seats YAMAHA WR 450F 2016 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 72 of 426

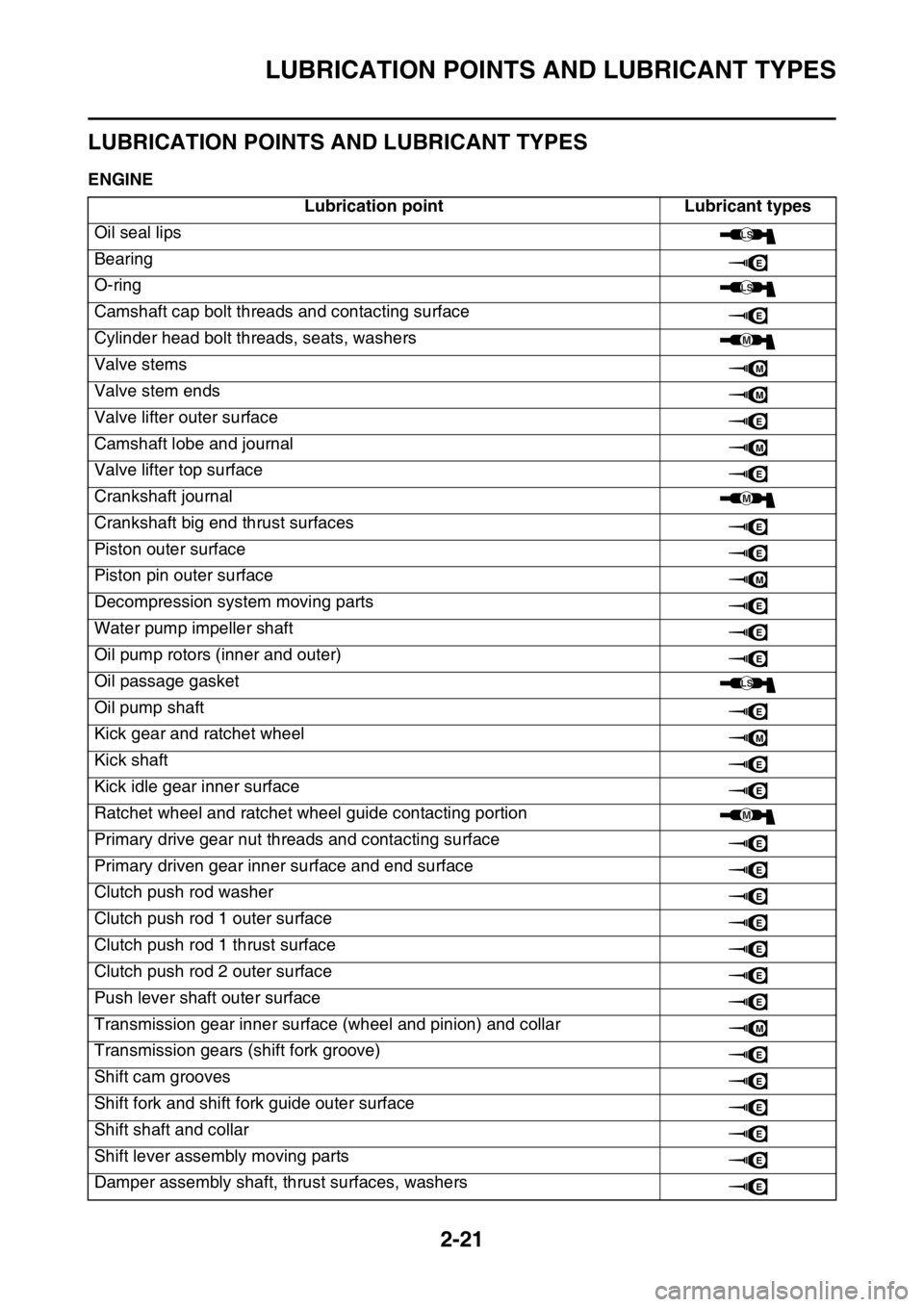

LUBRICATION POINTS AND LUBRICANT TYPES

2-21

EAS2GC1068

LUBRICATION POINTS AND LUBRICANT TYPES

EAS2GC1069ENGINE

Lubrication point Lubricant types

Oil seal lips

Bearing

O-ring

Camshaft cap bolt threads and contacting surface

Cylinder head bolt threads, seats, washers

Valve stems

Valve stem ends

Valve lifter outer surface

Camshaft lobe and journal

Valve lifter top surface

Crankshaft journal

Crankshaft big end thrust surfaces

Piston outer surface

Piston pin outer surface

Decompression system moving parts

Water pump impeller shaft

Oil pump rotors (inner and outer)

Oil passage gasket

Oil pump shaft

Kick gear and ratchet wheel

Kick shaft

Kick idle gear inner surface

Ratchet wheel and ratchet wheel guide contacting portion

Primary drive gear nut threads and contacting surface

Primary driven gear inner surface and end surface

Clutch push rod washer

Clutch push rod 1 outer surface

Clutch push rod 1 thrust surface

Clutch push rod 2 outer surface

Push lever shaft outer surface

Transmission gear inner surface (wheel and pinion) and collar

Transmission gears (shift fork groove)

