light YAMAHA XJ6-N 2016 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: XJ6-N, Model: YAMAHA XJ6-N 2016Pages: 104, PDF Size: 2.91 MB

Page 52 of 104

Periodic maintenance an d a djustment

6-8

6

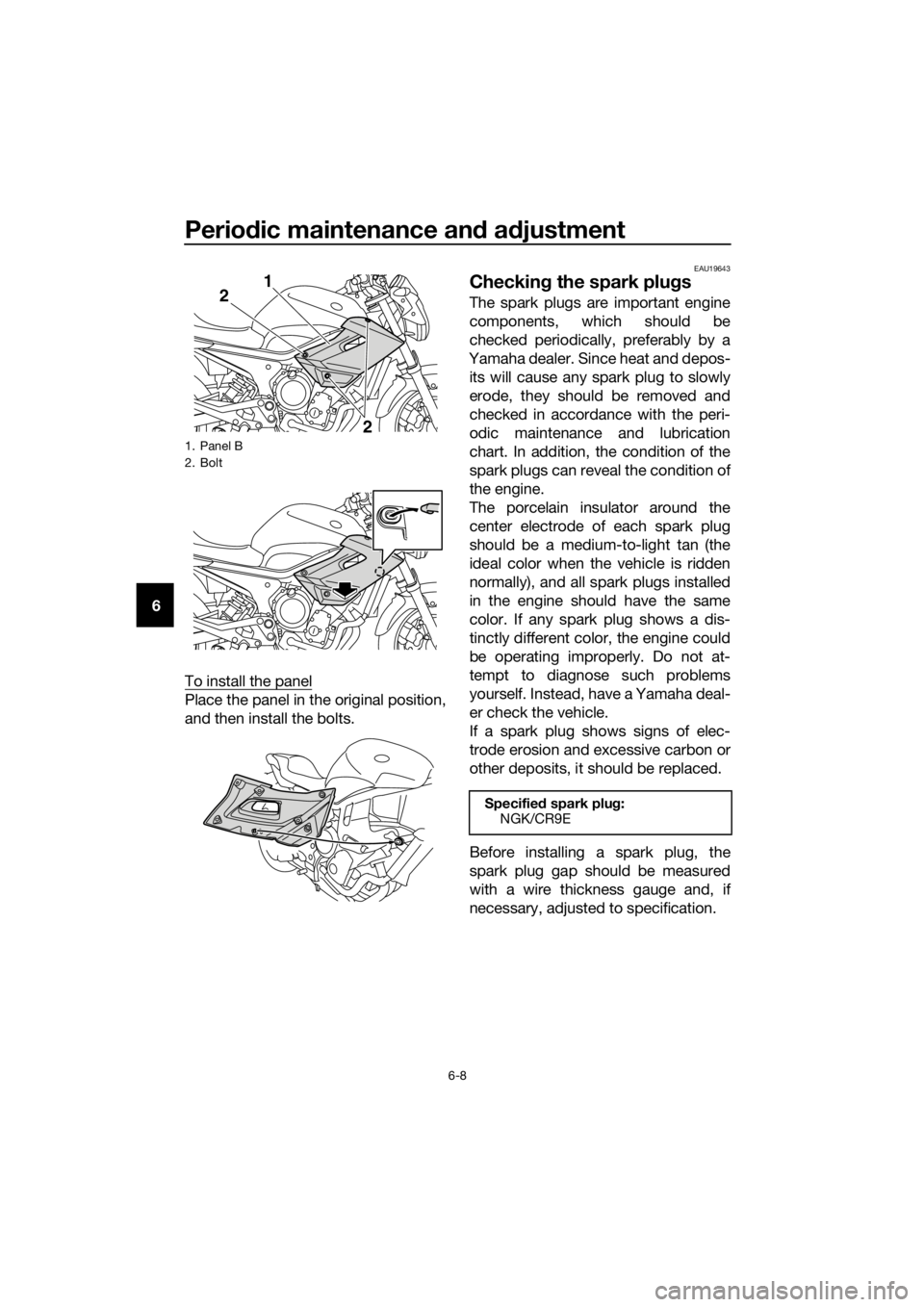

To install the panel

Place the panel in the original position,

and then install the bolts.

EAU19643

Checkin g the spark plu gs

The spark plugs are important engine

components, which should be

checked periodically, preferably by a

Yamaha dealer. Since heat and depos- its will cause any spark plug to slowly

erode, they should be removed and

checked in accordance with the peri-

odic maintenance and lubrication

chart. In addition, the condition of the

spark plugs can reveal the condition of

the engine.

The porcelain insulator around the

center electrode of each spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally), and all spark plugs installed

in the engine should have the same

color. If any spark plug shows a dis-

tinctly different color, the engine could

be operating improperly. Do not at-

tempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If a spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced.

