YAMAHA XJ6-S 2013 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2013, Model line: XJ6-S, Model: YAMAHA XJ6-S 2013Pages: 102, PDF Size: 2.7 MB

Page 51 of 102

PERIODIC MAINTENANCE AND ADJUSTMENT

6-7

6

EAU18680

TIP●

Air filter This model’s air filter is equipped with a disposable oil-coated paper element, which must not be cleaned with com- pressed air to avoid damaging it.

The air filter element needs to be replaced more frequently when riding in unusually wet or dusty areas.

●

Hydraulic brake service Regularly check and, if necessary, correct the brake fluid level.

Every two years replace the internal components of the brake master cylinders and calipers, and change the brake fluid.

Replace the brake hoses every four years and if cracked or damaged.

U36CE3E0.book Page 7 Wednesday, May 30, 2012 11:51 AM

Page 52 of 102

PERIODIC MAINTENANCE AND ADJUSTMENT

6-8

6

EAU18712

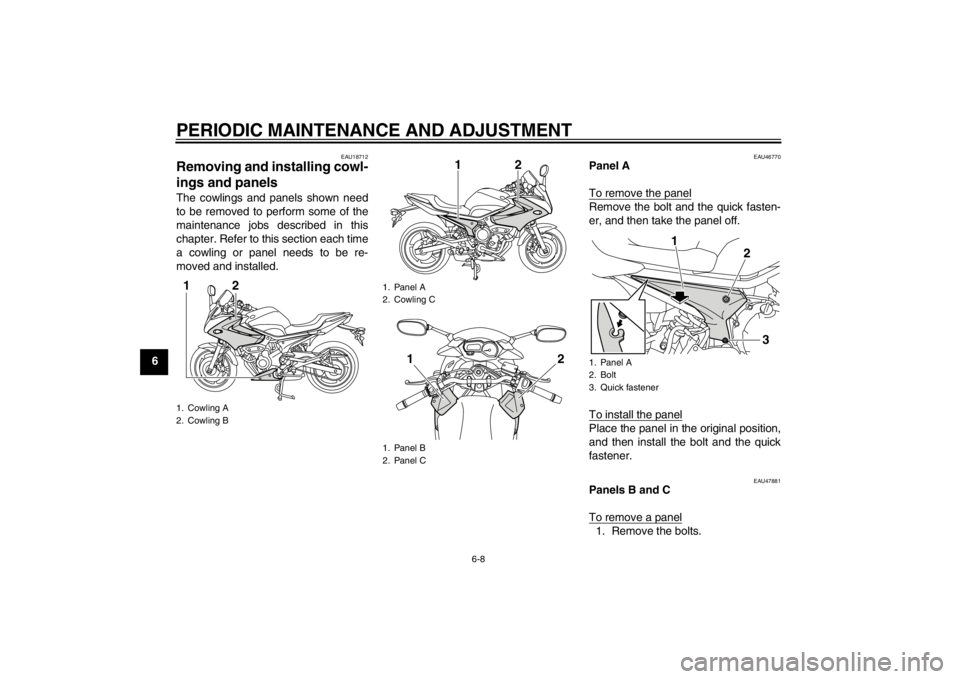

Removing and installing cowl-

ings and panels The cowlings and panels shown need

to be removed to perform some of the

maintenance jobs described in this

chapter. Refer to this section each time

a cowling or panel needs to be re-

moved and installed.

EAU46770

Panel A

To remove the panelRemove the bolt and the quick fasten-

er, and then take the panel off.

To install the panelPlace the panel in the original position,

and then install the bolt and the quick

fastener.

EAU47881

Panels B and C

To remove a panel1. Remove the bolts.

1. Cowling A

2. Cowling B12

1. Panel A

2. Cowling C

1. Panel B

2. Panel C

2

1

2

1

1. Panel A

2. Bolt

3. Quick fastener

1

2

3

U36CE3E0.book Page 8 Wednesday, May 30, 2012 11:51 AM

Page 53 of 102

PERIODIC MAINTENANCE AND ADJUSTMENT

6-9

6

2. Push the panel outwards to un-

hook the projection underneath

the panel, and then pull the panel

off as shown. To install a panel

Place the panel in the original position,

and then install the bolts.

