service YAMAHA WR 450F 2012 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2012, Model line: WR 450F, Model: YAMAHA WR 450F 2012Pages: 96, PDF Size: 2.47 MB

Page 31 of 96

INSTRUMENT AND CONTROL FUNCTIONS

3-16

234

5

6

7

8

9

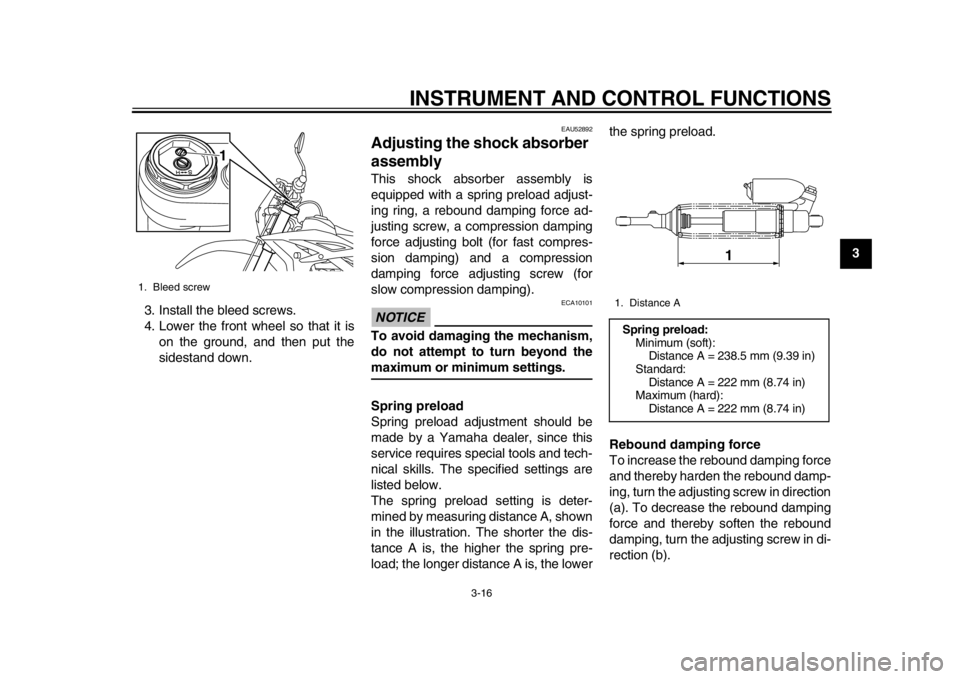

3. Install the bleed screws.

4. Lower the front wheel so that it is

on the ground, and then put the

sidestand down.

EAU52892

Adjusting the shock absorber

assembly This shock absorber assembly is

equipped with a spring preload adjust-

ing ring, a rebound damping force ad-

justing screw, a compression damping

force adjusting bolt (for fast compres-

sion damping) and a compression

damping force adjusting screw (for

slow compression damping).NOTICE

ECA10101

To avoid damaging the mechanism,

do not attempt to turn beyond themaximum or minimum settings.

