brake light YAMAHA XENTER 150 2012 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2012, Model line: XENTER 150, Model: YAMAHA XENTER 150 2012Pages: 84, PDF Size: 1.33 MB

Page 6 of 84

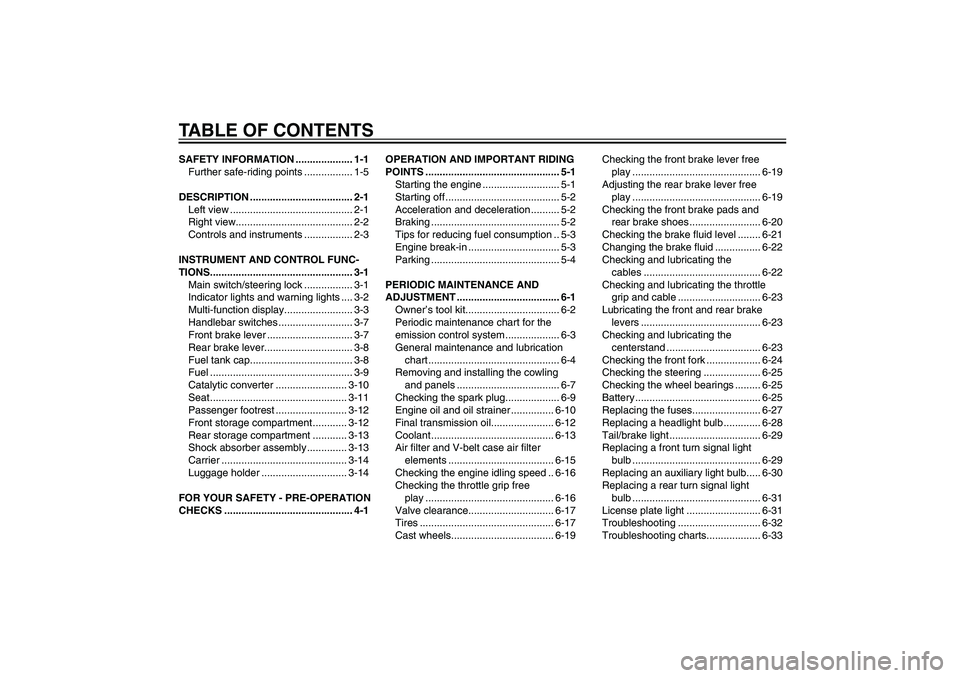

TABLE OF CONTENTSSAFETY INFORMATION .................... 1-1

Further safe-riding points ................. 1-5

DESCRIPTION .................................... 2-1

Left view ........................................... 2-1

Right view ......................................... 2-2

Controls and instruments ................. 2-3

INSTRUMENT AND CONTROL FUNC-

TIONS .................................................. 3-1

Main switch/steering lock ................. 3-1

Indicator lights and warning lights .... 3-2

Multi-function display ........................ 3-3

Handlebar switches .......................... 3-7

Front brake lever .............................. 3-7

Rear brake lever ............................... 3-8

Fuel tank cap .................................... 3-8

Fuel .................................................. 3-9

Catalytic converter ......................... 3-10

Seat ................................................ 3-11

Passenger footrest ......................... 3-12

Front storage compartment ............ 3-12

Rear storage compartment ............ 3-13

Shock absorber assembly .............. 3-13

Carrier ............................................ 3-14

Luggage holder .............................. 3-14

FOR YOUR SAFETY - PRE-OPERATION

CHECKS ............................................. 4-1OPERATION AND IMPORTANT RIDING

POINTS ............................................... 5-1

Starting the engine ........................... 5-1

Starting off ........................................ 5-2

Acceleration and deceleration .......... 5-2

Braking ............................................. 5-2

Tips for reducing fuel consumption .. 5-3

Engine break-in ................................ 5-3

Parking ............................................. 5-4

PERIODIC MAINTENANCE AND

ADJUSTMENT .................................... 6-1

Owner’s tool kit ................................. 6-2

Periodic maintenance chart for the

emission control system ................... 6-3

General maintenance and lubrication

chart .............................................. 6-4

Removing and installing the cowling

and panels .................................... 6-7

Checking the spark plug ................... 6-9

Engine oil and oil strainer ............... 6-10

Final transmission oil ...................... 6-12

Coolant ........................................... 6-13

Air fi lter and V-belt case air fi lter

elements ..................................... 6-15

Checking the engine idling speed .. 6-16

Checking the throttle grip free

play ............................................. 6-16

Valve clearance .............................. 6-17

Tires ............................................... 6-17

Cast wheels .................................... 6-19Checking the front brake lever free

