wheel YAMAHA XJ600S 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: XJ600S, Model: YAMAHA XJ600S 2000Pages: 101, PDF Size: 19.23 MB

Page 80 of 101

R

6-32

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9156_XJ600SN-E6/English/E-6.frame

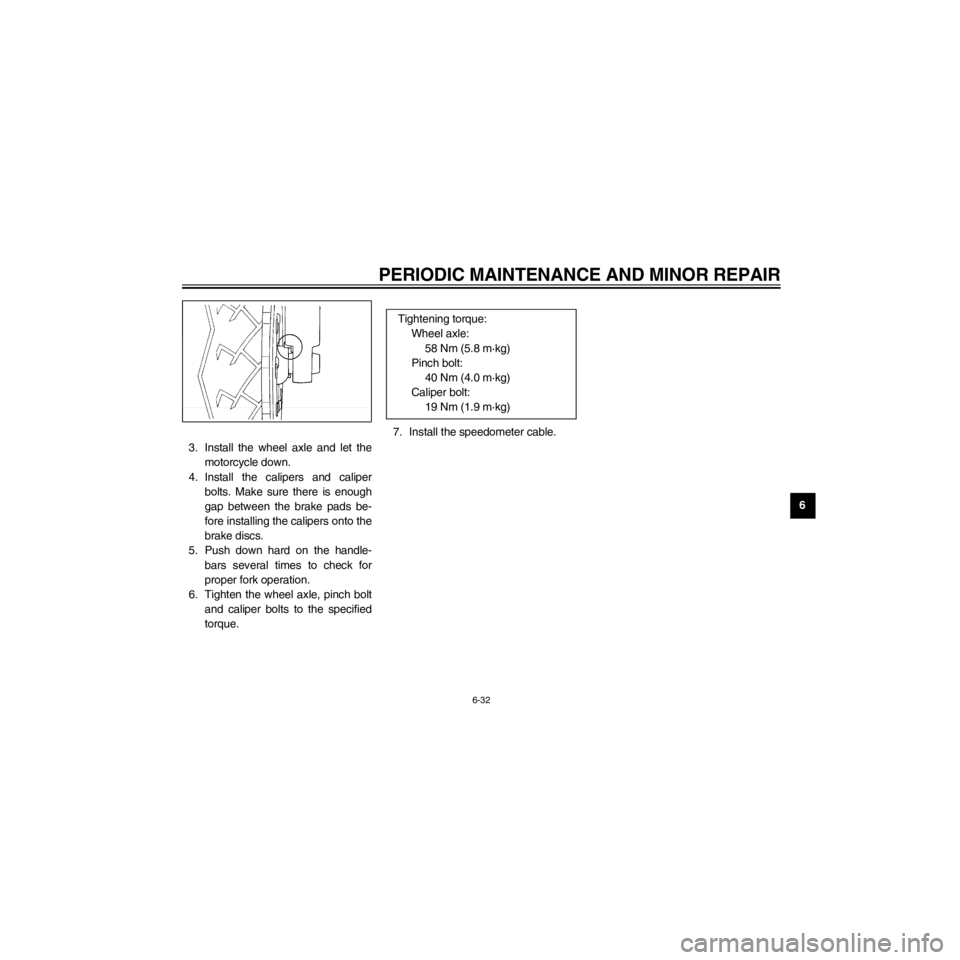

3. Install the wheel axle and let the

motorcycle down.

4. Install the calipers and caliper

bolts. Make sure there is enough

gap between the brake pads be-

fore installing the calipers onto the

brake discs.

5. Push down hard on the handle-

bars several times to check for

proper fork operation.