Shift cam grooves

Shift fork and shift fork guide outer surface

Shift shaft and collar

Shift lever assembly moving parts

Damper assembly shaft, thrust surfaces, washers

LS

E

LS

E

M

M

M

E

M

E

M

E

E

M

E

E

E

LS

E

M

E

E

M

E

E

E

E

E

E

E

M

E

E

E

E

E

E

Page 102 of 426

PERIODIC MAINTENANCE

3-4

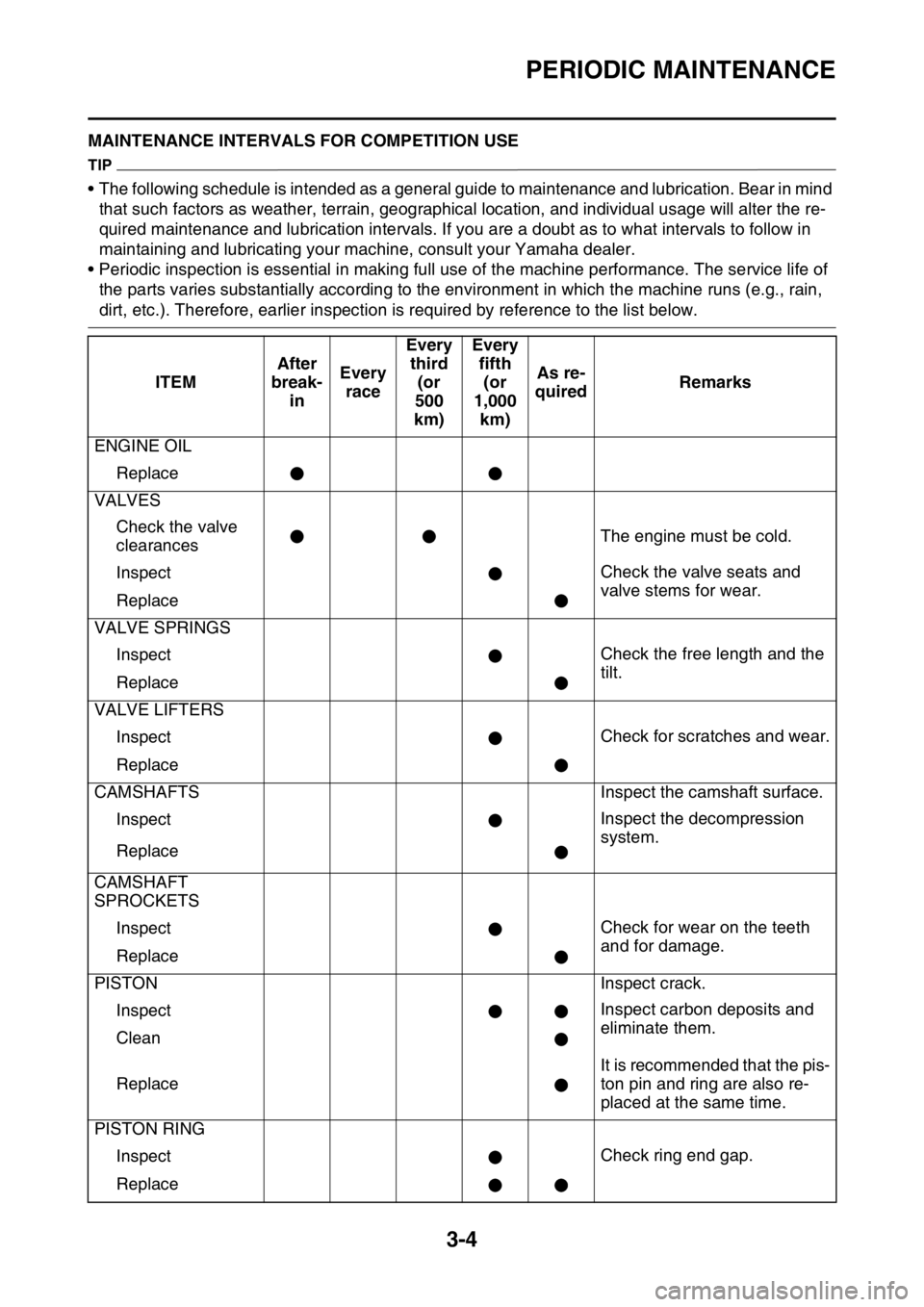

EAS2GC1078MAINTENANCE INTERVALS FOR COMPETITION USE

TIP

• The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as weather, terrain, geographical location, and individual usage will alter the re-

quired maintenance and lubrication intervals. If you ar e a doubt as to what intervals to follow in

maintaining and lubricating your ma chine, consult your Yamaha dealer.

