wheel YAMAHA XJ6-S 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: XJ6-S, Model: YAMAHA XJ6-S 2014Pages: 104, PDF Size: 2.84 MB

Page 66 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-21

6wei

ght of ri der, passen ger, car-

g o, an d accessories approve d

for this mo del.

WARNING

EWA10512

Never overloa d your vehicle. Opera-

tion of an overloa ded vehicle coul d

cause an acci dent.

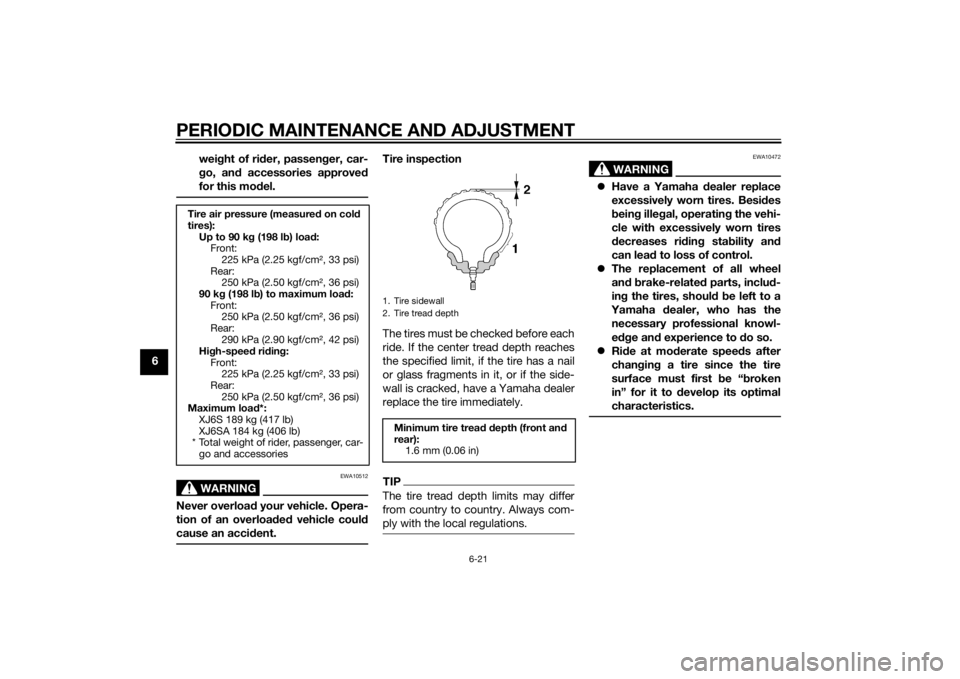

Tire inspection

The tires must be checked before each

ride. If the center tread depth reaches

the specified limit, if the tire has a nail

or glass fragments in it, or if the side-

wall is cracked, have a Yamaha dealer

replace the tire immediately.TIPThe tire tread depth limits may differ

from country to country. Always com-

ply with the local regulations.

WARNING

EWA10472

Have a Yamaha dealer replace

excessively worn tires. Besi des

b ein g ille gal, operatin g the vehi-

cle with excessively worn tires

d ecreases rid ing sta bility an d

can lead to loss of control.

The replacement of all wheel

and b rake-relate d parts, inclu d-

in g the tires, shoul d b e left to a

Yamaha dealer, who has the

necessary professional knowl-

e dge an d experience to do so.

Ride at mo derate speed s after

chan gin g a tire since the tire

surface must first be “ broken

in” for it to develop its optimal

characteristics.

Tire air pressure (measure d on col d

tires): Up to 90 k g (198 l b) loa d:

Front:

225 kPa (2.25 kgf/cm², 33 psi)

Rear: 250 kPa (2.50 kgf/cm², 36 psi)

90 k g (198 l b) to maximum load :

Front: 250 kPa (2.50 kgf/cm², 36 psi)

Rear: 290 kPa (2.90 kgf/cm², 42 psi)

Hi gh-spee d ri din g:

Front: 225 kPa (2.25 kgf/cm², 33 psi)

Rear:

250 kPa (2.50 kgf/cm², 36 psi)

Maximum loa d*:

XJ6S 189 kg (417 lb)

XJ6SA 184 kg (406 lb)

* Total weight of rider, passenger, car- go and accessories

1. Tire sidewall

2. Tire tread depthMinimum tire trea d d epth (front an d

rear): 1.6 mm (0.06 in)

