rem YAMAHA XCITY 250 2012 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2012, Model line: XCITY 250, Model: YAMAHA XCITY 250 2012Pages: 82, PDF Size: 1.89 MB

Page 26 of 82

INSTRUMENT AND CONTROL FUNCTIONS

3-10

3

NOTICE

ECA10701

Use only unleaded gasoline. The use

of leaded gasoline will cause unre-

pairable damage to the catalytic

converter.

EAU13932

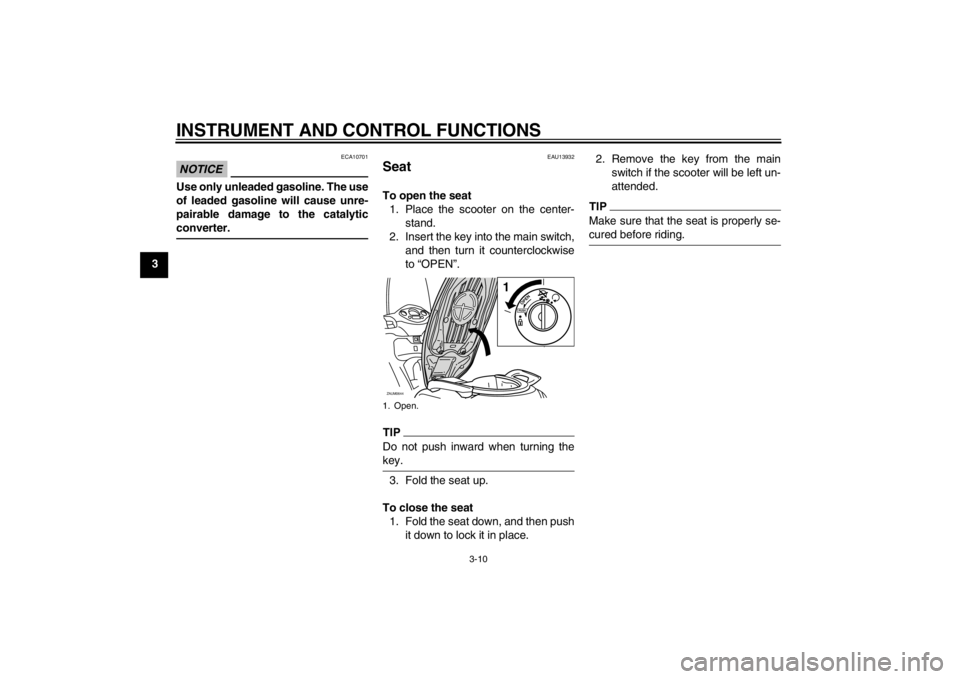

Seat To open the seat

1. Place the scooter on the center-

stand.

2. Insert the key into the main switch,

and then turn it counterclockwise

to “OPEN”.TIPDo not push inward when turning the

key.3. Fold the seat up.

To close the seat

1. Fold the seat down, and then push

it down to lock it in place.2. Remove the key from the main

switch if the scooter will be left un-

attended.

TIPMake sure that the seat is properly se-

cured before riding.

1. Open.ZAUM0644

PUSHOPEN

1

U5B2E4E0.book Page 10 Friday, June 1, 2012 9:06 AM

Page 28 of 82

INSTRUMENT AND CONTROL FUNCTIONS

3-12

3

●

Since the storage compartment

may get wet while the scooter is

being washed, wrap any articles

stored in the compartment in a

plastic bag.

●

Do not keep anything valuable

or breakable in the storage com-

partment.

To store a helmet in the storage com-

partment, place the helmet with the

front facing backward.TIP●

Some helmets cannot be stored in

the storage compartment because

of their size or shape.

●

Do not leave your scooter unat-

tended with the seat open.