play ............................................. 6-19

Adjusting the rear brake lever free

play ............................................. 6-19

Checking the front brake pads and

rear brake shoes ......................... 6-20

Checking the brake fl uid level ........ 6-21

Changing the brake fl uid ................ 6-22

Checking and lubricating the

cables ......................................... 6-22

Checking and lubricating the throttle

grip and cable ............................. 6-23

Lubricating the front and rear brake

levers .......................................... 6-23

Checking and lubricating the

centerstand ................................. 6-23

Checking the front fork ................... 6-24

Checking the steering .................... 6-25

Checking the wheel bearings ......... 6-25

Battery ............................................ 6-25

Replacing the fuses ........................ 6-27

Replacing a headlight bulb ............. 6-28

Tail/brake light ................................ 6-29

Replacing a front turn signal light

bulb ............................................. 6-29

Replacing an auxiliary light bulb ..... 6-30

Replacing a rear turn signal light

bulb ............................................. 6-31

License plate light .......................... 6-31

Troubleshooting ............................. 6-32

Troubleshooting charts ................... 6-33

52S-F8199-E0_CS.indd 652S-F8199-E0_CS.indd 6

2011/11/16 13:06:592011/11/16 13:06:59

Process BlackProcess Black

Page 14 of 84

1

2

3

4

5

6

7

8

9

2-1

EAU10401

DESCRIPTION1. Headlight (Page 6-28)

2. Auxiliary light (page 6-30)

3. Front turn signal light (page 6-29)

4. Brake fl uid reservoir (page 6-21)

5. Passenger footrest (page 3-12)

6. V-belt air fi lter case cover (page 6-15)

7. Centerstand (page 6-23)

EAU10410

Left view

8. Air fi lter (page 6-15)

9. Carrier (page 3-14)

10. Rear turn signal light (page 6-31)

EAU10401

DESCRIPTION

1, 2 3 4 5 6 7 8 9 10

52S-F8199-E0_CS.indd 2-152S-F8199-E0_CS.indd 2-1

2011/11/16 13:06:592011/11/16 13:06:59

Process BlackProcess Black

Page 15 of 84

1

2

3

4

5

6

7

8

9

2-2

EAU10401

DESCRIPTION

EAU10420

Right view1. Tail/brake light (page 6-29)

2. Muffl er (page 3-10)

3. Fuel tank cap (page 3-8)

4. Coolant reservoir (page 6-13)

5. Shock absorber assembly (page 3-13)

6. Seat (page 3-11)

7. Rear storage compartment (page 3-13)8. Spark plug (page 6-9)

9. Battery (page 6-25)

10. Fuse box (page 6-27)

1 2 3, 4 5 6 7 8 9, 10

52S-F8199-E0_CS.indd 2-252S-F8199-E0_CS.indd 2-2

2011/11/16 13:07:002011/11/16 13:07:00

Process BlackProcess Black

Page 23 of 84

1

2

3

4

5

6

7

8

9

3-7

EAU1044E

INSTRUMENT AND CONTROL FUNCTIONS

EAU12349

Handlebar switchesLeft

132

1. Dimmer switch “%/&”

2. Turn signal switch “4/6”

3. Horn switch “*”Right

1

1. Start switch “,”

EAU12400

Dimmer switch “&/%”

Set this switch to “&” for the high

beam and to “%” for the low beam.

EAU12460

Turn signal switch “4/6”

To signal a right-hand turn, push this

switch to “6”. To signal a left-hand

turn, push this switch to “4”. When

released, the switch returns to the

center position. To cancel the turn

signal lights, push the switch in after it

has returned to the center position.

EAU12500

Horn switch “*”

Press this switch to sound the horn.

EAUM1132

Start switch “,”

Push this switch while applying the

front or rear brake to crank the en-

gine with the starter. See page 5-1 for

starting instructions prior to starting

the engine.

EAUS2010

Front brake lever

1

1. Front brake leverThe front brake lever is located on

the right handlebar grip. To apply the

front brake, pull this lever toward the

handlebar grip.

This model is equipped with a unifi ed

brake system.

As this system is mechanical, addi-

tional free play can be felt in the front

brake lever when the rear brake lever

is being applied. See “Rear brake

lever” for detailed information on the

unifi ed brake system.

52S-F8199-E0_CS.indd 3-752S-F8199-E0_CS.indd 3-7

2011/11/16 13:07:002011/11/16 13:07:00

Process BlackProcess Black

Page 33 of 84

1

2

3

4

5

6

7

8

9

4-3

EAU15582

FOR YOUR SAFETY - PRE-OPERATION CHECKS

ITEM CHECKS PAGE

Wheels and tires• Check for damage.

• Check tire condition and tread depth.

• Check air pressure.

• Correct if necessary.6-17~6-19

Brake levers• Make sure that operation is smooth.

