lock YAMAHA WR 450F 2009 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2009, Model line: WR 450F, Model: YAMAHA WR 450F 2009Pages: 226, PDF Size: 14.26 MB

Page 154 of 226

5-56

ENGINE REMOVAL

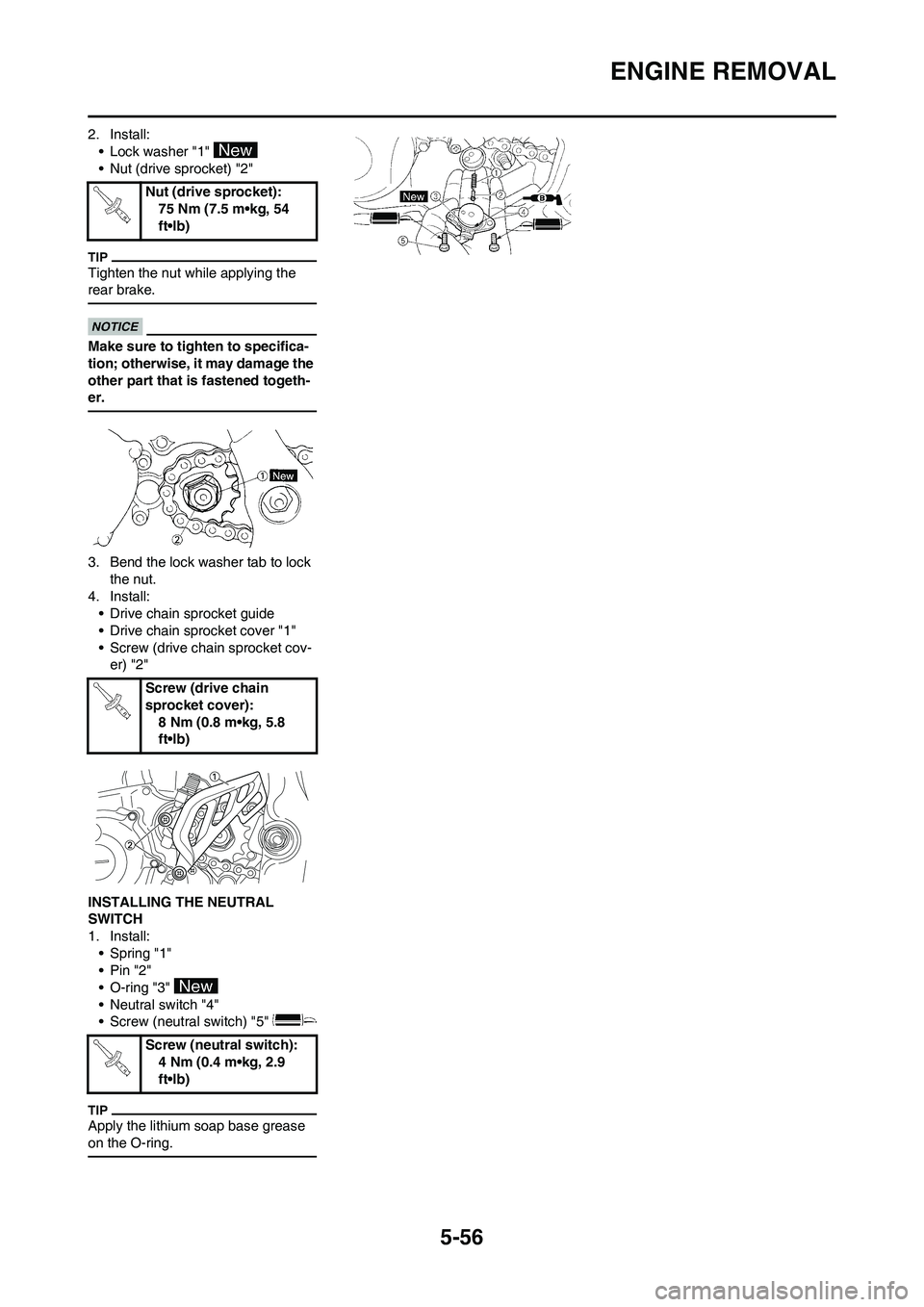

2. Install:

• Lock washer "1"

• Nut (drive sprocket) "2"

Tighten the nut while applying the

rear brake.

Make sure to tighten to specifica-

tion; otherwise, it may damage the

other part that is fastened togeth-

er.

3. Bend the lock washer tab to lock

the nut.

4. Install:

• Drive chain sprocket guide

• Drive chain sprocket cover "1"

• Screw (drive chain sprocket cov-

er) "2"

INSTALLING THE NEUTRAL

SWITCH

1. Install:

• Spring "1"

•Pin "2"

• O-ring "3"

• Neutral switch "4"

• Screw (neutral switch) "5"

Apply the lithium soap base grease

on the O-ring.

Nut (drive sprocket):

75 Nm (7.5 m•kg, 54

ft•lb)

Screw (drive chain

sprocket cover):

8 Nm (0.8 m•kg, 5.8

ft•lb)

Screw (neutral switch):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Page 168 of 226

