engine YAMAHA WR 450F 2014 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: WR 450F, Model: YAMAHA WR 450F 2014Pages: 98, PDF Size: 2.55 MB

Page 44 of 98

6-1

1

2

3

4

56

7

8

9

PERIODIC MAINTENANCE AND ADJUSTMENT

EAU17244

Periodic inspection, adjustment, and lu-

brication will keep your vehicle in the

safest and most efficient condition pos-

sible. Safety is an obligation of the vehi-

cle owner/operator. The most important

points of vehicle inspection, adjust-

ment, and lubrication are explained on

the following pages.

The intervals given in the periodic

maintenance charts should be simply

considered as a general guide under

normal riding conditions. However, de-

pending on the weather, terrain, geo-

graphical location, and individual use,

the maintenance intervals may need to

be shortened.

WARNING

EWA10321

Failure to properly maintain the ve-

hicle or performing maintenance ac-

tivities incorrectly may increase

your risk of injury or death during

service or while using the vehicle. If

you are not familiar with vehicle ser-

vice, have a Yamaha dealer performservice.

WARNING

EWA15122

Turn off the engine when performing

maintenance unless otherwise

specified.

A running engine has moving

parts that can catch on body

parts or clothing and electrical

parts that can cause shocks or

fires.

Running the engine while ser-

vicing can lead to eye injury,

burns, fire, or carbon monoxide

poisoning – possibly leading to

death. See page 1-2 for more in-

formation about carbon monox-ide.WARNING

EWA15460

Brake discs, calipers, drums, and

linings can become very hot during

use. To avoid possible burns, let

brake components cool beforetouching them.

EAU17302

Emission controls not only function to

ensure cleaner air, but are also vital to

proper engine operation and maximum

performance. In the following periodic

maintenance charts, the services relat-

ed to emissions control are grouped

separately. These services require

specialized data, knowledge, and

equipment. Maintenance, replacement,

or repair of the emission control devic-

es and systems may be performed by

any repair establishment or individual

that is certified (if applicable). Yamaha

dealers are trained and equipped to

perform these particular services.