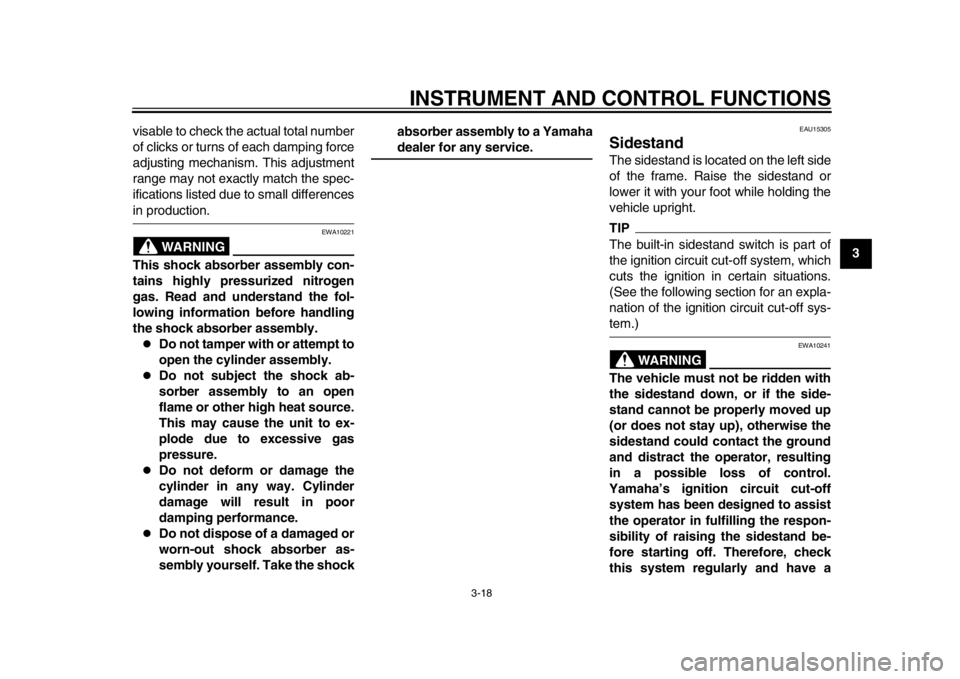

Spring preload

Spring preload adjustment should be

made by a Yamaha dealer, since this

service requires special tools and tech-

nical skills. The specified settings are

listed below.

The spring preload setting is deter-

mined by measuring distance A, shown

in the illustration. The shorter the dis-

tance A is, the higher the spring pre-

load; the longer distance A is, the lower the spring preload.

Rebound damping force

To increase the rebound damping force

and thereby harden the rebound damp-

ing, turn the adjusting screw in direction

(a). To decrease the rebound damping

force and thereby soften the rebound

damping, turn the adjusting screw in di-

rection (b).

1. Bleed screw

1

1. Distance ASpring preload:

Minimum (soft):

Distance A = 238.5 mm (9.39 in)

Standard: Distance A = 222 mm (8.74 in)

Maximum (hard): Distance A = 222 mm (8.74 in)

1

1DX-9-E0.book 16 ページ 2011年10月10日 月曜日 午後2時14分

Page 33 of 96

INSTRUMENT AND CONTROL FUNCTIONS

3-18

234

5

6

7

8

9

visable to check the actual total number

of clicks or turns of each damping force

adjusting mechanism. This adjustment

range may not exactly match the spec-

ifications listed due to small differences

in production.

WARNING

EWA10221

This shock absorber assembly con-

tains highly pressurized nitrogen

gas. Read and understand the fol-

lowing information before handling

the shock absorber assembly.

Do not tamper with or attempt to

open the cylinder assembly.

Do not subject the shock ab-

sorber assembly to an open

flame or other high heat source.

This may cause the unit to ex-

plode due to excessive gas

pressure.

Do not deform or damage the

cylinder in any way. Cylinder

damage will result in poor

damping performance.

Do not dispose of a damaged or

worn-out shock absorber as-

sembly yourself. Take the shock absorber assembly to a Yamaha

dealer for any service.

EAU15305

Sidestand The sidestand is located on the left side

of the frame. Raise the sidestand or

lower it with your foot while holding the

vehicle upright.TIPThe built-in sidestand switch is part of

the ignition circuit cut-off system, which

cuts the ignition in certain situations.

(See the following section for an expla-

nation of the ignition circuit cut-off sys-tem.)

WARNING

EWA10241

The vehicle must not be ridden with

the sidestand down, or if the side-

stand cannot be properly moved up

(or does not stay up), otherwise the

sidestand could contact the ground

and distract the operator, resulting

in a possible loss of control.

Yamaha’s ignition circuit cut-off

system has been designed to assist

the operator in fulfilling the respon-

sibility of raising the sidestand be-

fore starting off. Therefore, check

this system regularly and have a

1DX-9-E0.book 18 ページ 2011年10月10日 月曜日 午後2時14分

Page 42 of 96

OPERATION AND IMPORTANT RIDING POINTS

5-4

1

2

3

45

6

7

8

9

EAU52940

Engine break-in

WARNING

EWA10321

Failure to properly maintain the ve-

hicle or performing maintenance ac-

tivities incorrectly may increase

your risk of injury or death during

service or while using the vehicle. If

you are not familiar with vehicle ser-

vice, have a Yamaha dealer performservice.1. Before starting the engine, fill the fuel tank with the fuel.

2. Start and warm up the engine. Check the operation of the controls

and the engine stop switch. (See

page 3-7.) Then, restart the engine

and check its operation within no

more than 5 minutes after it is re-

started.

3. Operate the motorcycle in the low- er gears at moderate throttle open-

ings for five to eight minutes. Stop

the engine.

4. Check how the engine runs when the motorcycle is ridden with the

throttle 1/4 to 1/2 open (low to me-

dium speed) for about one hour. 5. Start the engine and check the op-

eration of the motorcycle through-

out its entire operating range.