6-5

FRONT WHEEL AND REAR WHEEL

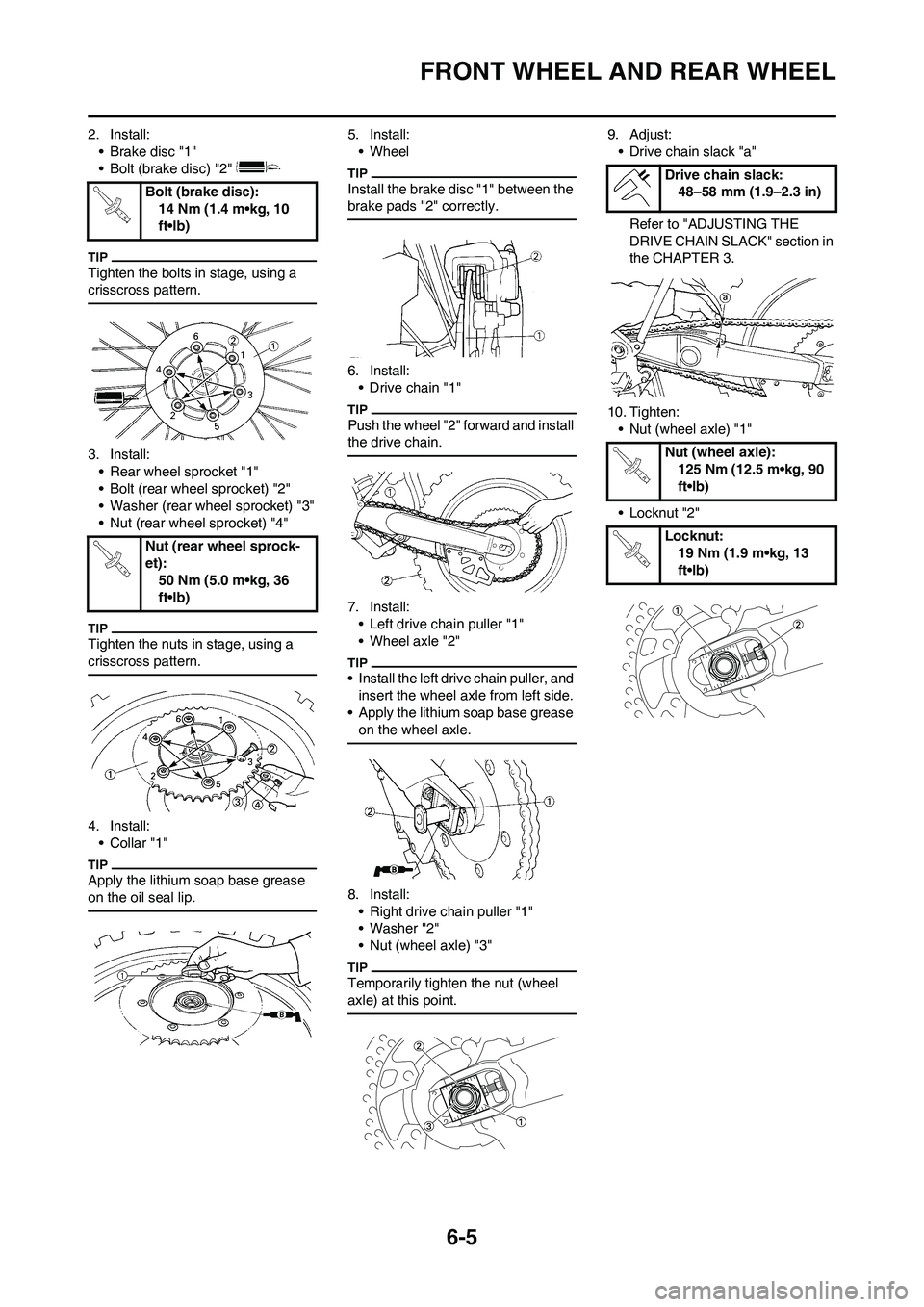

2. Install:

• Brake disc "1"

• Bolt (brake disc) "2"

Tighten the bolts in stage, using a

crisscross pattern.

3. Install:

• Rear wheel sprocket "1"

• Bolt (rear wheel sprocket) "2"

• Washer (rear wheel sprocket) "3"

• Nut (rear wheel sprocket) "4"

Tighten the nuts in stage, using a

crisscross pattern.

4. Install:

•Collar "1"

Apply the lithium soap base grease

on the oil seal lip.

5. Install:

• Wheel

Install the brake disc "1" between the

brake pads "2" correctly.

6. Install:

• Drive chain "1"

Push the wheel "2" forward and install

the drive chain.

7. Install:

• Left drive chain puller "1"

• Wheel axle "2"

• Install the left drive chain puller, and

insert the wheel axle from left side.

• Apply the lithium soap base grease

on the wheel axle.

8. Install:

• Right drive chain puller "1"

• Washer "2"

• Nut (wheel axle) "3"

Temporarily tighten the nut (wheel

axle) at this point.

9. Adjust:

• Drive chain slack "a"

Refer to "ADJUSTING THE

DRIVE CHAIN SLACK" section in

the CHAPTER 3.

10. Tighten:

• Nut (wheel axle) "1"

• Locknut "2" Bolt (brake disc):

14 Nm (1.4 m•kg, 10

ft•lb)

Nut (rear wheel sprock-

et):

50 Nm (5.0 m•kg, 36

ft•lb)

Drive chain slack:

48–58 mm (1.9–2.3 in)

Nut (wheel axle):

125 Nm (12.5 m•kg, 90

ft•lb)

Locknut:

19 Nm (1.9 m•kg, 13

ft•lb)

Page 173 of 226

6-10

FRONT BRAKE AND REAR BRAKE

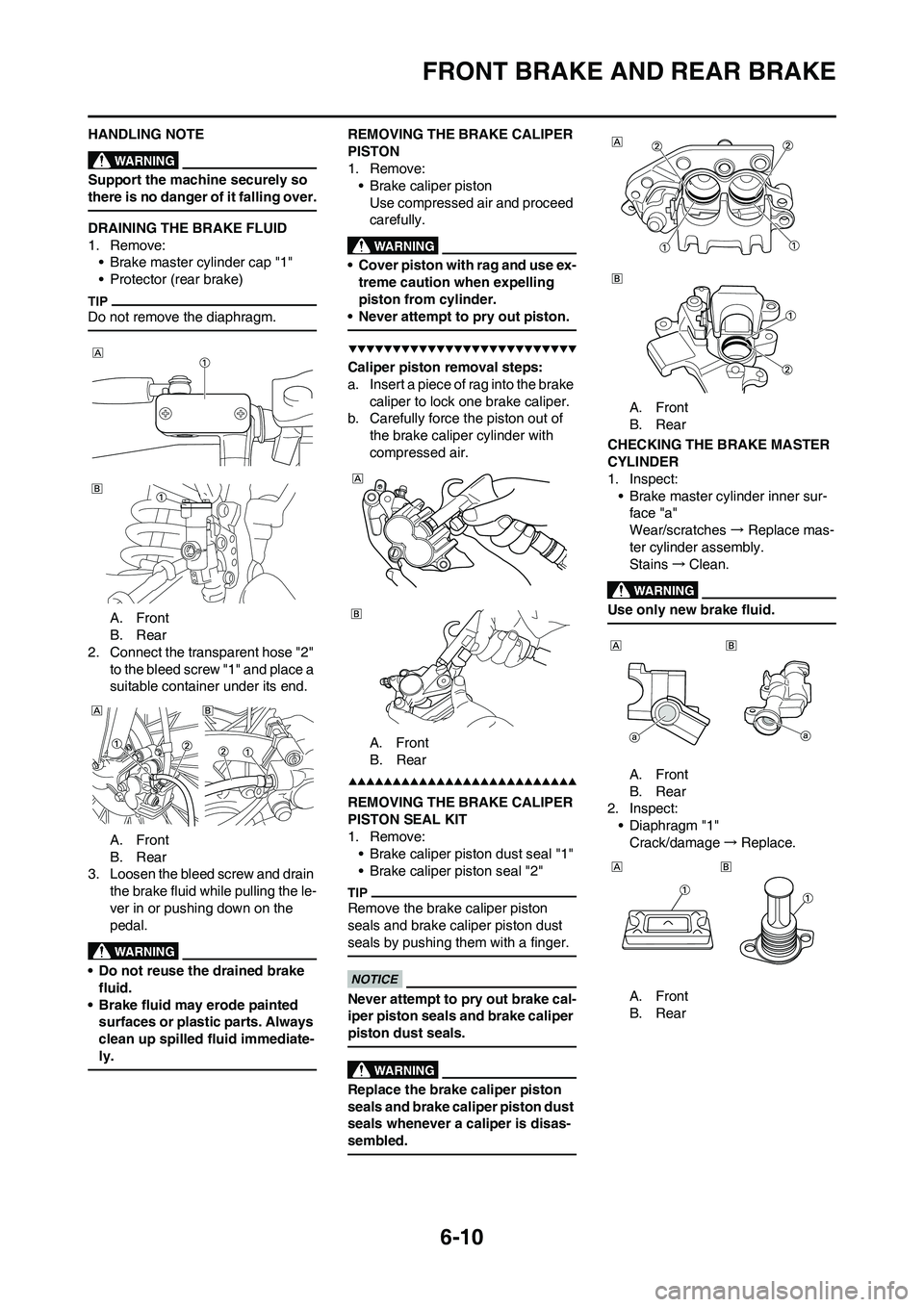

HANDLING NOTE

Support the machine securely so

there is no danger of it falling over.