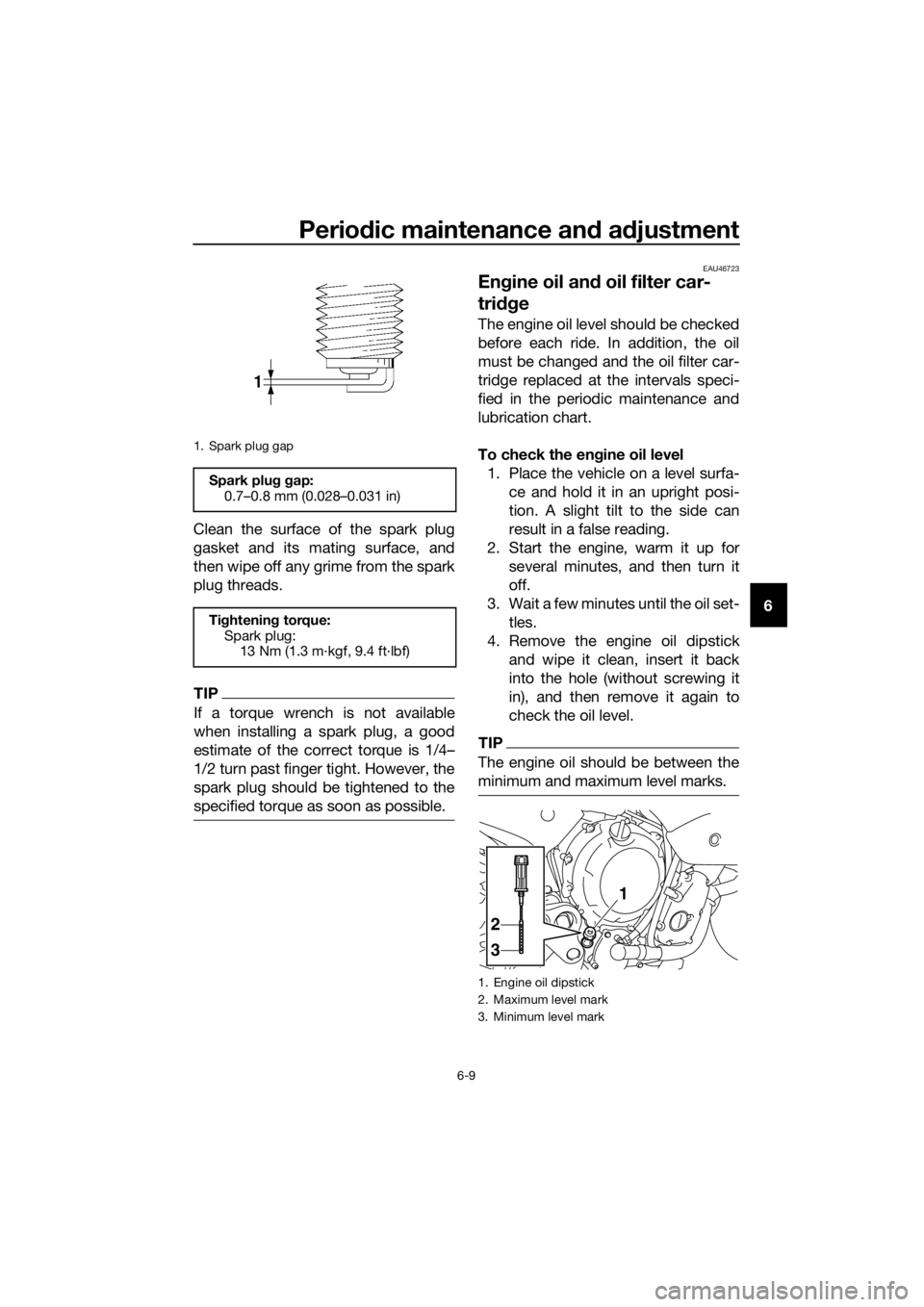

Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification.

1. Panel B

2. Bolt

1

2

2

Specified spark plu g:

NGK/CR9E

UB61E1E0.book Page 8 Wednesday, October 21, 2015 11:19 AM

Page 53 of 104

Periodic maintenance an d a djustment

6-9

6

Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

TIP

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.

EAU46723

En

gine oil an d oil filter car-

tri dge

The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

To check the en gine oil level

1. Place the vehicle on a level surfa- ce and hold it in an upright posi-

tion. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes until the oil set- tles.

4. Remove the engine oil dipstick and wipe it clean, insert it back

into the hole (without screwing it

in), and then remove it again to

check the oil level.

TIP

The engine oil should be between the

minimum and maximum level marks.

1. Spark plug gap

Spark plu g g ap:

0.7–0.8 mm (0.028–0.031 in)

Ti ghtening torque:

Spark plug: 13 Nm (1.3 m·kgf, 9.4 ft·lbf)