U36CE4E0.book Page 21 Tuesday, July 2, 2013 3:47 PM

Page 67 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-22

6

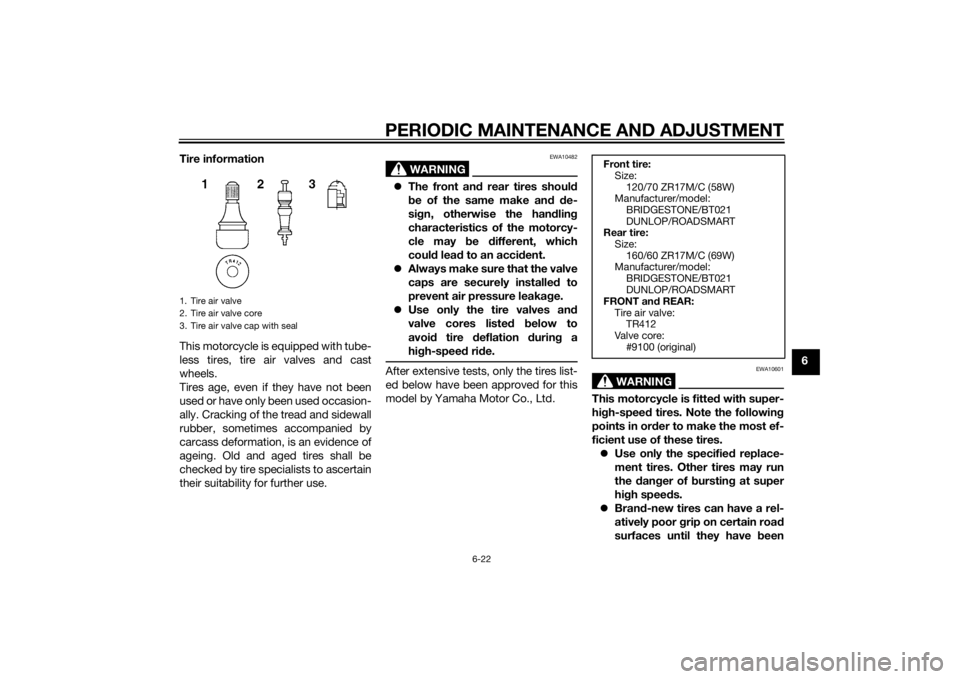

Tire information

This motorcycle is equipped with tube-

less tires, tire air valves and cast

wheels.

Tires age, even if they have not been

used or have only been used occasion-

ally. Cracking of the tread and sidewall

rubber, sometimes accompanied by

carcass deformation, is an evidence of

ageing. Old and aged tires shall be

checked by tire specialists to ascertain

their suitability for further use.

WARNING

EWA10482

The front an d rear tires shoul d

b e of the same make an d d e-

si gn, otherwise the han dlin g

characteristics of the motorcy-

cle may b e different, which

coul d lea d to an acci dent.

Always make sure that the valve

caps are securely installe d to

prevent air pressure leaka ge.

Use only the tire valves an d

valve cores liste d below to

avoi d tire deflation during a

hi gh-spee d ri de.After extensive tests, only the tires list-

ed below have been approved for this

model by Yamaha Motor Co., Ltd.

WARNING

EWA10601

This motorcycle is fitte d with super-

hi gh-spee d tires. Note the followin g

points in or der to make the most ef-

ficient use of these tires. Use only the specified replace-

ment tires. Other tires may run

the dan ger of bursting at super

hi gh spee ds.

Bran d-new tires can have a rel-

atively poor grip on certain roa d

surfaces until they have been

1. Tire air valve

2. Tire air valve core

3. Tire air valve cap with seal

Front tire:

Size:

120/70 ZR17M/C (58W)

Manufacturer/model:

BRIDGESTONE/BT021

DUNLOP/ROADSMART

Rear tire:

Size: 160/60 ZR17M/C (69W)

Manufacturer/model:

BRIDGESTONE/BT021

DUNLOP/ROADSMART

FRONT and REAR:

Tire air valve: TR412

Valve core:

#9100 (original)

U36CE4E0.book Page 22 Tuesday, July 2, 2013 3:47 PM

Page 68 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-23

6“

b roken in”. Therefore, it is a d-

visa ble before doin g any hi gh-

speed ridin g to ri de conserva-

tively for approximately 100 km

(60 mi) after installin g a new tire.

The tires must b e warmed up

b efore a hi gh-spee d run.

Always a djust the tire air pres-

sure accor din g to the operating

con ditions.