1DX-9-E2.book 1 ページ 2013年2月26日 火曜日 午後2時34分

Page 46 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-3

1

2

3

4

56

7

8

9

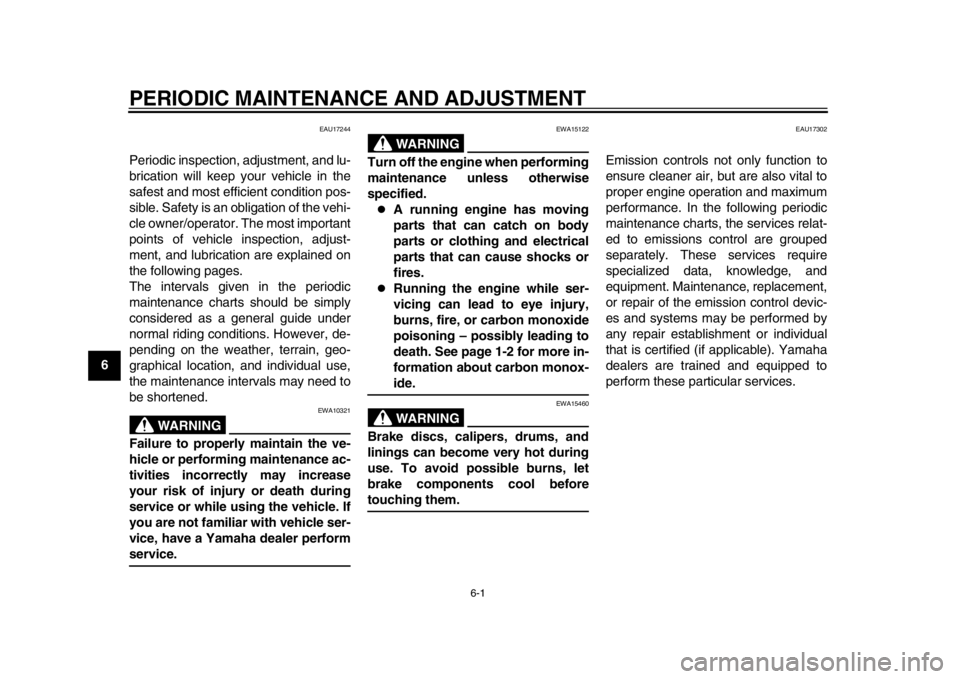

EAU52500

TIP

The annual checks must be performed every year, except if a kilometer-based maintenance, or for the UK, a

mileage-based maintenance, is performed instead.

From 7000 km (4200 mi) or 9 months, repeat the maintenance intervals starting from 3000 km (1800 mi) or 3 months.

Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and technicalskills.

EAU52510

Periodic maintenance chart for the emission control system NO. ITEM CHECKS AND MAINTENANCE JOBS INITIAL

ODOMETER

READINGS ANNUAL

CHECK

1000 km

(600 mi) or 1 month 3000 km

(1800 mi) or 3 months 5000 km

(3000 mi) or 6 months

1* Fuel line Check fuel hoses for cracks or damage.

2* Spark plug Check condition.

Clean and regap.

Replace if necessary.

3* Valves Check valve clearance.

Adjust.

4* Breather system Check ventilation hose for cracks or damage and drain any

deposits.

5* Fuel injection Adjust engine idling speed.

6 Muffler and

exhaust pipe Check the screw clamp(s) for looseness.

1DX-9-E2.book 3 ページ 2013年2月26日 火曜日 午後2時34分

Page 48 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-5

1

2

3

4

56

7

8

9

13 *Chassis fasteners Make sure that all nuts, bolts and screws are properly

tightened.

14 Brake lever pivot

shaft Lubricate with silicone grease.

15 Brake pedal pivot

shaft Lubricate with lithium-soap-based grease.

16 Clutch lever pivot

shaft Lubricate with lithium-soap-based grease.

17 Sidestand Check operation.

Lubricate with lithium-soap-based grease.

18 * Sidestand switch Check operation.

19 * Front fork Check operation and for oil leakage.

20 * Shock absorber

assembly Check operation and shock absorber for oil leakage.

21 * Rear suspension

relay arm and

connecting arm

pivoting points Check operation.

22 Engine oil Change.

Check oil level and vehicle for oil leakage.

23 Engine oil filter

element Replace.

24 * Cooling system Check hoses for cracks of damage.

Replace if necessary.

Check coolant level and vehicle for coolant leakage.

Change with ethylene glycol anti-freeze coolant. Every 1 year

25 * Front and rear

brake switches Check operation.