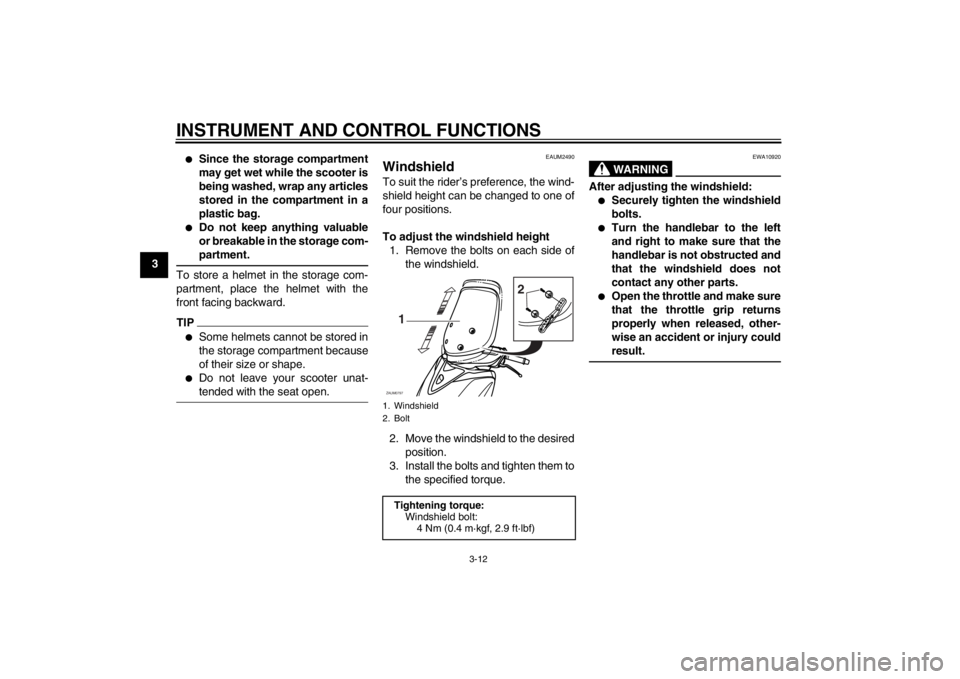

EAUM2490

Windshield To suit the rider’s preference, the wind-

shield height can be changed to one of

four positions.

To adjust the windshield height

1. Remove the bolts on each side of

the windshield.

2. Move the windshield to the desired

position.

3. Install the bolts and tighten them to

the specified torque.

WARNING

EWA10920

After adjusting the windshield:●

Securely tighten the windshield

bolts.

●

Turn the handlebar to the left

and right to make sure that the

handlebar is not obstructed and

that the windshield does not

contact any other parts.

●

Open the throttle and make sure

that the throttle grip returns

properly when released, other-

wise an accident or injury could

result.

1. Windshield

2. BoltTightening torque:

Windshield bolt:

4 Nm (0.4 m·kgf, 2.9 ft·lbf)ZAUM0797

1

2

U5B2E4E0.book Page 12 Friday, June 1, 2012 9:06 AM

Page 37 of 82

OPERATION AND IMPORTANT RIDING POINTS

5-3

5

EAU16793

Braking

WARNING

EWA10300

●

Avoid braking hard or suddenly

(especially when leaning over to

one side), otherwise the scooter

may skid or overturn.

●

Railroad crossings, streetcar

rails, iron plates on road con-

struction sites, and manhole

covers become extremely slip-

pery when wet. Therefore, slow

down when approaching such

areas and cross them with cau-

tion.

●

Keep in mind that braking on a

wet road is much more difficult.

●

Ride slowly down a hill, as brak-

ing downhill can be very diffi-

cult.

1. Close the throttle completely.

2. Apply both front and rear brakes

simultaneously while gradually in-

creasing the pressure.

EAU16820

Tips for reducing fuel con-

sumption Fuel consumption depends largely on

your riding style. Consider the following

tips to reduce fuel consumption:●

Avoid high engine speeds during

acceleration.

