engine oil YAMAHA WR 450F 2016 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 9 of 426

EAS2GC1007

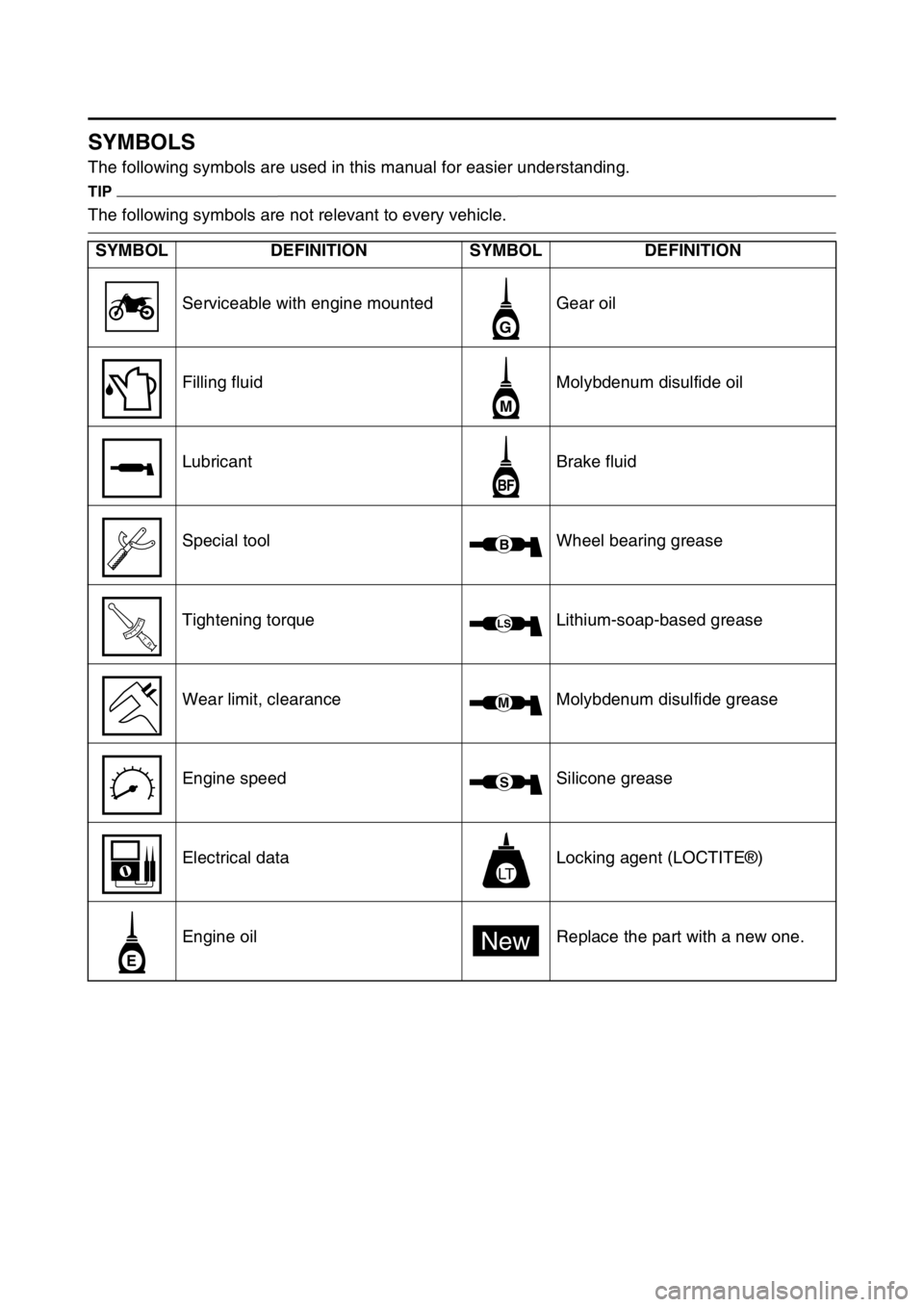

SYMBOLS

The following symbols are used in this manual for easier understanding.

TIP

The following symbols are not relevant to every vehicle.

SYMBOL DEFINITION SYMBOL DEFINITION

Serviceable with engine mounted Gear oil

Filling fluid Molybdenum disulfide oil

Lubricant Brake fluid

Special tool Wheel bearing grease

Tightening torque Lithium-soap-based grease

Wear limit, clearance Molybdenum disulfide grease

Engine speed Silicone grease

Electrical data Locking agent (LOCTITE®)

Engine oil Replace the part with a new one.

G

M

BF

B

T R..

