length YAMAHA WR 450F 2010 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: WR 450F, Model: YAMAHA WR 450F 2010Pages: 230, PDF Size: 13.87 MB

Page 186 of 230

6-18

FRONT FORK

HANDLING NOTE

Support the machine securely so

there is no danger of it falling over.

The front fork requires careful atten-

tion. So it is recommended that the

front fork be maintained at the deal-

ers.

To prevent an accidental explosion

of air, the following instructions

should be observed:

• The front fork with a built-in pis-

ton rod has a very sophisticated

internal construction and is par-

ticularly sensitive to foreign ma-

terial. Use enough care not to

allow any foreign material to

come in when the oil is replaced

or when the front fork is disas-

sembled and reassembled.

• Before removing the cap bolts or

front forks, be sure to extract the

air from the air chamber com-

pletely.

REMOVING THE FRONT FORK

CAP BOLT

1. Remove:

• Front fork cap bolt "1"

From the outer tube.

Before removing the front fork from

the machine, loosen the front fork cap

bolt.

2. Remove:

• Front fork cap bolt "1"

Hold the locknut "2" and remove the

front fork cap bolt.

REMOVING THE INNER TUBE

1. Remove:

• Dust seal "1"

• Stopper ring "2"

Using slotted-head screwdriver.

Take care not to scratch the inner

tube.

2. Remove:

• Inner tube "1"

Oil seal removal steps:

a. Push in slowly "a" the inner tube

just before it bottoms out and then

pull it back quickly "b".

b. Repeat this step until the inner

tube can be pulled out from the

outer tube.

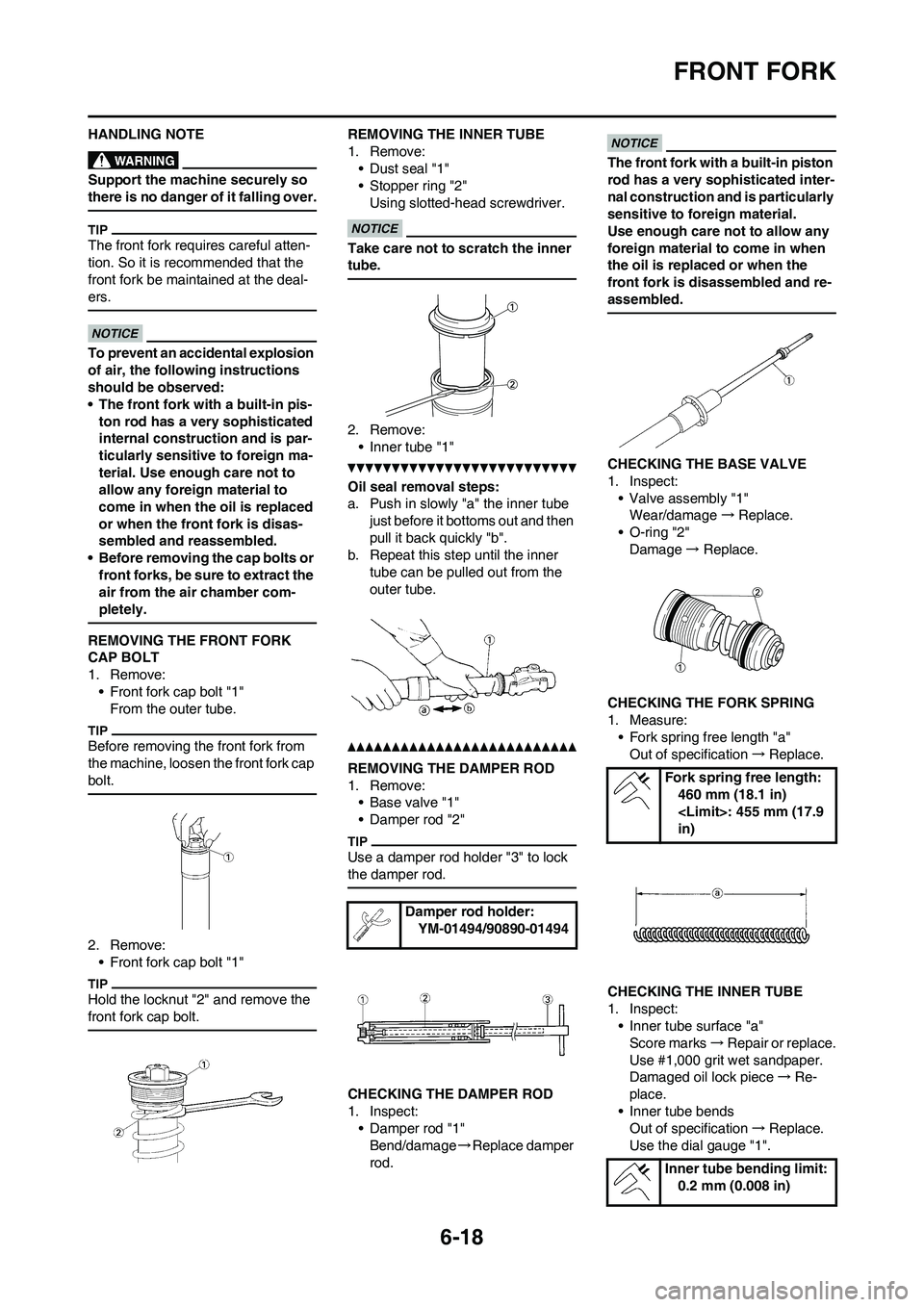

REMOVING THE DAMPER ROD

1. Remove:

• Base valve "1"

• Damper rod "2"

Use a damper rod holder "3" to lock

the damper rod.