●

Avoid high engine speeds with no

load on the engine.

●

Turn the engine off instead of let-

ting it idle for an extended length of

time (e.g., in traffic jams, at traffic

lights or at railroad crossings).

PUSHOPE

N

ZAUM0651

U5B2E4E0.book Page 3 Friday, June 1, 2012 9:06 AM

Page 38 of 82

OPERATION AND IMPORTANT RIDING POINTS

5-4

5

EAU16841

Engine break-in There is never a more important period

in the life of your engine than the period

between 0 and 1600 km (1000 mi). For

this reason, you should read the follow-

ing material carefully.

Since the engine is brand new, do not

put an excessive load on it for the first

1600 km (1000 mi). The various parts in

the engine wear and polish themselves

to the correct operating clearances.

During this period, prolonged full-throt-

tle operation or any condition that might

result in engine overheating must be

avoided.

EAUM2011

0–1000 km (0–600 mi)

Avoid prolonged operation above 1/3

throttle. NOTICE: After 1000 km (600

mi) of operation, be sure to replace

the engine oil and final transmission

oil.

[ECA11661]

1000–1600 km (600–1000 mi)

Avoid prolonged operation above 1/2

throttle.1600 km (1000 mi) and beyond

The vehicle can now be operated nor-

mally.

NOTICE

ECA10270

If any engine trouble should occur

during the engine break-in period,

immediately have a Yamaha dealer

check the vehicle.

EAU17213

Parking When parking, stop the engine, and

then remove the key from the main

switch.

WARNING

EWA10311

●

Since the engine and exhaust

system can become very hot,

park in a place where pedestri-

ans or children are not likely to

touch them and be burned.

●

Do not park on a slope or on soft

ground, otherwise the vehicle

may overturn, increasing the

risk of a fuel leak and fire.

●

Do not park near grass or other

flammable materials which

might catch fire.