DRAINING THE BRAKE FLUID

1. Remove:

• Brake master cylinder cap "1"

• Protector (rear brake)

Do not remove the diaphragm.

A. Front

B. Rear

2. Connect the transparent hose "2"

to the bleed screw "1" and place a

suitable container under its end.

A. Front

B. Rear

3. Loosen the bleed screw and drain

the brake fluid while pulling the le-

ver in or pushing down on the

pedal.

• Do not reuse the drained brake

fluid.

• Brake fluid may erode painted

surfaces or plastic parts. Always

clean up spilled fluid immediate-

ly.

REMOVING THE BRAKE CALIPER

PISTON

1. Remove:

• Brake caliper piston

Use compressed air and proceed

carefully.

• Cover piston with rag and use ex-

treme caution when expelling

piston from cylinder.

• Never attempt to pry out piston.

Caliper piston removal steps:

a. Insert a piece of rag into the brake

caliper to lock one brake caliper.

b. Carefully force the piston out of

the brake caliper cylinder with

compressed air.

A. Front

B. Rear

REMOVING THE BRAKE CALIPER

PISTON SEAL KIT

1. Remove:

• Brake caliper piston dust seal "1"

• Brake caliper piston seal "2"

Remove the brake caliper piston

seals and brake caliper piston dust

seals by pushing them with a finger.

Never attempt to pry out brake cal-

iper piston seals and brake caliper

piston dust seals.

Replace the brake caliper piston

seals and brake caliper piston dust

seals whenever a caliper is disas-

sembled.

A. Front

B. Rear

CHECKING THE BRAKE MASTER

CYLINDER

1. Inspect:

• Brake master cylinder inner sur-

face "a"

Wear/scratches → Replace mas-

ter cylinder assembly.

Stains→Clean.

Use only new brake fluid.

A. Front

B. Rear

2. Inspect:

• Diaphragm "1"

Crack/damage→Replace.

A. Front

B. Rear

Page 177 of 226

6-14

FRONT BRAKE AND REAR BRAKE

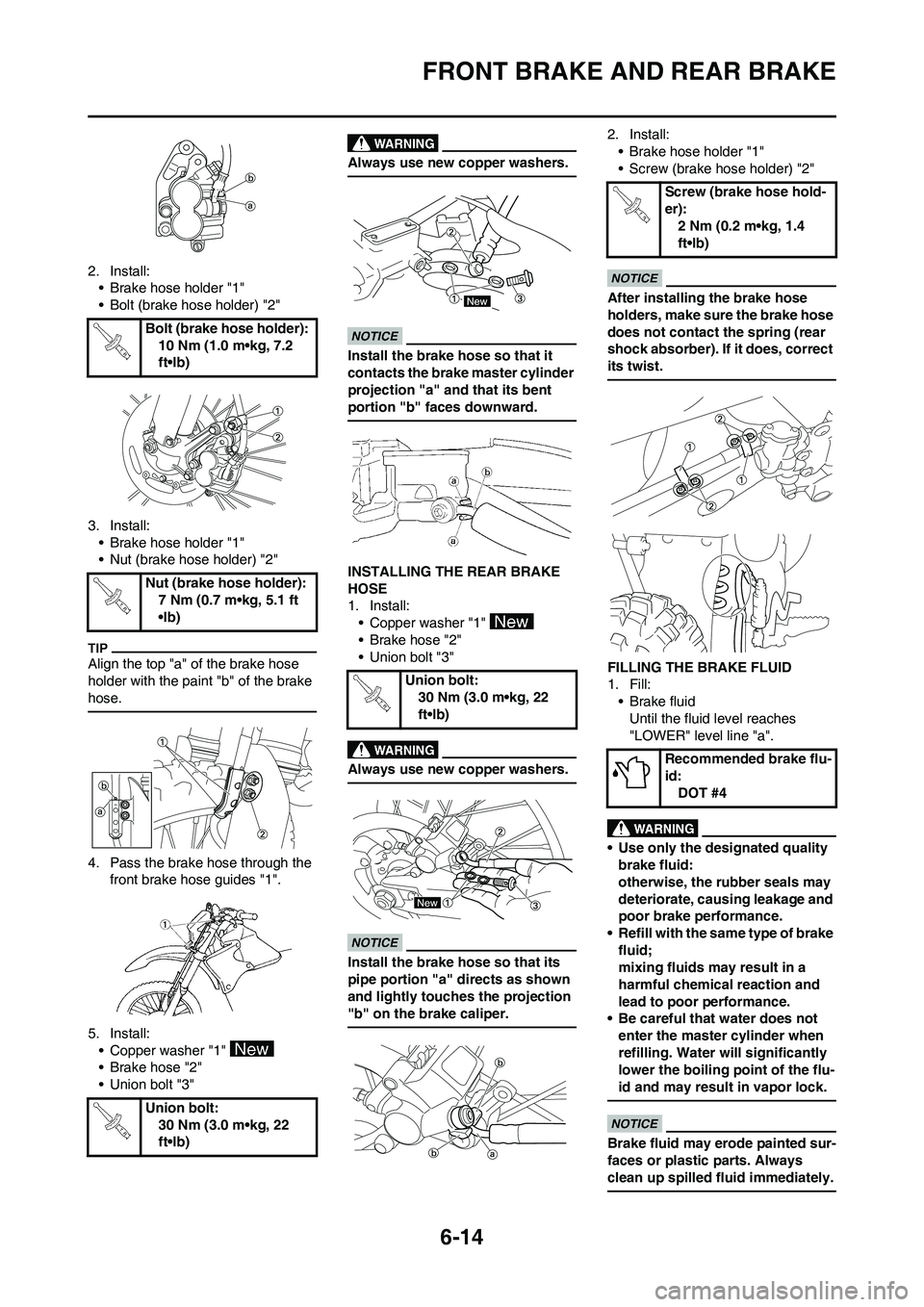

2. Install:

• Brake hose holder "1"

• Bolt (brake hose holder) "2"

3. Install:

• Brake hose holder "1"

• Nut (brake hose holder) "2"

Align the top "a" of the brake hose

holder with the paint "b" of the brake

hose.

4. Pass the brake hose through the

front brake hose guides "1".

5. Install:

• Copper washer "1"

• Brake hose "2"

• Union bolt "3"

Always use new copper washers.

Install the brake hose so that it

contacts the brake master cylinder

projection "a" and that its bent

portion "b" faces downward.