NO. ITEM CHECKS AND MAINTENANCE JOBS

INITIAL

ODOMETER

READINGS ANNUAL

CHECK

1000 km

(600 mi) or 1 month 3000 km

(1800 mi) or 3 months 5000 km

(3000 mi) or 6 months1DX-9-E2.book 5 ページ 2013年2月26日 火曜日 午後2時34分

Page 50 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-7

1

2

3

4

56

7

8

9

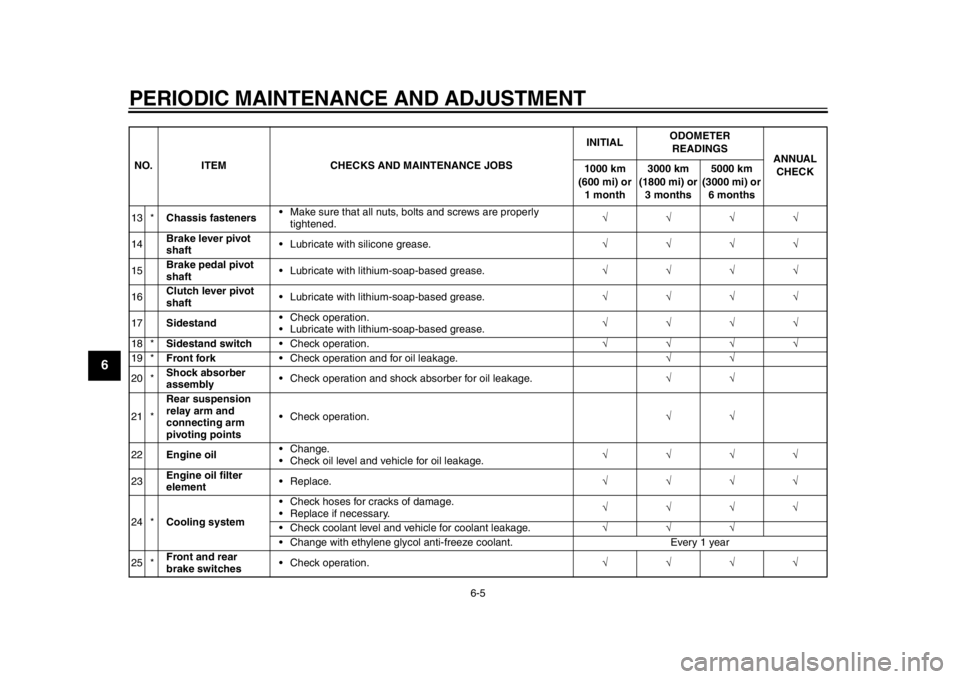

EAU18751

Removing and installing the

panel The panel shown needs to be removed

to perform some of the maintenance

jobs described in this chapter. Refer to

this section each time the panel needs

to be removed and installed.

EAU52872

Panel A

To remove the panel1. Remove the seat. (Seepage 3-13.)

2. Remove the bolts. 3. Pull the front part of the panel out-

ward, and then remove the panel

by pulling it off.

To install the panel

1. Place the panel in the original posi- tion, and then install the bolts.

2. Install the seat.

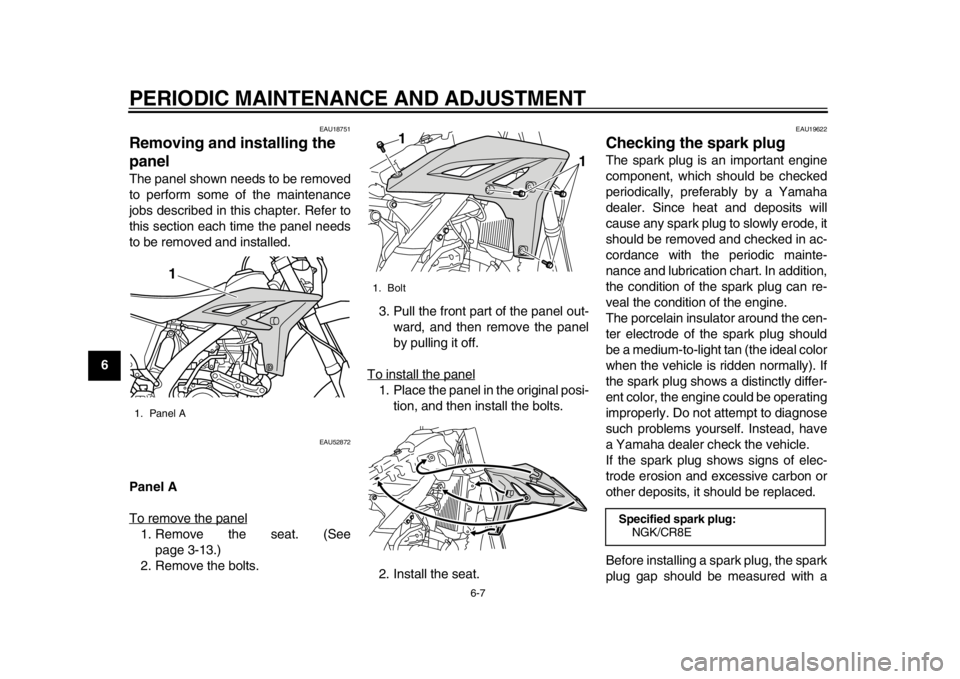

EAU19622

Checking the spark plug The spark plug is an important engine

component, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark plug to slowly erode, it

should be removed and checked in ac-

cordance with the periodic mainte-

nance and lubrication chart. In addition,

the condition of the spark plug can re-

veal the condition of the engine.