LS

M

S

LT

E

New

Page 13 of 426

1

GENERAL INFORMATION

LOCATION OF IMPORTANT LABELS............................................................ 1-1

DESCRIPTION .................................................................................................. 1-4

IDENTIFICATION ............................................................................................. 1-5

VEHICLE IDENTIFICATION NUMBER ...................................................... 1-5

ENGINE SERIAL NUMBER ....................................................................... 1-5

VEHICLE EMISSION CONTROL INFORMATION LABEL......................... 1-5

INCLUDED PARTS .......................................................................................... 1-6

SPARK PLUG WRENCH ........................................................................... 1-6

NIPPLE WRENCH...................................................................................... 1-6

HANDLEBAR PROTECTOR .. .................................................................... 1-6

FUEL HOSE JOINT COVER ...................................................................... 1-6

COUPLER FOR CONNECTING OPTIONAL PART................................... 1-6

IMPORTANT INFORMATION .......................................................................... 1-7

PREPARATION FOR REMOVAL A ND DISASSEMBLY............................ 1-7

REPLACEMENT PARTS............................................................................ 1-7

GASKETS, OIL SEALS AND O-RINGS ..................................................... 1-8

LOCK WASHERS/PLATES AND COTTER PINS ...................................... 1-8

BEARINGS AND OIL SEALS ..................................................................... 1-8

CIRCLIPS ................................................................................................... 1-8

BASIC SERVICE INFORMATION .................................................................... 1-9

ELECTRICAL SYSTEM.......... .................................................................... 1-9

SPECIAL TOOLS ........................................................................................... 1-13

CONTROL FUNCTIONS ................................................................................ 1-18

INDICATOR LIGHTS AND WARNING LIGHTS ....................................... 1-18

ENGINE STOP SWITCH .......................................................................... 1-18

START SWITCH....................................................................................... 1-18

CLUTCH LEVER ................................................................................... ... 1-18

SHIFT PEDAL .......................................................................................... 1-19

KICKSTARTER LEVER.......... .................................................................. 1-19

THROTTLE GRIP ..................................................................................... 1-19

FRONT BRAKE LEVER ........................................................................... 1-19

REAR BRAKE PEDAL.............................................................................. 1-19

SIDESTAND ............................................................................................. 1-20

STARTER KNOB/IDLE SCREW .............................................................. 1-20

FUEL TANK CAP ..................................................................................... 1-20

Page 18 of 426

DESCRIPTION

1-4

EAS2GC1009

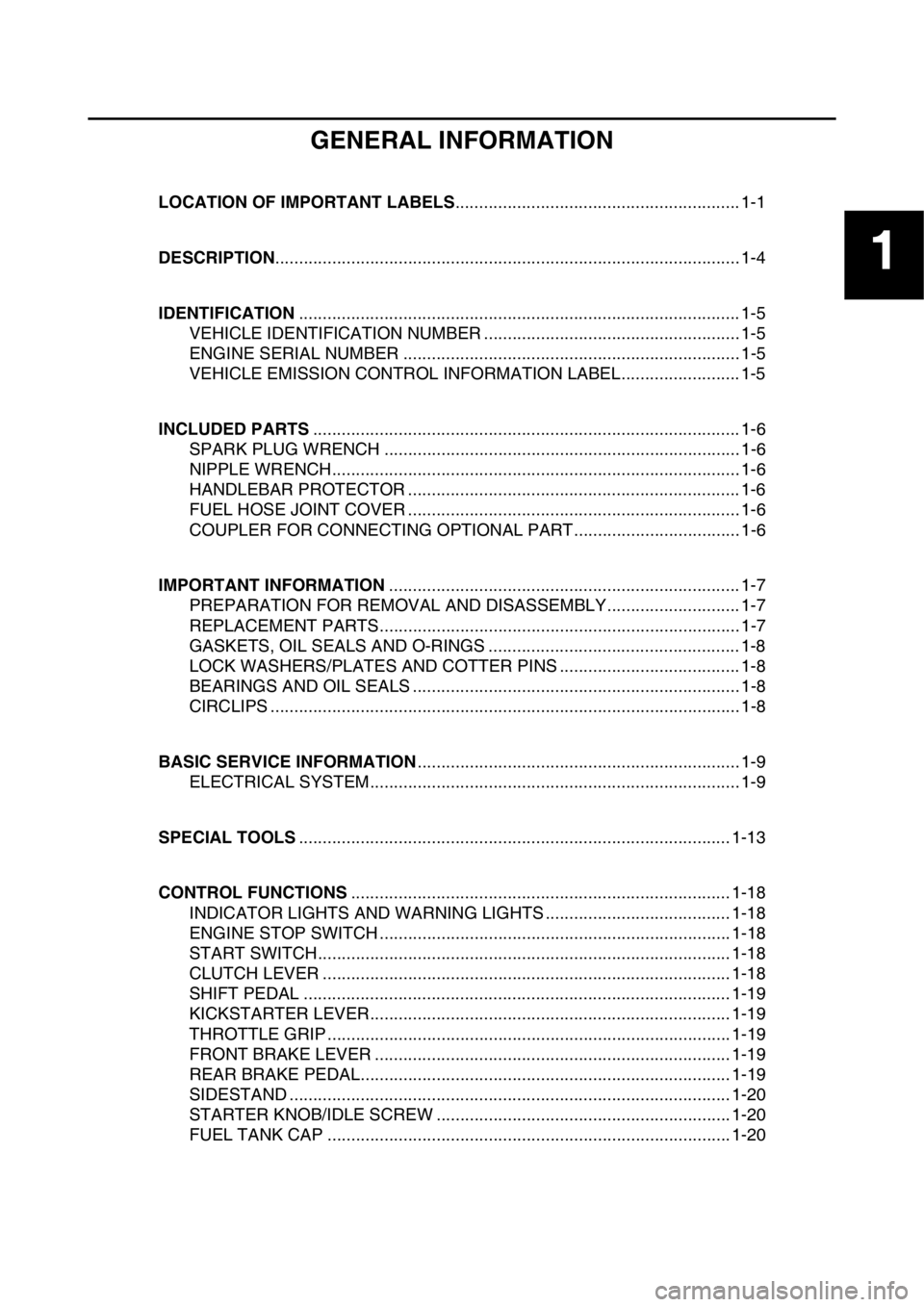

DESCRIPTION

TIP

Designs and specifications of the vehicle are subject to change without notice. Therefore, please

note that the descriptions in this manual may be different from those for the vehicle you have pur-