CHECKING THE DAMPER ROD

1. Inspect:

• Damper rod "1"

Bend/damage→Replace damper

rod.

The front fork with a built-in piston

rod has a very sophisticated inter-

nal construction and is particularly

sensitive to foreign material.

Use enough care not to allow any

foreign material to come in when

the oil is replaced or when the

front fork is disassembled and re-

assembled.

CHECKING THE BASE VALVE

1. Inspect:

• Valve assembly "1"

Wear/damage →Replace.

• O-ring "2"

Damage→ Replace.

CHECKING THE FORK SPRING

1. Measure:

• Fork spring free length "a"

Out of specification→Replace.

CHECKING THE INNER TUBE

1. Inspect:

• Inner tube surface "a"

Score marks→Repair or replace.

Use #1,000 grit wet sandpaper.

Damaged oil lock piece→Re-

place.

• Inner tube bends

Out of specification→Replace.

Use the dial gauge "1".

Damper rod holder:

YM-01494/90890-01494

Fork spring free length:

460 mm (18.1 in)

in)

Inner tube bending limit:

0.2 mm (0.008 in)

Page 207 of 230

6-39

REAR SHOCK ABSORBER

2. Install:

• Stopper ring (upper bearing) "1"

After installing the stopper ring, push

back the bearing until it contacts the

stopper ring.

3. Install:

• Lower bearing "1"

Install the bearing by pressing it on

the side having the manufacture's

marks or numbers.

INSTALLING THE SPRING (REAR

SHOCK ABSORBER)

1. Install:

• Spring "1"

• Upper spring guide "2"

• Lower spring guide "3"

2. Tighten:

•Adjuster "1"3. Adjust:

• Spring length (installed)

Refer to "ADJUSTING THE

REAR SHOCK ABSORBER

SPRING PRELOAD" section in

the CHAPTER 3.

4. Tighten:

• Locknut "1"

INSTALLING THE REAR SHOCK

ABSORBER

1. Install:

• Dust seal "1"

• O-ring "2"

• Collar "3"

• Apply the molybdenum disulfide

grease on the dust seal lips and col-

lars.

• Apply the lithium soap base grease

on the O-rings.

2. Install:

• Bushing "1"

• Collar "2"

• Dust seal "3"

• Apply the molybdenum disulfide

grease on the bearing and dust seal

lips.

• Install the dust seals with their lips

facing inward.

3. Install:

• Rear shock absorber4. Install:

• Bolt (rear shock absorber-frame)

"1"

• Washer "2"

• Nut (rear shock absorber-frame)

"3"

Apply the molybdenum disulfide

grease on the bolt.

5. Install:

• Bolt (rear shock absorber-relay

arm)"1"

• Nut (rear shock absorber-relay

arm) "2"

Apply the molybdenum disulfide

grease on the bolt.

6. Install:

• Rear frame "1"

• Bolt [rear frame (upper)] "2"

• Bolt [rear frame (lower)] "3" Installed depth of the

bearing "a":

4 mm (0.16 in)

Nut (rear shock absorb-

er-frame):

56 Nm (5.6 m•kg, 40

ft•lb)

Nut (rear shock absorb-

er-relay arm):

53 Nm (5.3 m•kg, 38

ft•lb)

Bolt [rear frame (upper)]:

38 Nm (3.8 m•kg, 27

ft•lb)

Bolt [rear frame (lower)]:

32 Nm (3.2 m•kg, 23

ft•lb)

Page 219 of 230

7-11

ELECTRIC STARTING SYSTEM

CHECKING AND REPAIRING THE

STARTER MOTOR

1. Check:

• Commutator

Dirt→Clean with 600 grit sandpa-

per.

2. Measure:

• Commutator diameter "a"

Out of specification→Replace the

starter motor.

3. Measure:

• Mica undercut "a"

Out of specification→Scrape the

mica to the proper measurement

with a hacksaw blade which has

been grounded to fit the commu-

tator.

The mica must be undercut to ensure

proper operation of the commutator.

4. Measure:

• Armature assembly resistances

(commutator and insulation)

Out of specification→Replace the

starter motor.

a. Measure the armature assembly

resistances with the pocket tester.b. If any resistance is out of specifi-

cation, replace the starter motor.

5. Measure:

• Brush length "a"

Out of specification→Replace the

brushes as a set.