The porcelain insulator around the cen-

ter electrode of the spark plug should

be a medium-to-light tan (the ideal color

when the vehicle is ridden normally). If

the spark plug shows a distinctly differ-

ent color, the engine could be operating

improperly. Do not attempt to diagnose

such problems yourself. Instead, have

a Yamaha dealer check the vehicle.

If the spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced.

Before installing a spark plug, the spark

plug gap should be measured with a

1. Panel A

1

1. Bolt

1 1

Specified spark plug:NGK/CR8E

1DX-9-E2.book 7 ページ 2013年2月26日 火曜日 午後2時34分

Page 51 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-8

2

3

4

567

8

9

wire thickness gauge and, if necessary,

adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and then

wipe off any grime from the spark plug

threads.

TIPIf a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn past finger tight. However, the spark

plug should be tightened to the speci-

fied torque as soon as possible.

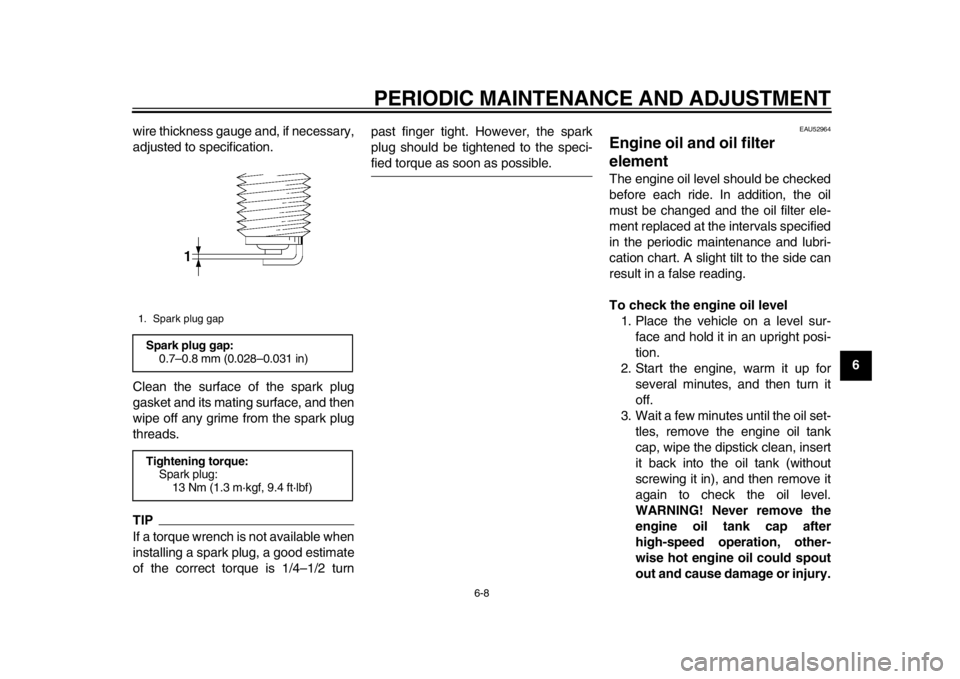

EAU52964

Engine oil and oil filter

element The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart. A slight tilt to the side can

result in a false reading.

To check the engine oil level

1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes until the oil set- tles, remove the engine oil tank

cap, wipe the dipstick clean, insert

it back into the oil tank (without

screwing it in), and then remove it

again to check the oil level.

WARNING! Never remove the

engine oil tank cap after

high-speed operation, other-

wise hot engine oil could spout

out and cause damage or injury.