chased.1. Clutch lever 12. Headlight

2. Multi-function display 13. Radiator

3. Front brake lever 14. Coolant drain bolt

4. Throttle grip 15. Rear brake pedal

5. Start switch 16. Air filter

6. Radiator cap 17. Drive chain

7. Fuel tank cap 18. Shift pedal

8. Engine stop switch 19. Oil level check window

9. Taillight 20. Starter knob/idle screw

10. Fuel tank 21. Front fork

11. Kickstarter lever

32

1

8

10

91 112 1376

54

15 14 21 20 19 18 17 16

Page 21 of 426

IMPORTANT INFORMATION

1-7

EAS20180

IMPORTANT INFORMATION

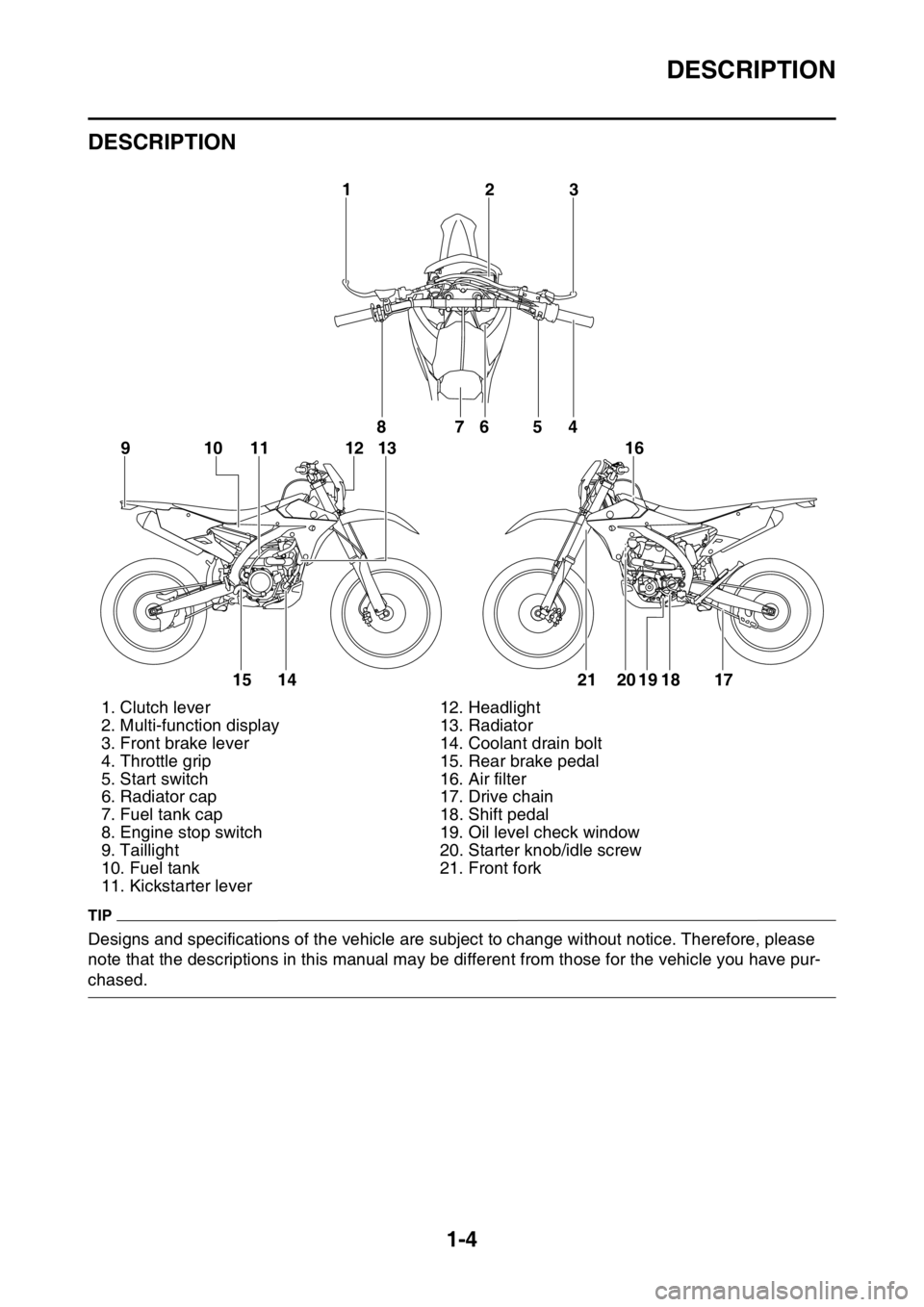

EAS2GC1020PREPARATION FOR REMOVAL AND DIS-

ASSEMBLY

1. Before the jobs, completely remove mud, dust, and the like in order to prevent the en-

try of them into the inside during the jobs.

• Before cleaning with high-pressure water of washers, cover the following parts.

Air duct

Silencer exhaust port

Drain hole on the cylinder head (right side)

Hole under the water pump housing

2. Use proper special tools and equipment. See “SPECIAL TOOLS”.

3. During disassembly, check and measure the required parts, and make a record of them

so that you may refer to the record when in-

stalling them. Moreover, arrange gears, cyl-

inders, pistons, and other parts for each

section so as not to confuse or lose them. 4. During disassembly, clean each of the parts,

and store them in trays for each section.

5. Flammable. Keep servicing areas away from any source of fire.

6. During servicing, take special care not to re-

ceive an injury or a burn on the engine, the

exhaust pipe, the silencer, or the like.

7. If coolant is left adhered to the chassis, paint

and plating will be damaged. Therefore,

rinse it out with water in good time.

EWA

WARNING

Coolant is potentially harmful and should

be handled with special care.

• If it enters your eyes, wash it away with wa-ter enough and then get medical attention

• If it splashes on your skin or clothes,

quickly wash it away with water and then

with soapy water.

• If it is swallowed, immediately induce vom-

iting and get medical attention.

EAS2GC1021REPLACEMENT PARTS

Make sure that the parts and grease or oil to be

used for repair of the vehicle, including periodic

replacement parts, are new YAMAHA genuine

parts and recommended parts.

Do not use any used parts, because these may

not be genuine though they have similar ap-

pearances or because the quality may be

changed by aging.