• Periodic inspection is essential in making full use of the machine performance. The service life of

the parts varies substantially according to the en vironment in which the machine runs (e.g., rain,

dirt, etc.). Therefore, earlier inspection is required by reference to the list below.

ITEM After

break- in Every

race Every

third (or

500

km) Every

fifth (or

1,000 km) As re-

quired Remarks

ENGINE OIL Replace

VALVES Check the valve

clearances The engine must be cold.

Inspect Check the valve seats and

valve stems for wear.

Replace

VALVE SPRINGS Inspect Check the free length and the

tilt.

Replace

VALVE LIFTERS Inspect Check for scratches and wear.

Replace

CAMSHAFTS Inspect the camshaft surface.

Inspect Inspect the decompression

system.

Replace

CAMSHAFT

SPROCKETS Inspect Check for wear on the teeth

and for damage.

Replace

PISTON Inspect crack.

Inspect Inspect carbon deposits and

eliminate them.

Clean

Replace It is recommended that the pis-

ton pin and ring are also re-

placed at the same time.

PISTON RING

Inspect Check ring end gap.

Replace

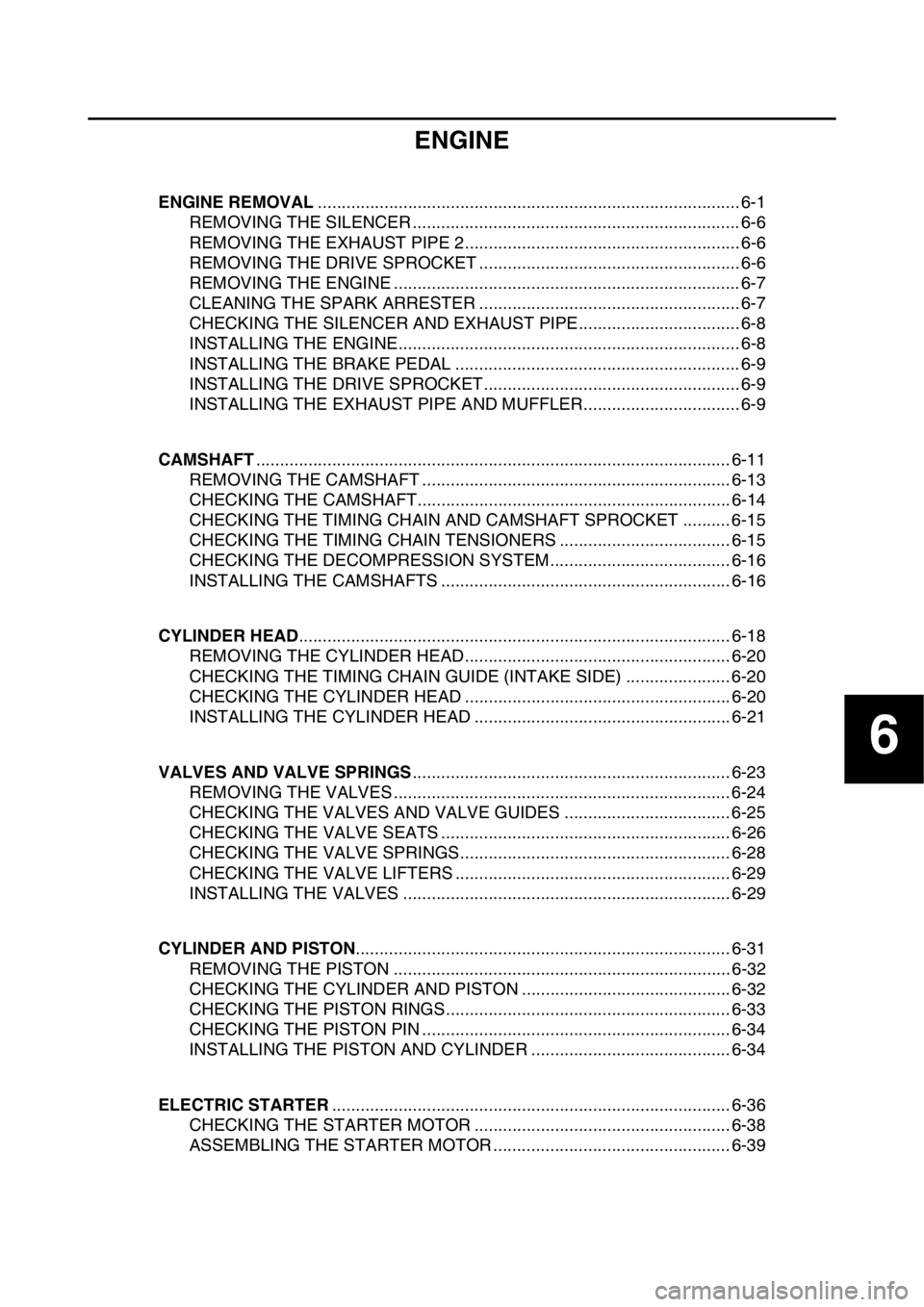

Page 225 of 426

6

ENGINE

ENGINE REMOVAL......................................................................................... 6-1

REMOVING THE SILENCER ..................................................................... 6-6

REMOVING THE EXHAUST PIPE 2.......................................................... 6-6

REMOVING THE DRIVE SPROCKET ....................................................... 6-6

REMOVING THE ENGINE ......................................................................... 6-7

CLEANING THE SPARK ARRESTER ....................................................... 6-7

CHECKING THE SILENCER AND EXHAUST PIPE.................................. 6-8

INSTALLING THE ENGINE........................................................................ 6-8

INSTALLING THE BRAKE PEDAL ............................................................ 6-9

INSTALLING THE DRIVE SPROCKET...................................................... 6-9

INSTALLING THE EXHAUST PIPE AND MUFFLER................................. 6-9

CAMSHAFT .................................................................................................... 6-11

REMOVING THE CAMSHAFT ................................................................. 6-13