EAU21963

Cast wheelsTo maximize the performance, durabil-

ity, and safe operation of your vehicle,

note the following points regarding the

specified wheels.

The wheel rims should be

checked for cracks, bends, warp-

age or other damage before each

ride. If any damage is found, have

a Yamaha dealer replace the

wheel. Do not attempt even the

smallest repair to the wheel. A de-

formed or cracked wheel must be

replaced.

The wheel should be balanced

whenever either the tire or wheel

has been changed or replaced. An

unbalanced wheel can result in

poor performance, adverse han-

dling characteristics, and a short-

ened tire life.

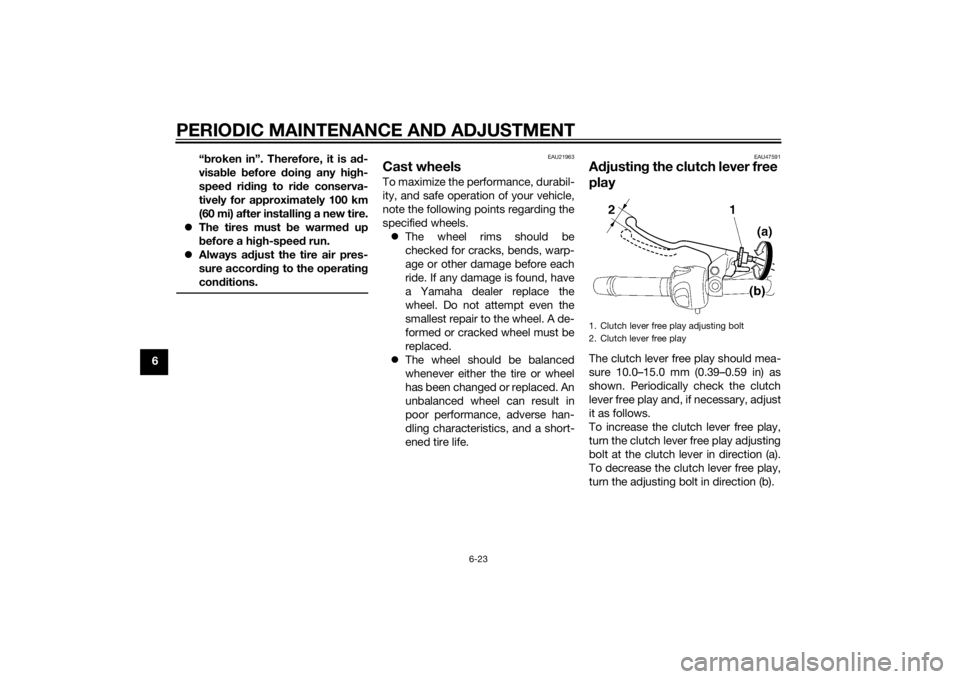

EAU47591

Adjustin g the clutch lever free

playThe clutch lever free play should mea-

sure 10.0–15.0 mm (0.39–0.59 in) as

shown. Periodically check the clutch

lever free play and, if necessary, adjust

it as follows.

To increase the clutch lever free play,

turn the clutch lever free play adjusting

bolt at the clutch lever in direction (a).

To decrease the clutch lever free play,

turn the adjusting bolt in direction (b).1. Clutch lever free play adjusting bolt

2. Clutch lever free play

U36CE4E0.book Page 23 Tuesday, July 2, 2013 3:47 PM

Page 73 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-28

6

EAU22733

Changin g the brake flui dHave a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the master cylinders and calipers as

well as the brake hoses replaced at the

intervals listed below or whenever they

are damaged or leaking.

Oil seals: Replace every two

years.

Brake hoses: Replace every four

years.