6. Tighten the wheel axle, pinch bolt

and caliper bolts to the specified

torque.7. Install the speedometer cable.Tightening torque:

Wheel axle:

58 Nm (5.8 mákg)

Pinch bolt:

40 Nm (4.0 mákg)

Caliper bolt:

19 Nm (1.9 mákg)

Page 81 of 101

L

6-33

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9156_XJ600SN-E6/English/E-6.frame

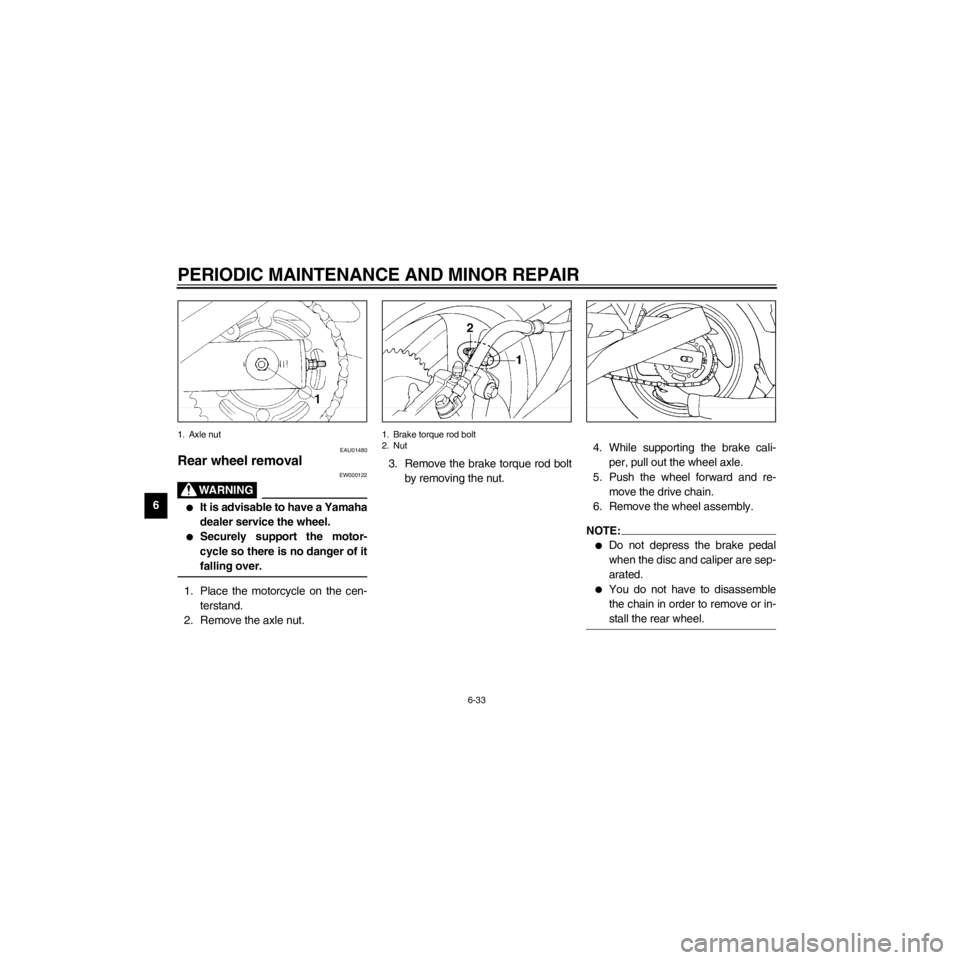

1. Axle nut

EAU01480

Rear wheel removal

EW000122

lIt is advisable to have a Yamaha

dealer service the wheel.

lSecurely support the motor-

cycle so there is no danger of it

falling over.

1. Place the motorcycle on the cen-

terstand.

2. Remove the axle nut.

1. Brake torque rod bolt

2. Nut

3. Remove the brake torque rod bolt

by removing the nut.

4. While supporting the brake cali-

per, pull out the wheel axle.

5. Push the wheel forward and re-

move the drive chain.

6. Remove the wheel assembly.

NOTE:

lDo not depress the brake pedal

when the disc and caliper are sep-

arated.

lYou do not have to disassemble

the chain in order to remove or in-

stall the rear wheel.

Page 82 of 101

R

6-34

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9156_XJ600SN-E6/English/E-6.frame

EAU01468

Rear wheel installation

1. Install the wheel assembly and in-

sert the axle.