1. Spark plug gapSpark plug gap:0.7–0.8 mm (0.028–0.031 in)

Tightening torque: Spark plug: 13 Nm (1.3 m·kgf, 9.4 ft·lbf)

1DX-9-E2.book 8 ページ 2013年2月26日 火曜日 午後2時34分

Page 52 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-9

1

2

3

4

56

7

8

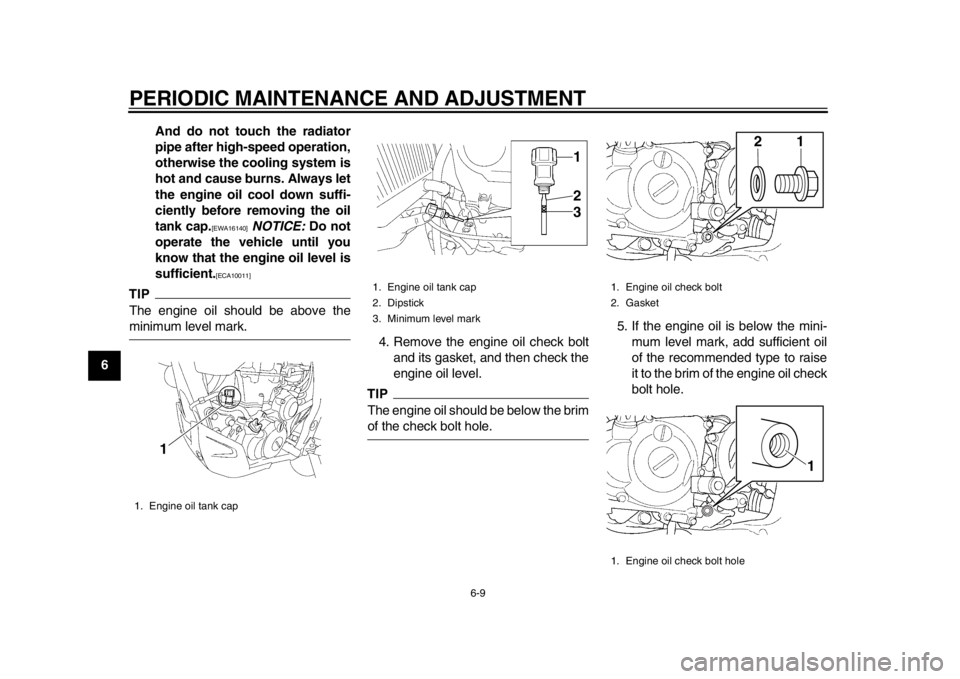

9And do not touch the radiator

pipe after high-speed operation,

otherwise the cooling system is

hot and cause burns. Always let

the engine oil cool down suffi-

ciently before removing the oil

tank cap.

[EWA16140]

NOTICE: Do not

operate the vehicle until you

know that the engine oil level is

sufficient.

[ECA10011]

TIPThe engine oil should be above theminimum level mark. 4. Remove the engine oil check bolt

and its gasket, and then check the

engine oil level.

TIPThe engine oil should be below the brimof the check bolt hole. 5. If the engine oil is below the mini-

mum level mark, add sufficient oil

of the recommended type to raise

it to the brim of the engine oil check

bolt hole.