U5B2E4E0.book Page 4 Friday, June 1, 2012 9:06 AM

Page 45 of 82

PERIODIC MAINTENANCE AND ADJUSTMENT

6-7

6

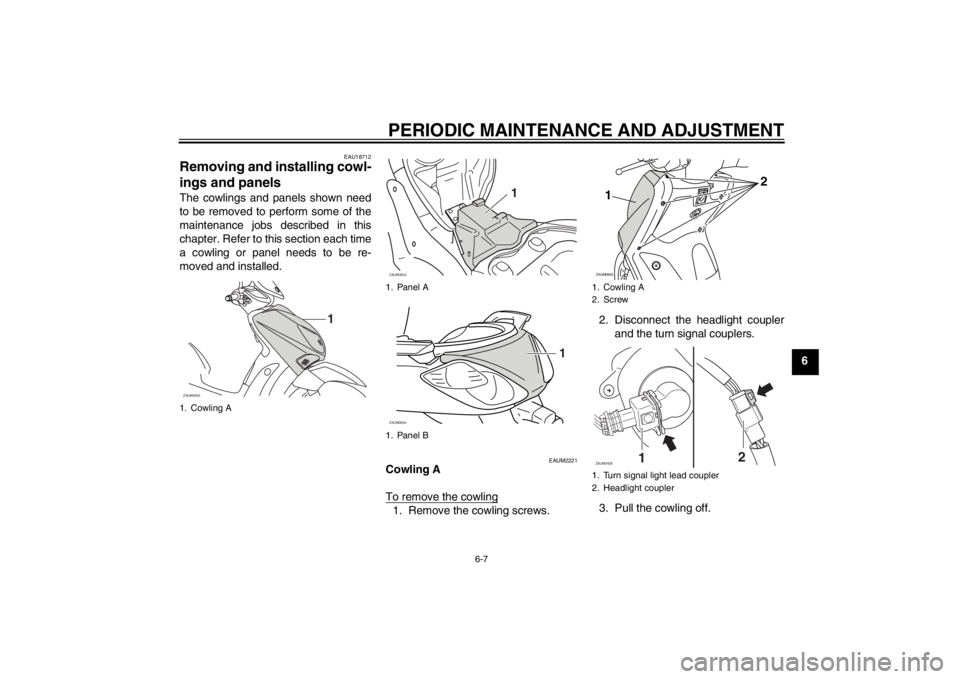

EAU18712

Removing and installing cowl-

ings and panels The cowlings and panels shown need

to be removed to perform some of the

maintenance jobs described in this

chapter. Refer to this section each time

a cowling or panel needs to be re-

moved and installed.

EAUM2221

Cowling A

To remove the cowling1. Remove the cowling screws.2. Disconnect the headlight coupler

and the turn signal couplers.

3. Pull the cowling off.

1. Cowling AZAUM0652

1

1. Panel A

1. Panel BZAUM0653

1

ZAUM0654

1

1. Cowling A

2. Screw

1. Turn signal light lead coupler

2. Headlight couplerZAUM0655

2

1

12

ZAUM0428

U5B2E4E0.book Page 7 Friday, June 1, 2012 9:06 AM

Page 46 of 82

PERIODIC MAINTENANCE AND ADJUSTMENT

6-8

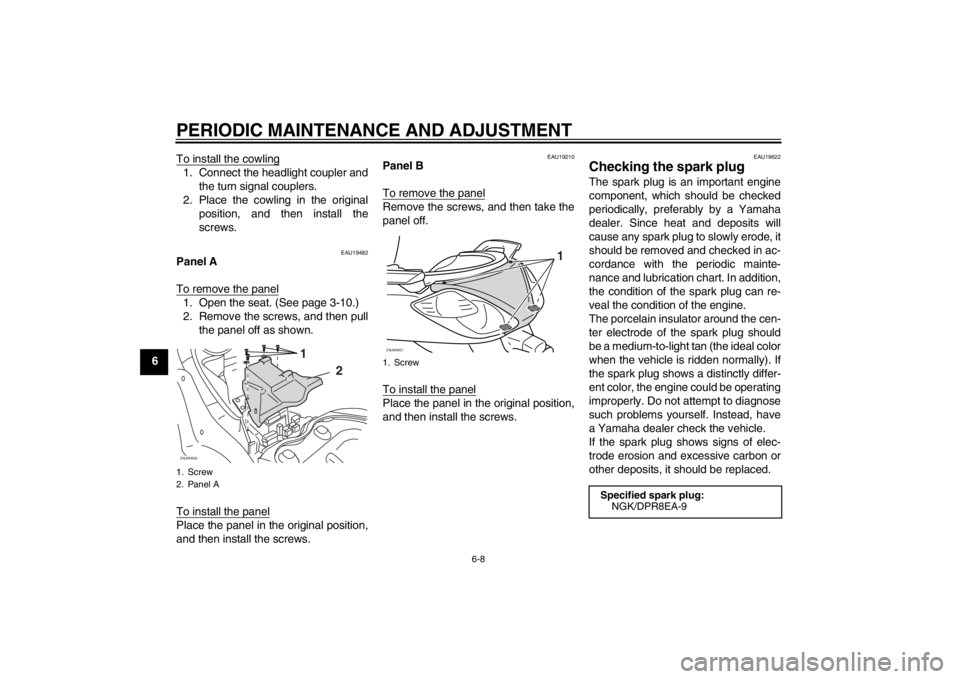

6To install the cowling

1. Connect the headlight coupler and

the turn signal couplers.

2. Place the cowling in the original

position, and then install the

screws.

EAU19482

Panel A

To remove the panel1. Open the seat. (See page 3-10.)

2. Remove the screws, and then pull

the panel off as shown.

To install the panelPlace the panel in the original position,

and then install the screws.

EAU19210

Panel B

To remove the panelRemove the screws, and then take the

panel off.