EAU46740

Cowling A

To remove the cowlingRemove the bolts, and then take the

cowling off.

To install the cowling

Place the cowling in the original posi-

tion, and then install the bolts.

EAU47582

Cowlings B and C

To remove a cowling1. Remove panel B (if removing cowl-

ing B) or panel C (if removing cowl-

ing C).

2. Remove the quick fastener and the bolts, and then take the cowl-

ing off.

1. Panel B

2. Bolt

1. Projection

2

1

1

1. Cowling A

2. Bolt

2

2

1

U36CE3E0.book Page 9 Wednesday, May 30, 2012 11:51 AM

Page 54 of 102

PERIODIC MAINTENANCE AND ADJUSTMENT

6-10

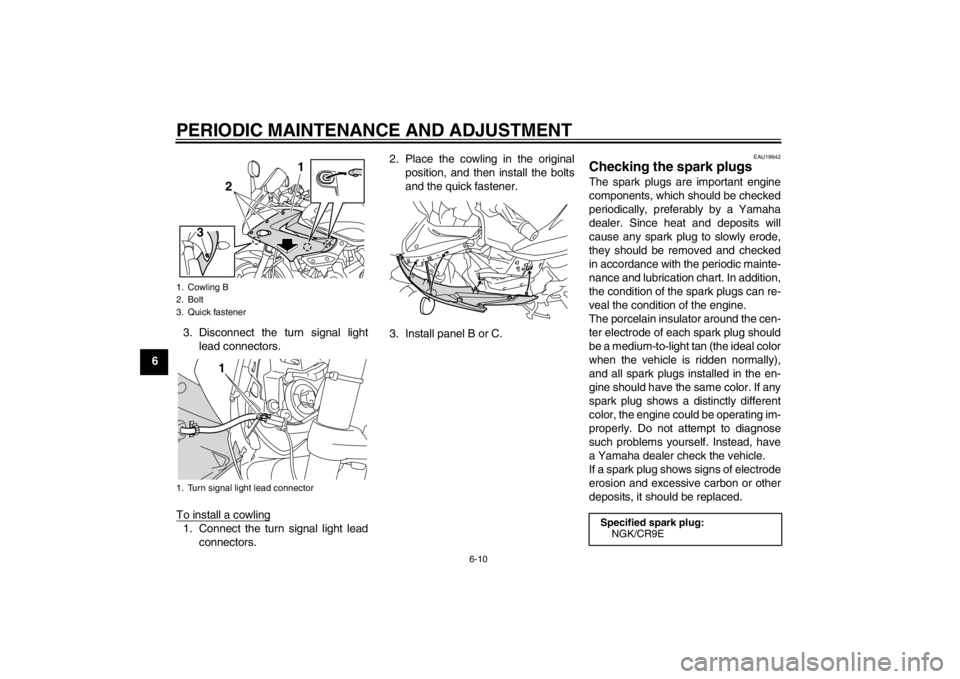

63. Disconnect the turn signal light

lead connectors.

To install a cowling

1. Connect the turn signal light lead connectors. 2. Place the cowling in the original

position, and then install the bolts

and the quick fastener.

3. Install panel B or C.

EAU19642

Checking the spark plugs The spark plugs are important engine

components, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark plug to slowly erode,

they should be removed and checked

in accordance with the periodic mainte-

nance and lubrication chart. In addition,

the condition of the spark plugs can re-

veal the condition of the engine.

The porcelain insulator around the cen-

ter electrode of each spark plug should

be a medium-to-light tan (the ideal color

when the vehicle is ridden normally),

and all spark plugs installed in the en-

gine should have the same color. If any

spark plug shows a distinctly different

color, the engine could be operating im-

properly. Do not attempt to diagnose

such problems yourself. Instead, have

a Yamaha dealer check the vehicle.

If a spark plug shows signs of electrode

erosion and excessive carbon or other

deposits, it should be replaced.