CHECKING THE CAMSHAFT.................................................................. 6-14

CHECKING THE TIMING CHAIN AND CAMSHAFT SPROCKET .......... 6-15

CHECKING THE TIMING CHAIN TENSIONERS .................................... 6-15

CHECKING THE DECOMPRESSION SYSTEM.............. ........................ 6-16

INSTALLING THE CAMSHAFTS ............................................................. 6-16

CYLINDER HEAD ........................................................................................... 6-18

REMOVING THE CYLINDER HEAD........................................................ 6-20

CHECKING THE TIMING CHAIN GUIDE (INTAKE SIDE) ...................... 6-20

CHECKING THE CYLINDER HEAD ........................................................ 6-20

INSTALLING THE CYLINDER HEAD ...................................................... 6-21

VALVES AND VALVE SPRINGS ................................................................... 6-23

REMOVING THE VALVES ....................................................................... 6-24

CHECKING THE VALVES AND VALVE GUIDES ................................... 6-25

CHECKING THE VALVE SEATS ............................................................. 6-26

CHECKING THE VALVE SPRINGS......................................................... 6-28

CHECKING THE VALVE LIFTERS .......................................................... 6-29

INSTALLING THE VALVES ..................................................................... 6-29

CYLINDER AND PISTON ............................................................................... 6-31

REMOVING THE PISTON ....................................................................... 6-32

CHECKING THE CYLINDER AND PISTON ............................................ 6-32

CHECKING THE PISTON RINGS............................................................ 6-33

CHECKING THE PISTON PIN ................................................................. 6-34

INSTALLING THE PISTON AND CYLINDER .......................................... 6-34

ELECTRIC STARTER .................................................................................... 6-36

CHECKING THE STARTER MOTOR ...................................................... 6-38