To install the panelPlace the panel in the original position,

and then install the screws.

EAU19622

Checking the spark plug The spark plug is an important engine

component, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark plug to slowly erode, it

should be removed and checked in ac-

cordance with the periodic mainte-

nance and lubrication chart. In addition,

the condition of the spark plug can re-

veal the condition of the engine.

The porcelain insulator around the cen-

ter electrode of the spark plug should

be a medium-to-light tan (the ideal color

when the vehicle is ridden normally). If

the spark plug shows a distinctly differ-

ent color, the engine could be operating

improperly. Do not attempt to diagnose

such problems yourself. Instead, have

a Yamaha dealer check the vehicle.

If the spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced.

1. Screw

2. Panel AZAUM0656

1

2

1. ScrewZAUM0657

1

Specified spark plug:

NGK/DPR8EA-9

U5B2E4E0.book Page 8 Friday, June 1, 2012 9:06 AM

Page 47 of 82

PERIODIC MAINTENANCE AND ADJUSTMENT

6-9

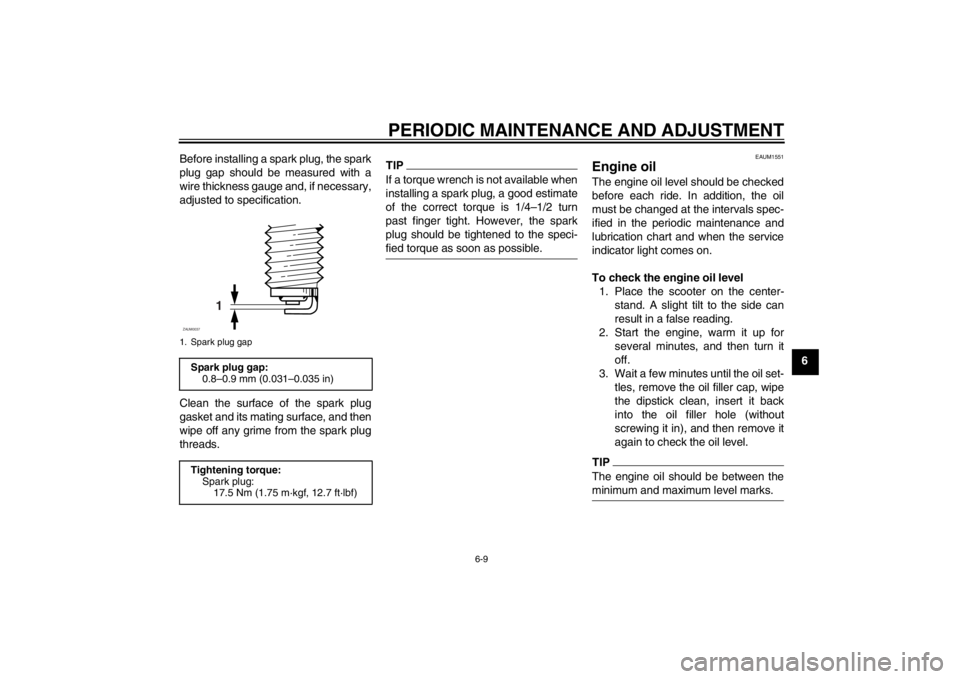

6 Before installing a spark plug, the spark

plug gap should be measured with a

wire thickness gauge and, if necessary,

adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and then

wipe off any grime from the spark plug

threads.

TIPIf a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn

past finger tight. However, the spark

plug should be tightened to the speci-

fied torque as soon as possible.

EAUM1551

Engine oil The engine oil level should be checked

before each ride. In addition, the oil

must be changed at the intervals spec-

ified in the periodic maintenance and

lubrication chart and when the service

indicator light comes on.

To check the engine oil level

1. Place the scooter on the center-

stand. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Wait a few minutes until the oil set-

tles, remove the oil filler cap, wipe

the dipstick clean, insert it back

into the oil filler hole (without

screwing it in), and then remove it

again to check the oil level.TIPThe engine oil should be between the

minimum and maximum level marks.