1. Cowling B

2. Bolt

3. Quick fastener

1. Turn signal light lead connector

3

1

21

Specified spark plug: NGK/CR9E

U36CE3E0.book Page 10 Wednesday, May 30, 2012 11:51 AM

Page 55 of 102

PERIODIC MAINTENANCE AND ADJUSTMENT

6-11

6

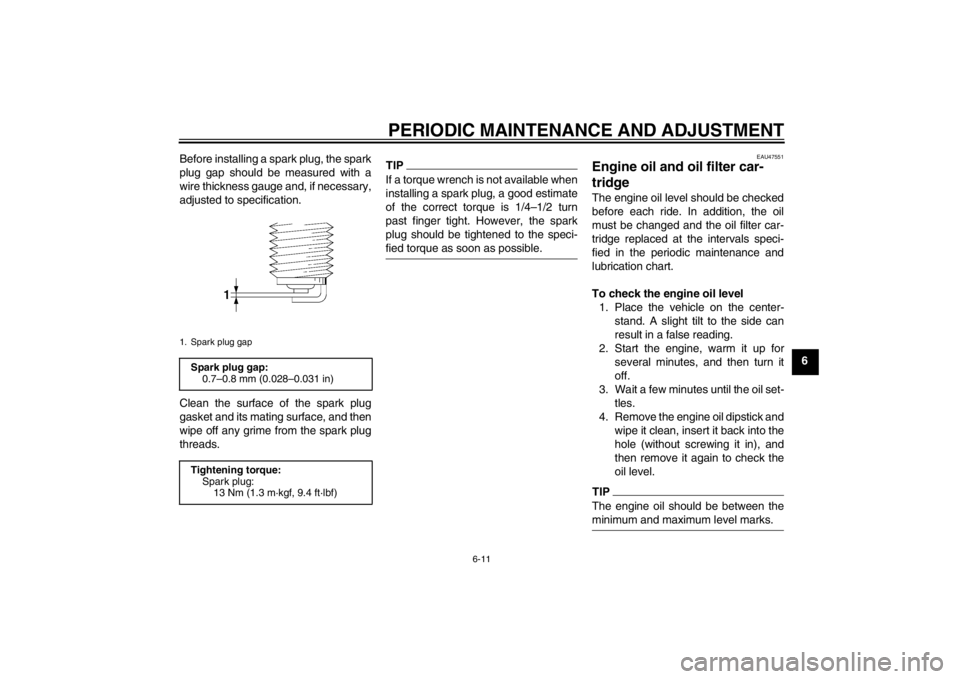

Before installing a spark plug, the spark

plug gap should be measured with a

wire thickness gauge and, if necessary,

adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and then

wipe off any grime from the spark plug

threads.

TIPIf a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn

past finger tight. However, the spark

plug should be tightened to the speci-

fied torque as soon as possible.