ASSEMBLING THE STARTER MOTOR .................................................. 6-39

Page 247 of 426

CYLINDER HEAD

6-20

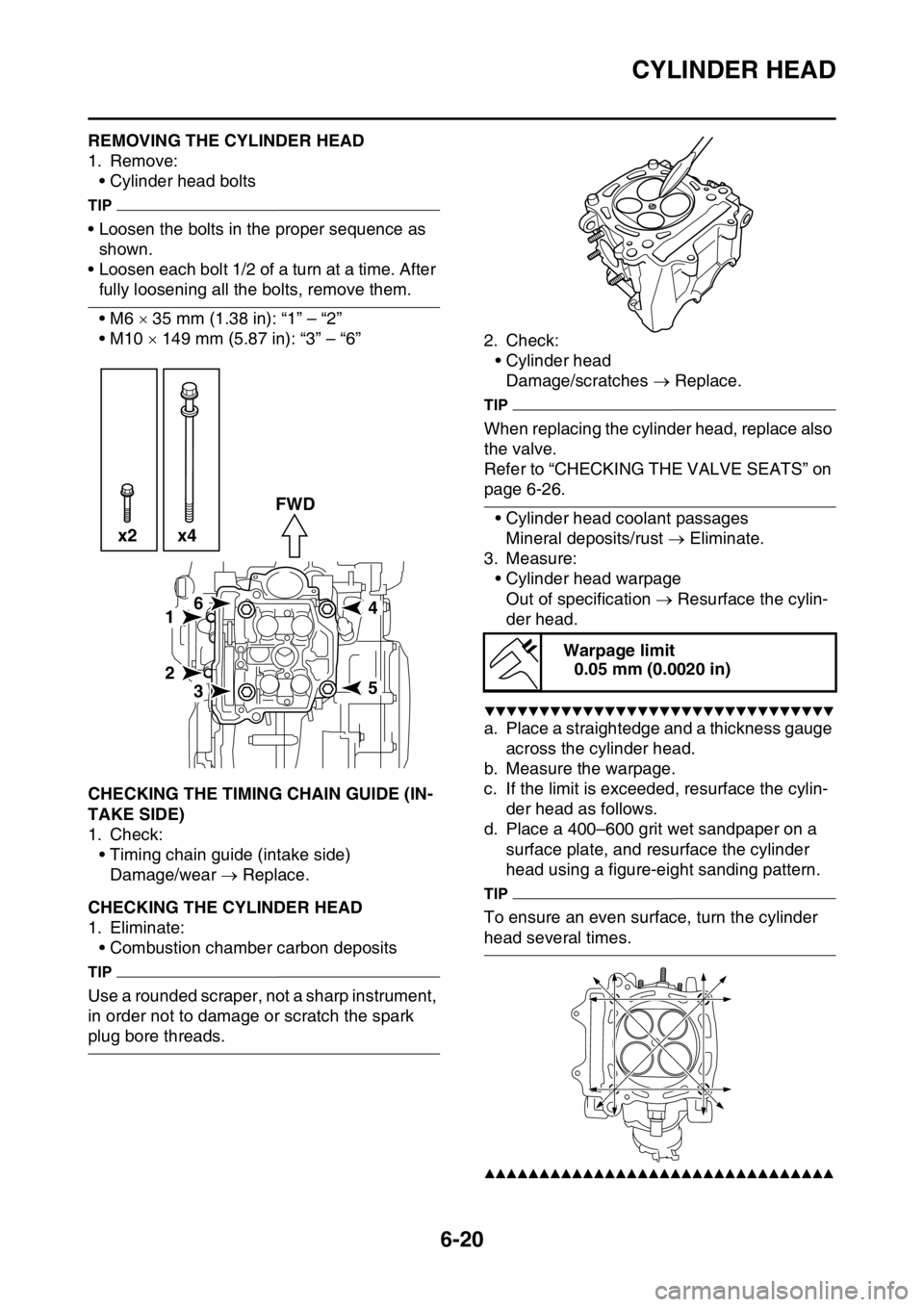

EAS2GC1245REMOVING THE CYLINDER HEAD

1. Remove:• Cylinder head bolts

TIP

• Loosen the bolts in the proper sequence as shown.

• Loosen each bolt 1/2 of a turn at a time. After

fully loosening all the bolts, remove them.

•M6 35 mm (1.38 in): “1” – “2”

• M10 149 mm (5.87 in): “3” – “6”

EAS2GC1246CHECKING THE TIMING CHAIN GUIDE (IN-

TAKE SIDE)

1. Check:

• Timing chain guide (intake side)Damage/wear Replace.

EAS2GC1247CHECKING THE CYLINDER HEAD

1. Eliminate:

• Combustion chamber carbon deposits

TIP

Use a rounded scraper, not a sharp instrument,

in order not to damage or scratch the spark

plug bore threads. 2. Check:

• Cylinder head

Damage/scratches Replace.

TIP

When replacing the cylinder head, replace also

the valve.

Refer to “CHECKING THE VALVE SEATS” on

page 6-26.

• Cylinder head coolant passagesMineral deposits/rust Eliminate.

3. Measure: • Cylinder head warpage

Out of specification Resurface the cylin-

der head.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Place a straightedge and a thickness gauge across the cylinder head.

b. Measure the warpage.

c. If the limit is exceeded, resurface the cylin-

der head as follows.

d. Place a 400–600 grit wet sandpaper on a

surface plate, and resurface the cylinder

head using a figure-eight sanding pattern.

TIP

To ensure an even surface, turn the cylinder

head several times.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

61

2

35

4

x2 x4

FWD

Warpage limit

0.05 mm (0.0020 in)

Page 251 of 426

VALVES AND VALVE SPRINGS

6-24

EAS2GC1250REMOVING THE VALVES

TIP

Before removing the internal parts of the cylin-

der head (e.g., valves, valve springs, valve

seats), make sure that the valves are properly

sealed.

1. Remove:• Valve lifter “1”

• Adjusting pad “2”

TIP

• Place a cloth in the timing chain space to pre-vent adjusting pads from falling into the crank-

case.

• Make a note of the positions of valve lifters and adjusting pads so that they can be rein-

stalled in their original places.

2. Check: • Valve sealingLeakage at the valve seat Check the

valve face, the valve seat, and the valve seat

contact width.

Refer to “CHECKING THE VALVE SEATS”

on page 6-26.

