torque YAMAHA WR 450F 2012 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2012, Model line: WR 450F, Model: YAMAHA WR 450F 2012Pages: 96, PDF Size: 2.47 MB

Page 45 of 96

PERIODIC MAINTENANCE AND ADJUSTMENT

6-2

2

3

4

567

8

9

EAU17311

Owner’s tool kit The service information included in this

manual and the tools provided in the

owner’s tool kit are intended to assist

you in the performance of preventive

maintenance and minor repairs. How-

ever, additional tools such as a torque

wrench may be necessary to perform

certain maintenance work correctly.TIPIf you do not have the tools or experi-

ence required for a particular job, havea Yamaha dealer perform it for you.

1DX-9-E0.book 2 ページ 2011年10月10日 月曜日 午後2時14分

Page 51 of 96

PERIODIC MAINTENANCE AND ADJUSTMENT

6-8

2

3

4

567

8

9

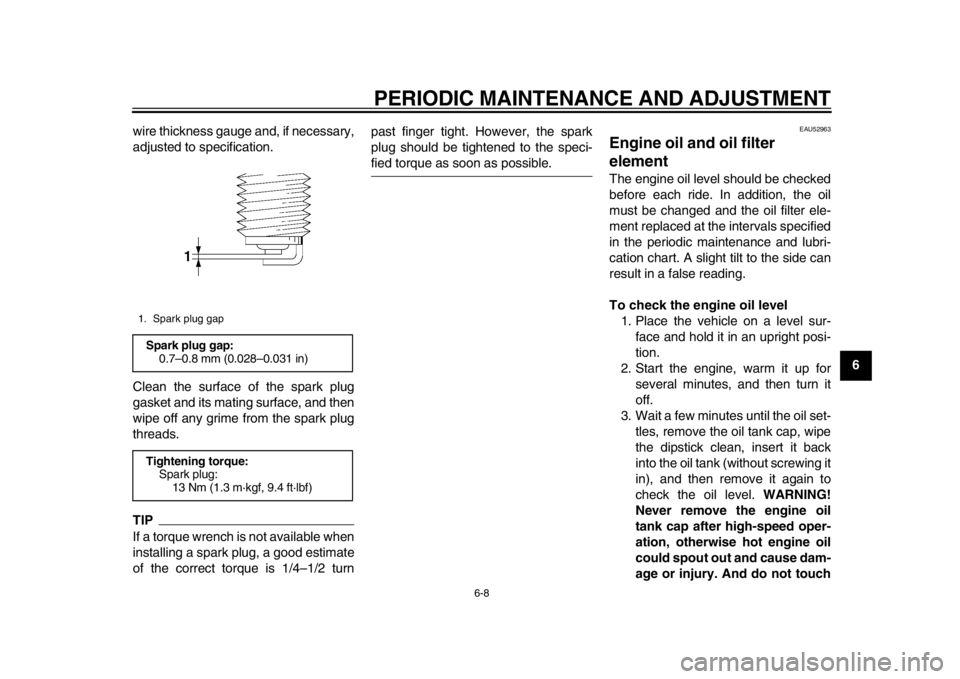

wire thickness gauge and, if necessary,

adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and then

wipe off any grime from the spark plug

threads.

TIPIf a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn past finger tight. However, the spark

plug should be tightened to the speci-

fied torque as soon as possible.

EAU52963

Engine oil and oil filter

element The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart. A slight tilt to the side can

result in a false reading.

To check the engine oil level

1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes until the oil set- tles, remove the oil tank cap, wipe

the dipstick clean, insert it back

into the oil tank (without screwing it

in), and then remove it again to

check the oil level. WARNING!

Never remove the engine oil

tank cap after high-speed oper-

ation, otherwise hot engine oil

could spout out and cause dam-

age or injury. And do not touch

1. Spark plug gapSpark plug gap: 0.7–0.8 mm (0.028–0.031 in)

Tightening torque: Spark plug: 13 Nm (1.3 m·kgf, 9.4 ft·lbf)