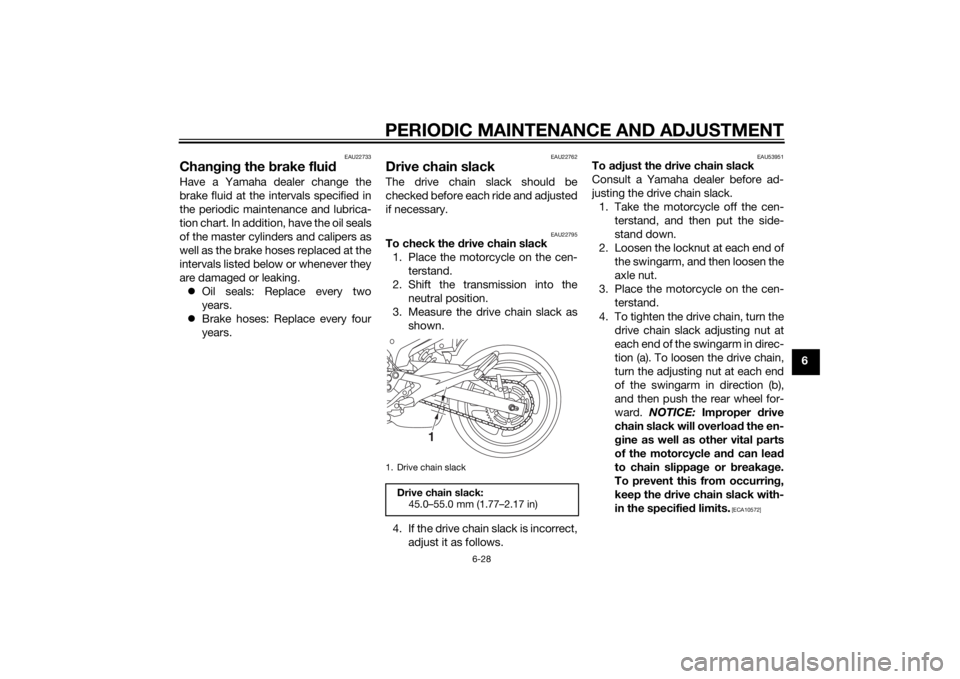

EAU22762

Drive chain slackThe drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU22795

To check the drive chain slack

1. Place the motorcycle on the cen- terstand.

2. Shift the transmission into the neutral position.

3. Measure the drive chain slack as shown.

4. If the drive chain slack is incorrect, adjust it as follows.

EAU53951

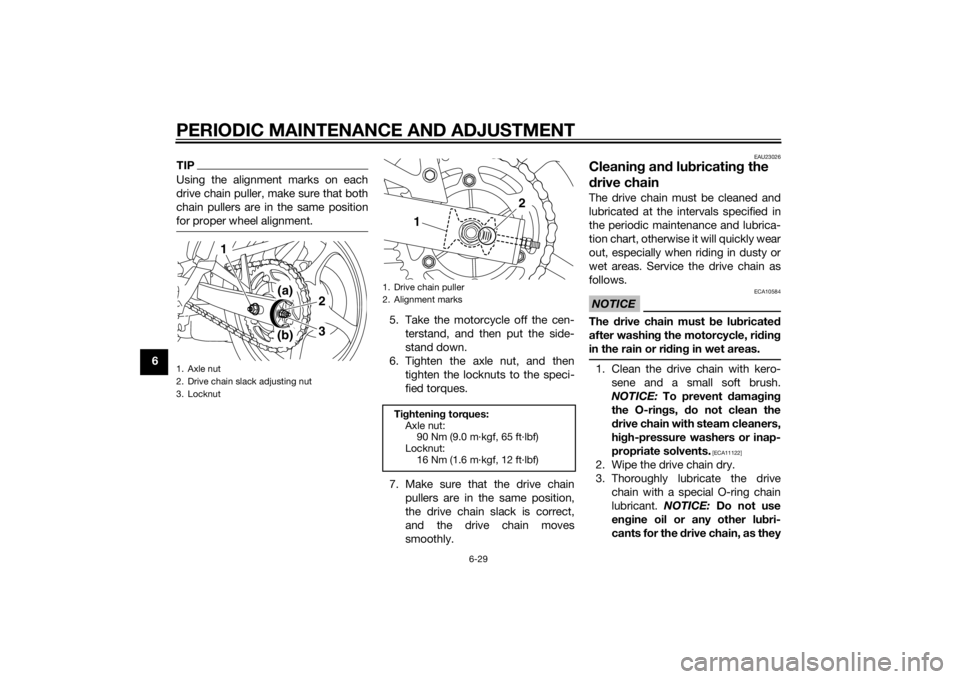

To a djust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Take the motorcycle off the cen- terstand, and then put the side-

stand down.

2. Loosen the locknut at each end of the swingarm, and then loosen the

axle nut.

3. Place the motorcycle on the cen- terstand.

4. To tighten the drive chain, turn the drive chain slack adjusting nut at

each end of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting nut at each end

of the swingarm in direction (b),

and then push the rear wheel for-

ward. NOTICE: Improper d rive

chain slack will overloa d the en-

g ine as well as other vital parts

of the motorcycle an d can lead

to chain slippa ge or b reakag e.