EAU47551

Engine oil and oil filter car-

tridge The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

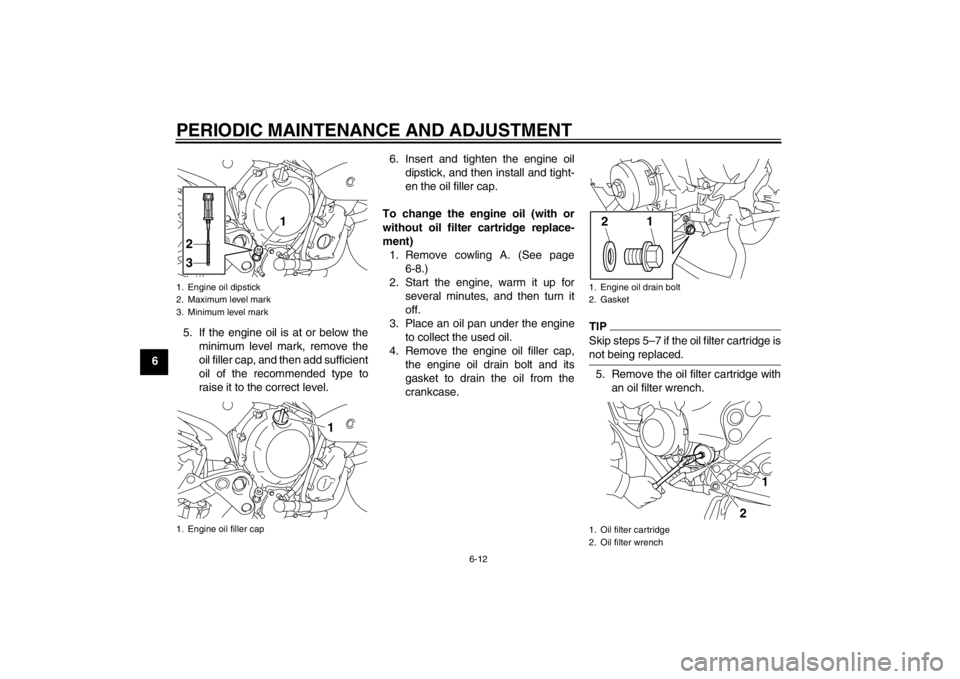

To check the engine oil level

1. Place the vehicle on the center- stand. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes until the oil set- tles.

4. Remove the engine oil dipstick and wipe it clean, insert it back into the

hole (without screwing it in), and

then remove it again to check the

oil level.TIPThe engine oil should be between the

minimum and maximum level marks.

1. Spark plug gapSpark plug gap:0.7–0.8 mm (0.028–0.031 in)

Tightening torque: Spark plug:13 Nm (1.3 m·kgf, 9.4 ft·lbf)

U36CE3E0.book Page 11 Wednesday, May 30, 2012 11:51 AM

Page 56 of 102

PERIODIC MAINTENANCE AND ADJUSTMENT

6-12

65. If the engine oil is at or below the

minimum level mark, remove the

oil filler cap, and then add sufficient

oil of the recommended type to

raise it to the correct level. 6. Insert and tighten the engine oil

dipstick, and then install and tight-

en the oil filler cap.

To change the engine oil (with or

without oil filter cartridge replace-

ment) 1. Remove cowling A. (See page 6-8.)

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Place an oil pan under the engine to collect the used oil.

4. Remove the engine oil filler cap, the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.

TIPSkip steps 5–7 if the oil filter cartridge is

not being replaced.5. Remove the oil filter cartridge withan oil filter wrench.