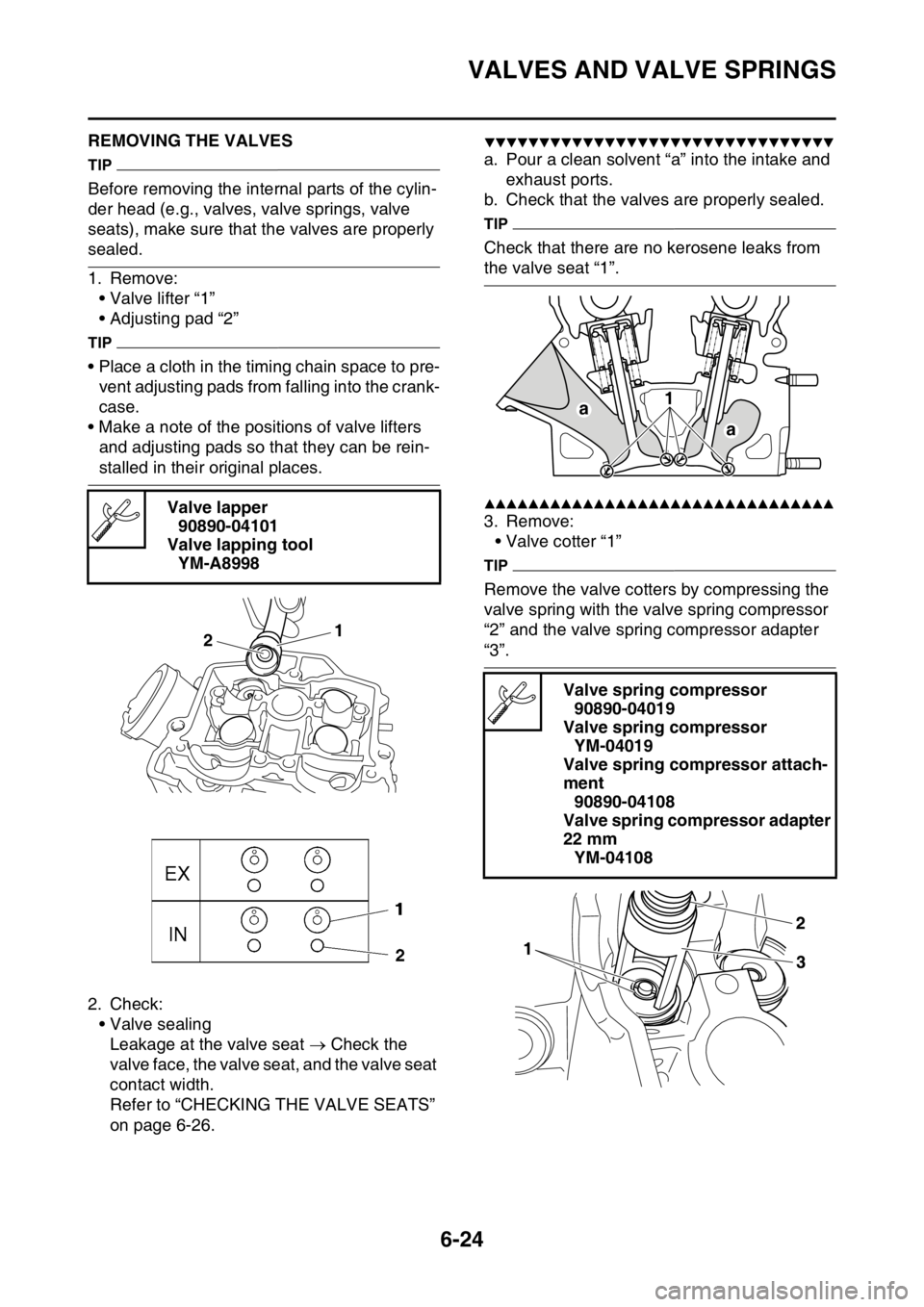

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Pour a clean solvent “a” into the intake and exhaust ports.

b. Check that the valves are properly sealed.

TIP

Check that there are no kerosene leaks from

the valve seat “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Remove: • Valve cotter “1”

TIP

Remove the valve cotters by compressing the

valve spring with the valve spring compressor

“2” and the valve spring compressor adapter

“3”.

Valve lapper

90890-04101

Valve lapping tool YM-A8998

1

2

Valve spring compressor

90890-04019

Valve spring compressor YM-04019

Valve spring compressor attach-

ment 90890-04108

Valve spring compressor adapter

22 mm YM-04108

a 1

a

Page 253 of 426

VALVES AND VALVE SPRINGS

6-26

c. After installing the valve guide, expand the hole in the valve guide with the valve guide

reamer “3” to obtain the proper valve-stem-

to-valve-guide clearance.