INSTALLING THE REAR BRAKE

HOSE

1. Install:

• Copper washer "1"

• Brake hose "2"

• Union bolt "3"

Always use new copper washers.

Install the brake hose so that its

pipe portion "a" directs as shown

and lightly touches the projection

"b" on the brake caliper.

2. Install:

• Brake hose holder "1"

• Screw (brake hose holder) "2"

After installing the brake hose

holders, make sure the brake hose

does not contact the spring (rear

shock absorber). If it does, correct

its twist.

FILLING THE BRAKE FLUID

1. Fill:

• Brake fluid

Until the fluid level reaches

"LOWER" level line "a".

• Use only the designated quality

brake fluid:

otherwise, the rubber seals may

deteriorate, causing leakage and

poor brake performance.

• Refill with the same type of brake

fluid;

mixing fluids may result in a

harmful chemical reaction and

lead to poor performance.

• Be careful that water does not

enter the master cylinder when

refilling. Water will significantly

lower the boiling point of the flu-

id and may result in vapor lock.

Brake fluid may erode painted sur-

faces or plastic parts. Always

clean up spilled fluid immediately.

Bolt (brake hose holder):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Nut (brake hose holder):

7 Nm (0.7 m•kg, 5.1 ft

•lb)

Union bolt:

30 Nm (3.0 m•kg, 22

ft•lb)

Union bolt:

30 Nm (3.0 m•kg, 22

ft•lb)

Screw (brake hose hold-

er):

2 Nm (0.2 m•kg, 1.4

ft•lb)

Recommended brake flu-

id:

DOT #4

Page 181 of 226

6-18

FRONT FORK

HANDLING NOTE

Support the machine securely so

there is no danger of it falling over.

The front fork requires careful atten-

tion. So it is recommended that the

front fork be maintained at the deal-

ers.

To prevent an accidental explosion

of air, the following instructions

should be observed:

• The front fork with a built-in pis-

ton rod has a very sophisticated

internal construction and is par-

ticularly sensitive to foreign ma-

terial. Use enough care not to

allow any foreign material to

come in when the oil is replaced

or when the front fork is disas-

sembled and reassembled.

• Before removing the cap bolts or

front forks, be sure to extract the

air from the air chamber com-

pletely.

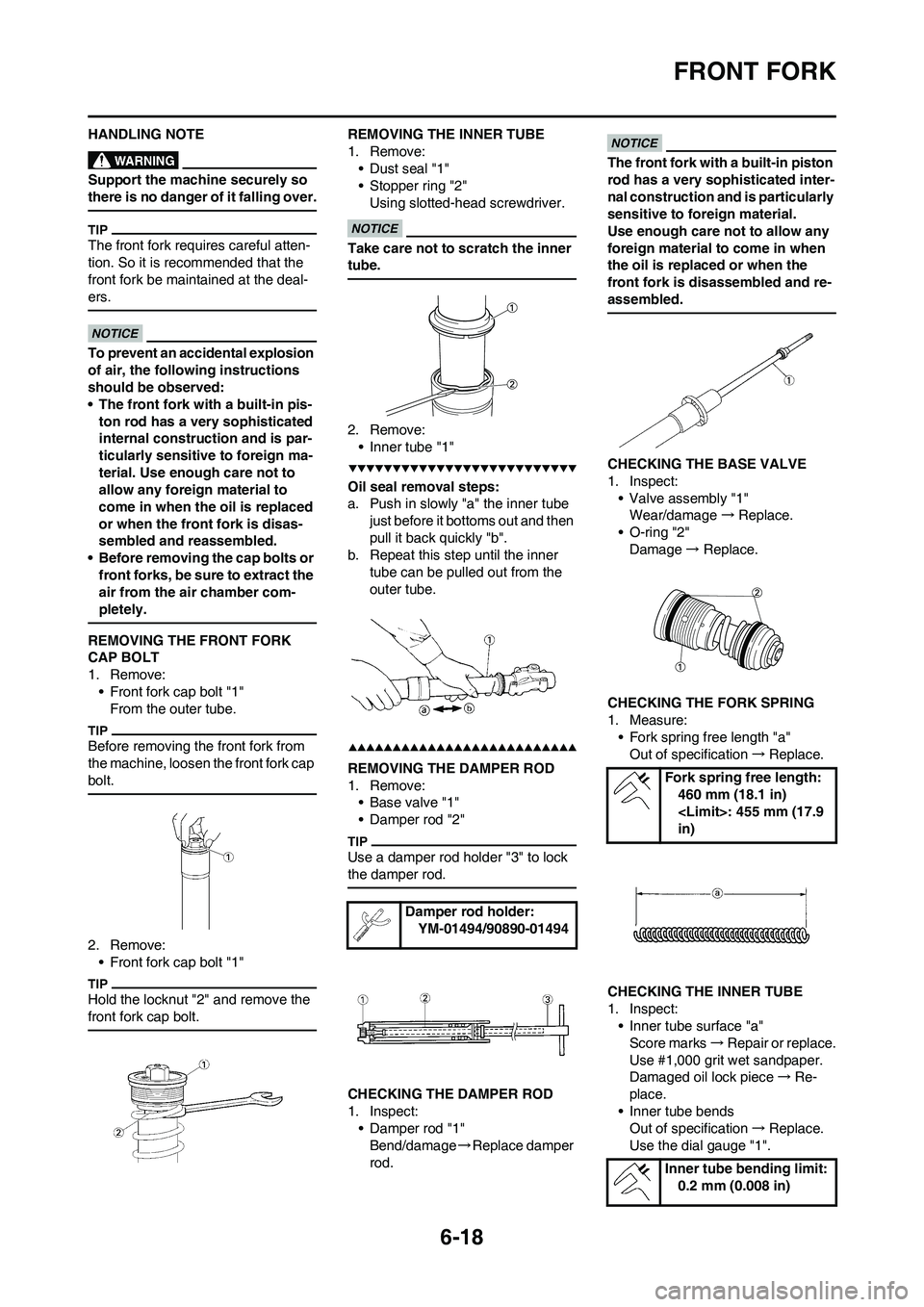

REMOVING THE FRONT FORK

CAP BOLT

1. Remove:

• Front fork cap bolt "1"

From the outer tube.

Before removing the front fork from

the machine, loosen the front fork cap

bolt.

2. Remove:

• Front fork cap bolt "1"

Hold the locknut "2" and remove the

front fork cap bolt.

REMOVING THE INNER TUBE

1. Remove:

• Dust seal "1"

• Stopper ring "2"

Using slotted-head screwdriver.

Take care not to scratch the inner

tube.

2. Remove:

• Inner tube "1"

Oil seal removal steps:

a. Push in slowly "a" the inner tube

just before it bottoms out and then

pull it back quickly "b".

b. Repeat this step until the inner

tube can be pulled out from the

outer tube.

REMOVING THE DAMPER ROD

1. Remove:

• Base valve "1"

• Damper rod "2"

Use a damper rod holder "3" to lock

the damper rod.

CHECKING THE DAMPER ROD

1. Inspect:

• Damper rod "1"

Bend/damage→Replace damper

rod.