1. Engine oil dipstick

2. Maximum level mark

3. Minimum level mark

1. Engine oil filler cap

1

2

3

1

1. Engine oil drain bolt

2. Gasket

1. Oil filter cartridge

2. Oil filter wrench

1

2

1

2

U36CE3E0.book Page 12 Wednesday, May 30, 2012 11:51 AM

Page 57 of 102

PERIODIC MAINTENANCE AND ADJUSTMENT

6-13

6

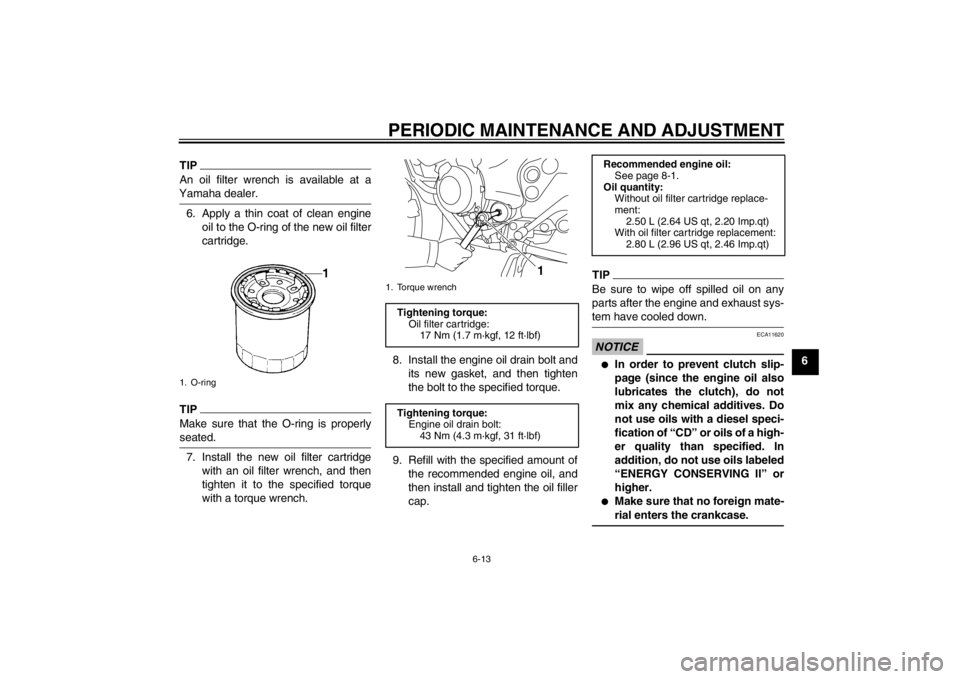

TIPAn oil filter wrench is available at a

Yamaha dealer.6. Apply a thin coat of clean engine oil to the O-ring of the new oil filter

cartridge.TIPMake sure that the O-ring is properly

seated.7. Install the new oil filter cartridgewith an oil filter wrench, and then

tighten it to the specified torque

with a torque wrench. 8. Install the engine oil drain bolt and

its new gasket, and then tighten

the bolt to the specified torque.

9. Refill with the specified amount of the recommended engine oil, and

then install and tighten the oil filler

cap.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA11620

●

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a high-

er quality than specified. In

addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

●

Make sure that no foreign mate-

rial enters the crankcase.

1. O-ring

1. Torque wrench

Tightening torque:Oil filter cartridge:17 Nm (1.7 m·kgf, 12 ft·lbf)

Tightening torque: Engine oil drain bolt:

43 Nm (4.3 m·kgf, 31 ft·lbf)

1

Recommended engine oil:See page 8-1.

Oil quantity: Without oil filter cartridge replace-

ment: 2.50 L (2.64 US qt, 2.20 Imp.qt)

With oil filter cartridge replacement:

2.80 L (2.96 US qt, 2.46 Imp.qt)

U36CE3E0.book Page 13 Wednesday, May 30, 2012 11:51 AM

Page 58 of 102

PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

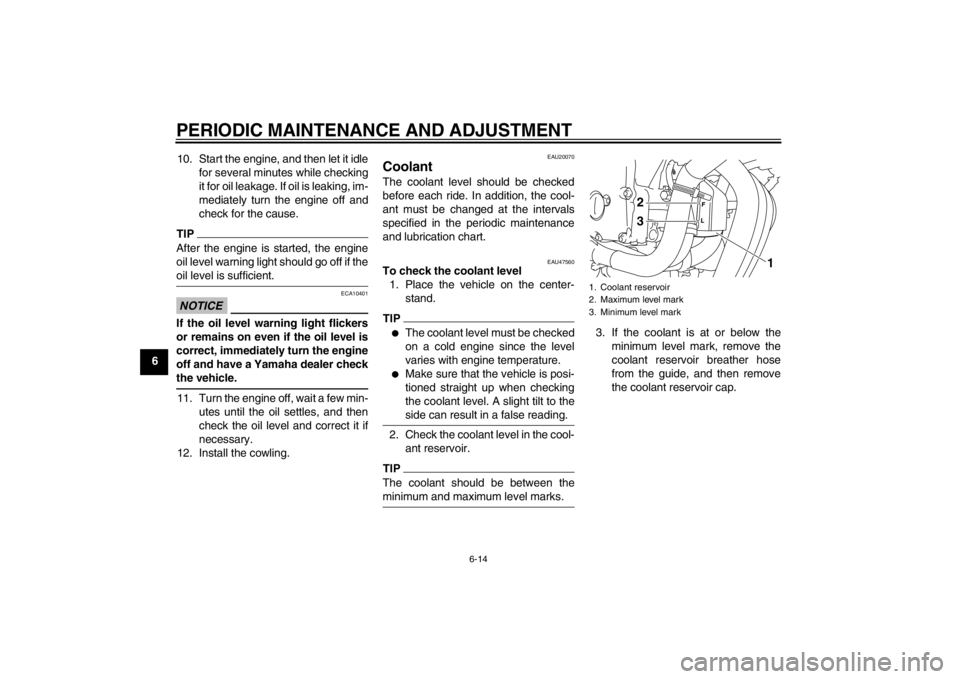

610. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking, im-

mediately turn the engine off and

check for the cause.