TIP

After replacing the valve guide, reface the valve

seat.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

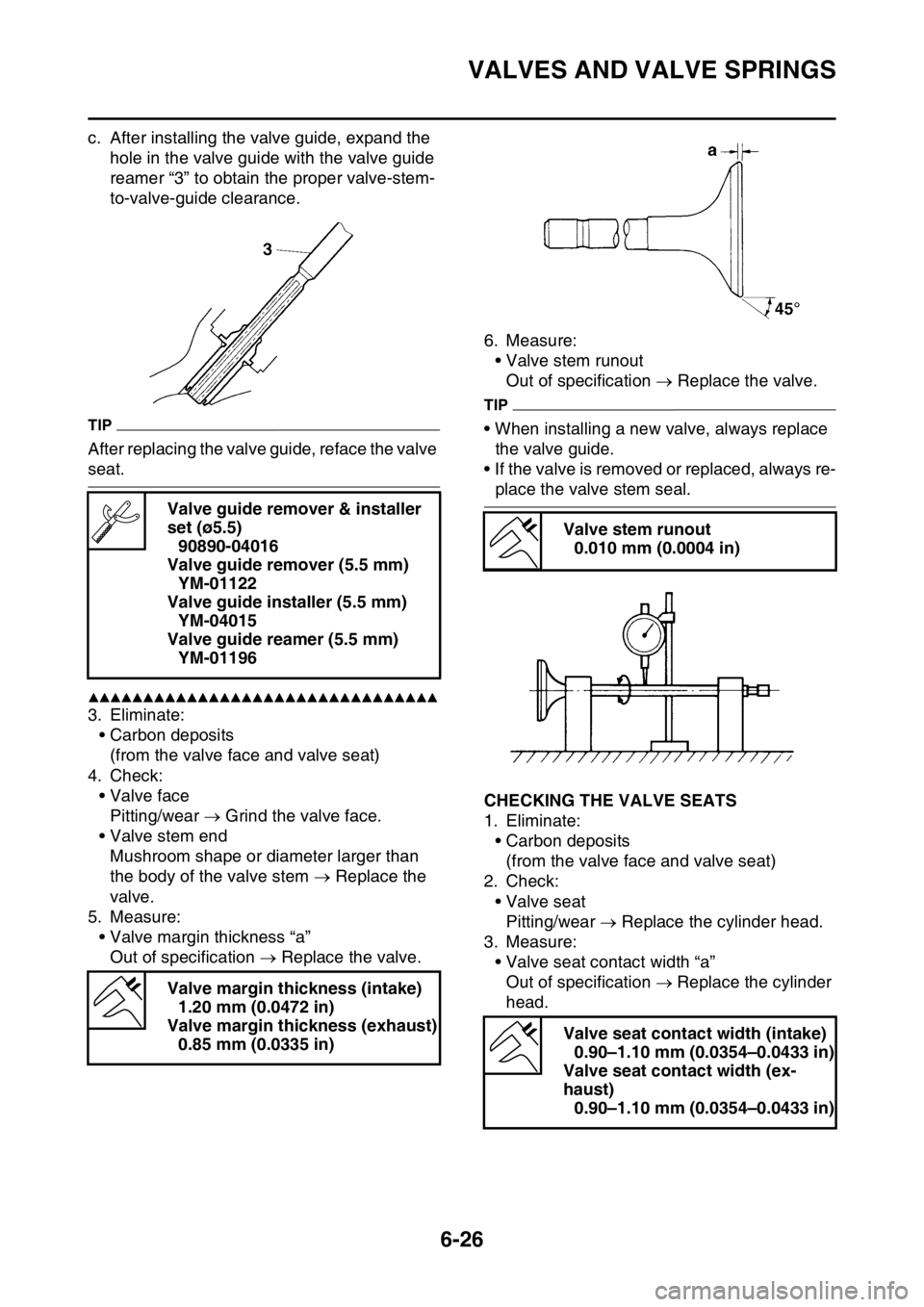

3. Eliminate:• Carbon deposits(from the valve face and valve seat)

4. Check: • Valve facePitting/wear Grind the valve face.

• Valve stem end Mushroom shape or diameter larger than

the body of the valve stem Replace the

valve.

5. Measure: • Valve margin thickness “a”

Out of specification Replace the valve. 6. Measure:

• Valve stem runout

Out of specification Replace the valve.

TIP

• When installing a new valve, always replace

the valve guide.

• If the valve is removed or replaced, always re-

place the valve stem seal.

EAS2GC1252CHECKING THE VALVE SEATS

1. Eliminate: • Carbon deposits(from the valve face and valve seat)

2. Check: • Valve seatPitting/wear Replace the cylinder head.

3. Measure: • Valve seat contact width “a”Out of specification Replace the cylinder

head.

Valve guide remover & installer

set (ø5.5)

90890-04016

Valve guide remover (5.5 mm) YM-01122

Valve guide installer (5.5 mm) YM-04015

Valve guide reamer (5.5 mm) YM-01196

Valve margin thickness (intake) 1.20 mm (0.0472 in)

Valve margin thickness (exhaust) 0.85 mm (0.0335 in)

Valve stem runout 0.010 mm (0.0004 in)

Valve seat contact width (intake) 0.90–1.10 mm (0.0354–0.0433 in)

Valve seat contact width (ex-

haust) 0.90–1.10 mm (0.0354–0.0433 in)

