maintenance YAMAHA WR 450F 2011 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2011, Model line: WR 450F, Model: YAMAHA WR 450F 2011Pages: 230, PDF Size: 13.77 MB

Page 41 of 230

2-10

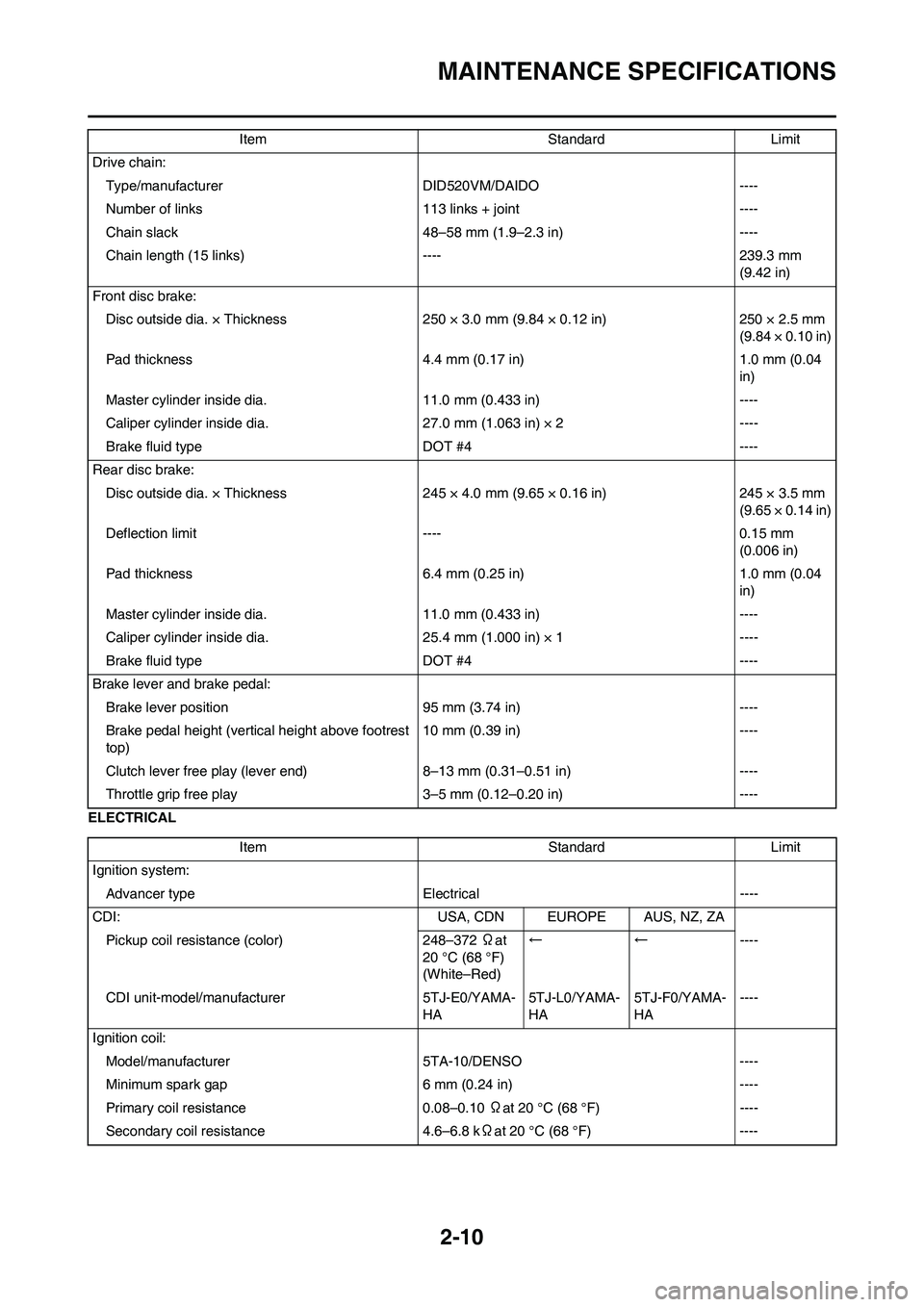

MAINTENANCE SPECIFICATIONS

ELECTRICALDrive chain:

Type/manufacturer DID520VM/DAIDO ----

Number of links 113 links + joint ----

Chain slack 48–58 mm (1.9–2.3 in) ----

Chain length (15 links) ---- 239.3 mm

(9.42 in)

Front disc brake:

Disc outside dia. × Thickness 250 × 3.0 mm (9.84 × 0.12 in) 250 × 2.5 mm

(9.84 × 0.10 in)

Pad thickness 4.4 mm (0.17 in) 1.0 mm (0.04

in)

Master cylinder inside dia. 11.0 mm (0.433 in) ----

Caliper cylinder inside dia. 27.0 mm (1.063 in) × 2 ----

Brake fluid type DOT #4 ----

Rear disc brake:

Disc outside dia. × Thickness 245 × 4.0 mm (9.65 × 0.16 in) 245 × 3.5 mm

(9.65 × 0.14 in)

Deflection limit ---- 0.15 mm

(0.006 in)

Pad thickness 6.4 mm (0.25 in) 1.0 mm (0.04

in)

Master cylinder inside dia. 11.0 mm (0.433 in) ----

Caliper cylinder inside dia. 25.4 mm (1.000 in) × 1 ----

Brake fluid type DOT #4 ----

Brake lever and brake pedal:

Brake lever position 95 mm (3.74 in) ----

Brake pedal height (vertical height above footrest

top)10 mm (0.39 in) ----

Clutch lever free play (lever end) 8–13 mm (0.31–0.51 in) ----

Throttle grip free play3–5 mm (0.12–0.20 in) ---- Item Standard Limit

Item Standard Limit

Ignition system:

Advancer type Electrical ----

CDI: USA, CDN EUROPE AUS, NZ, ZA

Pickup coil resistance (color) 248–372 Ωat

20 °C (68 °F)

(White–Red)←←----

CDI unit-model/manufacturer 5TJ-E0/YAMA-

HA5TJ-L0/YAMA-

HA5TJ-F0/YAMA-

HA----

Ignition coil:

Model/manufacturer 5TA-10/DENSO ----

Minimum spark gap 6 mm (0.24 in) ----

Primary coil resistance 0.08–0.10 Ωat 20 °C (68 °F) ----

Secondary coil resistance 4.6–6.8 kΩat 20 °C (68 °F) ----

Page 42 of 230

2-11

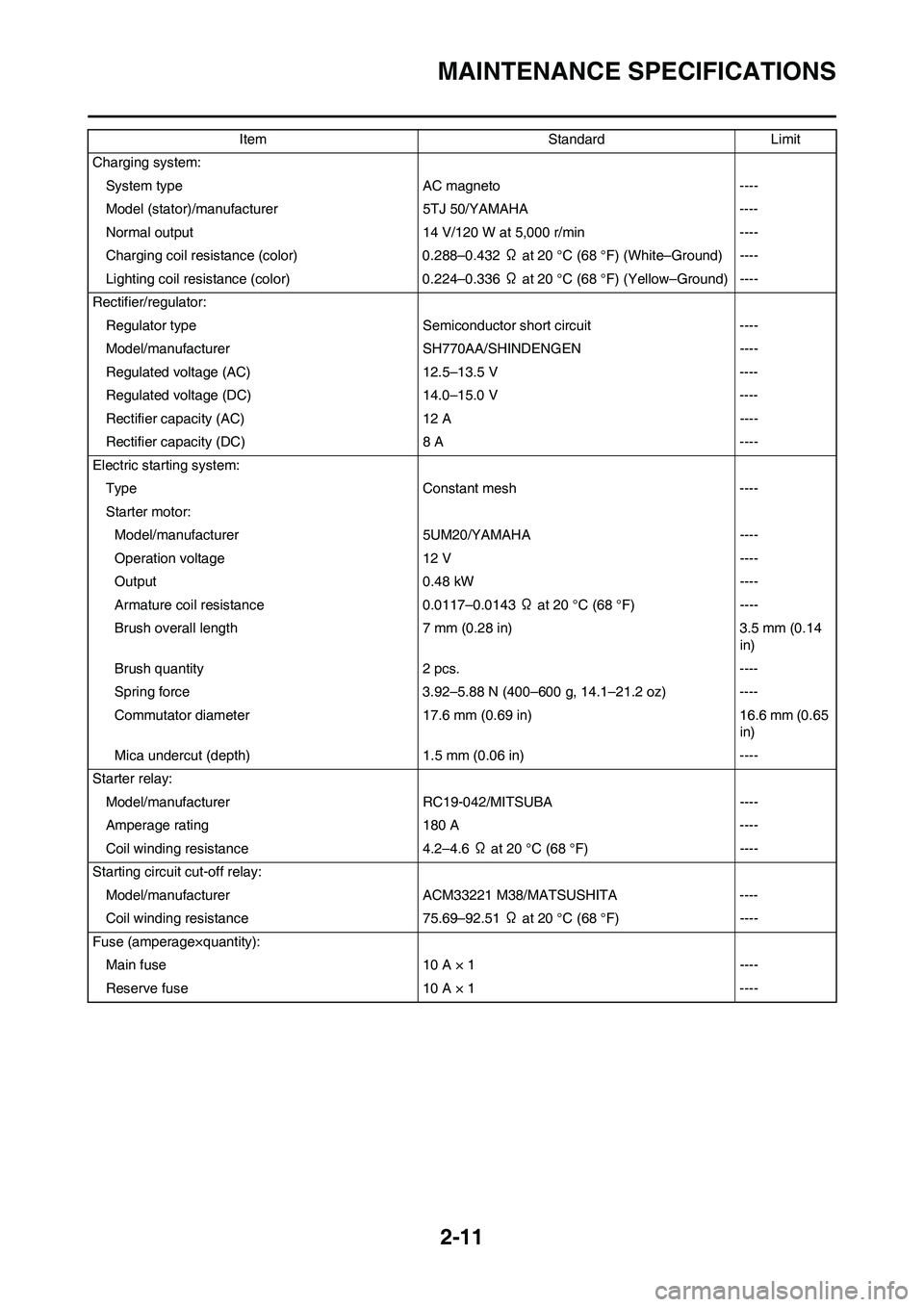

MAINTENANCE SPECIFICATIONS

Charging system:

System type AC magneto ----

Model (stator)/manufacturer 5TJ 50/YAMAHA ----

Normal output 14 V/120 W at 5,000 r/min ----

Charging coil resistance (color) 0.288–0.432 Ω at 20 °C (68 °F) (White–Ground) ----

Lighting coil resistance (color) 0.224–0.336 Ω at 20 °C (68 °F) (Yellow–Ground) ----

Rectifier/regulator:

Regulator type Semiconductor short circuit ----

Model/manufacturer SH770AA/SHINDENGEN ----

Regulated voltage (AC) 12.5–13.5 V ----

Regulated voltage (DC) 14.0–15.0 V ----

Rectifier capacity (AC) 12 A ----

Rectifier capacity (DC) 8 A ----

Electric starting system:

Type Constant mesh ----

Starter motor:

Model/manufacturer 5UM20/YAMAHA ----

Operation voltage 12 V ----

Output 0.48 kW ----

Armature coil resistance 0.0117–0.0143 Ω at 20 °C (68 °F) ----

Brush overall length 7 mm (0.28 in) 3.5 mm (0.14

in)

Brush quantity 2 pcs. ----

Spring force 3.92–5.88 N (400–600 g, 14.1–21.2 oz) ----

Commutator diameter 17.6 mm (0.69 in) 16.6 mm (0.65

in)

Mica undercut (depth) 1.5 mm (0.06 in) ----

Starter relay:

Model/manufacturerRC19-042/MITSUBA ----

Amperage rating 180 A ----

Coil winding resistance 4.2–4.6 Ω at 20 °C (68 °F) ----

Starting circuit cut-off relay:

Model/manufacturer ACM33221 M38/MATSUSHITA ----

Coil winding resistance 75.69–92.51 Ω at 20 °C (68 °F) ----

Fuse (amperage×quantity):