TIPAfter the engine is started, the engine

oil level warning light should go off if the

oil level is sufficient.NOTICE

ECA10401

If the oil level warning light flickers

or remains on even if the oil level is

correct, immediately turn the engine

off and have a Yamaha dealer check

the vehicle.11. Turn the engine off, wait a few min-utes until the oil settles, and then

check the oil level and correct it if

necessary.

12. Install the cowling.

EAU20070

Coolant The coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU47560

To check the coolant level 1. Place the vehicle on the center- stand.TIP●

The coolant level must be checked

on a cold engine since the level

varies with engine temperature.

●

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.

2. Check the coolant level in the cool-ant reservoir.TIPThe coolant should be between the

minimum and maximum level marks.

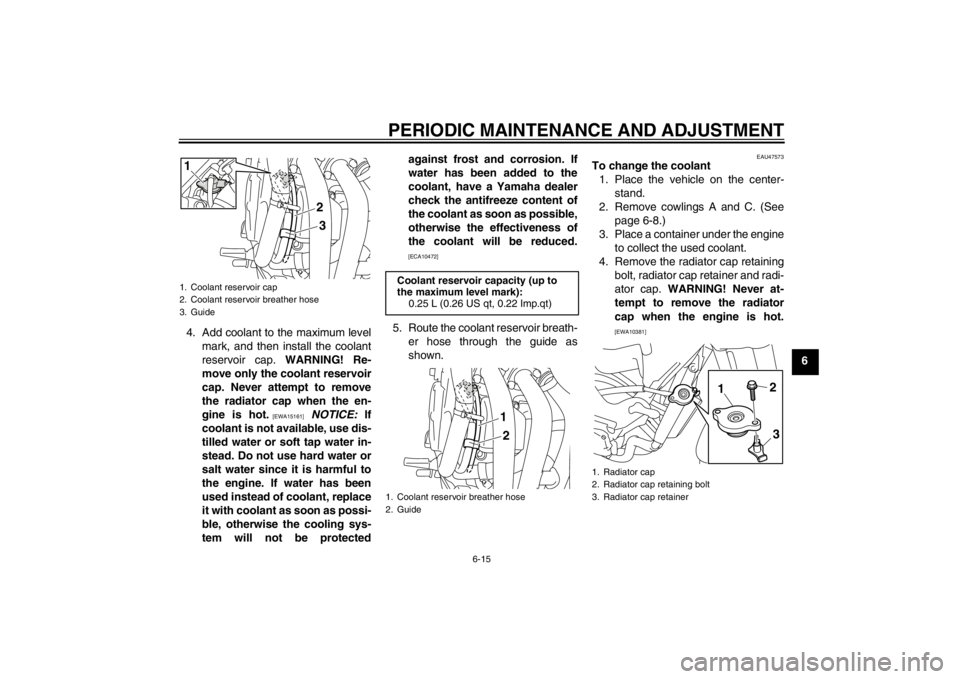

3. If the coolant is at or below theminimum level mark, remove the

coolant reservoir breather hose

from the guide, and then remove

the coolant reservoir cap.1. Coolant reservoir

2. Maximum level mark

3. Minimum level mark

1

2

3

U36CE3E0.book Page 14 Wednesday, May 30, 2012 11:51 AM

Page 59 of 102

PERIODIC MAINTENANCE AND ADJUSTMENT

6-15

6

4. Add coolant to the maximum level

mark, and then install the coolant

reservoir cap. WARNING! Re-

move only the coolant reservoir

cap. Never attempt to remove

the radiator cap when the en-

gine is hot.

[EWA15161]

NOTICE: If

coolant is not available, use dis-

tilled water or soft tap water in-

stead. Do not use hard water or

salt water since it is harmful to

the engine. If water has been

used instead of coolant, replace

it with coolant as soon as possi-

ble, otherwise the cooling sys-

tem will not be protected against frost and corrosion. If

water has been added to the

coolant, have a Yamaha dealer

check the antifreeze content of

the coolant as soon as possible,

otherwise the effectiveness of

the coolant will be reduced.

[ECA10472]

5. Route the coolant reservoir breath-

er hose through the guide as

shown.

EAU47573

To change the coolant1. Place the vehicle on the center- stand.