1. Spark plug gapSpark plug gap:

0.8–0.9 mm (0.031–0.035 in)

Tightening torque:

Spark plug:

17.5 Nm (1.75 m·kgf, 12.7 ft·lbf)

1

ZAUM0037

U5B2E4E0.book Page 9 Friday, June 1, 2012 9:06 AM

Page 48 of 82

PERIODIC MAINTENANCE AND ADJUSTMENT

6-10

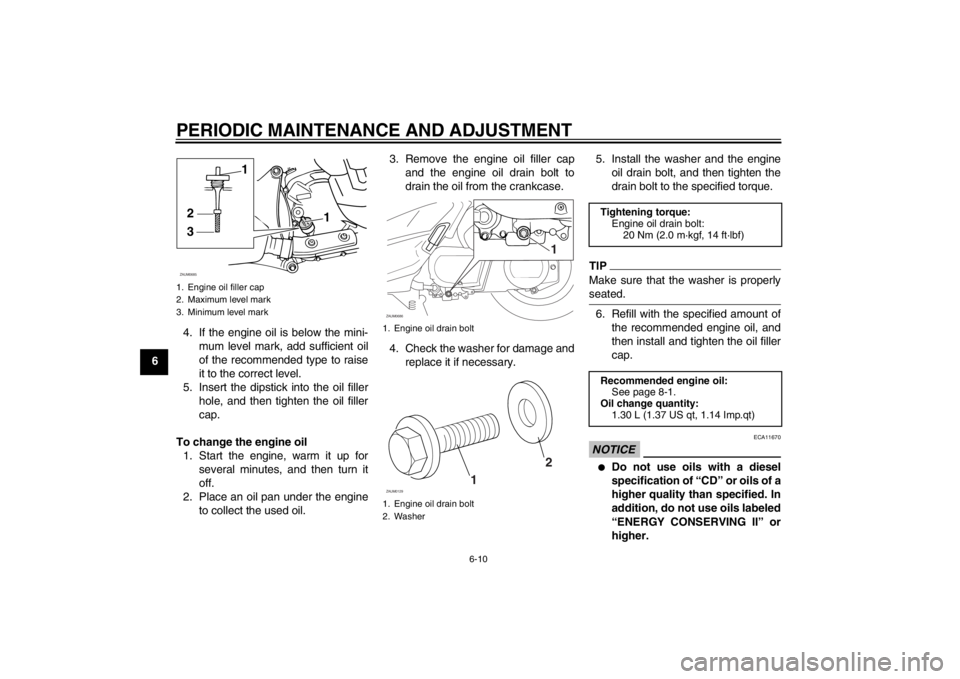

64. If the engine oil is below the mini-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Insert the dipstick into the oil filler

hole, and then tighten the oil filler

cap.

To change the engine oil

1. Start the engine, warm it up for

several minutes, and then turn it

off.

2. Place an oil pan under the engine

to collect the used oil.3. Remove the engine oil filler cap

and the engine oil drain bolt to

drain the oil from the crankcase.

4. Check the washer for damage and

replace it if necessary.5. Install the washer and the engine

oil drain bolt, and then tighten the

drain bolt to the specified torque.

TIPMake sure that the washer is properly

seated.6. Refill with the specified amount of

the recommended engine oil, and

then install and tighten the oil filler

cap.NOTICE

ECA11670

●

Do not use oils with a diesel

specification of “CD” or oils of a

higher quality than specified. In

addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

1. Engine oil filler cap

2. Maximum level mark

3. Minimum level mark

1

321ZAUM0685

1. Engine oil drain bolt

1. Engine oil drain bolt

2. Washer

11

ZAUM0686

12

ZAUM0129

Tightening torque:

Engine oil drain bolt:

20 Nm (2.0 m·kgf, 14 ft·lbf)

Recommended engine oil:

See page 8-1.