1. Engine oil tank cap

1

1. Engine oil tank cap

2. Dipstick

3. Minimum level mark

312

1. Engine oil check bolt

2. Gasket

1. Engine oil check bolt hole

21

1

1DX-9-E2.book 9 ページ 2013年2月26日 火曜日 午後2時34分

Page 53 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-10

2

3

4

567

8

9

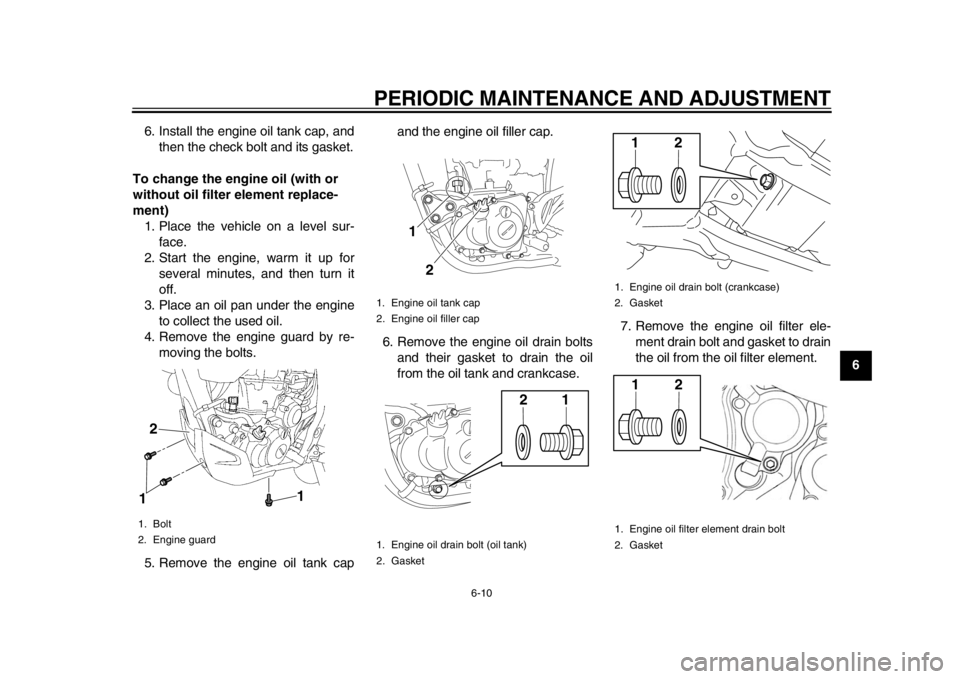

6. Install the engine oil tank cap, and

then the check bolt and its gasket.

To change the engine oil (with or

without oil filter element replace-

ment) 1. Place the vehicle on a level sur- face.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Place an oil pan under the engine to collect the used oil.

4. Remove the engine guard by re- moving the bolts.

5. Remove the engine oil tank cap and the engine oil filler cap.

6. Remove the engine oil drain bolts and their gasket to drain the oil

from the oil tank and crankcase. 7. Remove the engine oil filter ele-

ment drain bolt and gasket to drain

the oil from the oil filter element.