Page 22 of 426

IMPORTANT INFORMATION

1-8

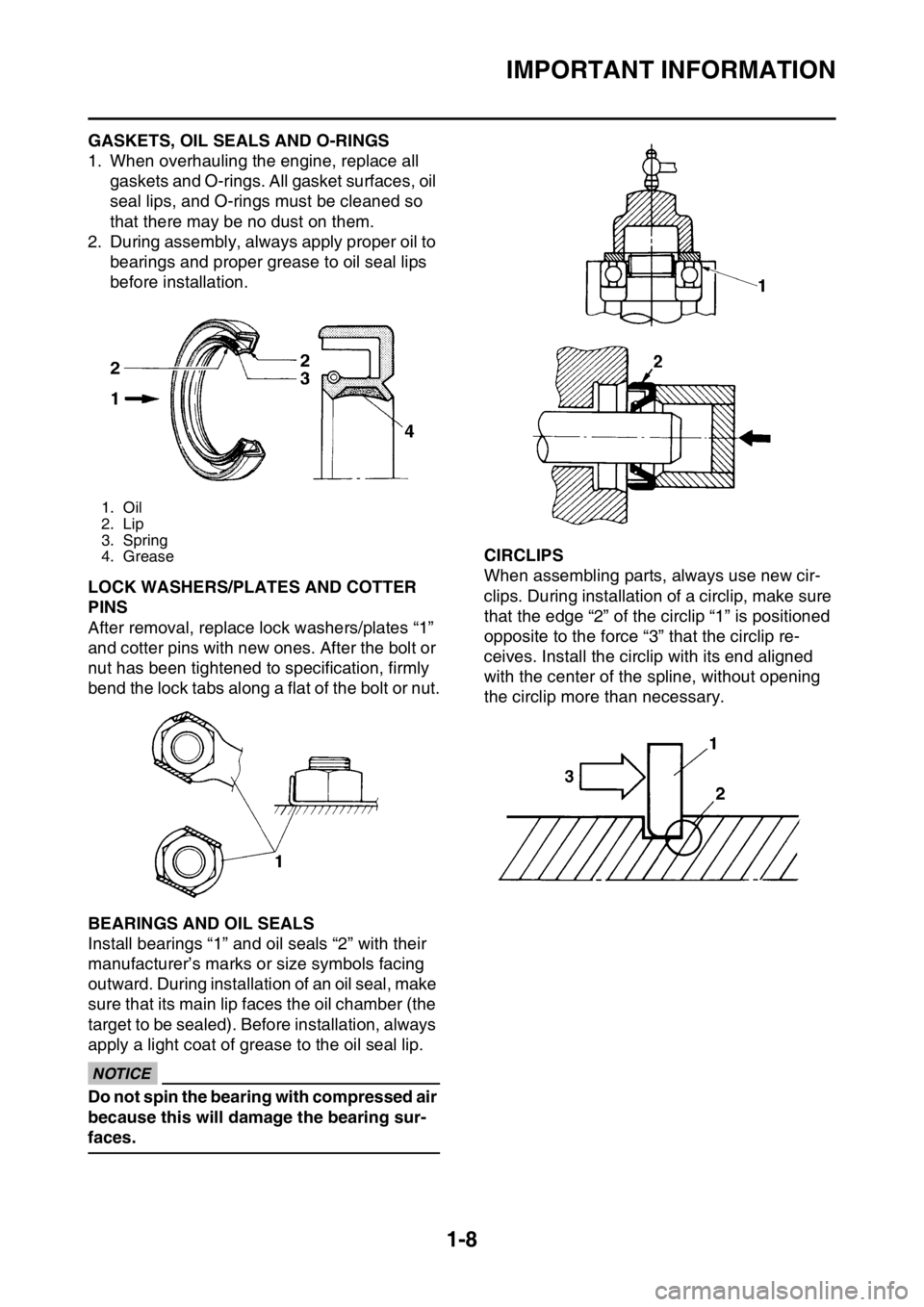

EAS2GC1022GASKETS, OIL SEALS AND O-RINGS

1. When overhauling the engine, replace all gaskets and O-rings. All gasket surfaces, oil

seal lips, and O-rings must be cleaned so

that there may be no dust on them.

2. During assembly, always apply proper oil to bearings and proper grease to oil seal lips

before installation.

EAS2GC1023LOCK WASHERS/PLATES AND COTTER

PINS

After removal, replace lock washers/plates “1”

and cotter pins with new ones. After the bolt or

nut has been tightened to specification, firmly

bend the lock tabs along a flat of the bolt or nut.

EAS2GC1024BEARINGS AND OIL SEALS

Install bearings “1” and oil seals “2” with their

manufacturer’s marks or size symbols facing

outward. During installation of an oil seal, make

sure that its main lip faces the oil chamber (the

target to be sealed). Before installation, always

apply a light coat of grease to the oil seal lip.

ECA

NOTICE

Do not spin the bearing with compressed air

because this will damage the bearing sur-

faces.

EAS2GC1025CIRCLIPS

When assembling parts, always use new cir-

clips. During installation of a circlip, make sure

that the edge “2” of the circlip “1” is positioned

opposite to the force “3” that the circlip re-

ceives. Install the circ lip with its end aligned

with the center of the spline, without opening

the circlip more than necessary.

1. Oil

2. Lip

3. Spring

4. Grease