2. Install and adjust the drive chain.

(See page 6-20 for details about

adjusting the drive chain slack.)

3. Install the axle nut.

4. Install the caliper and caliper bolts.

Make sure there is enough gap

between the brake pads before in-

stalling the caliper onto the brake

disc.

5. Take the motorcycle off the cen-

terstand.

6. Tighten the axle nut and brake

torque rod bolt to the specified

torques.

Tightening torque:

Axle nut:

105 Nm (10.5 mákg)

Brake torque rod bolt:

23 Nm (2.3 mákg)

EAU01008

Troubleshooting

Although Yamaha motorcycles receive

a rigid inspection before shipment from

the factory, trouble may occur during

operation.

Any problem in the fuel, compression,

or ignition systems can cause poor

starting and loss of power. The trouble-

shooting chart describes a quick, easy

procedure for making checks.

If your motorcycle requires any repair,

bring it to a Yamaha dealer. The skilled

technicians at a Yamaha dealership

have the tools, experience, and know-

how to properly service your motor-

cycle. Use only genuine Yamaha parts

on your motorcycle. Imitation parts may

look like Yamaha parts, but they are of-

ten inferior. Consequently, they have a

shorter service life and can lead to ex-

pensive repair bills.

Page 85 of 101

L

7-1

MOTORCYCLE CARE AND STORAGE

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9156_XJ600SN-E6/English/E-7.frame

Care

The exposure of its technology makes

a motorcycle charming but also vul-

nerable. Although high-quality compo-

nents are used, they are not all rust-

resistant. While a rusty exhaust pipe

may remain unnoticed on a car, it

does look unattractive on a motor-

cycle. Frequent and proper care, how-

ever, will keep your motorcycle

looking good, extend its life and main-

tain its performance. Moreover, the

warranty states that the vehicle must

be properly taken care of. For all these

reasons, it is recommended that you

observe the following cleaning and

storing precautions.Before cleaning

1. Cover up the muffler outlets with

plastic bags.

2. Make sure that all caps and covers

as well as all electrical couplers

and connectors, including the

spark plug caps, are tightly in-

stalled.

3. Remove extremely stubborn dirt,

like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such prod-

ucts onto seals, gaskets, sprock-

ets, the drive chain and wheel

axles. Always rinse the dirt and

degreaser off with water.CleaningAfter normal use

Remove dirt with warm water, a neutral

detergent and a soft clean sponge,

then rinse with plenty of clean water.

Use a tooth or bottle brush for hard-to-

reach parts. Tougher dirt and insects

will come off more easily if the area is

covered with a wet cloth for a few min-

utes before cleaning.

EAU01517

Page 86 of 101

R

7-2

MOTORCYCLE CARE AND STORAGE

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9156_XJ600SN-E6/English/E-7.frame

ECA00010

CAUTION:

lAvoid using strong acidic wheel

cleaners, especially on spoked

wheels. If you do use such

products for hard-to-remove

dirt, do not leave it on any long-

er than instructed, then thor-

oughly rinse it off with water,

immediately dry the area and

apply a corrosion protection

spray.

lImproper cleaning can damage

windshields, cowlings, panels

and other plastic parts. Use

only a soft, clean cloth or

sponge with mild detergent and

water to clean plastic.

lDo not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

cleaning products, solvent or

thinner, fuel (gasoline), rust re-

movers or inhibitors, brake flu-

id, antifreeze or electrolyte.

lDo not use high-pressure wash-

ers or steam-jet cleaners since

they cause water seepage and

deterioration in the following ar-

eas: seals (of wheel bearings,

swingarm bearings, forks and

brakes), electric components

(couplers, connectors, instru-

ments, switches and lights),

breather hoses and vents.

lFor motorcycles equipped with

a windshield: Do not use strong

cleaners or hard sponges as

they will cause dulling or

scratching. Some cleaning

compounds for plastic may

leave scratches on the wind-

shield. Test the product on a

small hidden part of the wind-

shield to make sure they do not

leave any marks. If the wind-

shield is scratched, use a quali-

ty plastic polishing compound

after washing.