1. Bolt

2. Engine guard2

1

1

1. Engine oil tank cap

2. Engine oil filler cap

1. Engine oil drain bolt (oil tank)

2. Gasket

1

2

21

1. Engine oil drain bolt (crankcase)

2. Gasket

1. Engine oil filter element drain bolt

2. Gasket

2121

1DX-9-E2.book 10 ページ 2013年2月26日 火曜日 午後2時34分

Page 54 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-11

1

2

3

4

56

7

8

9

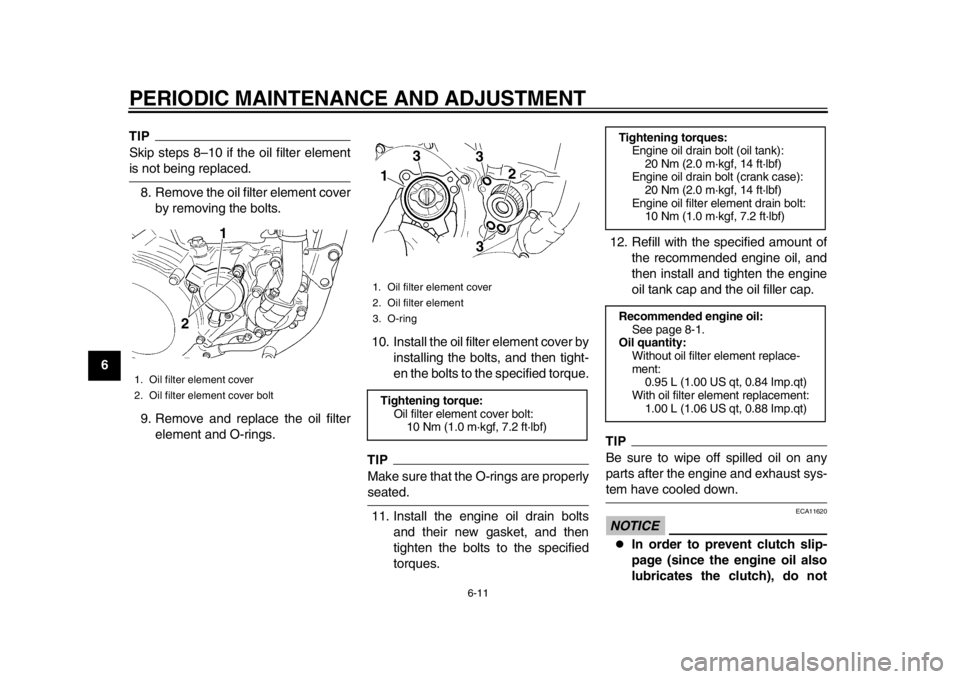

TIPSkip steps 8–10 if the oil filter elementis not being replaced.8. Remove the oil filter element cover by removing the bolts.

9. Remove and replace the oil filter element and O-rings. 10. Install the oil filter element cover by

installing the bolts, and then tight-

en the bolts to the specified torque.

TIPMake sure that the O-rings are properlyseated.

11. Install the engine oil drain bolts and their new gasket, and then

tighten the bolts to the specified

torques. 12. Refill with the specified amount of

the recommended engine oil, and

then install and tighten the engine

oil tank cap and the oil filler cap.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-tem have cooled down.NOTICE

ECA11620

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

1. Oil filter element cover

2. Oil filter element cover bolt

1

2

1. Oil filter element cover

2. Oil filter element

3. O-ringTightening torque:Oil filter element cover bolt:

10 Nm (1.0 m·kgf, 7.2 ft·lbf)1 2

3

3

3

Tightening torques: Engine oil drain bolt (oil tank):20 Nm (2.0 m·kgf, 14 ft·lbf)

Engine oil drain bolt (crank case):

20 Nm (2.0 m·kgf, 14 ft·lbf)

Engine oil filter element drain bolt: 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Recommended engine oil: See page 8-1.

Oil quantity:

Without oil filter element replace-

ment:0.95 L (1.00 US qt, 0.84 Imp.qt)

With oil filter element replacement: 1.00 L (1.06 US qt, 0.88 Imp.qt)

1DX-9-E2.book 11 ページ 2013年2月26日 火曜日 午後2時34分

Page 55 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-12

2

3

4

567

8

9

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a high-

er quality than specified. In

addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

Make sure that no foreign mate-rial enters the crankcase.

13. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking, im-

mediately turn the engine off and

check for the cause.

14. Turn the engine off, wait a few min- utes until the oil settles, and then

check the oil level and correct it if

necessary.