• Lubricate lever pivoting points if necessary.3-7~3-8, 6-23

Centerstand• Make sure that operation is smooth.

• Lubricate pivot if necessary.6-23

Chassis fasteners• Make sure that all nuts, bolts and screws are properly tightened.

• Tighten if necessary.-

Instruments, lights, signals

and switches• Check operation.

• Correct if necessary.3-2~3-7

52S-F8199-E0_CS.indd 4-352S-F8199-E0_CS.indd 4-3

2011/11/16 13:07:002011/11/16 13:07:00

Process BlackProcess Black

Page 34 of 84

1

2

3

4

5

6

7

8

9

5-1

EAU15943

OPERATION AND IMPORTANT RIDING POINTS

EAU15943

OPERATION AND IMPORTANT RIDING POINTS

EAU15951

Read the Owner’s Manual carefully

to become familiar with all controls.

If there is a control or function you

do not understand, ask your Yamaha

dealer.

EWA10271

WARNING

Failure to familiarize yourself with

the controls can lead to loss of

control, which could cause an ac-

cident or injury.

EAU45310

TIPThis model is equipped with a lean

angle sensor to stop the engine in

case of a turnover. To start the en-

gine after a turnover, be sure to turn

the main switch to “OFF” and then to

“ON”. Failing to do so will prevent the

engine from starting even though the

engine will crank when pushing the

start switch.

EAUT3680

Starting the engine

ECA10250

NOTICESee page 5-3 for engine break-in

instructions prior to operating the

vehicle for the � rst time.

1. Turn the key to “ON”.

The engine trouble warning light

and coolant temperature warning

light should come on for a few

seconds, then go off.

NOTICE:

If

a warning light does not go off,

have a Yamaha dealer check its

electrical circuit.

[ECAT1170]

2. Close the throttle completely.

3. Start the engine by pushing the

start switch while applying the

front or rear brake.

NOTICE:

For

maximum engine life, never ac-

celerate hard when the engine

is cold!

[ECA11041]

If the engine does not start, re-

lease the start switch, wait a few

seconds, and then try again.

Each starting attempt should be

as short as possible to preserve the battery. Do not crank the en-

gine more than 10 seconds on

any one attempt.

52S-F8199-E0_CS.indd 5-152S-F8199-E0_CS.indd 5-1

2011/11/16 13:07:002011/11/16 13:07:00

Process BlackProcess Black

Page 43 of 84

1

2

3

4

5

6

7

8

9

6-6

EAU1722A

PERIODIC MAINTENANCE AND ADJUSTMENT

EAUT2710

TIP● Air fi lter and V-belt fi lter

• This model’s air fi lter is equipped with a disposable oil-coated paper element, which must not be cleaned with

compressed air to avoid damaging it.

• The air fi lter element needs to be replaced and V-belt fi lter needs to be serviced more frequently when riding in

unusually wet or dusty areas.● Hydraulic brake service

• After disassembling the brake master cylinder and caliper, always change the fl uid. Regularly check the brake

fl uid level and fi ll the reservoir as required.

• Every two years replace the internal components of the brake master cylinder and caliper, and change the brake

fl uid.

• Replace the brake hose every four years and if cracked or damaged.NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi)6000 km

(3500 mi)

12000 km

(7000 mi)18000 km

(10500 mi)24000 km

(14000 mi)

23Moving parts and ca-

bles• Lubricate.

√√√√ √

24 * Throttle grip• Check operation.

• Check throttle grip free play, and adjust if necessary.

• Lubricate cable and grip housing.√√√√ √

25 *Lights, signals and

switches• Check operation.

• Adjust headlight beam.√√√√√ √

52S-F8199-E0_CS.indd 6-652S-F8199-E0_CS.indd 6-6

2011/11/16 13:07:012011/11/16 13:07:01

Process BlackProcess Black

Page 66 of 84

1

2

3

4

5

6

7

8

9

6-29

EAU1722A

PERIODIC MAINTENANCE AND ADJUSTMENT

EAU24181

Tail/brake light

1

1. Tail/brake lightThis model is equipped with an LED-

type tail/brake light.

If the tail/brake light does not come

on, have a Yamaha dealer check it.

EAUT3650

Replacing a front turn signal

light bulbIf a front turn signal light burns out, re-

place it as follows.

1. Remove cowling A. (See page

6-7.)

2. Remove the socket (together with

the bulb) by turning it counter-

clockwise.

1

1. Turn signal light bulb socket

3. Unhook the headlight bulb holder,

and then remove the burnt-out

bulb.

4. Place a new headlight bulb into

position, and then secure it with

the bulb holder.

5. Connect the coupler, and then in-

stall the headlight bulb cover.

6. Install the cowling together with

the headlight unit.