To prevent this from occurrin g,

keep the d rive chain slack with-

in the specifie d limits.

[ECA10572]

1. Drive chain slack

Drive chain slack:

45.0–55.0 mm (1.77–2.17 in)

1

U36CE4E0.book Page 28 Tuesday, July 2, 2013 3:47 PM

Page 74 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-29

6

TIPUsing the alignment marks on each

drive chain puller, make sure that both

chain pullers are in the same position

for proper wheel alignment.

5. Take the motorcycle off the cen-terstand, and then put the side-

stand down.

6. Tighten the axle nut, and then tighten the locknuts to the speci-

fied torques.

7. Make sure that the drive chain pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23026

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must be lu bricated

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Clean the drive chain with kero-

sene and a small soft brush.

NOTICE: To prevent d amaging

the O-ring s, do not clean the

d rive chain with steam cleaners,

hi gh-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

en gine oil or any other lu bri-

cants for the drive chain, as they

1. Axle nut

2. Drive chain slack adjusting nut

3. Locknut

3

1

2

(a)(b)

1. Drive chain puller

2. Alignment marksTi ghtenin g torques:

Axle nut: 90 Nm (9.0 m·kgf, 65 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

1

2

U36CE4E0.book Page 29 Tuesday, July 2, 2013 3:47 PM

Page 79 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-34

6

EAU45512

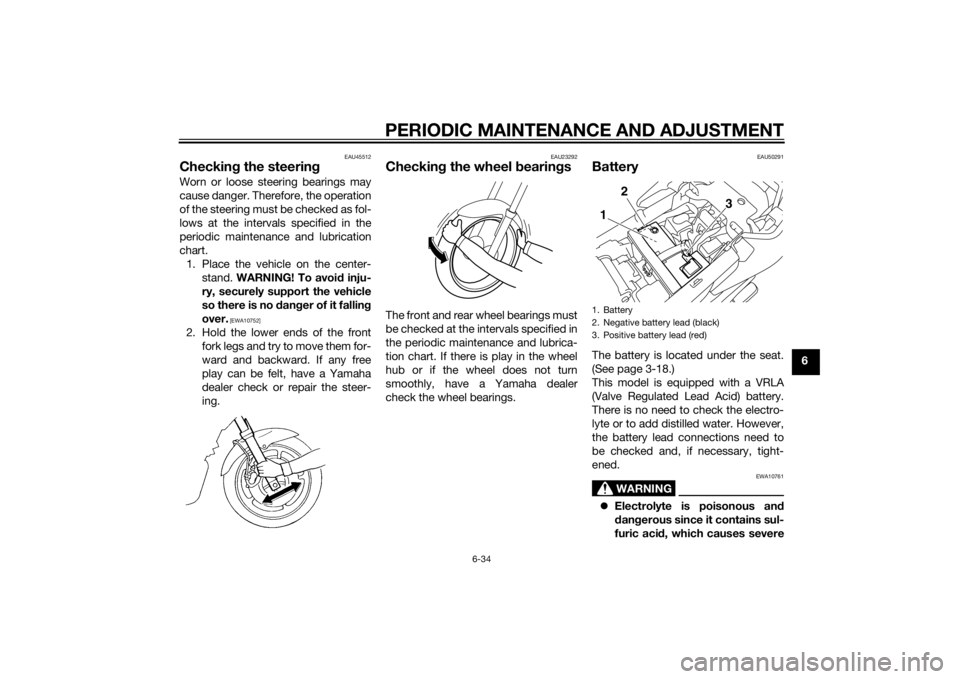

Checking the steerin gWorn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

chart.

1. Place the vehicle on the center- stand. WARNING! To avoi d inju-

ry, securely support the vehicle

so there is no d anger of it fallin g

over.

[EWA10752]

2. Hold the lower ends of the front fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steer-

ing.

EAU23292

Checkin g the wheel bearin gsThe front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer

check the wheel bearings.

EAU50291

BatteryThe battery is located under the seat.

(See page 3-18.)

This model is equipped with a VRLA

(Valve Regulated Lead Acid) battery.

There is no need to check the electro-

lyte or to add distilled water. However,

the battery lead connections need to

be checked and, if necessary, tight-

ened.