Restart the motorcycle and ride it

for about 10 to 15 more minutes.

The motorcycle will now be ready

to ride normally.

After the engine break-in period, thor-

oughly check the motorcycle for loose

parts, oil leakage and any other prob-

lems. Be sure to inspect and make ad-

justments thoroughly, especially cable

and drive chain slack and loose

spokes. In addition, check all fittings

and fasteners for looseness, and tight-

en if necessary.

NOTICE

ECA15560

When any of the following parts

have been replaced, they must

be broken in.

Cylinder or crankshaft:

About one hour of break-in op-

eration is necessary.

Piston, rings or transmission

gears:

These parts require about 30

minutes of break-in operation at

half-throttle or less. Observe the condition of the engine carefully

during operation.

If any engine trouble should oc-

cur during the engine break-in

period, immediately have a

Yamaha dealer check the vehi-cle.

1DX-9-E0.book 4 ページ 2011年10月10日 月曜日 午後2時14分

Page 44 of 96

6-1

1

2

3

4

56

7

8

9

PERIODIC MAINTENANCE AND ADJUSTMENT

EAU17244

Periodic inspection, adjustment, and lu-

brication will keep your vehicle in the

safest and most efficient condition pos-

sible. Safety is an obligation of the vehi-

cle owner/operator. The most important

points of vehicle inspection, adjust-

ment, and lubrication are explained on

the following pages.

The intervals given in the periodic

maintenance charts should be simply

considered as a general guide under

normal riding conditions. However, de-

pending on the weather, terrain, geo-

graphical location, and individual use,

the maintenance intervals may need to

be shortened.

WARNING

EWA10321

Failure to properly maintain the ve-

hicle or performing maintenance ac-

tivities incorrectly may increase

your risk of injury or death during

service or while using the vehicle. If

you are not familiar with vehicle ser-

vice, have a Yamaha dealer performservice.

WARNING

EWA15122

Turn off the engine when performing

maintenance unless otherwise

specified.

A running engine has moving

parts that can catch on body

parts or clothing and electrical

parts that can cause shocks or

fires.

Running the engine while ser-

vicing can lead to eye injury,

burns, fire, or carbon monoxide

poisoning – possibly leading to

death. See page 1-2 for more in-

formation about carbon monox-ide.WARNING

EWA15460

Brake discs, calipers, drums, and

linings can become very hot during

use. To avoid possible burns, let

brake components cool beforetouching them.

EAU17302

Emission controls not only function to

ensure cleaner air, but are also vital to

proper engine operation and maximum

performance. In the following periodic

maintenance charts, the services relat-

ed to emissions control are grouped

separately. These services require

specialized data, knowledge, and

equipment. Maintenance, replacement,

or repair of the emission control devic-

es and systems may be performed by

any repair establishment or individual

that is certified (if applicable). Yamaha

dealers are trained and equipped to

perform these particular services.

1DX-9-E0.book 1 ページ 2011年10月10日 月曜日 午後2時14分

Page 45 of 96

PERIODIC MAINTENANCE AND ADJUSTMENT

6-2

2

3

4

567

8

9

EAU17311

Owner’s tool kit The service information included in this

manual and the tools provided in the

owner’s tool kit are intended to assist

you in the performance of preventive

maintenance and minor repairs. How-

ever, additional tools such as a torque

wrench may be necessary to perform

certain maintenance work correctly.TIPIf you do not have the tools or experi-

ence required for a particular job, havea Yamaha dealer perform it for you.