1. Engine oil dipstick

2. Maximum level mark

3. Minimum level mark

1

2

3

UB61E1E0.book Page 9 Wednesday, October 21, 2015 11:19 AM

Page 55 of 104

Periodic maintenance an d a djustment

6-11

6

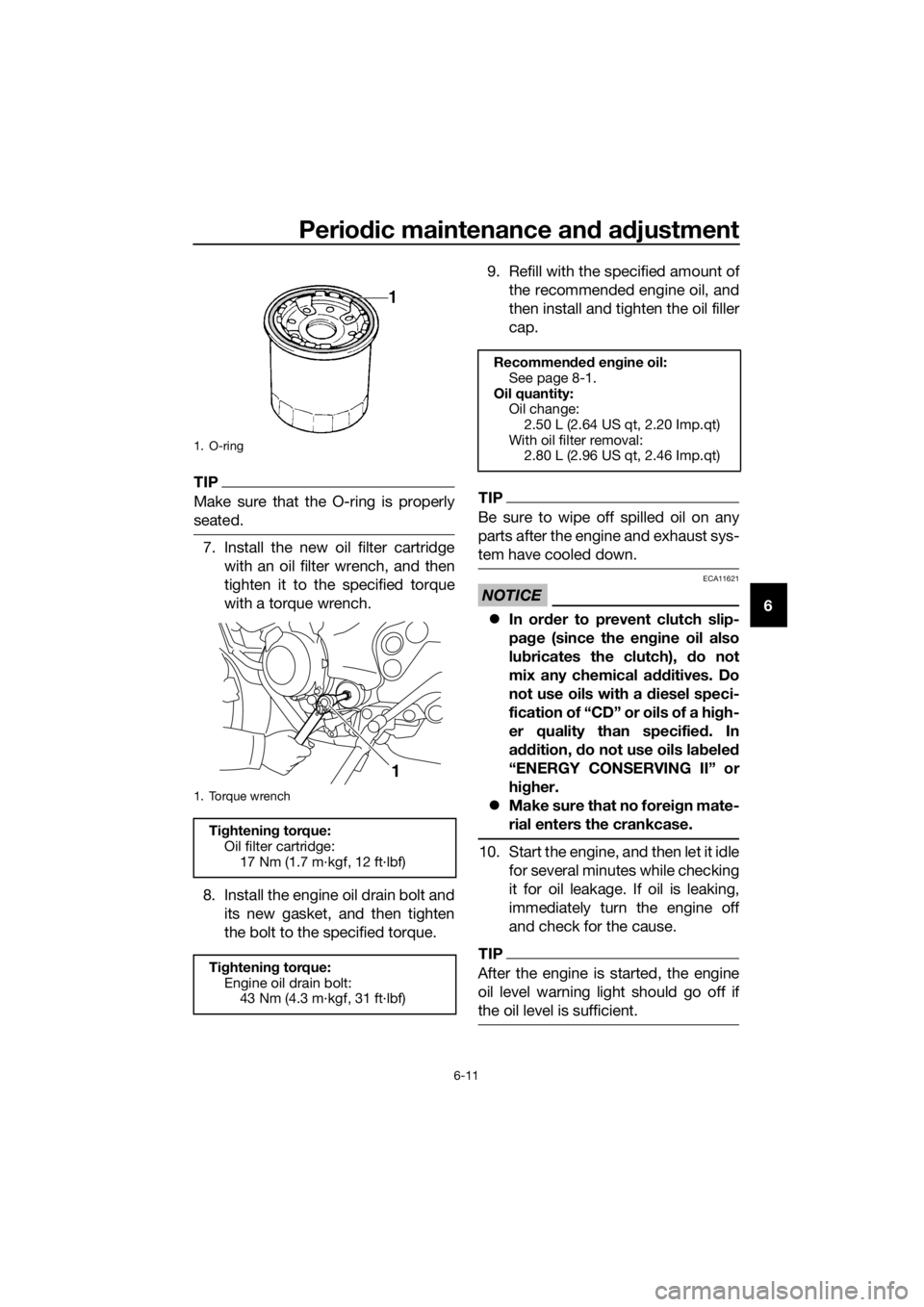

TIP

Make sure that the O-ring is properly

seated.

7. Install the new oil filter cartridge

with an oil filter wrench, and then

tighten it to the specified torque

with a torque wrench.

8. Install the engine oil drain bolt and its new gasket, and then tighten

the bolt to the specified torque. 9. Refill with the specified amount of

the recommended engine oil, and

then install and tighten the oil filler

cap.

TIP

Be sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.

NOTICE

ECA11621

In or der to prevent clutch slip-

pa ge (since the en gine oil also

lu bricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a hi gh-

er quality than specified . In

a dd ition, do not use oils la bele d

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.

10. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

TIP

After the engine is started, the engine

oil level warning light should go off if

the oil level is sufficient.

1. O-ring

1. Torque wrench

Tightening torque:

Oil filter cartridge: 17 Nm (1.7 m·kgf, 12 ft·lbf)

Ti ghtening torque:

Engine oil drain bolt: 43 Nm (4.3 m·kgf, 31 ft·lbf)

1

Recommen ded en gine oil:

See page 8-1.

Oil quantity: Oil change:

2.50 L (2.64 US qt, 2.20 Imp.qt)

With oil filter removal: 2.80 L (2.96 US qt, 2.46 Imp.qt)

UB61E1E0.book Page 11 Wednesday, October 21, 2015 11:19 AM

Page 56 of 104

Periodic maintenance an d a djustment

6-12

6

NOTICE

ECA10402

If the oil level warnin g li ght flickers

or remains on even if the oil level is

correct, immed iately turn the en gine

off an d have a Yamaha d ealer check

the vehicle.

11. Turn the engine off, wait a few mi- nutes until the oil settles, and then

check the oil level and correct it if

necessary.

12. Install the cowling.

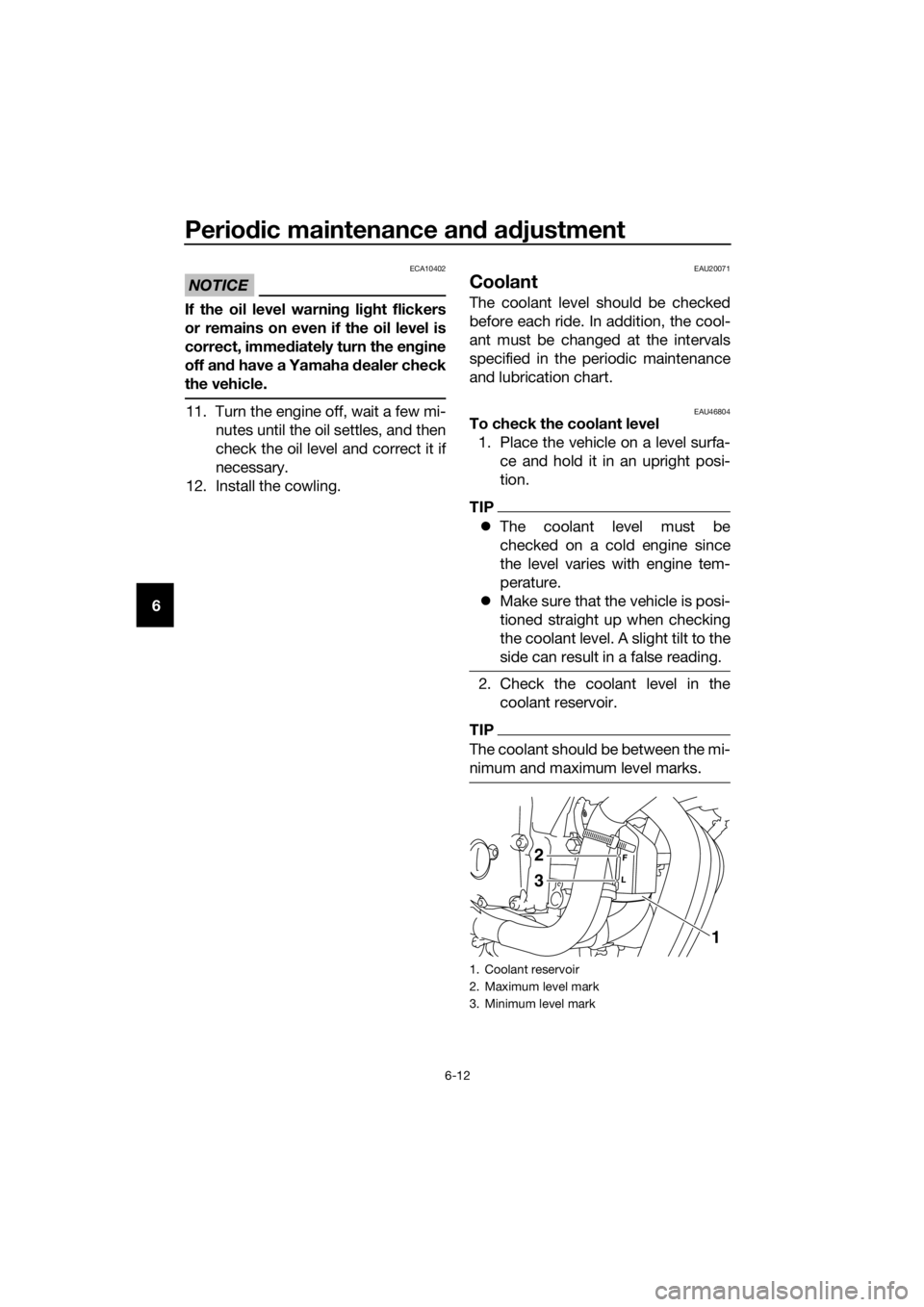

EAU20071

Coolant

The coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU46804To check the coolant level 1. Place the vehicle on a level surfa- ce and hold it in an upright posi-

tion.