WARNING

EWA10761

Electrolyte is poisonous an d

d an gerous since it contains sul-

furic aci d, which causes severe1. Battery

2. Negative battery lead (black)

3. Positive battery lead (red)1 2

3

U36CE4E0.book Page 34 Tuesday, July 2, 2013 3:47 PM

Page 86 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-41

6

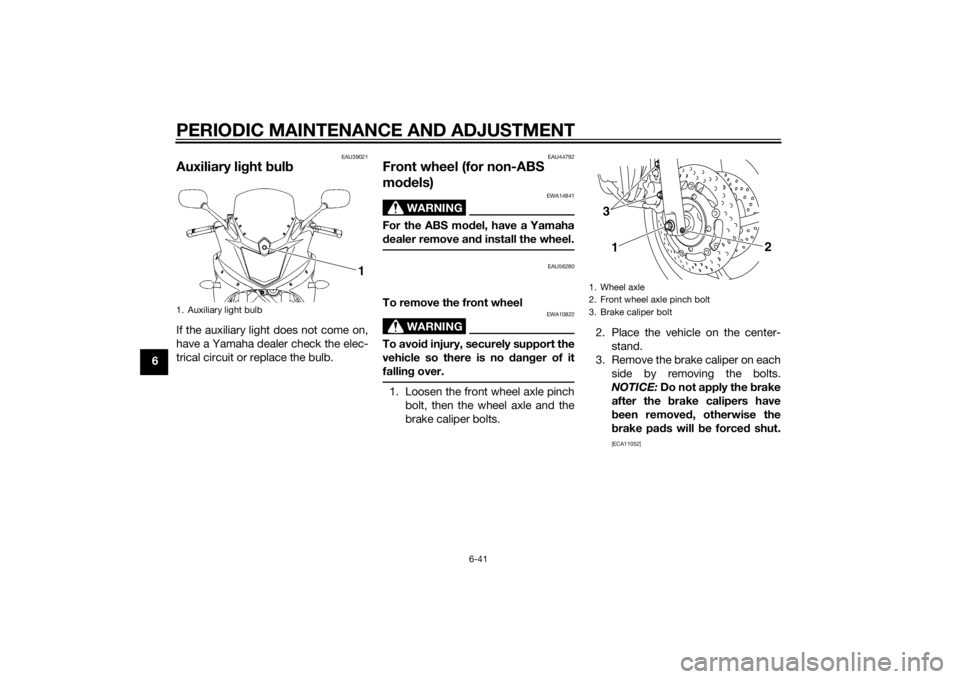

EAU39021

Auxiliary light bul bIf the auxiliary light does not come on,

have a Yamaha dealer check the elec-

trical circuit or replace the bulb.

EAU44792

Front wheel (for non-ABS

mo dels)

WARNING

EWA14841

For the ABS mo del, have a Yamaha

d ealer remove an d install the wheel.

EAU56280

To remove the front wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Loosen the front wheel axle pinch

bolt, then the wheel axle and the

brake caliper bolts. 2. Place the vehicle on the center-

stand.

3. Remove the brake caliper on each side by removing the bolts.

NOTICE: Do not apply the b rake

after the brake calipers have

b een removed , otherwise the

b rake pa ds will b e forced shut.

[ECA11052]