1DX-9-E0.book 8 ページ 2011年10月10日 月曜日 午後2時14分

Page 54 of 96

PERIODIC MAINTENANCE AND ADJUSTMENT

6-11

1

2

3

4

56

7

8

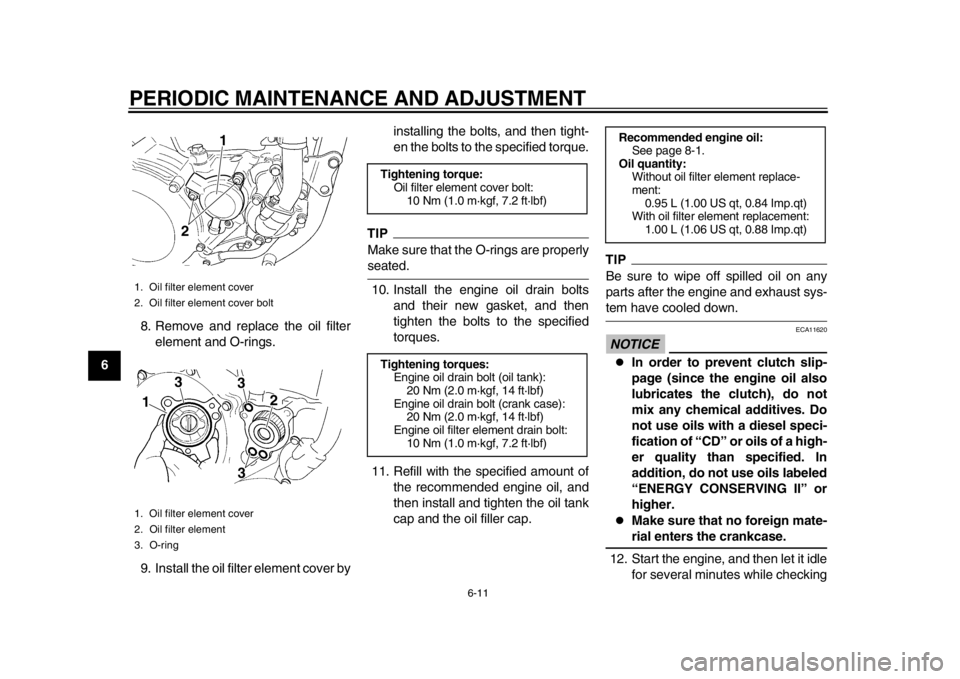

98. Remove and replace the oil filter

element and O-rings.

9. Install the oil filter element cover by installing the bolts, and then tight-

en the bolts to the specified torque.

TIPMake sure that the O-rings are properlyseated.

10. Install the engine oil drain bolts and their new gasket, and then

tighten the bolts to the specified

torques.

11. Refill with the specified amount of the recommended engine oil, and

then install and tighten the oil tank

cap and the oil filler cap.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-tem have cooled down.NOTICE

ECA11620

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a high-

er quality than specified. In

addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

Make sure that no foreign mate-rial enters the crankcase.

12. Start the engine, and then let it idle for several minutes while checking

1. Oil filter element cover

2. Oil filter element cover bolt

1. Oil filter element cover

2. Oil filter element

3. O-ring

1

2

1 2

3

3

3

Tightening torque: Oil filter element cover bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Tightening torques: Engine oil drain bolt (oil tank):20 Nm (2.0 m·kgf, 14 ft·lbf)

Engine oil drain bolt (crank case): 20 Nm (2.0 m·kgf, 14 ft·lbf)

Engine oil filter element drain bolt:

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Recommended engine oil: See page 8-1.

Oil quantity: Without oil filter element replace-

ment:

0.95 L (1.00 US qt, 0.84 Imp.qt)

With oil filter element replacement:

1.00 L (1.06 US qt, 0.88 Imp.qt)

1DX-9-E0.book 11 ページ 2011年10月10日 月曜日 午後2時14分

Page 55 of 96

PERIODIC MAINTENANCE AND ADJUSTMENT

6-12

2

3

4

567

8

9

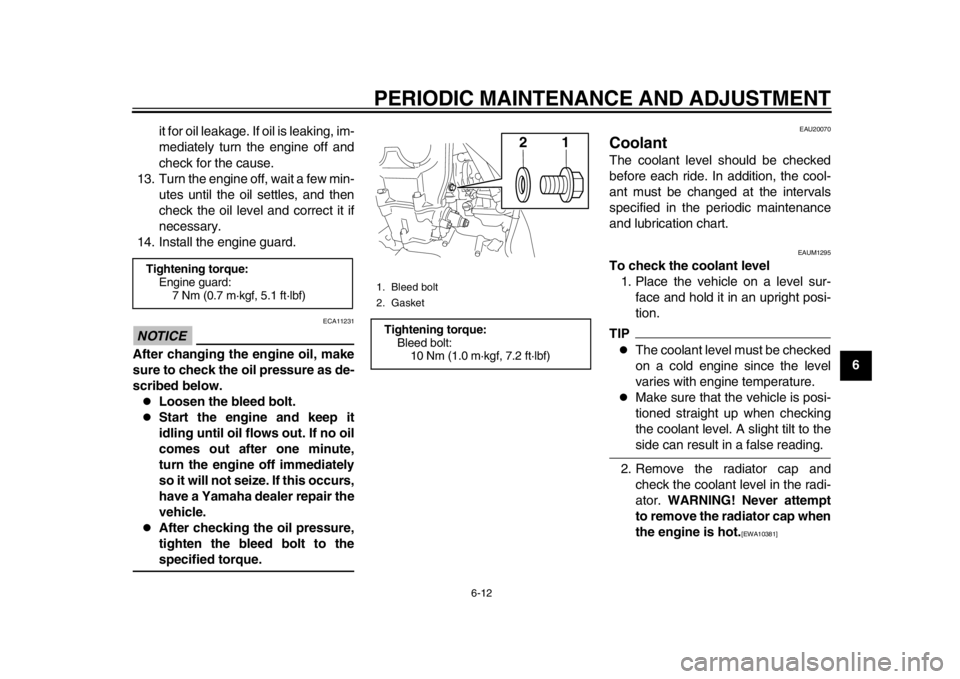

it for oil leakage. If oil is leaking, im-

mediately turn the engine off and

check for the cause.

13. Turn the engine off, wait a few min- utes until the oil settles, and then

check the oil level and correct it if

necessary.

14. Install the engine guard.

NOTICE

ECA11231

After changing the engine oil, make

sure to check the oil pressure as de-

scribed below.

Loosen the bleed bolt.

Start the engine and keep it

idling until oil flows out. If no oil

comes out after one minute,

turn the engine off immediately

so it will not seize. If this occurs,

have a Yamaha dealer repair the

vehicle.

After checking the oil pressure,

tighten the bleed bolt to thespecified torque.

EAU20070

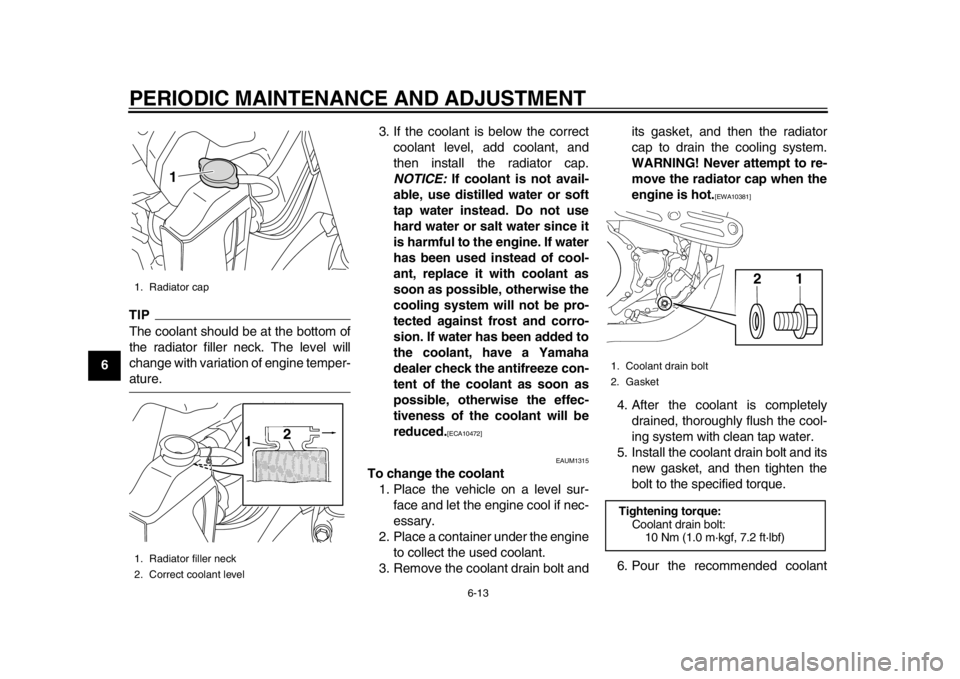

Coolant The coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAUM1295

To check the coolant level 1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion.TIP

The coolant level must be checked

on a cold engine since the level

varies with engine temperature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to theside can result in a false reading.