Page 254 of 426

VALVES AND VALVE SPRINGS

6-27

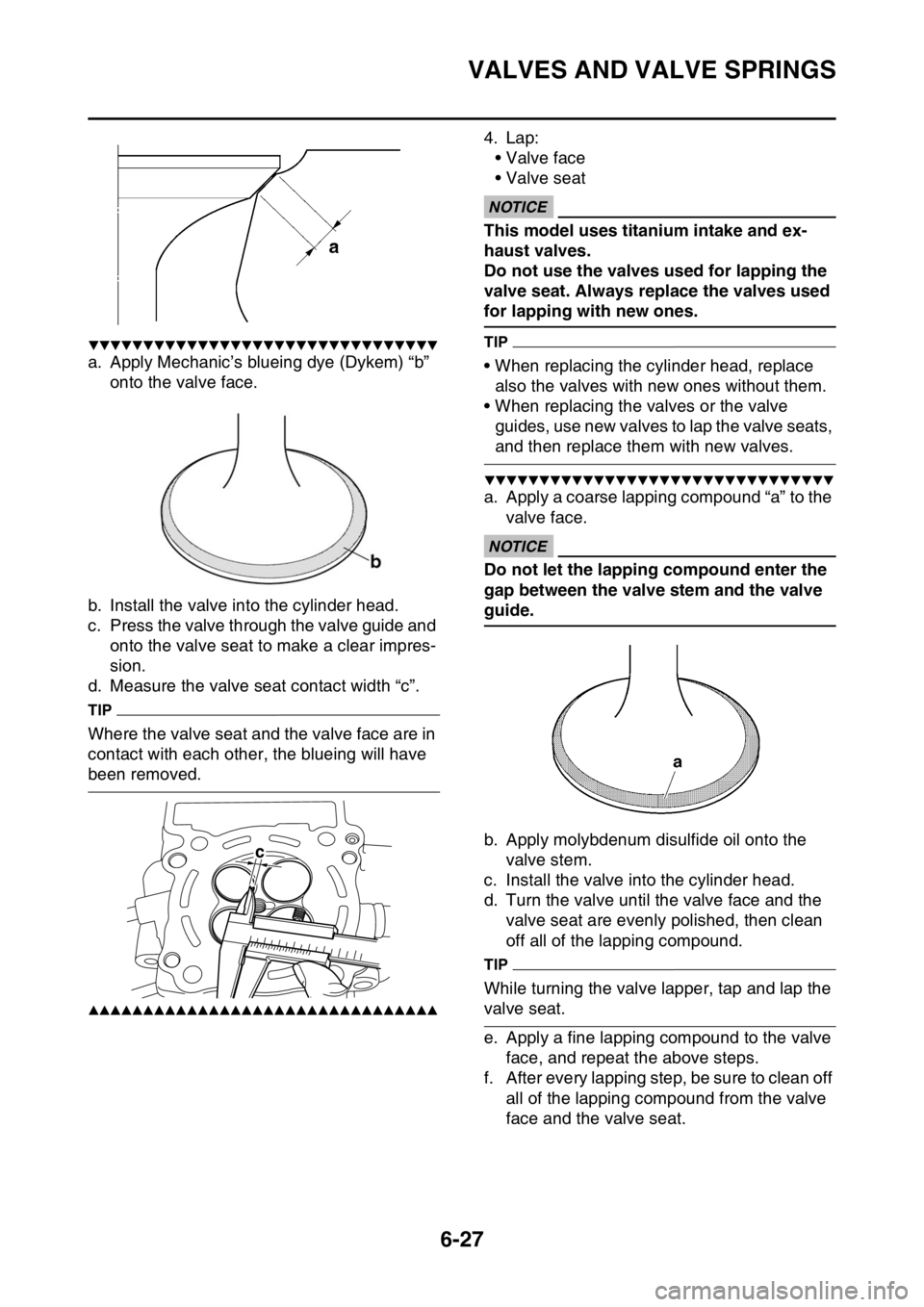

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Apply Mechanic’s blueing dye (Dykem) “b” onto the valve face.

b. Install the valve into the cylinder head.

c. Press the valve through the valve guide and onto the valve seat to make a clear impres-

sion.

d. Measure the valve seat contact width “c”.

TIP

Where the valve seat and the valve face are in

contact with each other, the blueing will have

been removed.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

4. Lap:

• Valve face

• Valve seat

ECA

NOTICE

This model uses titanium intake and ex-

haust valves.

Do not use the valves used for lapping the

valve seat. Always replace the valves used

for lapping with new ones.

TIP

• When replacing the cylinder head, replace also the valves with new ones without them.

• When replacing the valves or the valve guides, use new valves to lap the valve seats,

and then replace them with new valves.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Apply a coarse lapping compound “a” to the

valve face.

ECA

NOTICE

Do not let the lapping compound enter the

gap between the valve stem and the valve

guide.

b. Apply molybdenum disulfide oil onto the valve stem.

c. Install the valve into the cylinder head.

d. Turn the valve until the valve face and the valve seat are evenly polished, then clean

off all of the lapping compound.

TIP

While turning the valve lapper, tap and lap the

valve seat.

e. Apply a fine lapping co mpound to the valve

face, and repeat the above steps.

f. After every lapping step, be sure to clean off all of the lapping compound from the valve

face and the valve seat.

c