TIP

The coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.

2. Check the coolant level in the

coolant reservoir.

TIP

The coolant should be between the mi-

nimum and maximum level marks.

1. Coolant reservoir

2. Maximum level mark

3. Minimum level mark

1

2

3

UB61E1E0.book Page 12 Wednesday, October 21, 2015 11:19 AM

Page 67 of 104

Periodic maintenance an d a djustment

6-23

6

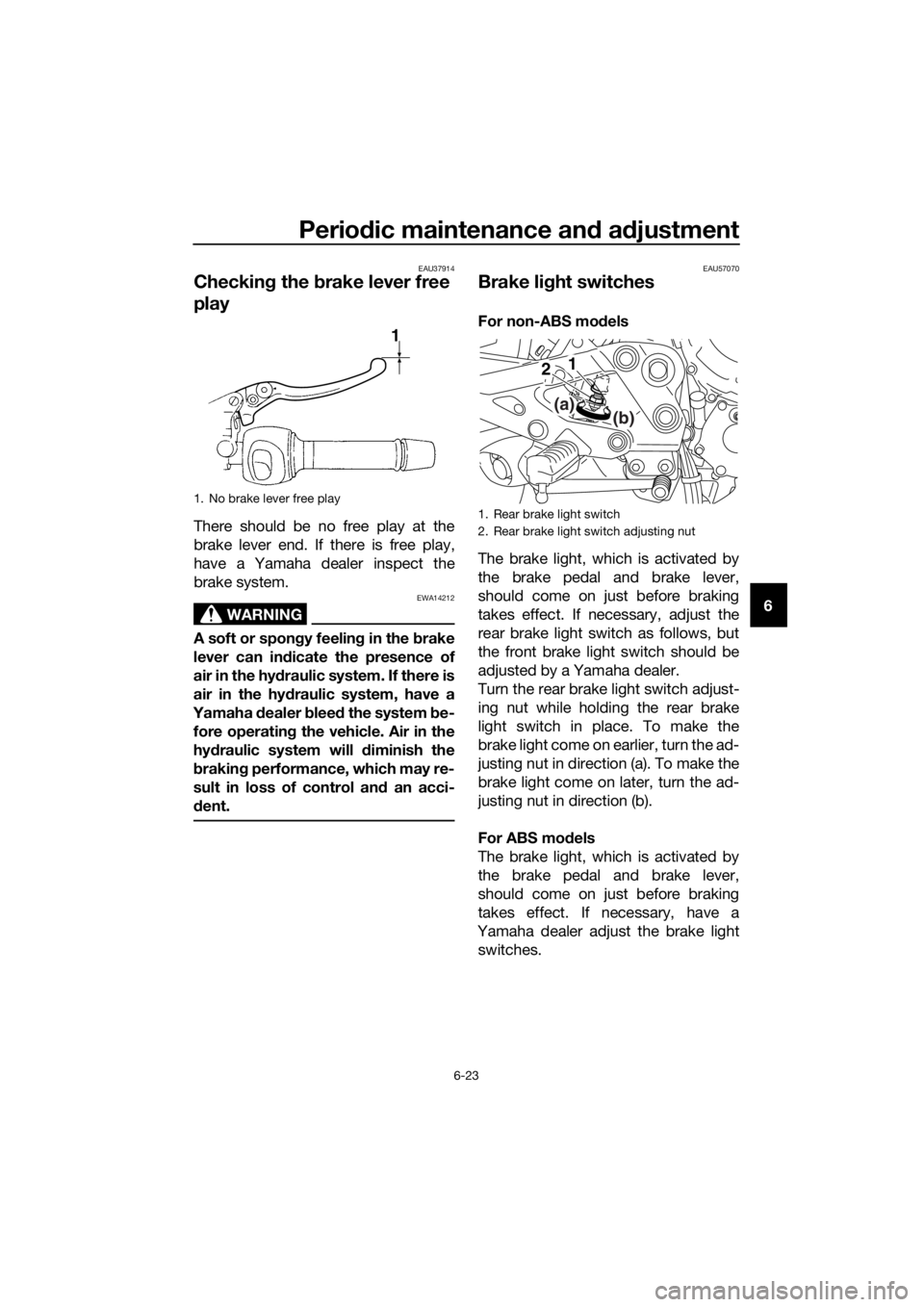

EAU37914

Checkin g the brake lever free

play

There should be no free play at the

brake lever end. If there is free play,

have a Yamaha dealer inspect the

brake system.

WARNING

EWA14212

A soft or spon gy feelin g in the b rake

lever can in dicate the presence of

air in the hy draulic system. If there is

air in the hy draulic system, have a

Yamaha dealer blee d the system be-

fore operatin g the vehicle. Air in the

hy draulic system will diminish the

b rakin g performance, which may re-

sult in loss of control an d an acci-

d ent.

EAU57070

Brake li ght switches

For non-ABS mo dels

The brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, adjust the

rear brake light switch as follows, but

the front brake light switch should be

adjusted by a Yamaha dealer.

Turn the rear brake light switch adjust-

ing nut while holding the rear brake

light switch in place. To make the

brake light come on earlier, turn the ad-

justing nut in direction (a). To make the

brake light come on later, turn the ad-

justing nut in direction (b).

For ABS mo dels

The brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, have a

Yamaha dealer adjust the brake light switches.

1. No brake lever free play

1

1. Rear brake light switch

2. Rear brake light switch adjusting nut

1

2

(a)

(b)

UB61E1E0.book Page 23 Wednesday, October 21, 2015 11:19 AM

Page 78 of 104

Periodic maintenance an d a djustment

6-34

6 3. Fully charge the battery before

installation. NOTICE: When in-

stallin g the battery, be sure the

key is turne d to “OFF”, then

connect the positive lea d b efore

connectin g the ne gative lead .

[ECA16841]

4. After installation, make sure that

the battery leads are properly con-

nected to the battery terminals.