15. Install the engine guard by install- ing the bolts.

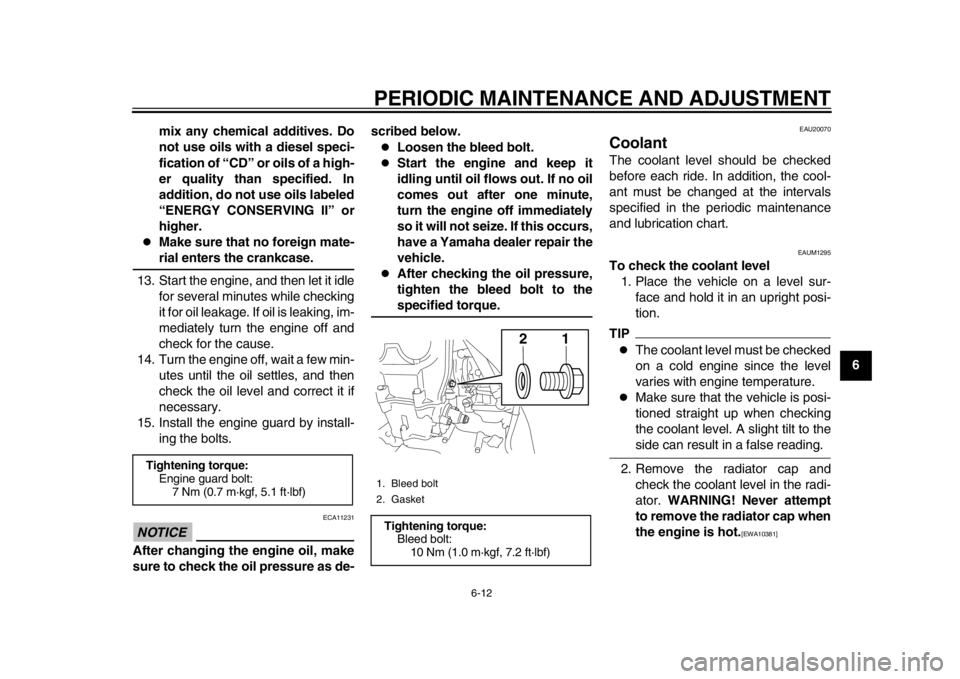

NOTICE

ECA11231

After changing the engine oil, make

sure to check the oil pressure as de- scribed below.

Loosen the bleed bolt.

Start the engine and keep it

idling until oil flows out. If no oil

comes out after one minute,

turn the engine off immediately

so it will not seize. If this occurs,

have a Yamaha dealer repair the

vehicle.

After checking the oil pressure,

tighten the bleed bolt to thespecified torque.

EAU20070

Coolant The coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAUM1295

To check the coolant level

1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion.TIP

The coolant level must be checked

on a cold engine since the level

varies with engine temperature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to theside can result in a false reading.

2. Remove the radiator cap and check the coolant level in the radi-

ator. WARNING! Never attempt

to remove the radiator cap when

the engine is hot.

[EWA10381]

Tightening torque: Engine guard bolt:

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

1. Bleed bolt

2. GasketTightening torque:Bleed bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

21

1DX-9-E2.book 12 ページ 2013年2月26日 火曜日 午後2時34分

Page 56 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-13

1

2

3

4

56

7

8

9

TIPThe coolant should be at the bottom of

the radiator filler neck. The level will

change with variation of engine temper-ature.3. If the coolant is below the correct

coolant level, add coolant, and

then install the radiator cap.

NOTICE: If coolant is not avail-

able, use distilled water or soft

tap water instead. Do not use

hard water or salt water since it

is harmful to the engine. If water

has been used instead of cool-

ant, replace it with coolant as

soon as possible, otherwise the

cooling system will not be pro-

tected against frost and corro-

sion. If water has been added to

the coolant, have a Yamaha

dealer check the antifreeze con-

tent of the coolant as soon as

possible, otherwise the effec-

tiveness of the coolant will be

reduced.

[ECA10472]

EAUM1315

To change the coolant 1. Place the vehicle on a level sur- face and let the engine cool if nec-

essary.

2. Place a container under the engine to collect the used coolant.

3. Remove the coolant drain bolt and its gasket, and then the radiator

cap to drain the cooling system.

WARNING! Never attempt to re-

move the radiator cap when the

engine is hot.

[EWA10381]

4. After the coolant is completely drained, thoroughly flush the cool-

ing system with clean tap water.

5. Install the coolant drain bolt and its new gasket, and then tighten the

bolt to the specified torque.

6. Pour the recommended coolant

1. Radiator cap

1. Radiator filler neck

2. Correct coolant level

1

2

1

1. Coolant drain bolt

2. GasketTightening torque:

Coolant drain bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

21

1DX-9-E2.book 13 ページ 2013年2月26日 火曜日 午後2時34分