Oil change quantity:

1.30 L (1.37 US qt, 1.14 Imp.qt)

U5B2E4E0.book Page 10 Friday, June 1, 2012 9:06 AM

Page 49 of 82

PERIODIC MAINTENANCE AND ADJUSTMENT

6-11

6

●

Be sure no foreign material en-

ters the crankcase.

7. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking, im-

mediately turn the engine off and

check for the cause.

8. Reset the oil change indicator.

(See page 3-5.)

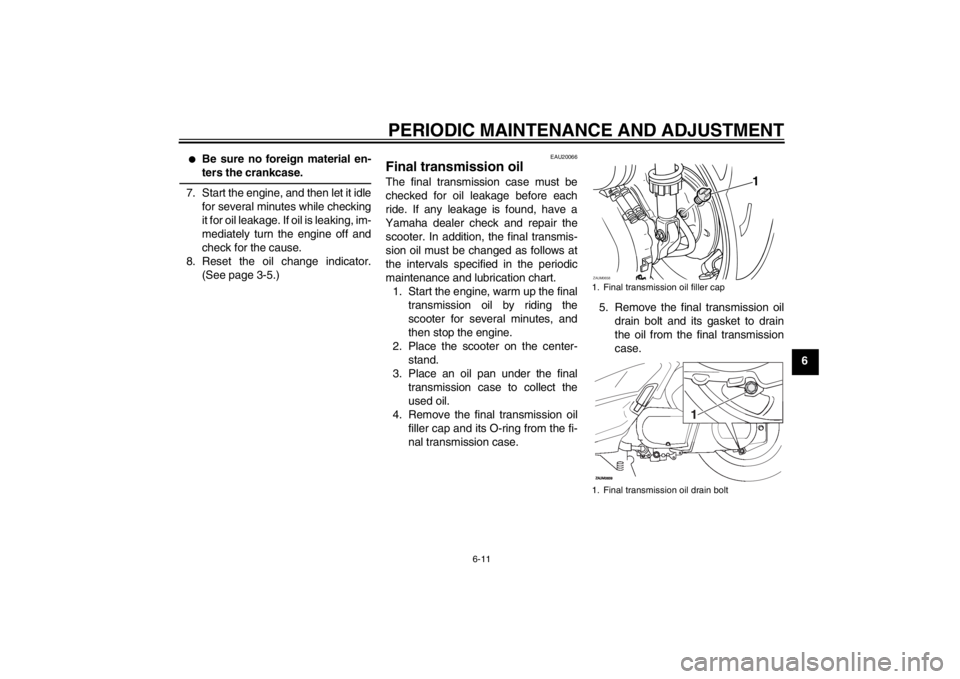

EAU20066

Final transmission oil The final transmission case must be

checked for oil leakage before each

ride. If any leakage is found, have a

Yamaha dealer check and repair the

scooter. In addition, the final transmis-

sion oil must be changed as follows at

the intervals specified in the periodic

maintenance and lubrication chart.

1. Start the engine, warm up the final

transmission oil by riding the

scooter for several minutes, and

then stop the engine.

2. Place the scooter on the center-

stand.

3. Place an oil pan under the final

transmission case to collect the

used oil.

4. Remove the final transmission oil

filler cap and its O-ring from the fi-

nal transmission case.5. Remove the final transmission oil

drain bolt and its gasket to drain

the oil from the final transmission

case.

1. Final transmission oil filler cap

1. Final transmission oil drain bolt

1

ZAUM0658

U5B2E4E0.book Page 11 Friday, June 1, 2012 9:06 AM

Page 50 of 82

PERIODIC MAINTENANCE AND ADJUSTMENT

6-12

66. Install the final transmission oil

drain bolt and its new gasket, and

then tighten the bolt to the speci-

fied torque.