Page 31 of 426

SPECIAL TOOLS

1-17

Valve spring compressor at-

tachment

90890-04108

Valve spring compressor

adapter 22 mm

YM-04108This tool is used to discon-

nect or connect the valve and

the valve spring.

Rotor puller

90890-04142

Rotor puller

YM-04142 This tool is used to remove

the rotor.

Crankcase separating tool

90890-04152

Crankcase separating tool

YU-A9642 This tool is used to remove

the crankshaft.

Ignition checker

90890-06754

Oppama pet–4000 spark

checker

YM-34487 This tool is used to check the

spark performance of the ig-

nition coil.

Digital tachometer

90890-06760

Digital tachometer

YU-39951-B This tool is used to measure

the engine speed.

Yamaha bond No. 1215

90890-85505

(Three bond No.1215®) This sealant (Bond) is used

for crankcase mating sur-

face, etc.

Tool name/Part number How to use Illustration

Page 42 of 426

STARTING AND BREAK-IN

1-28

EAS2GC1048

STARTING AND BREAK-IN

EAS2GC1049FUEL

Always use the recommended fuel as stated

below. Also, be sure to use new gasoline the

day of a race.

ECA

NOTICE

Use only unleaded gasoline. The use of

leaded gasoline will cause severe damage

to the engine internal parts such as valves,

piston rings, and exhaust system, etc.

TIP

Your Yamaha engine has been designed to use

premium unleaded gasoline with a pump oc-

tane number [(R+M)/2] of 91 or higher, or a re-

search octane number of 95 or higher. If

knocking (or pinging) occurs, use a gasoline of

a different brand.