NOTICE

ECA16531

Always keep the battery char ged .

Storin g a d ischar ged battery can

cause permanent b attery damag e.

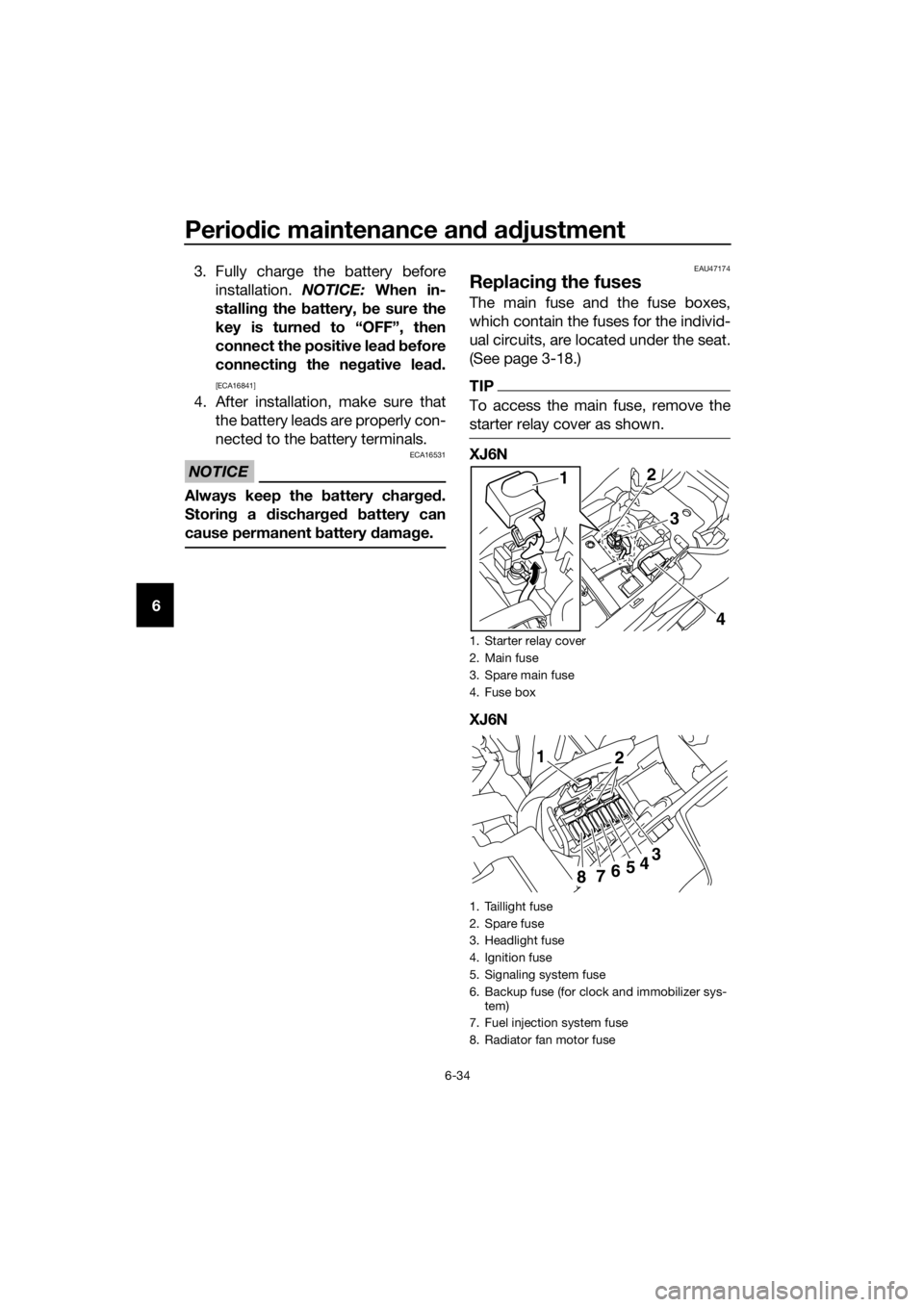

EAU47174

Replacin g the fuses

The main fuse and the fuse boxes,

which contain the fuses for the individ-

ual circuits, are located under the seat.

(See page 3-18.)

TIP

To access the main fuse, remove the

starter relay cover as shown.

XJ6N

XJ6N

1. Starter relay cover

2. Main fuse

3. Spare main fuse

4. Fuse box

1. Taillight fuse

2. Spare fuse

3. Headlight fuse

4. Ignition fuse

5. Signaling system fuse

6. Backup fuse (for clock and immobilizer sys-

tem)