Main fuse 10 A × 1 ----

Reserve fuse 10 A × 1 ----Item Standard Limit

Page 60 of 230

3-1

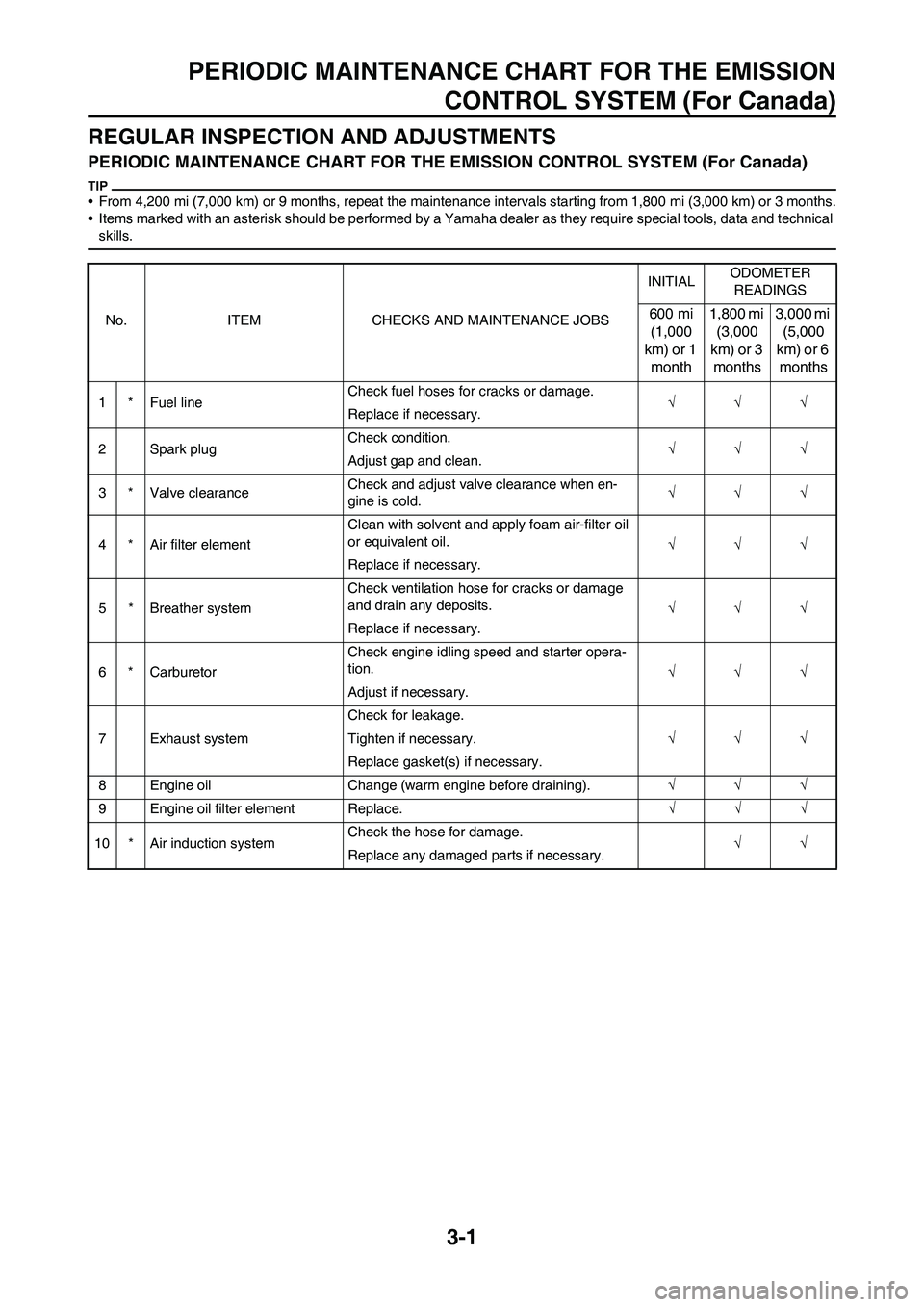

PERIODIC MAINTENANCE CHART FOR THE EMISSIONCONTROL SYSTEM (For Canada)

REGULAR INSPECTION AND ADJUSTMENTS

PERIODIC MAINTENANCE CHART FO R THE EMISSION CONTROL SYSTEM (For Canada)

• From 4,200 mi (7,000 km) or 9 months, repeat the maintenanc e intervals starting from 1,800 mi (3,000 km) or 3 months.

• Items marked with an asterisk should be performed by a Yam aha dealer as they require special tools, data and technical

skills.

No. ITEM CHECKS AND MAINTENANCE JOBS INITIAL

ODOMETER

READINGS600 mi (1,000

km) or 1 month 1,800 mi

(3,000

km) or 3 months 3,000 mi

(5,000

km) or 6 months

1 * Fuel line Check fuel hoses for cracks or damage.

√√√

Replace if necessary.

2 Spark plug Check condition.

√√√

Adjust gap and clean.

3 * Valve clearance Check and adjust valve clearance when en-

gine is cold.

√√√

4 * Air filter element Clean with solvent and apply foam air-filter oil

or equivalent oil.

√√√

Replace if necessary.

5 * Breather system Check ventilation hose for cracks or damage

and drain any deposits.

√√√

Replace if necessary.

6 * Carburetor Check engine idling speed and starter opera-

tion.

√√√

Adjust if necessary.

7 Exhaust system Check for leakage.

√√√

Tighten if necessary.

Replace gasket(s) if necessary.

8 Engine oil Change (warm engine before draining). √√√

9 Engine oil filter element Replace. √√√

10 * Air induction system Check the hose for damage.

√√

Replace any damaged parts if necessary.