EWA

WARNING

• For refueling, be sure to stop the engine and use enough care not to spill any fuel.

Also be sure to avoid refueling close to a

fire.

• Refuel after the engine, exhaust pipe, etc.

have cooled off.

Gasohol (For USA and Canada)

There are two types of gasohol: gasohol con-

taining ethanol and that containing methanol.

Gasohol containing ethanol can be used if the

ethanol content does not exceed 10%. Gasohol

containing methanol is not recommended by

Yamaha because it can cause damage to the

fuel system or vehicle performance problems.

EAS2GC1050HANDLING NOTEEWA

WARNING

Never start or run the engine in a closed ar-

ea. The exhaust fumes are poisonous; they

can cause loss of consciousness and death

in a very short time. Always operate the ma-

chine in a well-ventilated area.

ECA

NOTICE

• Unlike a two-stroke engine, this engine cannot be kick started when the throttle is

open because the kickstarter may kick

back. Also, if the throttle is open the air/

fuel mixture may be too lean for the engine

to start.

• Before starting the machine, perform the

checks in the pre-operation check list.

EAS2GC1051AIR FILTER MAINTENANCE

According to “CLEANING THE AIR FILTER

ELEMENT” section in the CHAPTER 3, apply

the Yamaha foam air filter oil or other quality

foam air filter oil to the element. (Excess oil in

the element may adversely affect engine start-

ing.)

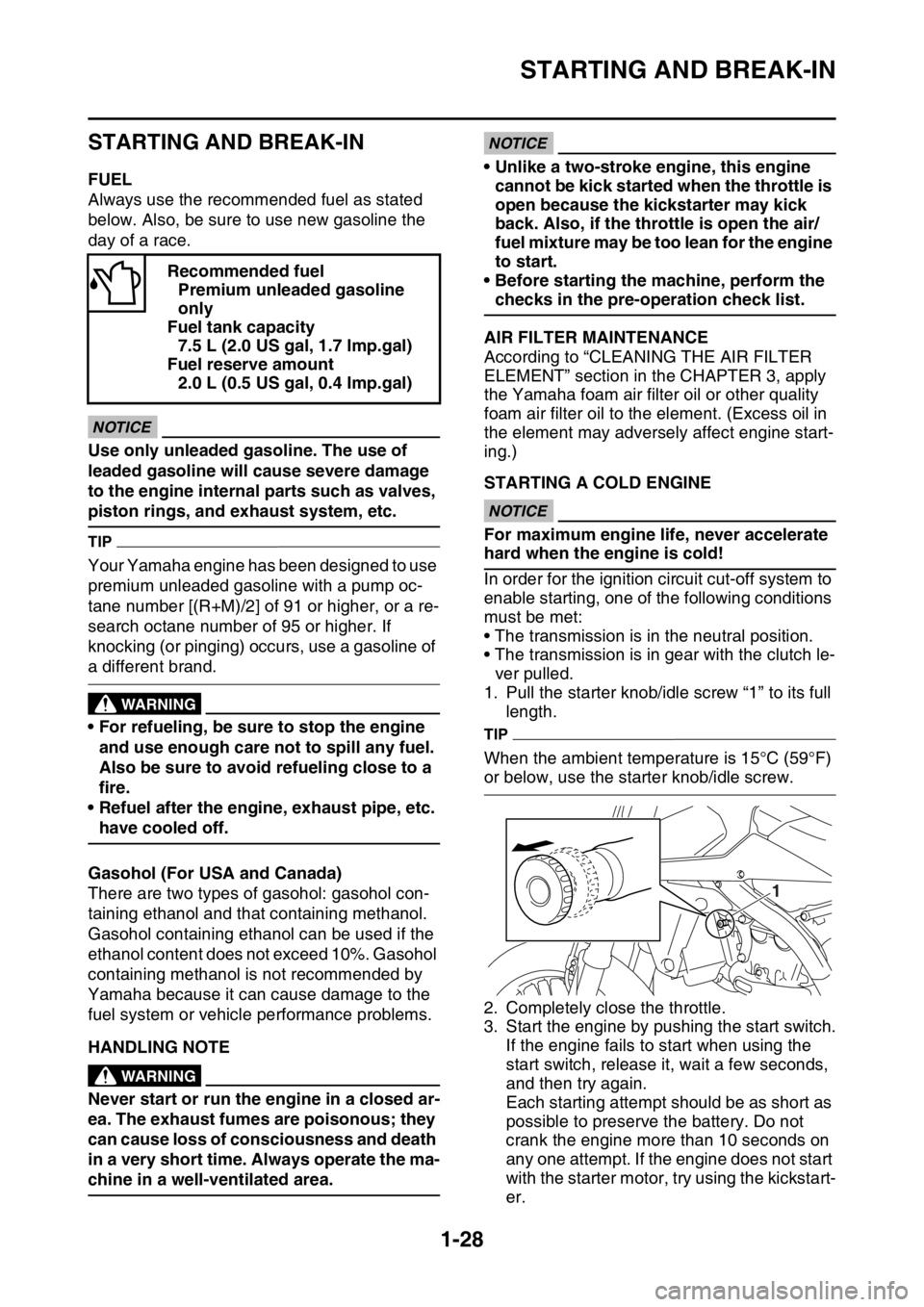

EAS2GC1052STARTING A COLD ENGINEECA

NOTICE

For maximum engine life, never accelerate

hard when the engine is cold!