1DX-9-E0.book 2 ページ 2011年10月10日 月曜日 午後2時14分

Page 49 of 96

PERIODIC MAINTENANCE AND ADJUSTMENT

6-6

2

3

4

567

8

9

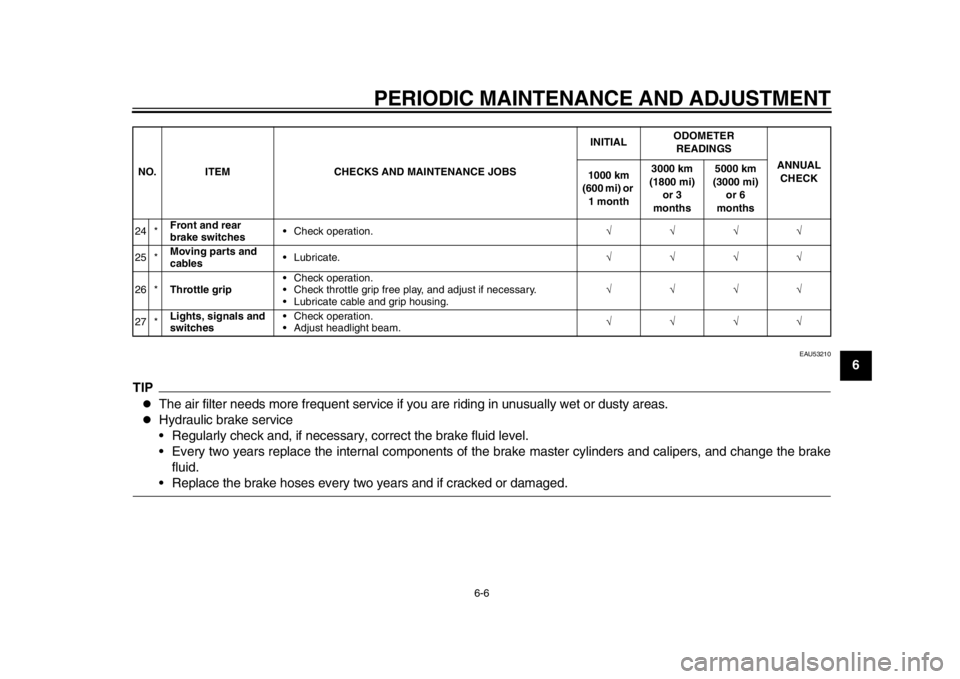

EAU53210

TIP

The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

Hydraulic brake service

Regularly check and, if necessary, correct the brake fluid level.

Every two years replace the internal components of the brake master cylinders and calipers, and change the brake

fluid. Replace the brake hoses every tw o years and if cracked or damaged.

24 *Front and rear

brake switches Check operation.

25 * Moving parts and

cables Lubricate.

26 * Throttle grip Check operation.

Check throttle grip free play, and adjust if necessary.

Lubricate cable and grip housing.

27 * Lights, signals and

switches Check operation.

Adjust headlight beam.

NO. ITEM CHECKS AND MAINTENANCE JOBS

INITIAL

ODOMETER

READINGS

ANNUAL CHECK

1000 km

(600 mi) or

1 month 3000 km

(1800 mi) or 3

months 5000 km

(3000 mi) or 6

months

1DX-9-E0.book 6 ページ 2011年10月10日 月曜日 午後2時14分

Page 69 of 96

PERIODIC MAINTENANCE AND ADJUSTMENT

6-26

2

3

4

567

8

9

EAU23025

Cleaning and lubricating the

drive chain The drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10583

The drive chain must be lubricated

after washing the motorcycle, ridingin the rain or riding in wet areas.

1. Clean the drive chain with kero- sene and a small soft brush.

NOTICE: To prevent damaging

the O-rings, do not clean the

drive chain with steam cleaners,

high-pressure washers or inap-

propriate solvents.

[ECA11121]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

engine oil or any other lubri-

cants for the drive chain, as they may contain substances that

could damage the O-rings.

[ECA11111]

EAU23095

Checking and lubricating the

cables The operation of all control cables and

the condition of the cables should be

checked before each ride, and the ca-

bles and cable ends should be lubricat-

ed if necessary. If a cable is damaged

or does not move smoothly, have a

Yamaha dealer check or replace it.

WARNING! Damage to the outer

housing of cables may result in in-

ternal rusting and cause interfer-

ence with cable movement. Replace

damaged cables as soon as possi-

ble to prevent unsafe condi-

tions.

[EWA10711]

Recommended lubricant:

Yamaha Chain and Cable Lube or

engine oil

1DX-9-E0.book 26 ページ 2011年10月10日 月曜日 午後2時14分

Page 78 of 96

PERIODIC MAINTENANCE AND ADJUSTMENT

6-35

1

2

3

4

56

7

8

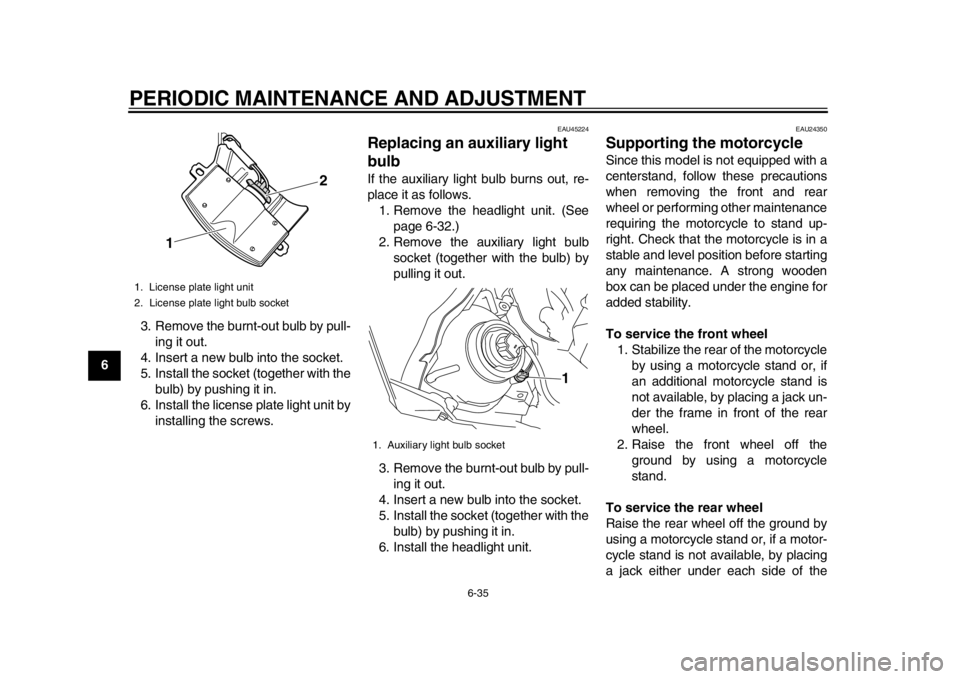

93. Remove the burnt-out bulb by pull-

ing it out.

4. Insert a new bulb into the socket.

5. Install the socket (together with the bulb) by pushing it in.

6. Install the license plate light unit by installing the screws.

EAU45224

Replacing an auxiliary light

bulb If the auxiliary light bulb burns out, re-

place it as follows.1. Remove the headlight unit. (See page 6-32.)

2. Remove the auxiliary light bulb socket (together with the bulb) by

pulling it out.

3. Remove the burnt-out bulb by pull- ing it out.

4. Insert a new bulb into the socket.

5. Install the socket (together with the bulb) by pushing it in.

6. Install the headlight unit.

EAU24350

Supporting the motorcycle Since this model is not equipped with a

centerstand, follow these precautions

when removing the front and rear

wheel or performing other maintenance

requiring the motorcycle to stand up-

right. Check that the motorcycle is in a

stable and level position before starting

any maintenance. A strong wooden

box can be placed under the engine for

added stability.

To service the front wheel 1. Stabilize the rear of the motorcycle by using a motorcycle stand or, if

an additional motorcycle stand is

not available, by placing a jack un-

der the frame in front of the rear

wheel.

2. Raise the front wheel off the ground by using a motorcycle

stand.

To service the rear wheel

Raise the rear wheel off the ground by

using a motorcycle stand or, if a motor-

cycle stand is not available, by placing

a jack either under each side of the

1. License plate light unit

2. License plate light bulb socket

1 2

1. Auxiliary light bulb socket

1

1DX-9-E0.book 35 ページ 2011年10月10日 月曜日 午後2時14分

Page 82 of 96

PERIODIC MAINTENANCE AND ADJUSTMENT

6-39

1

2

3

4

56

7

8

9

EAU25871

Troubleshooting Although Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur dur-

ing operation. Any problem in the fuel,

compression, or ignition systems, for

example, can cause poor starting and

loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look like

Yamaha parts, but they are often inferi-

or, have a shorter service life and can

lead to expensive repair bills.

WARNING

EWA15141

When checking the fuel system, do

not smoke, and make sure there are

no open flames or sparks in the ar-

ea, including pilot lights from waterheaters or furnaces. Gasoline or

gasoline vapors can ignite or ex-

plode, causing severe injury or

property damage.

Tightening torques:

Axle nut:125 Nm (12.5 m·kgf, 90 ft·lbf)

Locknut:

19 Nm (1.9 m·kgf, 13 ft·lbf)

1DX-9-E0.book 39 ページ 2011年10月10日 月曜日 午後2時14分

Page 89 of 96

8-1

2

3

4

5

6

789

SPECIFICATIONS

EAU50973

Dimensions:Overall length: 2315 mm (91.1 in)

Overall width: 825 mm (32.5 in)

Overall height: 1275 mm (50.2 in)

Seat height:

960 mm (37.8 in)

Wheelbase: 1475 mm (58.1 in)

Ground clearance: 335 mm (13.19 in)

Minimum turning radius:

2400 mm (94.5 in)Weight:Curb weight: 129 kg (284 lb)Noise and vibration level:Noise level (77/311/EEC): 80.2 dB(A)

Vibration on seat (EN1032, ISO5008): Will not exceed 0.5 m/s

2

Vibration on handlebar (EN1032, ISO5008): Will not exceed 2.5 m/s

2

Engine:Engine type: Liquid cooled 4-stroke, DOHC

Cylinder arrangement:

Single cylinder

Displacement: 449 cm

3

Bore stroke:

95.0 63.4 mm (3.74 2.50 in) Compression ratio:

12.30 : 1

Starting system:

Electric starter and kickstarter

Lubrication system: Dry sump

Engine oil:Recommended brand:

YAMALUBE

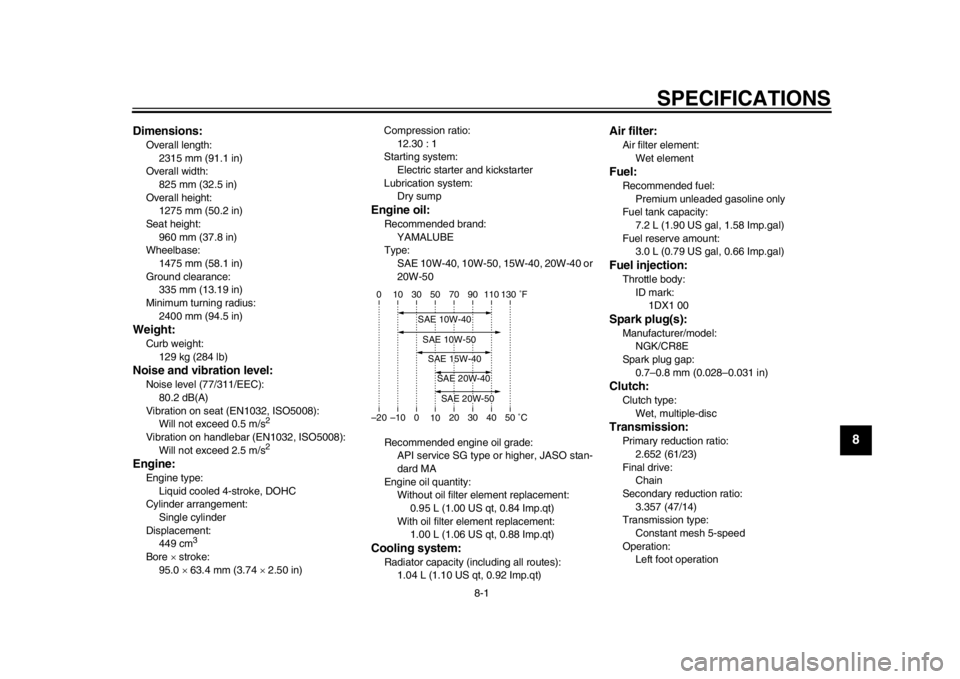

Type: SAE 10W-40, 10W-50, 15W-40, 20W-40 or

20W-50

Recommended engine oil grade: API service SG type or higher, JASO stan-

dard MA

Engine oil quantity: Without oil filter element replacement:

0.95 L (1.00 US qt, 0.84 Imp.qt)

With oil filter element replacement: 1.00 L (1.06 US qt, 0.88 Imp.qt)Cooling system:Radiator capacity (including all routes): 1.04 L (1.10 US qt, 0.92 Imp.qt)

Air filter:Air filter element:

Wet elementFuel:Recommended fuel: Premium unleaded gasoline only

Fuel tank capacity:

7.2 L (1.90 US gal, 1.58 Imp.gal)

Fuel reserve amount: 3.0 L (0.79 US gal, 0.66 Imp.gal)Fuel injection:Throttle body:

ID mark: 1DX1 00Spark plug(s):Manufacturer/model: NGK/CR8E

Spark plug gap: 0.7–0.8 mm (0.028–0.031 in)Clutch:Clutch type: Wet, multiple-discTransmission:Primary reduction ratio:

2.652 (61/23)

Final drive: Chain

Secondary reduction ratio: 3.357 (47/14)

Transmission type:

Constant mesh 5-speed

Operation: Left foot operation

–20 –10 0 1020 30 40 50 �C

10 30 50 70 90 110

0 130 �F

SAE 20W-50SAE 20W-40SAE 15W-40SAE 10W-40SAE 10W-50

1DX-9-E0.book 1 ページ 2011年10月10日 月曜日 午後2時14分