Page 61 of 230

3-2

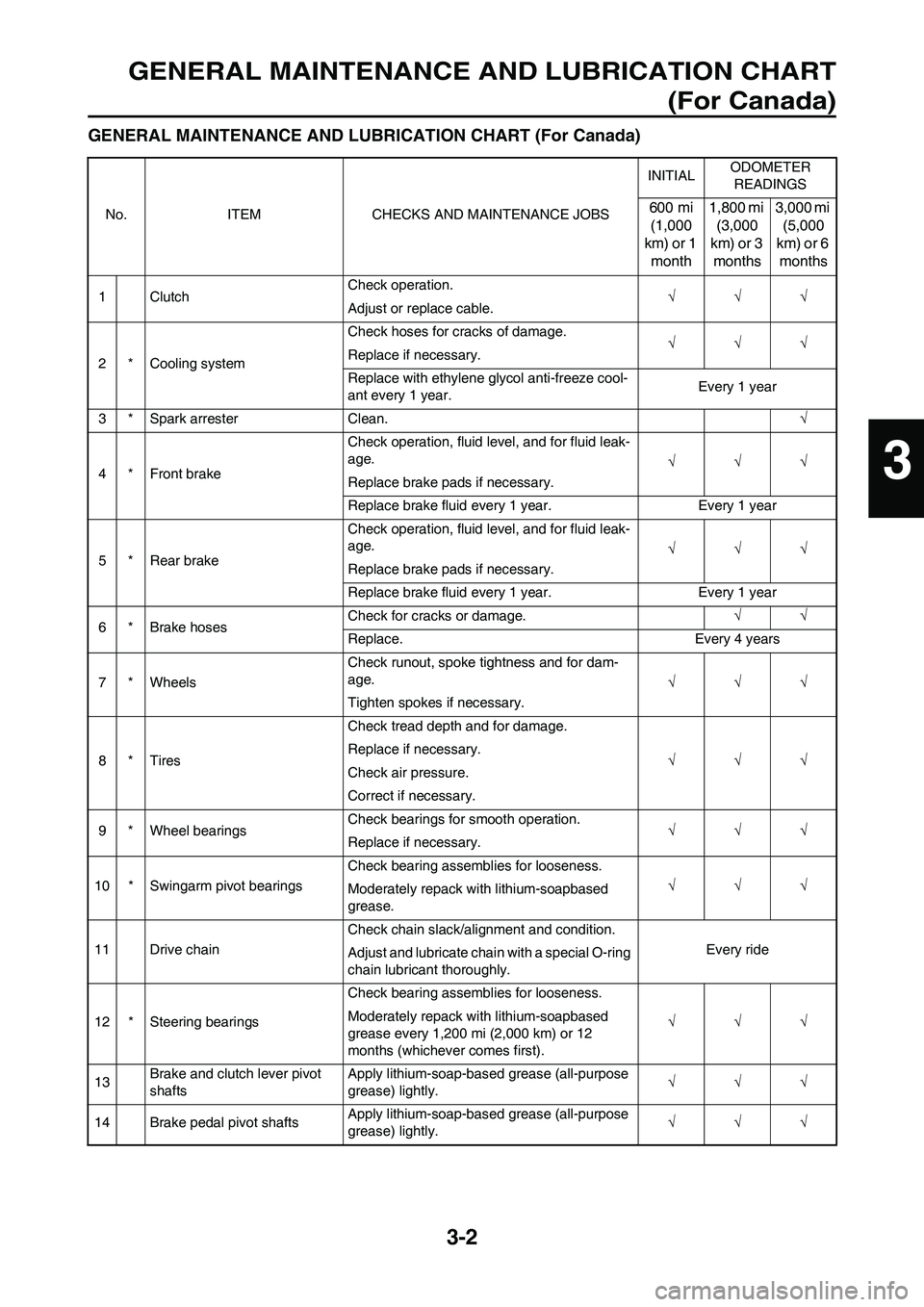

GENERAL MAINTENANCE AND LUBRICATION CHART

(For Canada)

GENERAL MAINTENANCE AND LUBRICATION CHART (For Canada)

No. ITEM CHECKS AND MAINTENANCE JOBSINITIALODOMETER

READINGS600 mi

(1,000

km) or 1

month1,800 mi

(3,000

km) or 3

months3,000 mi

(5,000

km) or 6

months

1 ClutchCheck operation.

√√√

Adjust or replace cable.

2 * Cooling systemCheck hoses for cracks of damage.

√√√

Replace if necessary.

Replace with ethylene glycol anti-freeze cool-

ant every 1 year.Every 1 year

3 * Spark arrester Clean.√

4 * Front brakeCheck operation, fluid level, and for fluid leak-

age.

√√√

Replace brake pads if necessary.

Replace brake fluid every 1 year. Every 1 year

5 * Rear brakeCheck operation, fluid level, and for fluid leak-

age.

√√√

Replace brake pads if necessary.

Replace brake fluid every 1 year. Every 1 year

6 * Brake hosesCheck for cracks or damage.√√

Replace. Every 4 years

7 * WheelsCheck runout, spoke tightness and for dam-

age.

√√√

Tighten spokes if necessary.

8*TiresCheck tread depth and for damage.

√√√ Replace if necessary.

Check air pressure.

Correct if necessary.

9 * Wheel bearingsCheck bearings for smooth operation.

√√√

Replace if necessary.

10 * Swingarm pivot bearingsCheck bearing assemblies for looseness.

√√√

Moderately repack with lithium-soapbased

grease.

11 Drive chainCheck chain slack/alignment and condition.

Every ride

Adjust and lubricate chain with a special O-ring

chain lubricant thoroughly.

12 * Steering bearingsCheck bearing assemblies for looseness.

√√√ Moderately repack with lithium-soapbased

grease every 1,200 mi (2,000 km) or 12

months (whichever comes first).