In order for the ignition circuit cut-off system to

enable starting, one of the following conditions

must be met:

• The transmission is in the neutral position.

• The transmission is in gear with the clutch le- ver pulled.

1. Pull the starter knob/idle screw “1” to its full length.

TIP

When the ambient temperature is 15°C (59°F)

or below, use the starter knob/idle screw.

2. Completely close the throttle.

3. Start the engine by pushing the start switch.If the engine fails to start when using the

start switch, release it, wait a few seconds,

and then try again.

Each starting attempt should be as short as

possible to preserve the battery. Do not

crank the engine more than 10 seconds on

any one attempt. If the engine does not start

with the starter motor, try using the kickstart-

er.

Recommended fuel

Premium unleaded gasoline

only

Fuel tank capacity 7.5 L (2.0 US gal, 1.7 lmp.gal)

Fuel reserve amount 2.0 L (0.5 US gal, 0.4 Imp.gal)

1

Page 44 of 426

STARTING AND BREAK-IN

1-30

EAS2GC1053STARTING A WARM ENGINE

Follow the same procedure as for starting a

cold engine with the exception that the starter is

not required when the engine is warm.

TIP

If it fails to start, fully open the throttle grip and

give 10 to 20 slow kicks to clear the engine of

the rich air-fuel mixture retained in it.

EAS2GC1054BREAK-IN PROCEDURES

A break-in is important so that rotating portion,

sliding surfaces, and mounted areas may fit

one another, and that the rider may become ac-

customed to the machine.

ECA

NOTICE

Before running, do maintenance on the air

filter element.

Refer to “CLEANING THE AIR FILTER ELE-

MENT” on page 3-14.

1. After warming up the engine, drive it for about 20 minutes at a throttle opening of 1/2

or less.

TIP

This model is equipped with an engine auto-

stop system. The engine stops automatically if

left idling for 7 minutes. If the engine stops,

push the start switch or push down the kick-

starter lever to restart the engine.

2. Make a pit stop, and check mounted areas

for looseness, oil leaks, or other problems.

3. Then, drive it for about 40 minutes at a throt- tle opening of 3/4 or less.

4. Make a pit stop again, and thoroughly check mounted areas for looseness, oil leaks, or

other problems. Thorough checks and ad-

justments are required in particular for

stretch of cables, free play of the brake,

stretch of the drive chain, looseness of the

spoke, and so on.

ECA

NOTICE

After a break-in or after each race, always

check the points shown in “TORQUE-

CHECK POINTS” for tightening torques and

retighten them. (Refer to “TORQUE-CHECK

POINTS” on page 1-32.)

Also when the following parts are replaced,

a break-in is required.

• Cylinder and Crankshaft: A break-in is re-quired for about an hour.

• Piston, Piston ring, Valve, Camshaft, and

Gear: A break-in is required for about 30

minutes at a throttle opening of 1/2 or less.

Observe the condition of the engine careful-

ly during a break-in.

For checkpoints for a break-in, see “MAIN-

TENANCE AFTER BREAK-IN”. If any prob-

lem is found, immediately stop the engine

and make a checkup.

Page 45 of 426

MAINTENANCE AFTER BREAK-IN

1-31

EAS2GC1055

MAINTENANCE AFTER BREAK-IN

After a break-in, perform careful maintenance

to get ready for the next practice or race.

Refer to “PRE-OPERATION INSPECTION

AND MAINTENANCE” on page 3-9.

EAS2GC1056MAJOR MAINTENANCE

1. For the engine• Leaks around the engineCheck for pressure l eaks from the cylinder

head or the cylinder, oil leaks from the

crankcase or the case cover, leaks from the

coolant system, and other leaks.

• Check that the valve, the cylinder head, the cylinder, the piston, and the piston ring fit

one another, and that contact between the

valve and the cylinder head, and that be-

tween the cylinder and the piston are cor-

rect.

• Engine oil change Drain the oil, and check for dirt and foreign

materials such as metal chips. (If any foreign

material is mixed, disassemble and check

the crankcase.)

Pour the specified amount of the recom-

mended oil.

• AC magneto

Check for looseness in mounted areas of

the rotor and the stator.

Check that the connector is not being dis-

connected.