7. Refill with the specified amount of

the recommended final transmis-

sion oil. WARNING! Make sure

that no foreign material enters

the final transmission case.

Make sure that no oil gets on the

tire or wheel.

[EWA11311]

8. Install the final transmission oil fill-

er cap and its new O-ring, and then

tighten the oil filler cap.

9. Check the final transmission case

for oil leakage. If oil is leaking,

check for the cause.

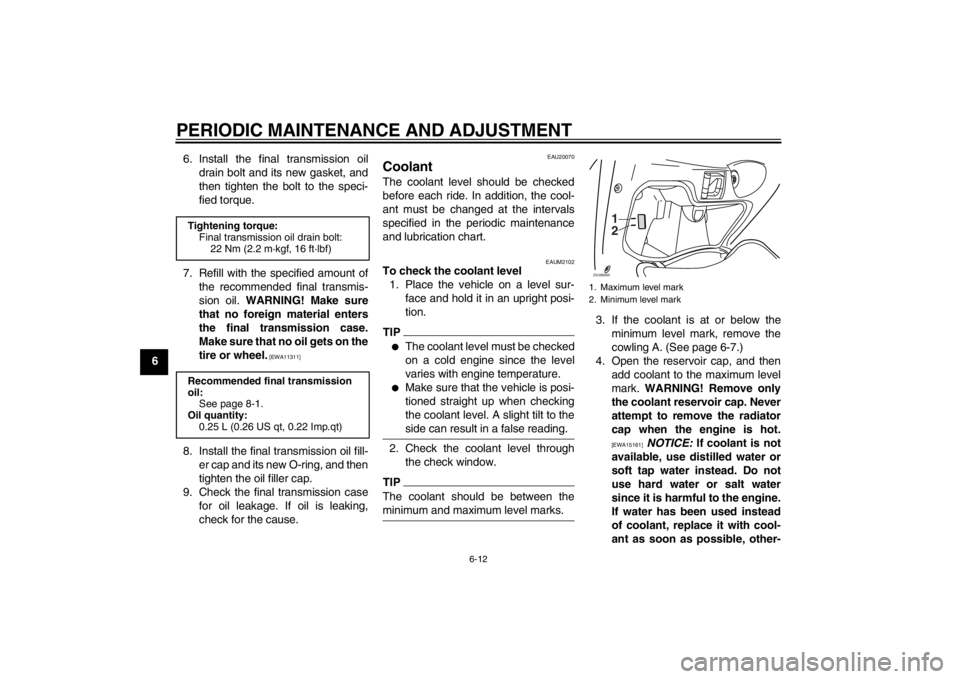

EAU20070

Coolant The coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAUM2102

To check the coolant level

1. Place the vehicle on a level sur-

face and hold it in an upright posi-

tion.TIP●

The coolant level must be checked

on a cold engine since the level

varies with engine temperature.

●

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.

2. Check the coolant level through

the check window.TIPThe coolant should be between the

minimum and maximum level marks.

3. If the coolant is at or below the

minimum level mark, remove the

cowling A. (See page 6-7.)

4. Open the reservoir cap, and then

add coolant to the maximum level

mark. WARNING! Remove only

the coolant reservoir cap. Never

attempt to remove the radiator

cap when the engine is hot.

[EWA15161]

NOTICE: If coolant is not

available, use distilled water or

soft tap water instead. Do not

use hard water or salt water

since it is harmful to the engine.

If water has been used instead

of coolant, replace it with cool-

ant as soon as possible, other-

Tightening torque:

Final transmission oil drain bolt:

22 Nm (2.2 m·kgf, 16 ft·lbf)

Recommended final transmission

oil:

See page 8-1.

Oil quantity:

0.25 L (0.26 US qt, 0.22 Imp.qt)

1. Maximum level mark

2. Minimum level mark

1

2

ZAUM0660

U5B2E4E0.book Page 12 Friday, June 1, 2012 9:06 AM