13Brake and clutch lever pivot

shaftsApply lithium-soap-based grease (all-purpose

grease) lightly.√√√

14 Brake pedal pivot shaftsApply lithium-soap-based grease (all-purpose

grease) lightly.√√√

3

Page 62 of 230

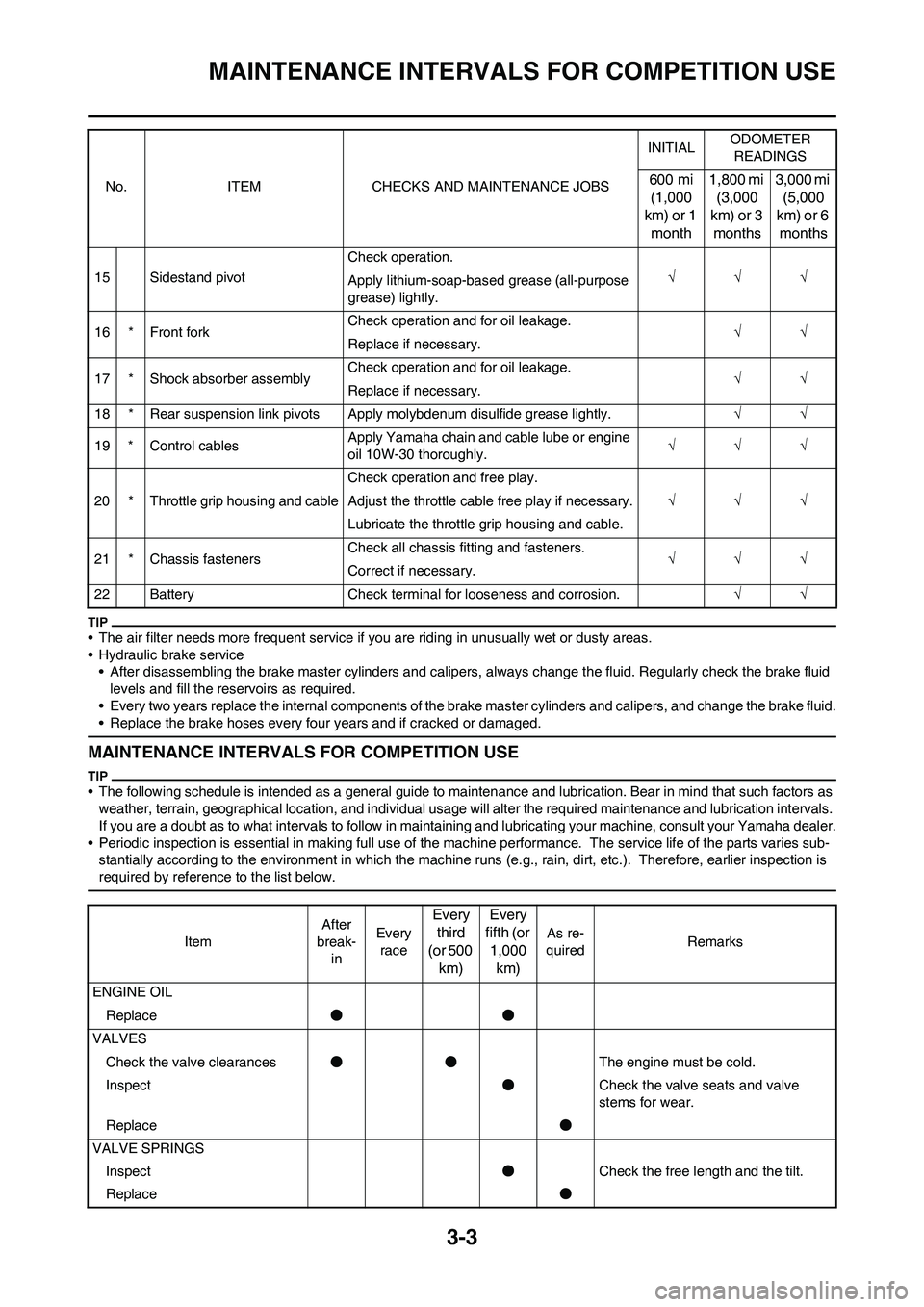

3-3

MAINTENANCE INTERVALS FOR COMPETITION USE

• The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

• Hydraulic brake service

• After disassembling the brake master cylinders and calipers, always change the fluid. Regularly check the brake fluid

levels and fill the reservoirs as required.

• Every two years replace the internal components of the brake master cylinders and calipers, and change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.

MAINTENANCE INTERVALS FOR COMPETITION USE

• The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as

weather, terrain, geographical location, and individual usage will alter the required maintenance and lubrication intervals.

If you are a doubt as to what intervals to follow in maintaining and lubricating your machine, consult your Yamaha dealer.

• Periodic inspection is essential in making full use of the machine performance. The service life of the parts varies sub-

stantially according to the environment in which the machine runs (e.g., rain, dirt, etc.). Therefore, earlier inspection is

required by reference to the list below.

15 Sidestand pivotCheck operation.

√√√

Apply lithium-soap-based grease (all-purpose

grease) lightly.

16 * Front forkCheck operation and for oil leakage.

√√

Replace if necessary.

17 * Shock absorber assemblyCheck operation and for oil leakage.

√√

Replace if necessary.

18 * Rear suspension link pivots Apply molybdenum disulfide grease lightly.√√

19 * Control cablesApply Yamaha chain and cable lube or engine

oil 10W-30 thoroughly.√√√

20 * Throttle grip housing and cableCheck operation and free play.

√√√ Adjust the throttle cable free play if necessary.

Lubricate the throttle grip housing and cable.

21 * Chassis fastenersCheck all chassis fitting and fasteners.

√√√

Correct if necessary.

22 Battery Check terminal for looseness and corrosion.√√ No. ITEM CHECKS AND MAINTENANCE JOBSINITIALODOMETER

READINGS

600 mi

(1,000

km) or 1

month1,800 mi

(3,000

km) or 3

months3,000 mi

(5,000

km) or 6

months

ItemAfter

break-

inEvery

race

Every

third

(or 500

km)Every

fifth (or

1,000

km)

As re-

quiredRemarks

ENGINE OIL

Replace●●

VALVES

Check the valve clearances●●The engine must be cold.

Inspect●Check the valve seats and valve

stems for wear.

Replace●

VALVE SPRINGS

Inspect●Check the free length and the tilt.

Replace●

Page 63 of 230

3-4

MAINTENANCE INTERVALS FOR COMPETITION USE

VALVE LIFTERS

Inspect●Check for scratches and wear.

Replace●

CAMSHAFTS Inspect the camshaft surface.

Inspect●Inspect the decompression system.

Replace●

CAMSHAFT SPROCKETS

Inspect●Check for wear on the teeth and for

damage.

Replace●

PISTON

Inspect●●Inspect crack.

Clean●Inspect carbon deposits and eliminate

them.

Replace●It is recommended that the piston pin

and ring are also replaced at the same

time.

PISTON RING

Inspect●Check ring end gap.

Replace●●

PISTON PIN

Inspect●

Replace●

CYLINDER HEAD Inspect carbon deposits and eliminate

them.

Inspect and clean●Change gasket.

CYLINDER

Inspect and clean●Inspect score marks.

Replace●Inspect wear.

CLUTCH

Inspect and adjust●●Inspect housing, friction plate, clutch

plate and spring.

Replace●

TRANSMISSION

Inspect●

Replace bearing●

SHIFT FORK, SHIFT CAM,

GUIDE BAR

Inspect●Inspect wear.

ROTOR NUT

Retighten●●

MUFFLER

Inspect and retighten●●

Clean●

Replace● ItemAfter

break-

inEvery

race

Every

third

(or 500

km)Every

fifth (or

1,000

km)