The front fork with a built-in piston

rod has a very sophisticated inter-

nal construction and is particularly

sensitive to foreign material.

Use enough care not to allow any

foreign material to come in when

the oil is replaced or when the

front fork is disassembled and re-

assembled.

CHECKING THE BASE VALVE

1. Inspect:

• Valve assembly "1"

Wear/damage →Replace.

• O-ring "2"

Damage→ Replace.

CHECKING THE FORK SPRING

1. Measure:

• Fork spring free length "a"

Out of specification→Replace.

CHECKING THE INNER TUBE

1. Inspect:

• Inner tube surface "a"

Score marks→Repair or replace.

Use #1,000 grit wet sandpaper.

Damaged oil lock piece→Re-

place.

• Inner tube bends

Out of specification→Replace.

Use the dial gauge "1".

Damper rod holder:

YM-01494/90890-01494

Fork spring free length:

460 mm (18.1 in)

in)

Inner tube bending limit:

0.2 mm (0.008 in)

Page 182 of 226

6-19

FRONT FORK

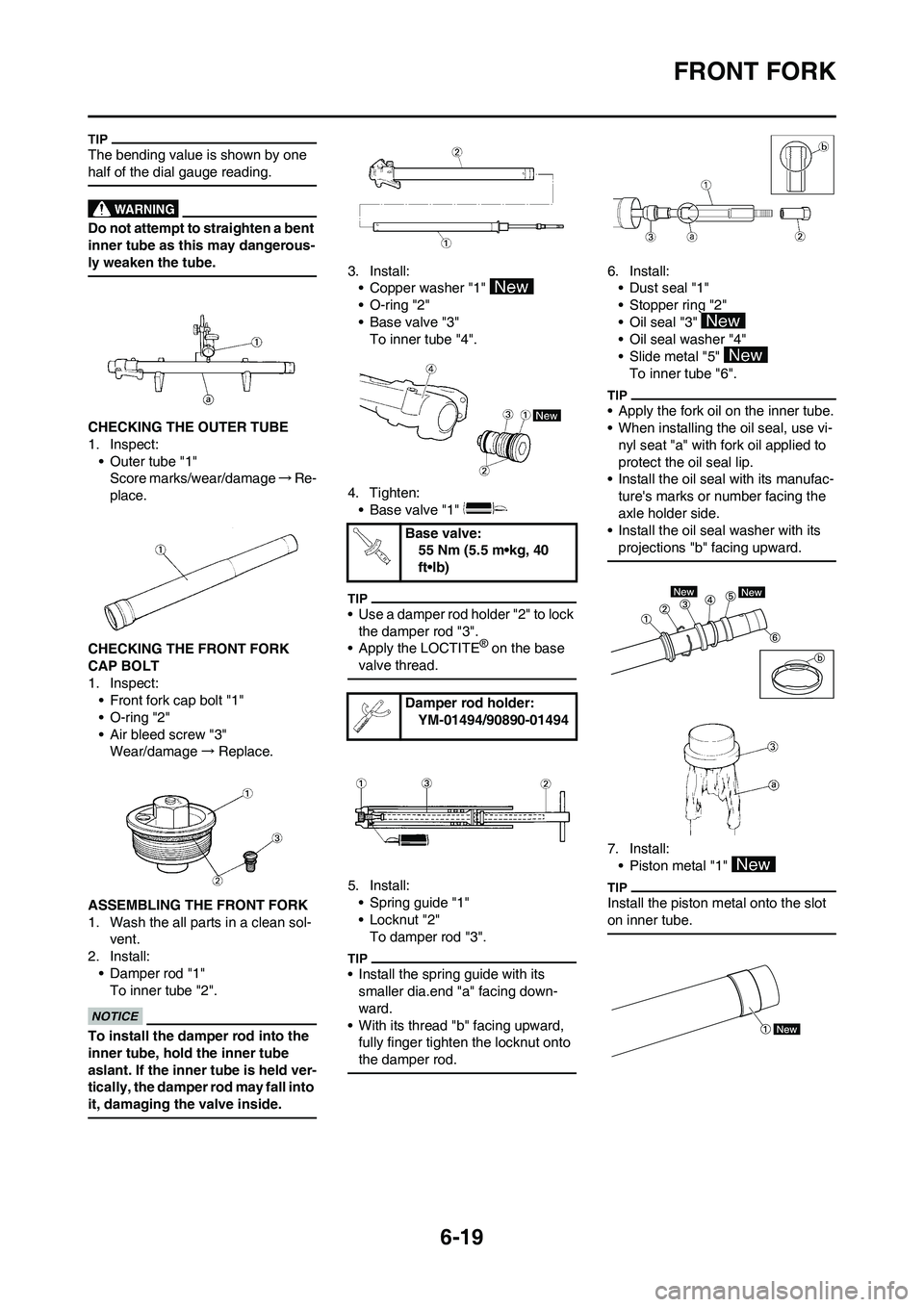

The bending value is shown by one

half of the dial gauge reading.

Do not attempt to straighten a bent

inner tube as this may dangerous-

ly weaken the tube.

CHECKING THE OUTER TUBE

1. Inspect:

• Outer tube "1"

Score marks/wear/damage→Re-

place.

CHECKING THE FRONT FORK

CAP BOLT

1. Inspect:

• Front fork cap bolt "1"

• O-ring "2"

• Air bleed screw "3"

Wear/damage→Replace.

ASSEMBLING THE FRONT FORK

1. Wash the all parts in a clean sol-

vent.

2. Install:

• Damper rod "1"

To inner tube "2".

To install the damper rod into the

inner tube, hold the inner tube

aslant. If the inner tube is held ver-

tically, the damper rod may fall into

it, damaging the valve inside.

3. Install:

• Copper washer "1"

• O-ring "2"

• Base valve "3"

To inner tube "4".

4. Tighten:

• Base valve "1"

• Use a damper rod holder "2" to lock

the damper rod "3".

• Apply the LOCTITE

® on the base

valve thread.

5. Install:

• Spring guide "1"

• Locknut "2"

To damper rod "3".

• Install the spring guide with its

smaller dia.end "a" facing down-

ward.

• With its thread "b" facing upward,

fully finger tighten the locknut onto

the damper rod.

6. Install:

• Dust seal "1"

• Stopper ring "2"

• Oil seal "3"

• Oil seal washer "4"

• Slide metal "5"

To inner tube "6".

• Apply the fork oil on the inner tube.

• When installing the oil seal, use vi-

nyl seat "a" with fork oil applied to

protect the oil seal lip.

• Install the oil seal with its manufac-

ture's marks or number facing the

axle holder side.

• Install the oil seal washer with its

projections "b" facing upward.

7. Install:

• Piston metal "1"

Install the piston metal onto the slot

on inner tube.