2. Remove the radiator cap and check the coolant level in the radi-

ator. WARNING! Never attempt

to remove the radiator cap when

the engine is hot.

[EWA10381]

Tightening torque: Engine guard: 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

1. Bleed bolt

2. GasketTightening torque:Bleed bolt:

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

21

1DX-9-E0.book 12 ページ 2011年10月10日 月曜日 午後2時14分

Page 56 of 96

PERIODIC MAINTENANCE AND ADJUSTMENT

6-13

1

2

3

4

56

7

8

9

TIPThe coolant should be at the bottom of

the radiator filler neck. The level will

change with variation of engine temper-ature.3. If the coolant is below the correct

coolant level, add coolant, and

then install the radiator cap.

NOTICE: If coolant is not avail-

able, use distilled water or soft

tap water instead. Do not use

hard water or salt water since it

is harmful to the engine. If water

has been used instead of cool-

ant, replace it with coolant as

soon as possible, otherwise the

cooling system will not be pro-

tected against frost and corro-

sion. If water has been added to

the coolant, have a Yamaha

dealer check the antifreeze con-

tent of the coolant as soon as

possible, otherwise the effec-

tiveness of the coolant will be

reduced.

[ECA10472]

EAUM1315

To change the coolant 1. Place the vehicle on a level sur- face and let the engine cool if nec-

essary.

2. Place a container under the engine to collect the used coolant.

3. Remove the coolant drain bolt and its gasket, and then the radiator

cap to drain the cooling system.

WARNING! Never attempt to re-

move the radiator cap when the

engine is hot.

[EWA10381]

4. After the coolant is completely drained, thoroughly flush the cool-

ing system with clean tap water.

5. Install the coolant drain bolt and its new gasket, and then tighten the

bolt to the specified torque.

6. Pour the recommended coolant

1. Radiator cap

1. Radiator filler neck

2. Correct coolant level

1

2

1

1. Coolant drain bolt

2. GasketTightening torque:

Coolant drain bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

21

1DX-9-E0.book 13 ページ 2011年10月10日 月曜日 午後2時14分

Page 68 of 96

PERIODIC MAINTENANCE AND ADJUSTMENT

6-25

1

2

3

4

56

7

8

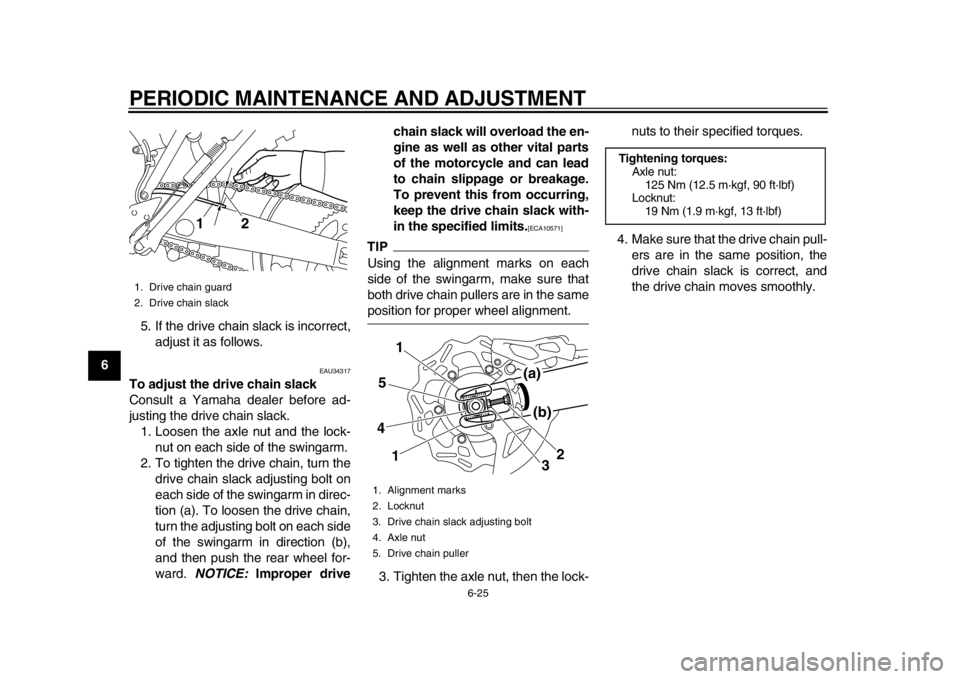

95. If the drive chain slack is incorrect,

adjust it as follows.