As re-

quiredRemarks

Page 64 of 230

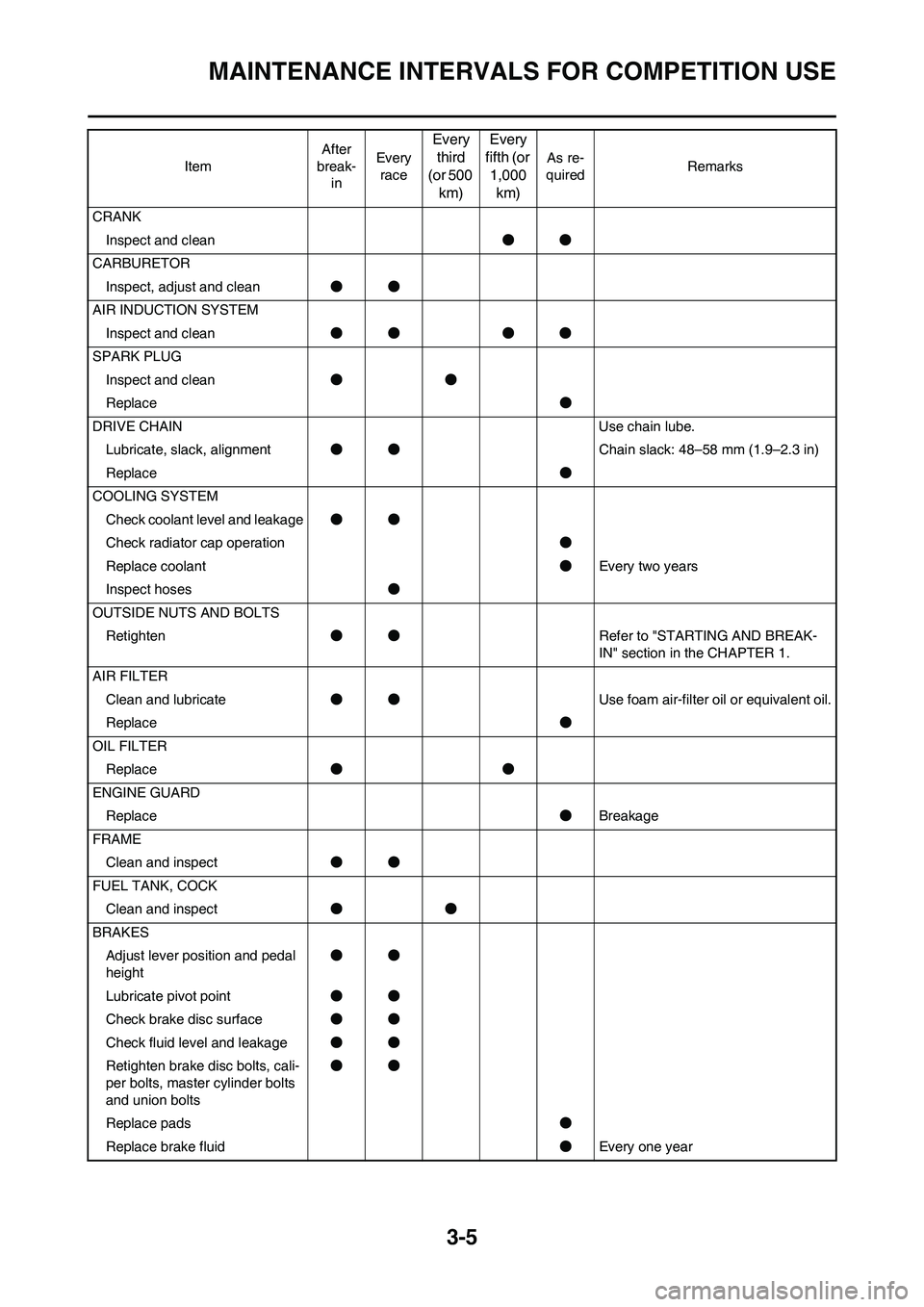

3-5

MAINTENANCE INTERVALS FOR COMPETITION USE

CRANK

Inspect and clean●●

CARBURETOR

Inspect, adjust and clean●●

AIR INDUCTION SYSTEM

Inspect and clean●● ●●

SPARK PLUG

Inspect and clean●●

Replace●

DRIVE CHAIN Use chain lube.

Lubricate, slack, alignment●●Chain slack: 48–58 mm (1.9–2.3 in)

Replace●

COOLING SYSTEM

Check coolant level and leakage●●

Check radiator cap operation●

Replace coolant●Every two years

Inspect hoses●

OUTSIDE NUTS AND BOLTS

Retighten●●Refer to "STARTING AND BREAK-

IN" section in the CHAPTER 1.

AIR FILTER

Clean and lubricate●●Use foam air-filter oil or equivalent oil.

Replace●

OIL FILTER

Replace●●

ENGINE GUARD

Replace●Breakage

FRAME

Clean and inspect●●

FUEL TANK, COCK

Clean and inspect●●

BRAKES

Adjust lever position and pedal

height●●

Lubricate pivot point●●

Check brake disc surface●●

Check fluid level and leakage●●

Retighten brake disc bolts, cali-

per bolts, master cylinder bolts

and union bolts●●

Replace pads●

Replace brake fluid●Every one year ItemAfter

break-

inEvery

race

Every

third

(or 500

km)Every

fifth (or

1,000

km)

As re-

quiredRemarks

Page 65 of 230

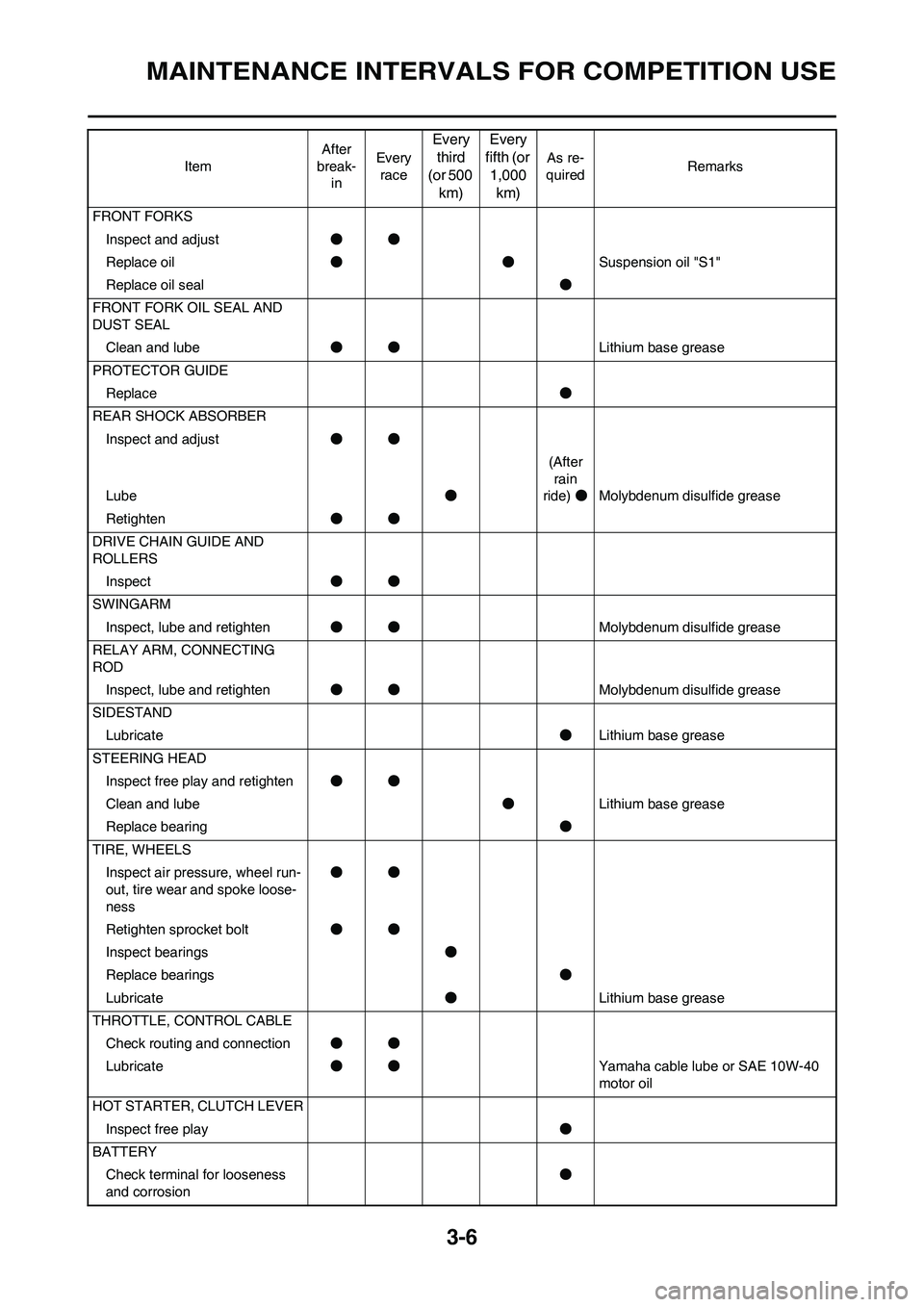

3-6

MAINTENANCE INTERVALS FOR COMPETITION USE

FRONT FORKS

Inspect and adjust●●

Replace oil●●Suspension oil "S1"