Base valve:

55 Nm (5.5 m•kg, 40

ft•lb)

Damper rod holder:

YM-01494/90890-01494

Page 184 of 226

6-21

FRONT FORK

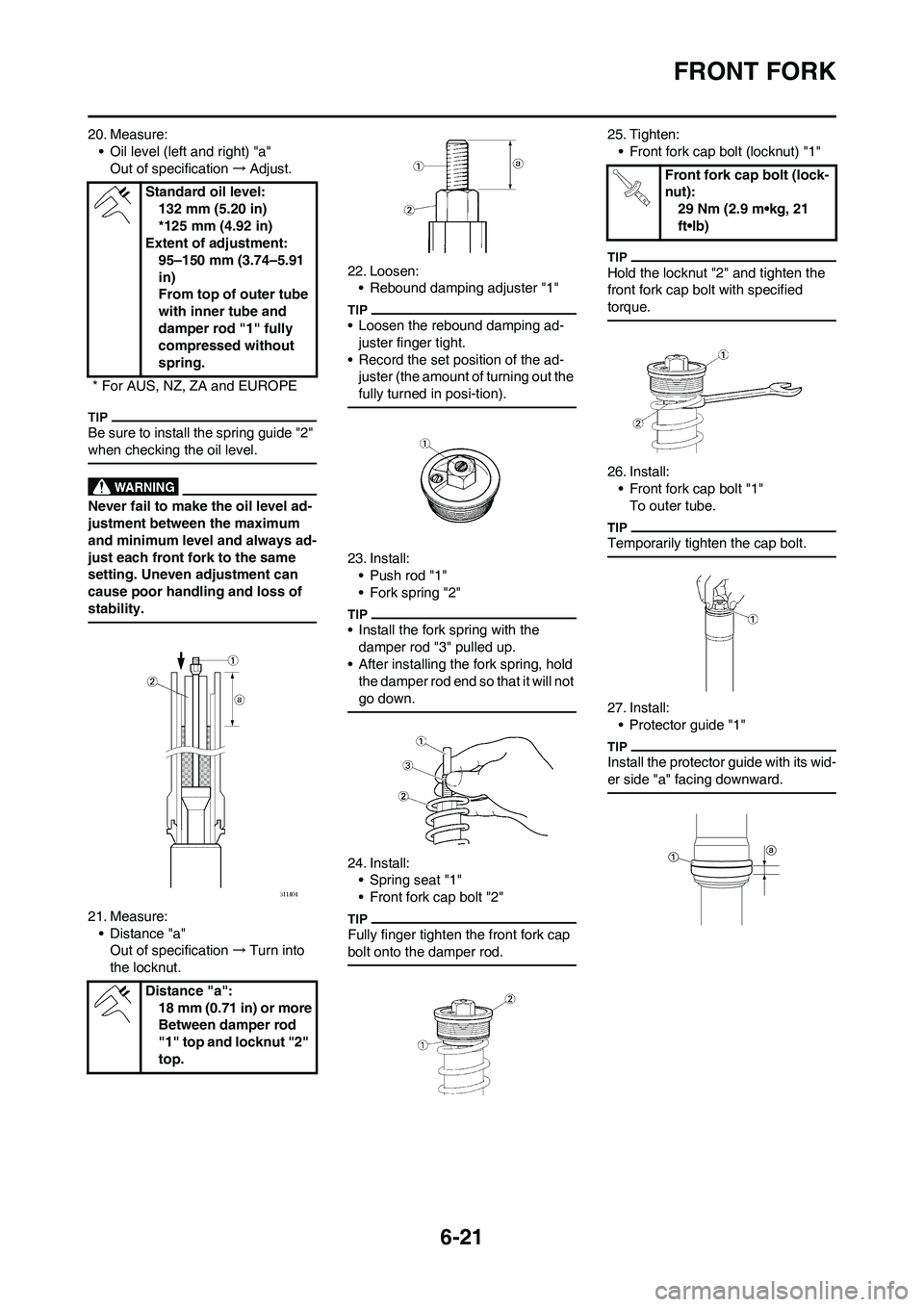

20. Measure:

• Oil level (left and right) "a"

Out of specification→Adjust.

Be sure to install the spring guide "2"

when checking the oil level.

Never fail to make the oil level ad-

justment between the maximum

and minimum level and always ad-

just each front fork to the same

setting. Uneven adjustment can

cause poor handling and loss of

stability.

21. Measure:

• Distance "a"

Out of specification→Turn into

the locknut.22. Loosen:

• Rebound damping adjuster "1"

• Loosen the rebound damping ad-

juster finger tight.

• Record the set position of the ad-

juster (the amount of turning out the

fully turned in posi-tion).

23. Install:

• Push rod "1"

• Fork spring "2"

• Install the fork spring with the

damper rod "3" pulled up.

• After installing the fork spring, hold

the damper rod end so that it will not

go down.

24. Install:

• Spring seat "1"

• Front fork cap bolt "2"

Fully finger tighten the front fork cap

bolt onto the damper rod.

25. Tighten:

• Front fork cap bolt (locknut) "1"

Hold the locknut "2" and tighten the

front fork cap bolt with specified

torque.

26. Install:

• Front fork cap bolt "1"

To outer tube.

Temporarily tighten the cap bolt.

27. Install:

• Protector guide "1"

Install the protector guide with its wid-

er side "a" facing downward.

Standard oil level:

132 mm (5.20 in)

*125 mm (4.92 in)

Extent of adjustment:

95–150 mm (3.74–5.91

in)

From top of outer tube

with inner tube and

damper rod "1" fully

compressed without

spring.

* For AUS, NZ, ZA and EUROPE

Distance "a":

18 mm (0.71 in) or more

Between damper rod

"1" top and locknut "2"

top.

Front fork cap bolt (lock-

nut):

29 Nm (2.9 m•kg, 21

ft•lb)