EAU34317

To adjust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack.1. Loosen the axle nut and the lock- nut on each side of the swingarm.

2. To tighten the drive chain, turn the drive chain slack adjusting bolt on

each side of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting bolt on each side

of the swingarm in direction (b),

and then push the rear wheel for-

ward. NOTICE: Improper drive chain slack will overload the en-

gine as well as other vital parts

of the motorcycle and can lead

to chain slippage or breakage.

To prevent this from occurring,

keep the drive chain slack with-

in the specified limits.

[ECA10571]

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain pullers are in the sameposition for proper wheel alignment.

3. Tighten the axle nut, then the lock- nuts to their specified torques.

4. Make sure that the drive chain pull- ers are in the same position, the

drive chain slack is correct, and

the drive chain moves smoothly.

1. Drive chain guard

2. Drive chain slack

12

1. Alignment marks

2. Locknut

3. Drive chain slack adjusting bolt

4. Axle nut

5. Drive chain puller

1

1

5

4 32

(a)

(b)

Tightening torques: Axle nut:125 Nm (12.5 m·kgf, 90 ft·lbf)

Locknut: 19 Nm (1.9 m·kgf, 13 ft·lbf)

1DX-9-E0.book 25 ページ 2011年10月10日 月曜日 午後2時14分

Page 80 of 96

![YAMAHA WR 450F 2012 Owners Manual PERIODIC MAINTENANCE AND ADJUSTMENT

6-37

1

2

3

4

56

7

8

9installing the spacers, be sure

to install them on the correct

side.

[ECA17700]

2. Lift the wheel up between the fork legs.

TIPMake sure that YAMAHA WR 450F 2012 Owners Manual PERIODIC MAINTENANCE AND ADJUSTMENT

6-37

1

2

3

4

56

7

8

9installing the spacers, be sure

to install them on the correct

side.

[ECA17700]

2. Lift the wheel up between the fork legs.

TIPMake sure that](/img/51/52459/w960_52459-79.png)

PERIODIC MAINTENANCE AND ADJUSTMENT

6-37

1

2

3

4

56

7

8

9installing the spacers, be sure

to install them on the correct

side.

[ECA17700]

2. Lift the wheel up between the fork legs.

TIPMake sure that there is enough space

between the brake pads before install-

ing the brake caliper onto the brakedisc.

3. Insert the wheel axle from the right-hand side.

4. Install the axle nut.

5. Lower the front wheel so that it is on the ground, and then put the

sidestand down.

6. Tighten the axle nut to the speci- fied torque.

7. Tighten the front wheel axle pinch bolts to the specified torque, and

then install the rubber cap. 8. Push down hard on the handlebar

several times to check for proper

fork operation.

EAU25080

Rear wheel

EAU45183

To remove the rear wheel

WARNING

EWA10821

To avoid injury, securely support the

vehicle so there is no danger of itfalling over.

1. Loosen the axle nut.

2. Lift the rear wheel off the ground according to the procedure on

page 6-35.

3. Remove the axle nut and washer.

4. Loosen the locknut on each side of the swingarm.

Tightening torque:Axle nut:

90 Nm (9.0 m·kgf, 65 ft·lbf)

Tightening torque: Front wheel axle pinch bolt:12 Nm (1.2 m·kgf, 8.7 ft·lbf)