Replace oil seal●

FRONT FORK OIL SEAL AND

DUST SEAL

Clean and lube●●Lithium base grease

PROTECTOR GUIDE

Replace●

REAR SHOCK ABSORBER

Inspect and adjust●●

Lube●(After

rain

ride)●Molybdenum disulfide grease

Retighten●●

DRIVE CHAIN GUIDE AND

ROLLERS

Inspect●●

SWINGARM

Inspect, lube and retighten●●Molybdenum disulfide grease

RELAY ARM, CONNECTING

ROD

Inspect, lube and retighten●●Molybdenum disulfide grease

SIDESTAND

Lubricate●Lithium base grease

STEERING HEAD

Inspect free play and retighten●●

Clean and lube●Lithium base grease

Replace bearing●

TIRE, WHEELS

Inspect air pressure, wheel run-

out, tire wear and spoke loose-

ness●●

Retighten sprocket bolt●●

Inspect bearings●

Replace bearings●

Lubricate●Lithium base grease

THROTTLE, CONTROL CABLE

Check routing and connection●●

Lubricate●●Yamaha cable lube or SAE 10W-40

motor oil

HOT STARTER, CLUTCH LEVER

Inspect free play●

BATTERY

Check terminal for looseness

and corrosion● ItemAfter

break-

inEvery

race

Every

third

(or 500

km)Every

fifth (or

1,000

km)

As re-

quiredRemarks

Page 66 of 230

3-7

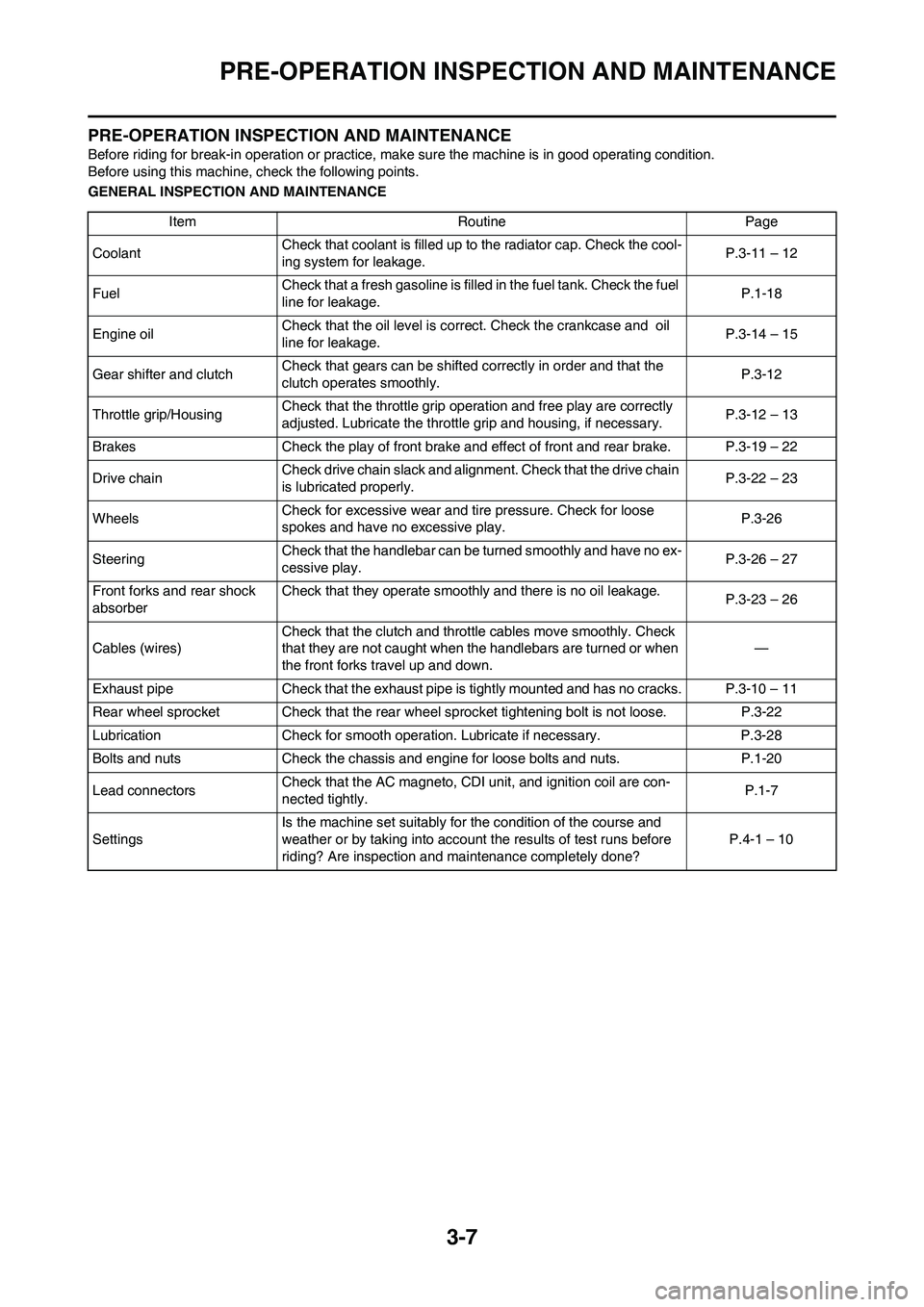

PRE-OPERATION INSPECTION AND MAINTENANCE

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation or practice, make sure the machine is in good operating condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap. Check the cool-

ing system for leakage.P.3-11 – 12

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the fuel

line for leakage.P.1-18

Engine oilCheck that the oil level is correct. Check the crankcase and oil

line for leakage.P.3-14 – 15

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-12

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-12 – 13

Brakes Check the play of front brake and effect of front and rear brake. P.3-19 – 22

Drive chainCheck drive chain slack and alignment. Check that the drive chain

is lubricated properly.P.3-22 – 23

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-26

SteeringCheck that the handlebar can be turned smoothly and have no ex-

cessive play.P.3-26 – 27

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage.