1. Auxiliary light bulb

1

1. Wheel axle

2. Front wheel axle pinch bolt

3. Brake caliper bolt

13

2

U36CE4E0.book Page 41 Tuesday, July 2, 2013 3:47 PM

Page 87 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-42

6

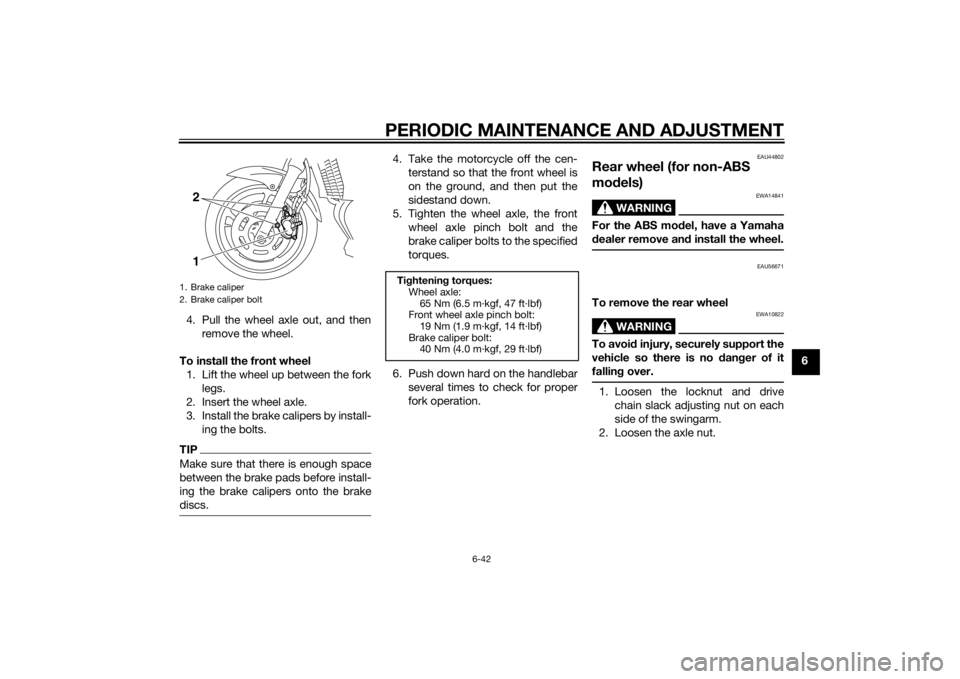

4. Pull the wheel axle out, and then

remove the wheel.

To install the front wheel 1. Lift the wheel up between the fork legs.

2. Insert the wheel axle.

3. Install the brake calipers by install- ing the bolts.

TIPMake sure that there is enough space

between the brake pads before install-

ing the brake calipers onto the brake

discs.

4. Take the motorcycle off the cen-terstand so that the front wheel is

on the ground, and then put the

sidestand down.

5. Tighten the wheel axle, the front wheel axle pinch bolt and the

brake caliper bolts to the specified

torques.

6. Push down hard on the handlebar several times to check for proper

fork operation.

EAU44802

Rear wheel (for non-ABS

mo dels)

WARNING

EWA14841

For the ABS mo del, have a Yamaha

d ealer remove an d install the wheel.

EAU56671

To remove the rear wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Loosen the locknut and drive

chain slack adjusting nut on each

side of the swingarm.

2. Loosen the axle nut.

1. Brake caliper

2. Brake caliper bolt

1 2

Ti ghtenin g torques:

Wheel axle: 65 Nm (6.5 m·kgf, 47 ft·lbf)

Front wheel axle pinch bolt:

19 Nm (1.9 m·kgf, 14 ft·lbf)

Brake caliper bolt: 40 Nm (4.0 m·kgf, 29 ft·lbf)

U36CE4E0.book Page 42 Tuesday, July 2, 2013 3:47 PM

Page 88 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-43

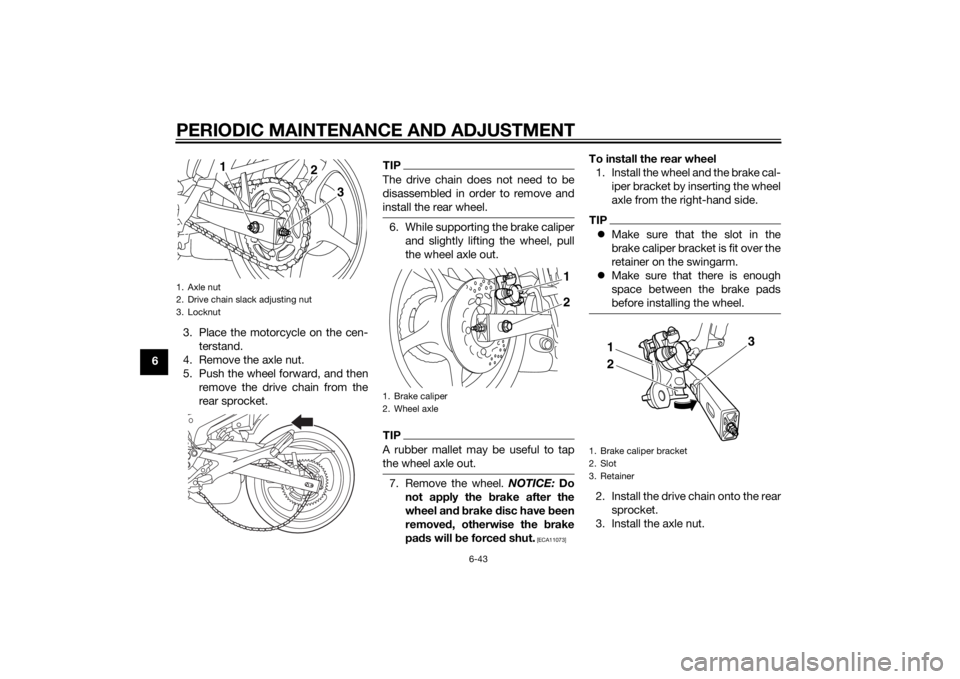

63. Place the motorcycle on the cen-

terstand.