2. Remove cowlings A and C. (See page 6-8.)

3. Place a container under the engine to collect the used coolant.

4. Remove the radiator cap retaining bolt, radiator cap retainer and radi-

ator cap. WARNING! Never at-

tempt to remove the radiator

cap when the engine is hot.

[EWA10381]

1. Coolant reservoir cap

2. Coolant reservoir breather hose

3. Guide

3

1

2

Coolant reservoir capacity (up to

the maximum level mark):0.25 L (0.26 US qt, 0.22 Imp.qt)

1. Coolant reservoir breather hose

2. Guide

2

1

1. Radiator cap

2. Radiator cap retaining bolt

3. Radiator cap retainer

2

1

3

U36CE3E0.book Page 15 Wednesday, May 30, 2012 11:51 AM

Page 60 of 102

PERIODIC MAINTENANCE AND ADJUSTMENT

6-16

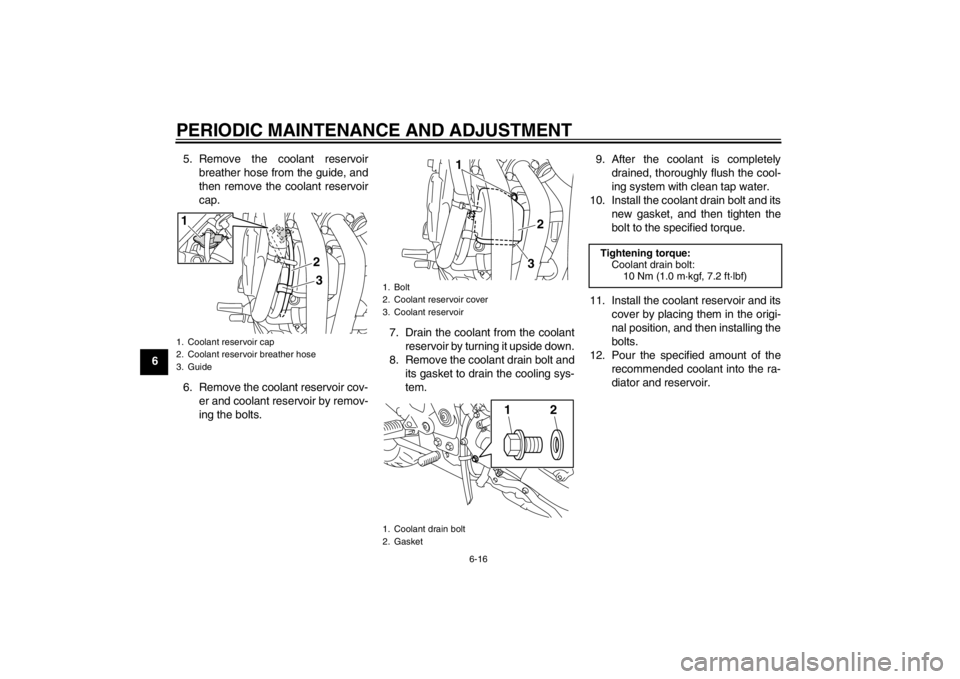

65. Remove the coolant reservoir

breather hose from the guide, and

then remove the coolant reservoir

cap.

6. Remove the coolant reservoir cov- er and coolant reservoir by remov-

ing the bolts. 7. Drain the coolant from the coolant

reservoir by turning it upside down.

8. Remove the coolant drain bolt and its gasket to drain the cooling sys-

tem. 9. After the coolant is completely

drained, thoroughly flush the cool-

ing system with clean tap water.

10. Install the coolant drain bolt and its new gasket, and then tighten the

bolt to the specified torque.

11. Install the coolant reservoir and its cover by placing them in the origi-

nal position, and then installing the

bolts.

12. Pour the specified amount of the recommended coolant into the ra-

diator and reservoir.

1. Coolant reservoir cap

2. Coolant reservoir breather hose

3. Guide

3

1

2

1. Bolt

2. Coolant reservoir cover

3. Coolant reservoir

1. Coolant drain bolt

2. Gasket

23

1

2

1

Tightening torque:

Coolant drain bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

U36CE3E0.book Page 16 Wednesday, May 30, 2012 11:51 AM