7. Fuel injection system fuse

8. Radiator fan motor fuse

2

4

3

1

1

2

3

4

5

6

7

8

UB61E1E0.book Page 34 Wednesday, October 21, 2015 11:19 AM

Page 79 of 104

Periodic maintenance an d a djustment

6-35

6

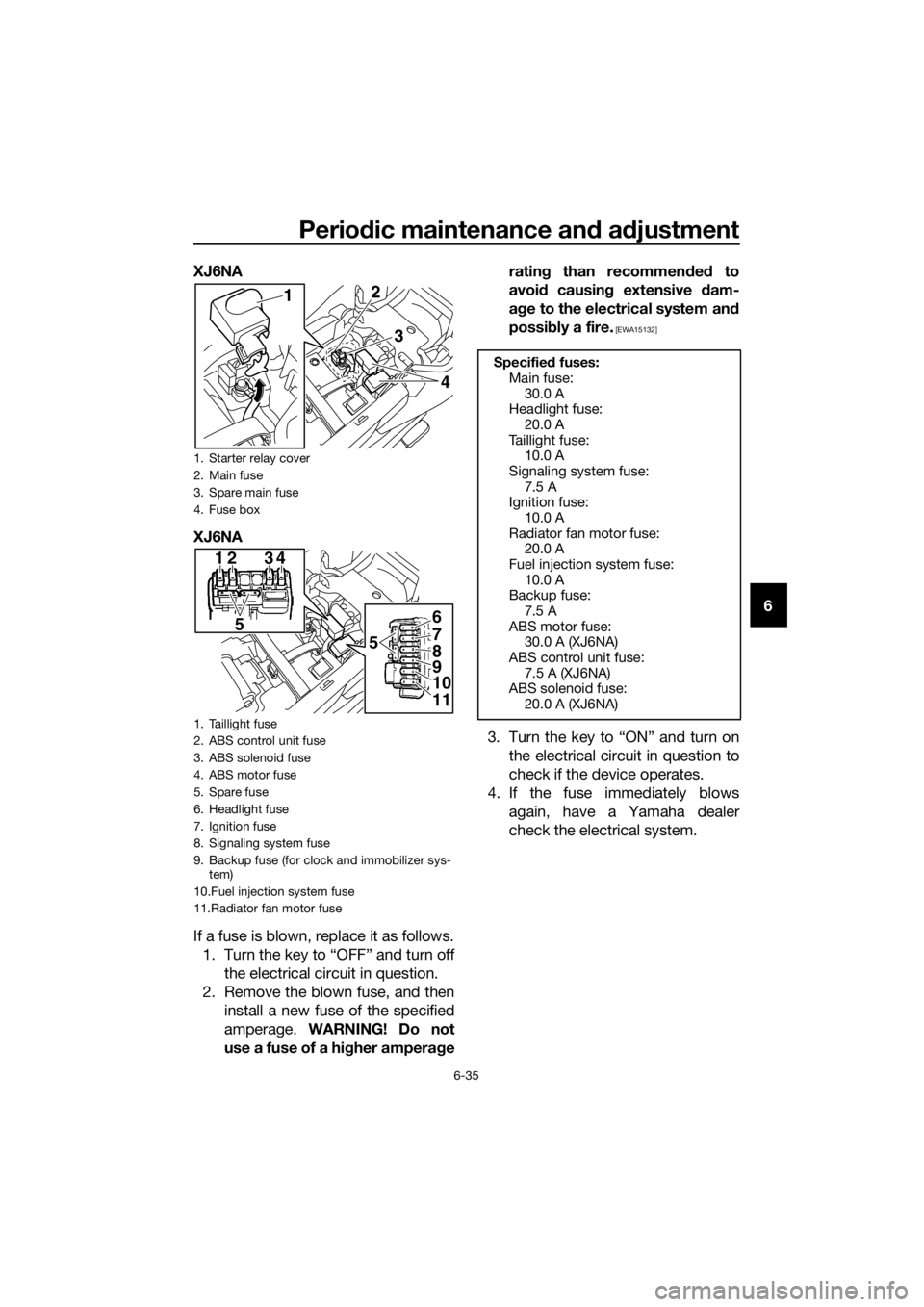

XJ6NA

XJ6NA

If a fuse is blown, replace it as follows.

1. Turn the key to “OFF” and turn off the electrical circuit in question.

2. Remove the blown fuse, and then install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a hi gher ampera ge ratin

g than recommen ded to

avoi d causin g extensive dam-

a g e to the electrical system an d

possi bly a fire.

[EWA15132]

3. Turn the key to “ON” and turn on

the electrical circuit in question to

check if the device operates.

4. If the fuse immediately blows again, have a Yamaha dealer

check the electrical system.

1. Starter relay cover

2. Main fuse

3. Spare main fuse

4. Fuse box

1. Taillight fuse

2. ABS control unit fuse

3. ABS solenoid fuse

4. ABS motor fuse

5. Spare fuse

6. Headlight fuse

7. Ignition fuse

8. Signaling system fuse

9. Backup fuse (for clock and immobilizer sys-tem)

10.Fuel injection system fuse

11.Radiator fan motor fuse

2

4

3

1

1

5 56

7

8

9

10

11

234

Specified

fuses:

Main fuse: 30.0 A

Headlight fuse:

20.0 A

Taillight fuse: 10.0 A

Signaling system fuse: 7.5 A

Ignition fuse:

10.0 A

Radiator fan motor fuse: 20.0 A

Fuel injection system fuse: 10.0 A

Backup fuse:

7.5 A

ABS motor fuse: 30.0 A (XJ6NA)

ABS control unit fuse: 7.5 A (XJ6NA)

ABS solenoid fuse:

20.0 A (XJ6NA)

UB61E1E0.book Page 35 Wednesday, October 21, 2015 11:19 AM

Page 80 of 104

Periodic maintenance an d a djustment

6-36

6

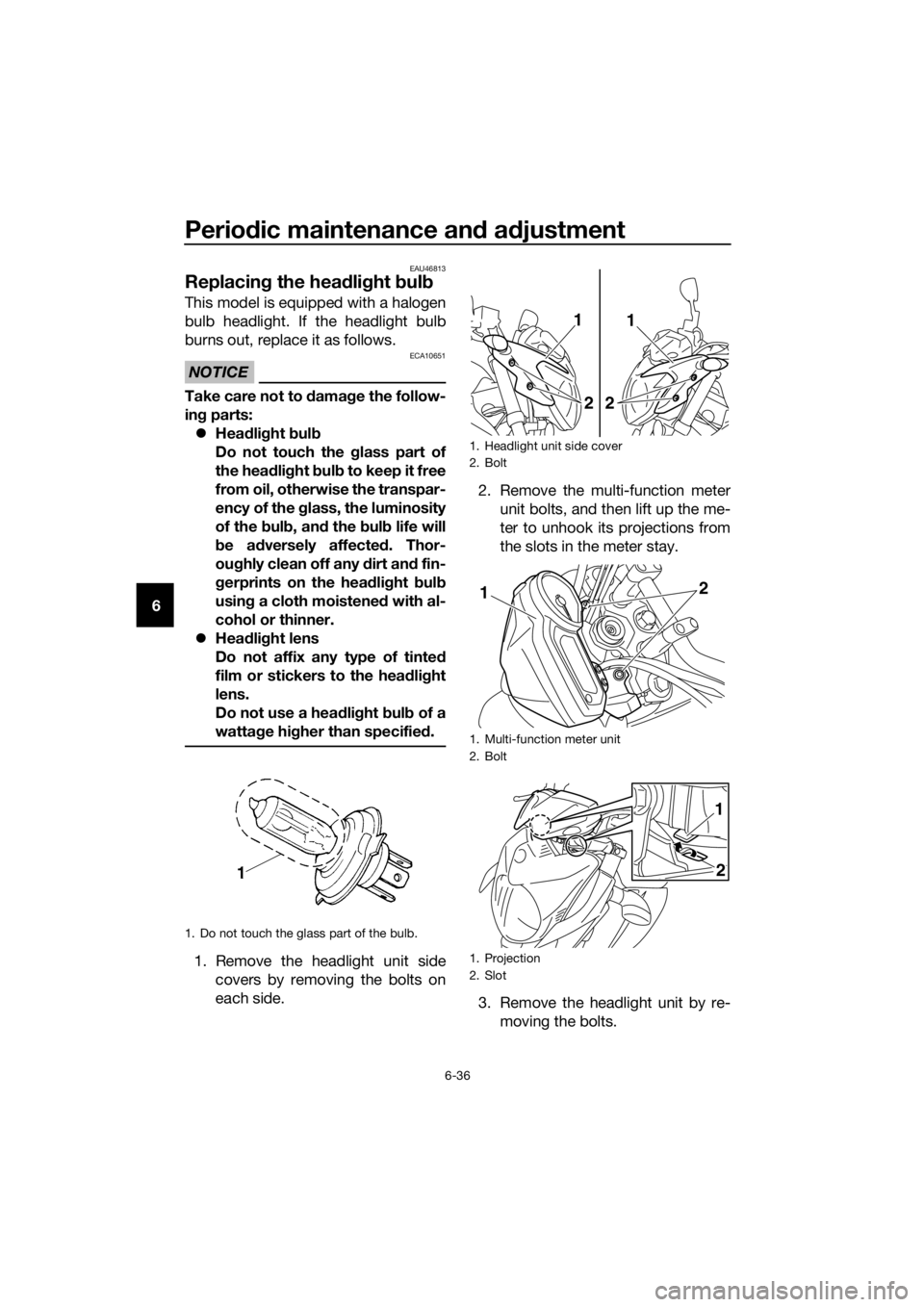

EAU46813

Replacin g the hea dlig ht bul b

This model is equipped with a halogen

bulb headlight. If the headlight bulb

burns out, replace it as follows.

NOTICE

ECA10651

Take care not to damag e the follow-

in g parts:

Hea dlig ht bul b

Do not touch the glass part of

the hea dlig ht bul b to keep it free

from oil, otherwise the transpar-

ency of the glass, the luminosity

of the b ulb, an d the b ulb life will

b e ad versely affected . Thor-

ou ghly clean off any dirt an d fin-

g erprints on the hea dlig ht bul b

usin g a cloth moistened with al-

cohol or thinner.

Hea dlig ht lens

Do not affix any type of tinted

film or stickers to the hea dlig ht

lens.

Do not use a hea dlig ht bul b of a

wattag e higher than specifie d.

1. Remove the headlight unit side

covers by removing the bolts on

each side. 2. Remove the multi-function meter

unit bolts, and then lift up the me-

ter to unhook its projections from

the slots in the meter stay.

3. Remove the headlight unit by re- moving the bolts.

1. Do not touch the glass part of the bulb.

1. Headlight unit side cover

2. Bolt

1. Multi-function meter unit

2. Bolt

1. Projection

2. Slot

11

22

1 2

1

2

UB61E1E0.book Page 36 Wednesday, October 21, 2015 11:19 AM

Page 81 of 104

Periodic maintenance an d a djustment

6-37

6

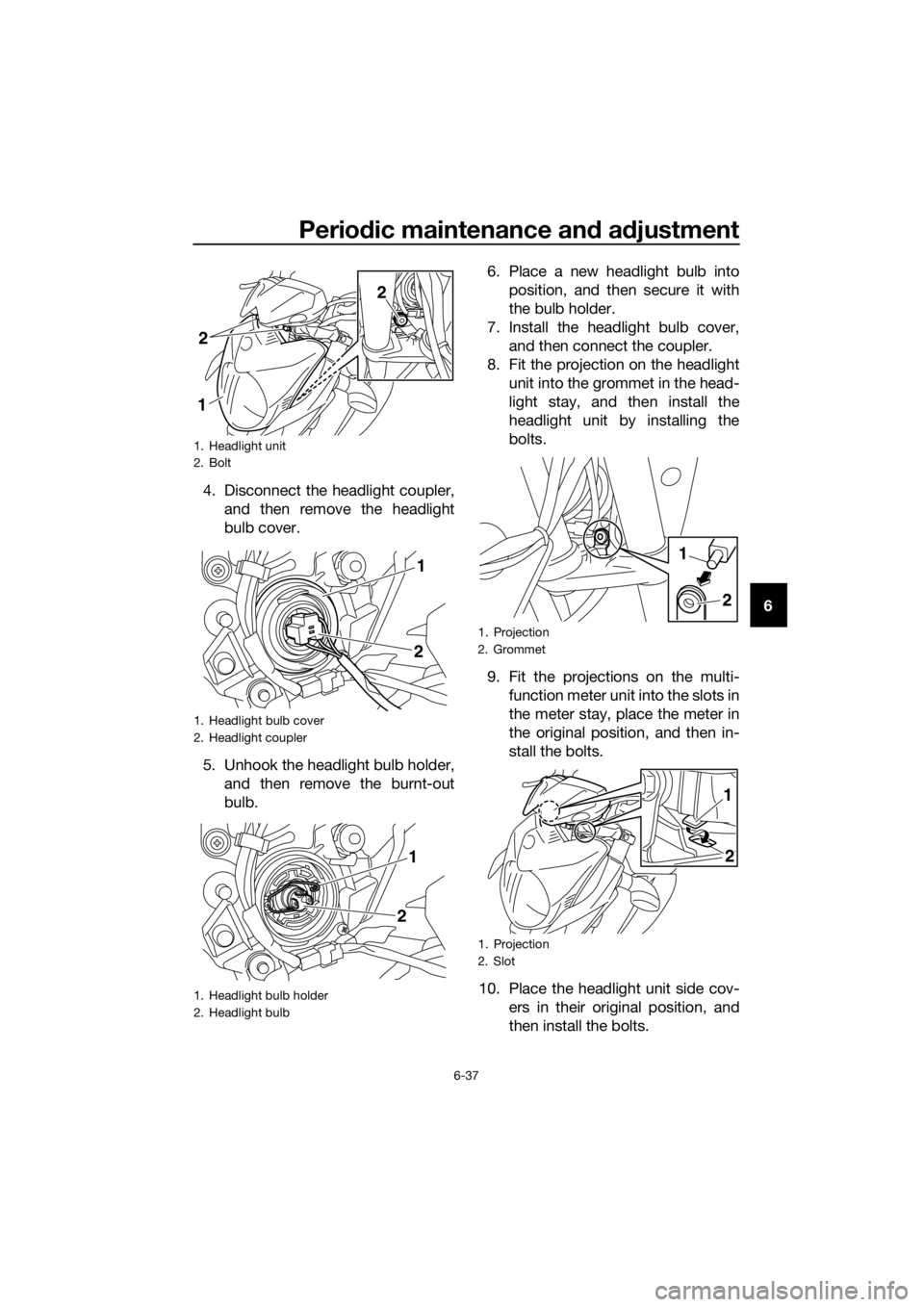

4. Disconnect the headlight coupler,

and then remove the headlight

bulb cover.