Page 192 of 226

6-29

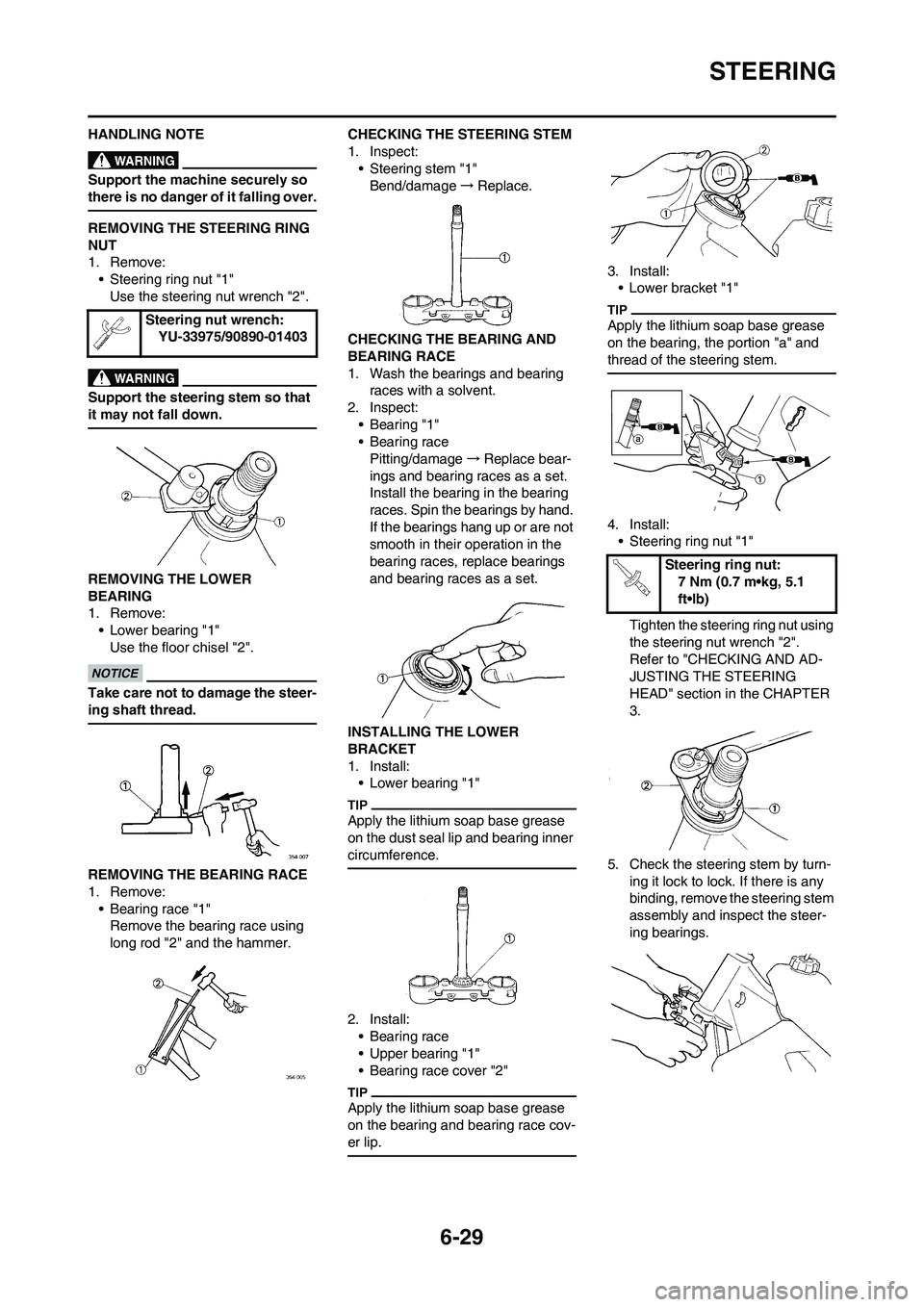

STEERING

HANDLING NOTE

Support the machine securely so

there is no danger of it falling over.

REMOVING THE STEERING RING

NUT

1. Remove:

• Steering ring nut "1"

Use the steering nut wrench "2".

Support the steering stem so that

it may not fall down.

REMOVING THE LOWER

BEARING

1. Remove:

• Lower bearing "1"

Use the floor chisel "2".

Take care not to damage the steer-

ing shaft thread.

REMOVING THE BEARING RACE

1. Remove:

• Bearing race "1"

Remove the bearing race using

long rod "2" and the hammer.CHECKING THE STEERING STEM

1. Inspect:

• Steering stem "1"

Bend/damage→Replace.

CHECKING THE BEARING AND

BEARING RACE

1. Wash the bearings and bearing

races with a solvent.

2. Inspect:

•Bearing "1"

• Bearing race

Pitting/damage→Replace bear-

ings and bearing races as a set.

Install the bearing in the bearing

races. Spin the bearings by hand.

If the bearings hang up or are not

smooth in their operation in the

bearing races, replace bearings

and bearing races as a set.

INSTALLING THE LOWER

BRACKET

1. Install:

• Lower bearing "1"

Apply the lithium soap base grease

on the dust seal lip and bearing inner

circumference.

2. Install:

• Bearing race

• Upper bearing "1"

• Bearing race cover "2"

Apply the lithium soap base grease

on the bearing and bearing race cov-

er lip.

3. Install:

• Lower bracket "1"

Apply the lithium soap base grease

on the bearing, the portion "a" and

thread of the steering stem.

4. Install:

• Steering ring nut "1"

Tighten the steering ring nut using

the steering nut wrench "2".

Refer to "CHECKING AND AD-

JUSTING THE STEERING

HEAD" section in the CHAPTER

3.

5. Check the steering stem by turn-

ing it lock to lock. If there is any

binding, remove the steering stem

assembly and inspect the steer-

ing bearings. Steering nut wrench:

YU-33975/90890-01403

Steering ring nut:

7 Nm (0.7 m•kg, 5.1

ft•lb)