6. Measure:

• Brush spring force

Out of specification→Replace the

brush springs as a set.ASSEMBLING THE STARTER

MOTOR

1. Install:

• Brush spring "1"

• Brush "2"

2. Install:

• Armature assembly "1"

Install while holding down the

brush using a thin screw driver.

Be careful not to damage the brush

during installation.

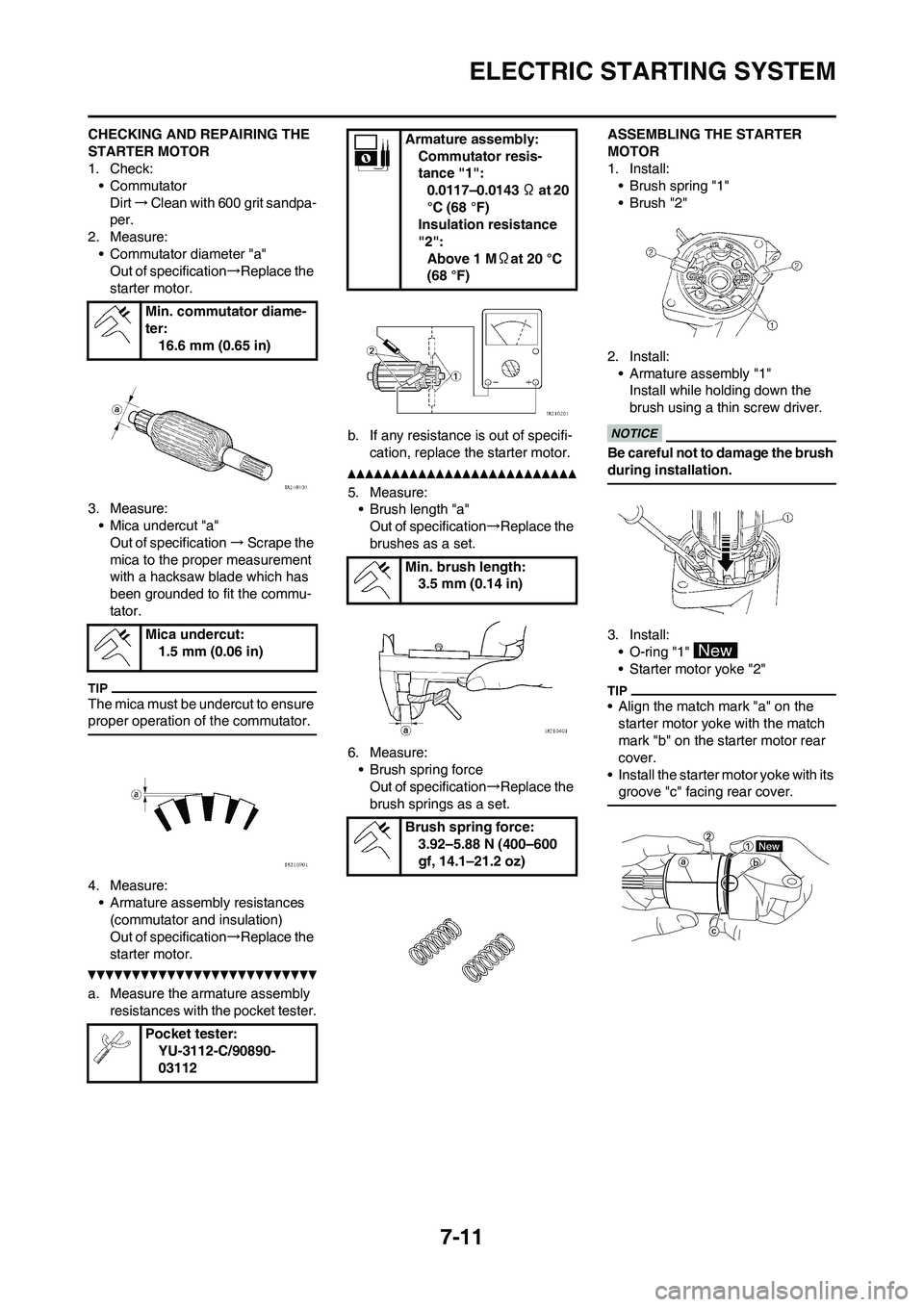

3. Install:

• O-ring "1"

• Starter motor yoke "2"

• Align the match mark "a" on the

starter motor yoke with the match

mark "b" on the starter motor rear

cover.

• Install the starter motor yoke with its

groove "c" facing rear cover.

Min. commutator diame-

ter:

16.6 mm (0.65 in)

Mica undercut:

1.5 mm (0.06 in)

Pocket tester:

YU-3112-C/90890-

03112

Armature assembly:

Commutator resis-

tance "1":

0.0117–0.0143 Ω at 20

°C (68 °F)

Insulation resistance

"2":

Above 1 MΩat 20 °C

(68 °F)

Min. brush length:

3.5 mm (0.14 in)

Brush spring force:

3.92–5.88 N (400–600

gf, 14.1–21.2 oz)