7. Have a Yamaha dealer adjust the

headlight beam if necessary.

52S-F8199-E0_CS.indd 6-2952S-F8199-E0_CS.indd 6-29

2011/11/16 13:07:022011/11/16 13:07:02

Process BlackProcess Black

Page 73 of 84

1

2

3

4

5

6

7

8

9

7-2

EAU25991

SCOOTER CARE AND STORAGE

with water, diluted mild deter-

gent with water may be used.

Be sure to rinse off any deter-

gent residue using plenty of

water, as it is harmful to plastic

parts.

● Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

cleaning products, solvent or

thinner, fuel (gasoline), rust

removers or inhibitors, brake

� uid, antifreeze or electrolyte.● Do not use high-pressure

washers or steam-jet cleaners

since they cause water seep-

age and deterioration in the

following areas: seals (of wheel

and swingarm bearings, fork

and brakes), electric compo-

nents (couplers, connectors,

instruments, switches and

lights), breather hoses and

vents.● For vehicles equipped with a

windshield: Do not use strong

cleaners or hard sponges

as they will cause dulling or

scratching. Some cleaning

compounds for plastic may

leave scratches on the wind-

shield. Test the product on a

small hidden part of the wind-

shield to make sure that it does

not leave any marks. If the

windshield is scratched, use a

quality plastic polishing com-

pound after washing.

After normal use

Remove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt

and insects will come off more easily

if the area is covered with a wet cloth

for a few minutes before cleaning.

After riding in the rain, near the sea or

on salt-sprayed roads

Since sea salt or salt sprayed on the

roads during winter are extremely cor-

rosive in combination with water, carry

out the following steps after each ride

in the rain, near the sea or on salt-

sprayed roads.TIPSalt sprayed on roads in the winter

may remain well into spring.

1. Clean the scooter with cold water

and a mild detergent after the en-

gine has cooled down.

NOTICE:

Do not use warm water since it

increases the corrosive action

of the salt.

[ECA10791]

2. Apply a corrosion protection

spray on all metal, including

chrome- and nickel-plated, sur-

faces to prevent corrosion.

After cleaning

1. Dry the scooter with a chamois or

an absorbing cloth.

2. Use a chrome polish to shine

chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally in-

duced discoloring of stainless-

52S-F8199-E0_CS.indd 7-252S-F8199-E0_CS.indd 7-2

2011/11/16 13:07:022011/11/16 13:07:02

Process BlackProcess Black

Page 74 of 84

1

2

3

4

5

6

7

8

9

7-3

EAU25991

SCOOTER CARE AND STORAGE

steel exhaust systems can be

removed through polishing.)

3. To prevent corrosion, it is recom-

mended to apply a corrosion pro-

tection spray on all metal, includ-

ing chrome- and nickel-plated,

surfaces.

4. Use spray oil as a universal

cleaner to remove any remaining

dirt.

5. Touch up minor paint damage

caused by stones, etc.

6. Wax all painted surfaces.

7. Let the scooter dry completely

before storing or covering it.

EWA10942

WARNING

Contaminants on the brakes or

tires can cause loss of control.● Make sure that there is no oil

or wax on the brakes or tires.

If necessary, clean the brake

discs and brake linings with a

regular brake disc cleaner or

acetone, and wash the tires

with warm water and a mild de-

tergent.● Before operating the vehicle,

test its braking performance

and cornering behavior.

ECA10800

NOTICE● Apply spray oil and wax spar-

ingly and make sure to wipe off

any excess.● Never apply oil or wax to any

rubber and plastic parts, but

treat them with a suitable care

product.● Avoid using abrasive polishing

compounds as they will wear

away the paint.

TIP● Consult a Yamaha dealer for ad-

vice on what products to use.● Washing, rainy weather or humid

climates can cause the headlight

lens to fog. Turning the headlight

on for a short period of time will

help remove the moisture from

the lens.

EAU36563

StorageShort-term

Always store your scooter in a cool,

dry place and, if necessary, protect

it against dust with a porous cover.

Be sure the engine and the exhaust

system are cool before covering the

scooter.

ECA10820

NOTICE● Storing the scooter in a poorly

ventilated room or covering it

with a tarp, while it is still wet,

will allow water and humidity to

seep in and cause rust.● To prevent corrosion, avoid

damp cellars, stables (because

of the presence of ammonia)

and areas where strong chemi-

cals are stored.

Long-term

Before storing your scooter for several

months:

1. Follow all the instructions in the

“Care” section of this chapter.

2. Fill up the fuel tank and add fuel

stabilizer (if available) to prevent

52S-F8199-E0_CS.indd 7-352S-F8199-E0_CS.indd 7-3

2011/11/16 13:07:022011/11/16 13:07:02

Process BlackProcess Black