After riding in the rain, near the sea or

on salt-sprayed roads

Since sea salt or salt sprayed on the

roads in the winter are extremely corro-

sive in combination with water, carry

out the following steps after each ride

in the rain, near the sea or on salt-

sprayed roads. (Salt sprayed in the

winter may remain on the roads well

into spring.)

Page 89 of 101

L

7-5

MOTORCYCLE CARE AND STORAGE

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9156_XJ600SN-E6/English/E-7.frame

c. Install the spark plug caps onto the

spark plugs and place the spark

plugs on the cylinder head so that

the electrodes are grounded. (This

will limit sparking during the next

step.)

d. Turn the engine over several times

with the starter. (This will coat the

cylinder walls with oil.)

e. Remove the spark plug caps from

the spark plugs, install the spark

plugs and then the spark plug

caps.

EWA00003

When turning the engine over, be

sure to ground the spark plug elec-

trodes to prevent damage or injury

from sparking.

6. Lubricate all control cables and

the pivoting points of all levers and

pedals as well as of the side-

stand/centerstand.7. Check and, if necessary, correct

the tire air pressure, then raise the

motorcycle so that both of its

wheels are off the ground. Alterna-

tively, turn the wheels a little every

month in order to prevent the tires

from becoming degraded in one

spot.

8. Cover up the muffler outlets with

plastic bags to prevent moisture

from entering.

9. Remove the battery and fully

charge it. Store it in a cool, dry

place and recharge it once a

month. Do not store the battery in

an excessively cold or warm place

(less than 0ûC or more than 30ûC).

For more information, see ÒBattery

storageÓ in the chapter ÒPERIOD-

IC MAINTENANCE AND MINOR

REPAIRSÓ.

NOTE:

Make any necessary repairs before

storing the motorcycle.

Page 91 of 101

L

8-1

SPECIFICATIONS

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9156_XJ600SN-E6/English/E-8.frame

Specifications

Model XJ600S / XJ600N

Dimensions

Overall length 2,170 mm

Overall width 735 mm

Overall height

XJ600S 1,205 mm

XJ600N 1,090 mm

Seat hight 770 mm

Wheelbase 1,445 mm

Ground clearance 150 mm

Minimum turning radius 2,700 mm

Basic weight (with oil and full fuel tank)