• Silencer Check the main body and stay for cracks.

Check for leaks.

• Mounting bolts and nuts Check for looseness in mounted areas of

parts, as well as engine mounting bolts and

engine brackets.

2. For the chassis

• Check welds and mounted areas of the frame, the swingarm, the link, the bracket,

and so on, for looseness and cracks.

• Wheel (s) Check the wheel for runout. Check the

spoke for looseness.

• Brake(s) Check the brake disc mounting bolt for

looseness.

Check that the reservoir contains the speci-

fied amount of brake fluid. Check for leaks. • Cable

Grease and adjust cables.

•Drive chain

Lubricate the drive chain and adjust its ten-

sion.

• Fuel tank

Clean the inside of the fuel tank. Check for

leaks.

• Suspension

Check for oil leaks in the front fork or the rear

shock absorber. Check that the mounted

conditions are good.

• Sprocket Check for looseness in the sprocket mount-

ed on the rear wheel.

• Mounting bolts and nuts

Check mounted areas for looseness.

ECA

NOTICE

After a break-in or before each race, always

check the points shown in “TORQUE-

CHECK POINTS” for tightening torques and

retighten them. (Refer to “TORQUE-CHECK

POINTS” on page 1-32.)

• Greasing and oilingAlways grease or oil the specified points.

Page 48 of 426

MOTORCYCLE CARE AND STORAGE

1-34

EAS2GC1058

MOTORCYCLE CARE AND STOR-

AGE

EAS2GC1059CARE

While the open design of a motorcycle reveals

the attractiveness of the technology, it also

makes it more vulnerable. Rust and corrosion

can develop even if high-quality components

are used. A rusty exhaust pipe may go unno-

ticed on a car, however, it detracts from the

overall appearance of a motorcycle. Frequent

and proper care does not only comply with the

terms of the warranty, but it will also keep your

motorcycle looking good, extend its life and op-

timize its performance.

Before cleaning

1. Cover the muffler outlet with a plastic bag af-ter the engine has cooled down.

2. Make sure that all caps and covers as well as all electrical coup lers and connectors, in-

cluding the spark plug cap, are tightly in-

stalled.

3. Remove extremely stubborn dirt, like oil

burnt onto the crankcase, with a degreasing

agent and a brush, but never apply such

products onto seals, gaskets, sprockets, the

drive chain and wheel axles. Always rinse

the dirt and degreaser off with water.

Cleaning

ECA

NOTICE

• Avoid using strong acidic wheel cleaners, especially on spoked wheels. If such prod-

ucts are used on hard-to-remove dirt, do

not leave the cleaner on the affected area

any longer than instructed. Also, thor-

oughly rinse the area off with water, imme-

diately dry it, and then apply a corrosion

protection spray.

• Improper cleaning can damage plastic parts (such as cowlings, panels, wind-

shields, headlight lenses, meter lenses,

etc.) and the mufflers. Use only a soft,

clean cloth or sponge with water to clean

plastic. However, if the plastic parts can-

not be thoroughly cleaned with water, di-

luted mild detergent with water may be

used. Be sure to rinse off any detergent

residue using plenty of water, as it is

harmful to plastic parts. • Do not use any harsh chemical products

on plastic parts. Be sure to avoid using

cloths or sponges which have been in con-

tact with strong or abrasive cleaning prod-

ucts, solvent or thinner, fuel (gasoline),

rust removers or inhibitors, brake fluid,

antifreeze or electrolyte.

• Do not use high-pressure washers or steam-jet cleaners since they cause water

seepage and deterioration in the following

areas: seals (of wheel and swingarm bear-

ings, fork and brakes), electric compo-

nents (couplers, connectors, instruments,

switches and lights), breather hoses and

vents.

• For motorcycles equipped with a wind-

shield: Do not use strong cleaners or hard

sponges as they will cause dulling or

scratching. Some cleaning compounds for

plastic may leave scratches on the wind-

shield. Test the product on a small hidden

part of the windshield to make sure that it

does not leave any marks. If the wind-

shield is scratched, use a quality plastic

polishing compound after washing.

After normal use

Remove dirt with warm water, a mild detergent,

and a soft, clean sponge, and then rinse thor-

oughly with clean water. Use a toothbrush or

bottlebrush for hard-to-reach areas. Stubborn

dirt and insects will come off more easily if the

area is covered with a wet cloth for a few min-

utes before cleaning.

After riding in the rain, near the sea or on salt-

sprayed roads

Since sea salt or salt sprayed on roads during

winter are extremely corrosive in combination

with water, carry out the following steps after

each ride in the rain, near the sea or on salt-

sprayed roads.

TIP

Salt sprayed on roads in the winter may remain

well into spring.

1. Clean the motorcycle with cold water and a mild detergent, after the engine has cooled

down.

NOTICE: Do not use warm water since it

increases the corrosive action of the salt.