.

Resetting tripmeter A (TRIP A)

1. Check that the timer is in operation. If the

timer is not in operation, start the timer by

pushing the “SLCT1” button and “SLCT2”

button at the same time.

2. Reset tripmeter A (TRIP A) display by

pushing the “RST” button for 2 seconds or

more.

NOTE:

If reset, and travel distance display will go

on flashing for four seconds.

Resetting tripmeter A (TRIP A) and timer

1. Check that the timer is not in operation. If

the timer is in operation, stop it by pushing

the “SLCT1” button and “SLCT2” button at

the same time.

2. Reset all measured data by pushing the

“RST” button for 2 seconds or more.

NOTE:

Resetting will reset the timer display and

travel distance display and put measurement

on standby.

Auto start attempt will put measurement on

standby as such. Likewise, manual start

attempt will put measurement on standby as

such.

Correcting tripmeter A (TRIP A)

1. Change the travel distance display by

pushing the “SLCT1” button (plus) or

“SLCT2” button (minus). A long push on

the button will fast-forward the change.

NOTE:

Change can be made any time while timer

measurement is or is not being made.

Page 80 of 794

1 - 25

GEN

INFO

BREAK-IN PROCEDURES

1. Before starting the engine, fill the fuel tank

with the fuel.

2. Perform the pre-operation checks on the

machine.

3. Start and warm up the engine. Check the

idle speed, and check the operation of the

controls and the “ENGINE STOP” button.

Then, restart the engine and check its

operation within no more than 5 minutes

after it is restarted.

4. Operate the machine in the lower gears at

moderate throttle openings for five to eight

minutes.

5. Check how the engine runs when the

machine is ridden with the throttle 1/4 to 1/2

open (low to medium speed) for about one

hour.

6. Restart the engine and check the operation

of the machine throughout its entire operat-

ing range. Restart the machine and oper-

ate it for about 10 to 15 more minutes. The

machine will now be ready to race.

CAUTION:

After the break-in or before each race,

you must check the entire machine for

loose fittings and fasteners as per

“TORQUE-CHECK POINTS”.

Tighten all such fasteners as required.

When any of the following parts have

been replaced, they must be broken in.

CYLINDER AND CRANKSHAFT:

About one hour of break-in operation is

necessary.

PISTON, RING, VALVES, CAMSHAFTS

AND GEARS:

These parts require about 30 minutes of

break-in operation at half-throttle or less.

Observe the condition of the engine care-

fully during operation.

STARTING AND BREAK-IN

Page 616 of 794

5 - 39

CHAS

EC5B0000

HANDLEBAR

Extent of removal:

1 Handlebar removal

Extent of removal Order Part name Q’ty Remarks

HANDLEBAR REMOVAL

Preparation for removal Headlight

1 Hot starter cable 1 Disconnect at the lever side.

2 Hot starter lever holder 1

3 Clutch cable 1 Disconnect at the lever side.

4 Clutch lever holder 1 Disconnect the clutch switch lead.

5“ENGINE STOP” button 1 Disconnect the “ENGINE STOP” button

lead.

6 Master cylinder 1 Refer to “REMOVAL POINTS”.

7 Start switch 1 Disconnect the start switch lead.

8 Throttle cable cap 1

9 Throttle cable #1 (pulled) 1 Disconnect at the throttle side.

10 Throttle cable #2 (pushed) 1 Disconnect at the throttle side.

11 Grip (right) 1 Refer to “REMOVAL POINTS”.

12 Tube guide 1

13 Grip (left) 1 Refer to “REMOVAL POINTS”.

14 Handlebar holder (upper) 2

15 Handlebar 1

16 Handlebar holder (lower) 2

1

HANDLEBAR

Page 626 of 794

5 - 44

CHASHANDLEBAR

10. Install:

•Start switch 1

•Master cylinder 2

•Master cylinder bracket 3

•Bolt (master cylinder bracket) 4

•Clamp 5

NOTE:

•The start switch and master cylinder bracket

should be installed according to the dimen-

sions shown.

•Install the bracket so that the arrow mark a

faces upward.

•First tighten the bolt on the upper side of the

master cylinder bracket, and then tighten the

bolt on the lower side.

T R..9 Nm (0.9 m · kg, 6.5 ft · lb)

Zero mm

(Zero in)Zero mm

(Zero in)

11. Install:

•“ENGINE STOP” button 1

•Clutch lever holder 2

•Bolt (clutch lever holder) 3

•Hot starter lever holder 4

•Bolt (hot starter lever holder) 5

•Clamp 6

NOTE:

•The “ENGINE STOP” button, clutch lever

holder and clamp should be installed accord-

ing to the dimensions shown.

•Pass the “ENGINE STOP” button lead in the

middle of the clutch lever holder.

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

12. Install:

•Clutch cable 1

•Hot starter cable 2

NOTE:

Apply the lithium soap base grease on the

clutch cable end and hot starter cable end.

Page 682 of 794

6 - 3

–+ELECIGNITION SYSTEM

SPARK GAP TEST

1. Disconnect the ignition coil from spark

plug.

2. Remove the ignition coil cap.

3. Connect the dynamic spark tester 1 (igni-

tion checker 2) as shown.

•Ignition coil 3

•Spark plug 4

ÈFor USA and CDN

ÉExcept for USA and CDN

4. Kick the kickstarter.

5. Check the ignition spark gap.

6. Start engine, and increase spark gap until

misfire occurs. (for USA and CDN only)

Minimum spark gap:

6.0 mm (0.24 in)

È

É

COUPLERS, LEADS AND IGNITION COIL

CONNECTION INSPECTION

1. Check:

•Couplers and leads connection

Rust/dust/looseness/short-circuit →

Repair or replace.

•Ignition coil and spark plug as they are fit-

ted

Push in the ignition coil until it closely

contacts the spark plug hole in the cylin-

der head cover.

EC625001

“ENGINE STOP” BUTTON INSPECTION

1. Inspect:

•“ENGINE STOP” button conduct

No continuity while being pushed → Replace.

Continuity while being freed → Replace.

2. Inspect:

•Rubber part

a

Tears/damage → Replace. Tester (+) lead

→ Black lead

1

Tester (–) lead

→ Black lead

2

B

1 B

2 Tester selec-

tor position

PUSH IN

Ω

×

×× × 1

FREE

a