1. Axle nut

2. Washer1

2

1DX-9-E0.book 37 ページ 2011年10月10日 月曜日 午後2時14分

Page 81 of 96

PERIODIC MAINTENANCE AND ADJUSTMENT

6-38

2

3

4

567

8

9

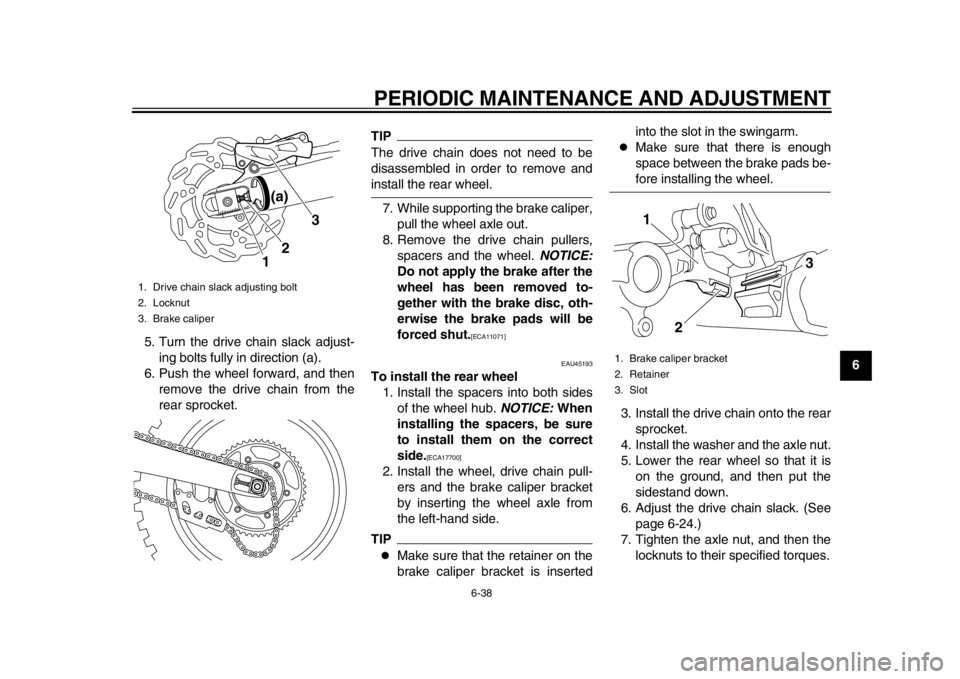

5. Turn the drive chain slack adjust-

ing bolts fully in direction (a).

6. Push the wheel forward, and then remove the drive chain from the

rear sprocket.

TIPThe drive chain does not need to be

disassembled in order to remove andinstall the rear wheel.

7. While supporting the brake caliper, pull the wheel axle out.

8. Remove the drive chain pullers, spacers and the wheel. NOTICE:

Do not apply the brake after the

wheel has been removed to-

gether with the brake disc, oth-

erwise the brake pads will be

forced shut.

[ECA11071]

EAU45193

To install the rear wheel 1. Install the spacers into both sides of the wheel hub. NOTICE: When

installing the spacers, be sure

to install them on the correct

side.

[ECA17700]

2. Install the wheel, drive chain pull- ers and the brake caliper bracket

by inserting the wheel axle from

the left-hand side.

TIP

Make sure that the retainer on the

brake caliper bracket is inserted into the slot in the swingarm.

Make sure that there is enough

space between the brake pads be-fore installing the wheel.

3. Install the drive chain onto the rear sprocket.

4. Install the washer and the axle nut.

5. Lower the rear wheel so that it is on the ground, and then put the

sidestand down.

6. Adjust the drive chain slack. (See page 6-24.)

7. Tighten the axle nut, and then the locknuts to their specified torques.

1. Drive chain slack adjusting bolt

2. Locknut

3. Brake caliper

1 2

3

(a)

1. Brake caliper bracket

2. Retainer

3. Slot

1

2

3

1DX-9-E0.book 38 ページ 2011年10月10日 月曜日 午後2時14分

Page 82 of 96

PERIODIC MAINTENANCE AND ADJUSTMENT

6-39

1

2

3

4

56

7

8

9

EAU25871

Troubleshooting Although Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur dur-

ing operation. Any problem in the fuel,

compression, or ignition systems, for

example, can cause poor starting and

loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look like

Yamaha parts, but they are often inferi-

or, have a shorter service life and can

lead to expensive repair bills.

WARNING

EWA15141

When checking the fuel system, do

not smoke, and make sure there are

no open flames or sparks in the ar-

ea, including pilot lights from waterheaters or furnaces. Gasoline or

gasoline vapors can ignite or ex-

plode, causing severe injury or

property damage.

Tightening torques:

Axle nut:125 Nm (12.5 m·kgf, 90 ft·lbf)

Locknut:

19 Nm (1.9 m·kgf, 13 ft·lbf)

1DX-9-E0.book 39 ページ 2011年10月10日 月曜日 午後2時14分