5. Unhook the headlight bulb holder, and then remove the burnt-out

bulb. 6. Place a new headlight bulb into

position, and then secure it with

the bulb holder.

7. Install the headlight bulb cover, and then connect the coupler.

8. Fit the projection on the headlight unit into the grommet in the head-

light stay, and then install the

headlight unit by installing the

bolts.

9. Fit the projections on the multi- function meter unit into the slots in

the meter stay, place the meter in

the original position, and then in-

stall the bolts.

10. Place the headlight unit side cov- ers in their original position, and

then install the bolts.

1. Headlight unit

2. Bolt

1. Headlight bulb cover

2. Headlight coupler

1. Headlight bulb holder

2. Headlight bulb

1

2

2

2 1

1

2

1. Projection

2. Grommet

1. Projection

2. Slot

2

1

1

2

UB61E1E0.book Page 37 Wednesday, October 21, 2015 11:19 AM

Page 82 of 104

Periodic maintenance an d a djustment

6-38

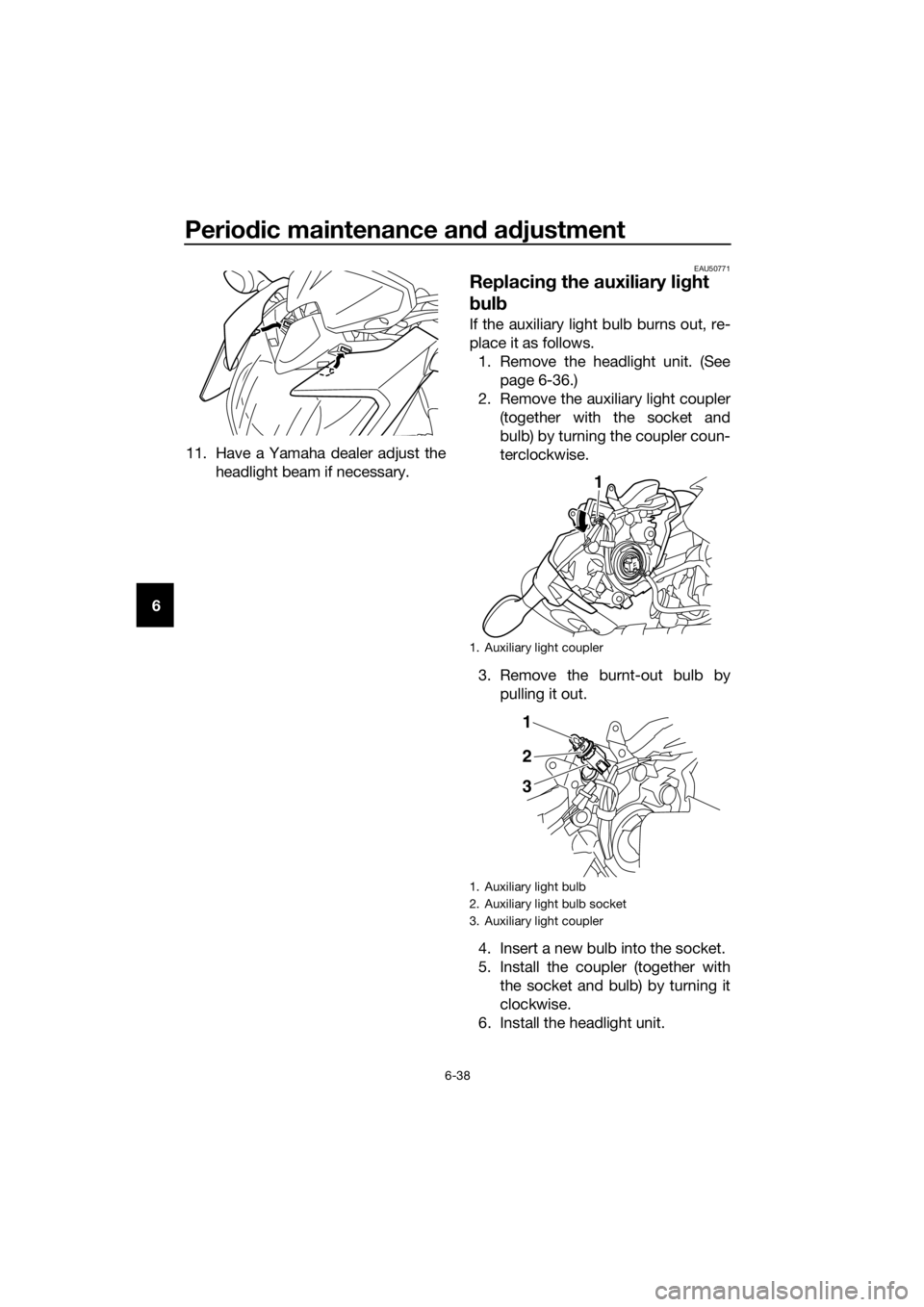

6 11. Have a Yamaha dealer adjust the

headlight beam if necessary.

EAU50771

Replacin g the auxiliary li ght

b ul b

If the auxiliary light bulb burns out, re-

place it as follows.

1. Remove the headlight unit. (See page 6-36.)

2. Remove the auxiliary light coupler (together with the socket and

bulb) by turning the coupler coun-

terclockwise.

3. Remove the burnt-out bulb by pulling it out.

4. Insert a new bulb into the socket.

5. Install the coupler (together with the socket and bulb) by turning it

clockwise.

6. Install the headlight unit.

1. Auxiliary light coupler

1. Auxiliary light bulb

2. Auxiliary light bulb socket

3. Auxiliary light coupler

1

1

2

3

UB61E1E0.book Page 38 Wednesday, October 21, 2015 11:19 AM