P.3-23 – 26

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.—

Exhaust pipe Check that the exhaust pipe is tightly mounted and has no cracks. P.3-10 – 11

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-22

Lubrication Check for smooth operation. Lubricate if necessary. P.3-28

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-20

Lead connectorsCheck that the AC magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-7

SettingsIs the machine set suitably for the condition of the course and

weather or by taking into account the results of test runs before

riding? Are inspection and maintenance completely done?P.4-1 – 10

Page 72 of 230

3-13

ENGINE

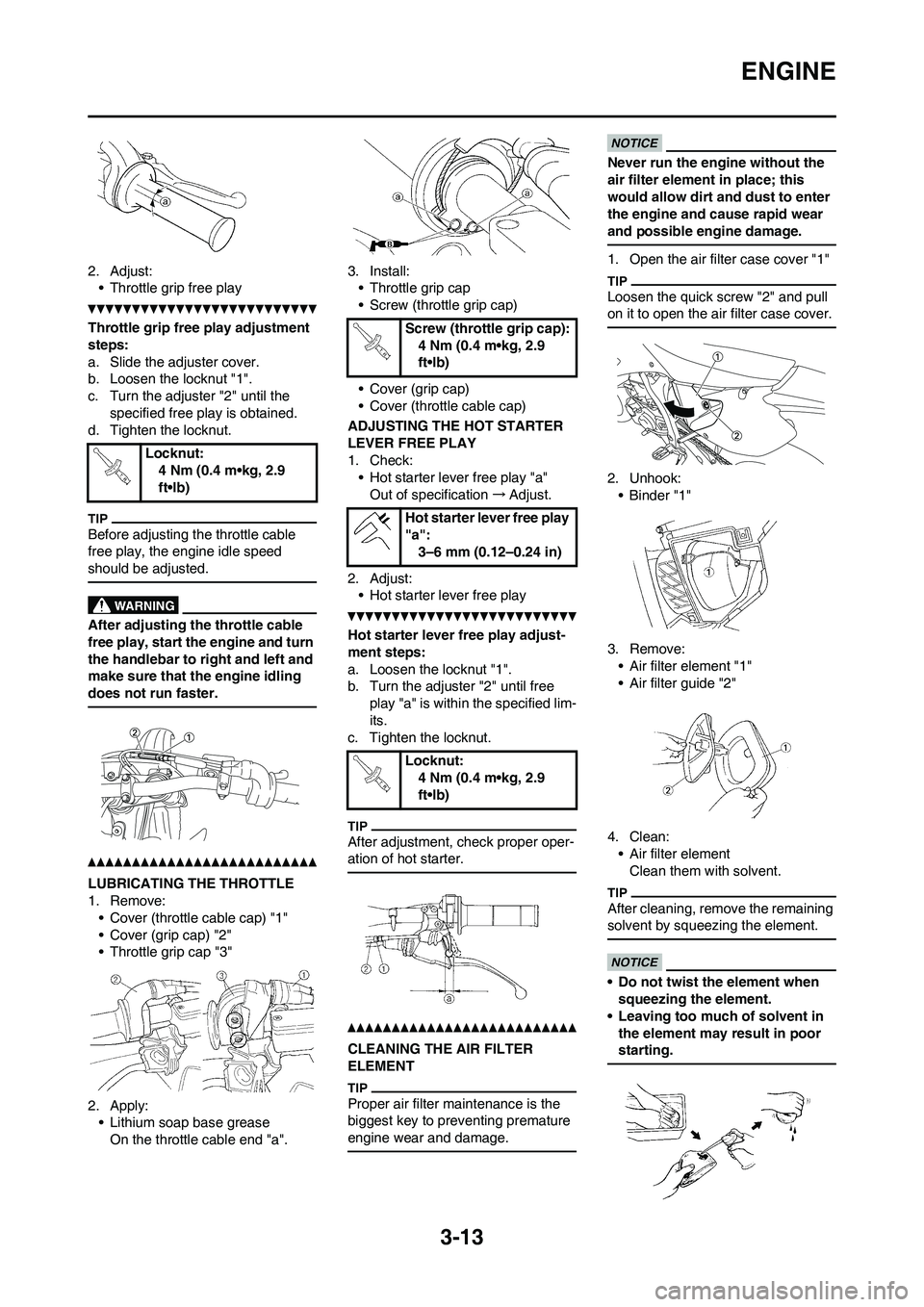

2. Adjust:

• Throttle grip free play

Throttle grip free play adjustment

steps:

a. Slide the adjuster cover.

b. Loosen the locknut "1".

c. Turn the adjuster "2" until the

specified free play is obtained.

d. Tighten the locknut.

Before adjusting the throttle cable

free play, the engine idle speed

should be adjusted.

After adjusting the throttle cable

free play, start the engine and turn

the handlebar to right and left and

make sure that the engine idling

does not run faster.

LUBRICATING THE THROTTLE

1. Remove:

• Cover (throttle cable cap) "1"

• Cover (grip cap) "2"

• Throttle grip cap "3"

2. Apply:

• Lithium soap base grease

On the throttle cable end "a".3. Install:

• Throttle grip cap

• Screw (throttle grip cap)

• Cover (grip cap)

• Cover (throttle cable cap)

ADJUSTING THE HOT STARTER

LEVER FREE PLAY

1. Check:

• Hot starter lever free play "a"

Out of specification→Adjust.

2. Adjust:

• Hot starter lever free play

Hot starter lever free play adjust-

ment steps:

a. Loosen the locknut "1".

b. Turn the adjuster "2" until free

play "a" is within the specified lim-

its.

c. Tighten the locknut.

After adjustment, check proper oper-

ation of hot starter.

CLEANING THE AIR FILTER

ELEMENT

Proper air filter maintenance is the

biggest key to preventing premature

engine wear and damage.

Never run the engine without the

air filter element in place; this

would allow dirt and dust to enter

the engine and cause rapid wear

and possible engine damage.

1. Open the air filter case cover "1"

Loosen the quick screw "2" and pull

on it to open the air filter case cover.

2. Unhook:

•Binder "1"

3. Remove:

• Air filter element "1"

• Air filter guide "2"

4. Clean:

• Air filter element

Clean them with solvent.

After cleaning, remove the remaining

solvent by squeezing the element.

• Do not twist the element when

squeezing the element.

• Leaving too much of solvent in

the element may result in poor

starting.

Locknut:

4 Nm (0.4 m•kg, 2.9

ft•lb)

Screw (throttle grip cap):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Hot starter lever free play

"a":

3–6 mm (0.12–0.24 in)

Locknut:

4 Nm (0.4 m•kg, 2.9

ft•lb)