4. Remove the axle nut.

5. Push the wheel forward, and then remove the drive chain from the

rear sprocket.

TIPThe drive chain does not need to be

disassembled in order to remove and

install the rear wheel.6. While supporting the brake caliperand slightly lifting the wheel, pull

the wheel axle out.TIPA rubber mallet may be useful to tap

the wheel axle out.7. Remove the wheel. NOTICE: Do

not apply the b rake after the

wheel an d b rake disc have b een

remove d, otherwise the brake

pa ds will be force d shut.

[ECA11073]

To install the rear wheel

1. Install the wheel and the brake cal- iper bracket by inserting the wheel

axle from the right-hand side.TIPMake sure that the slot in the

brake caliper bracket is fit over the

retainer on the swingarm.

Make sure that there is enough

space between the brake pads

before installing the wheel.2. Install the drive chain onto the rear

sprocket.

3. Install the axle nut.

1. Axle nut

2. Drive chain slack adjusting nut

3. Locknut

1

3

2

1. Brake caliper

2. Wheel axle

1

2

1. Brake caliper bracket

2. Slot

3. Retainer

2 31

U36CE4E0.book Page 43 Tuesday, July 2, 2013 3:47 PM

Page 89 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-44

6

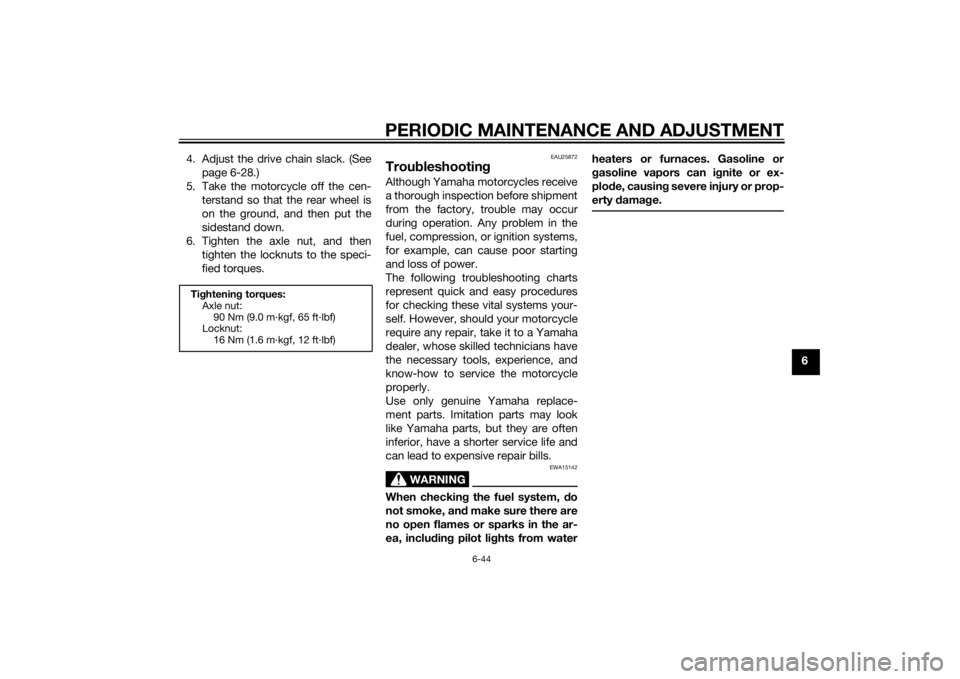

4. Adjust the drive chain slack. (See

page 6-28.)

5. Take the motorcycle off the cen- terstand so that the rear wheel is

on the ground, and then put the

sidestand down.

6. Tighten the axle nut, and then tighten the locknuts to the speci-

fied torques.

EAU25872

Trou bleshootin gAlthough Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition systems,

for example, can cause poor starting

and loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWA15142

When checkin g the fuel system, d o

not smoke, an d make sure there are

no open flames or sparks in the ar-

ea, inclu din g pilot li ghts from water heaters or furnaces. Gasoline or

g

asoline vapors can i gnite or ex-

plo de, causin g severe injury or prop-

erty damag e.

Tightenin g torques:

Axle nut: 90 Nm (9.0 m·kgf, 65 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

U36CE4E0.book Page 44 Tuesday, July 2, 2013 3:47 PM