Page 199 of 226

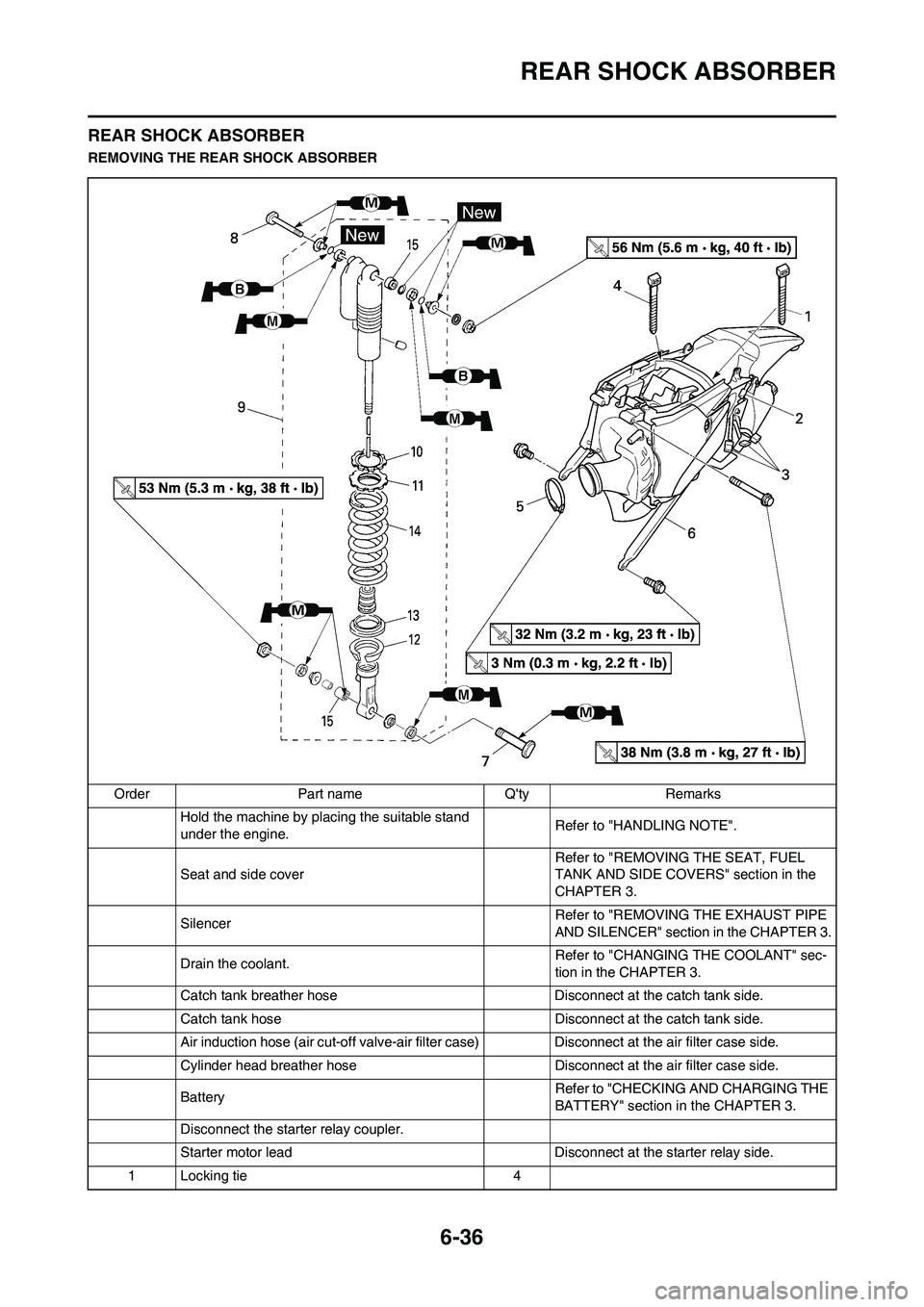

6-36

REAR SHOCK ABSORBER

REAR SHOCK ABSORBER

REMOVING THE REAR SHOCK ABSORBER

Order Part name Q'ty Remarks

Hold the machine by placing the suitable stand

under the engine.Refer to "HANDLING NOTE".

Seat and side cover Refer to "REMOVING THE SEAT, FUEL

TANK AND SIDE COVERS" section in the

CHAPTER 3.

Silencer Refer to "REMOVING THE EXHAUST PIPE

AND SILENCER" section in the CHAPTER 3.

Drain the coolant.Refer to "CHANGING THE COOLANT" sec-

tion in the CHAPTER 3.

Catch tank breather hose Disconnect at the catch tank side.

Catch tank hose Disconnect at the catch tank side.

Air induction hose (air cut-off valve-air filter case) Disconnect at the air filter case side.

Cylinder head breather hose Disconnect at the air filter case side.

BatteryRefer to "CHECKING AND CHARGING THE

BATTERY" section in the CHAPTER 3.

Disconnect the starter relay coupler.

Starter motor lead Disconnect at the starter relay side.

1 Locking tie 4

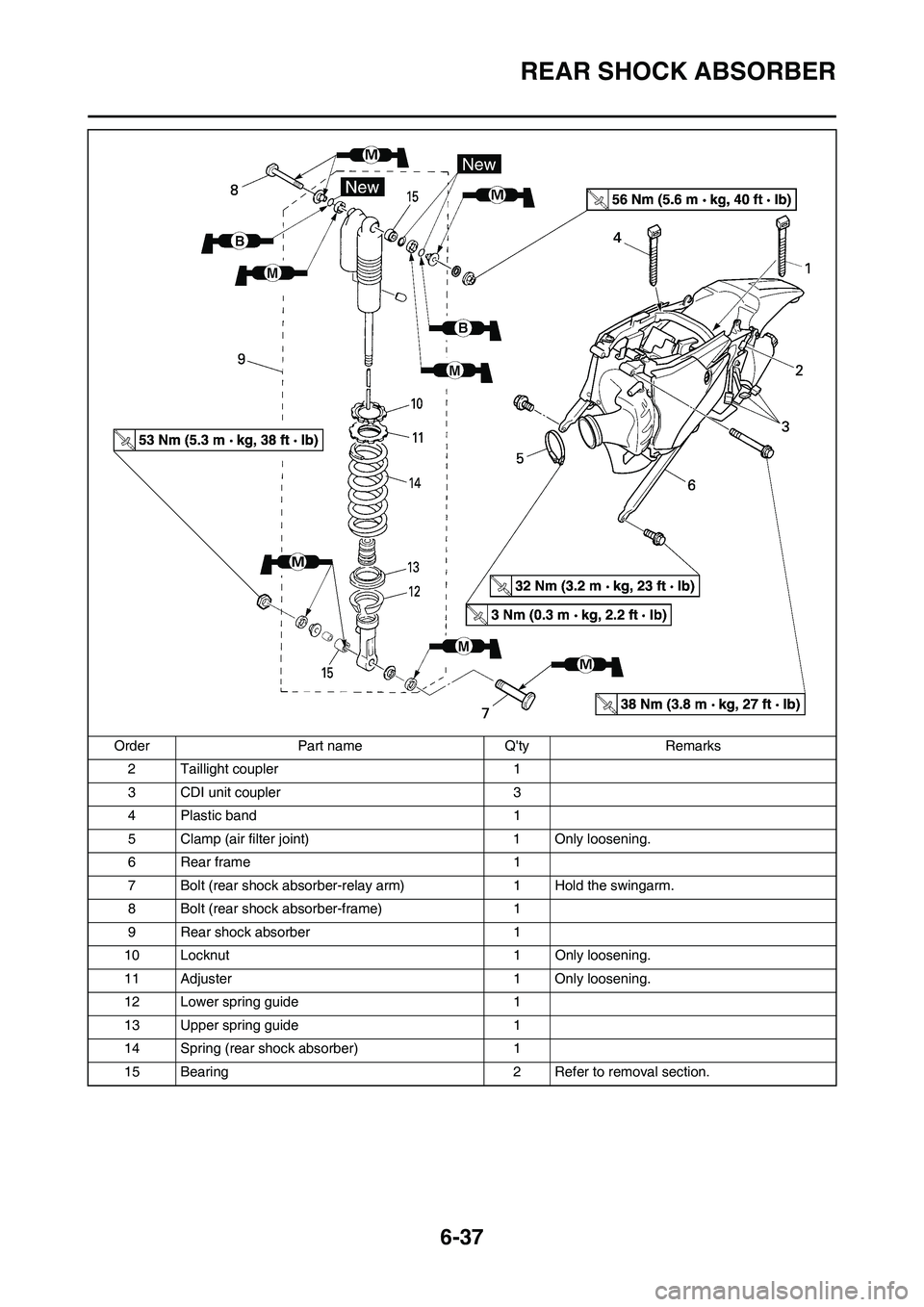

Page 200 of 226

6-37

REAR SHOCK ABSORBER

2 Taillight coupler 1

3 CDI unit coupler 3

4 Plastic band 1

5 Clamp (air filter joint) 1 Only loosening.

6Rear frame 1

7 Bolt (rear shock absorber-relay arm) 1 Hold the swingarm.

8 Bolt (rear shock absorber-frame) 1

9 Rear shock absorber 1

10 Locknut 1 Only loosening.

11 Adjuster 1 Only loosening.

12 Lower spring guide 1

13 Upper spring guide 1

14 Spring (rear shock absorber) 1

15 Bearing 2 Refer to removal section. Order Part name Q'ty Remarks