XJ600S 213 kg

XJ600N 210 kg

Engine

Engine type Air-cooled 4-stroke, DOHC

Cylinder arrangement Forward-inclined parallel

4-cyclinder

Displacement 598 cm

3

Bore´ Stroke 58.5 ´ 55.7 mm

Compression ratio 10:1

Starting system Electric starter

Lubrication system Wet sump

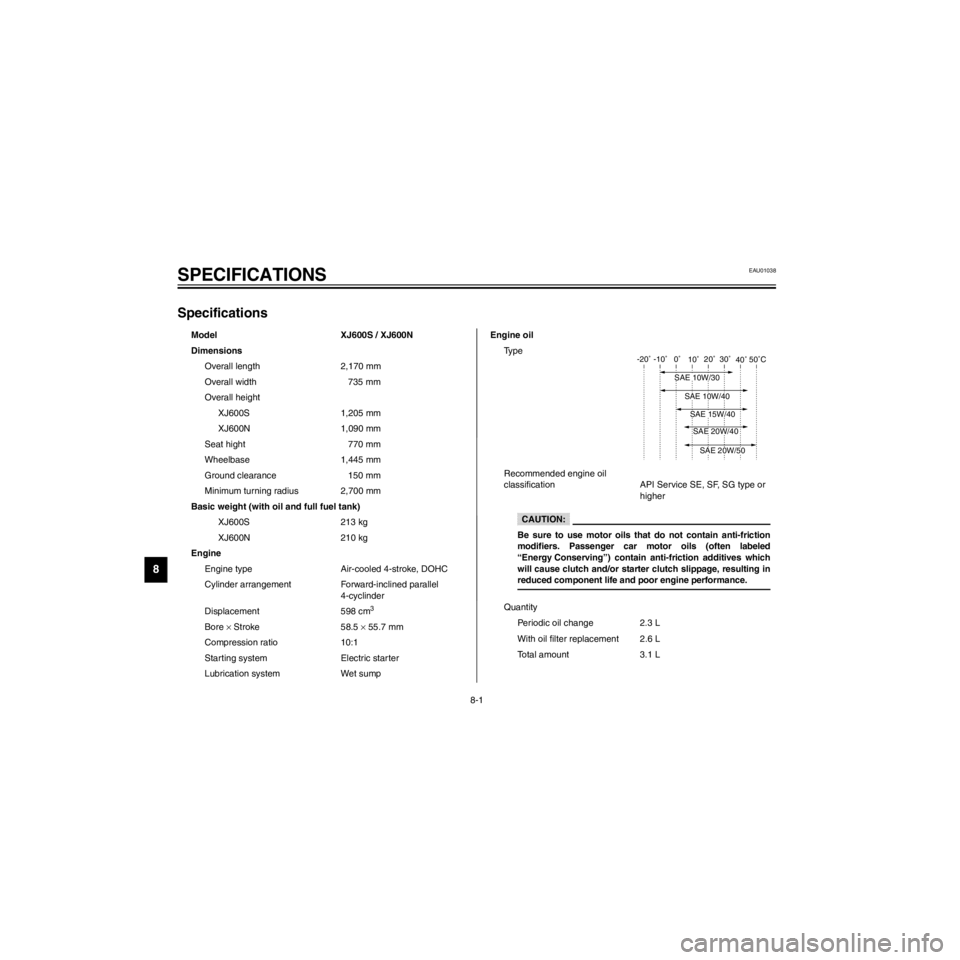

Engine oil

Ty p e

Recommended engine oil

classiÞcation API Service SE, SF, SG type or

higher

Quantity

Periodic oil change 2.3 L

With oil Þlter replacement 2.6 L

Total amount 3.1 L

-20û -10û 0û

10û20û 30û

40û50ûC

SAE 10W/30

SAE 15W/40

SAE 20W/40

SAE 20W/50

SAE 10W/40

CAUTION:

Be sure to use motor oils that do not contain anti-friction

modifiers. Passenger car motor oils (often labeled

ÒEnergy ConservingÓ) contain anti-friction additives which

will cause clutch and/or starter clutch slippage, resulting in

reduced component life and poor engine performance.

EAU01038

Page 93 of 101

L

8-3

SPECIFICATIONS

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9156_XJ600SN-E6/English/E-8.frame

Maximum load*

XJ600S 184 kg

XJ600N 187 kg

Air pressure (cold tire)

Up to 90 kg load*

Front 200 kPa (2.00 kg/cm

2, 2.00 bar)

Rear 225 kPa (2.25 kg/cm

2, 2.25 bar)

90 kg load ~ maximum load*

Front 200 kPa (2.00 kg/cm

2, 2.00 bar)

Rear 250 kPa (2.50 kg/cm

2, 2.50 bar)

High speed riding

Front 200 kPa (2.00 kg/cm

2, 2.00 bar)

Rear 250 kPa (2.50 kg/cm

2, 2.50 bar)

* Load is total weight of cargo, rider, passenger and accessories.

Wheels

Front

Ty p e C a s t

Size 17 ´ MT 2.50

Rear

Ty p e C a s t

Size 18 ´ MT 3.50Brakes

Front

Type Dual disc brake

Operation Right hand operation

Fluid DOT 4 or DOT 3

Rear

Type Single disc brake

Operation Right foot operation

Fluid DOT 4 or DOT 3

Suspension

Front

Type Telescopic fork

Rear

Type Swingarm (monocross suspension)

Shock absorbers

Front Coil spring/oil damper

Rear Coil spring/gas-oil damper

Wheel travel

Front 140 mm

Rear 110 mm

Electrical systems

Ignition system T.C.I. (digital)

Page 99 of 101

L

INDEX

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9156_XJ600SN-E6/English/EEIX.frame

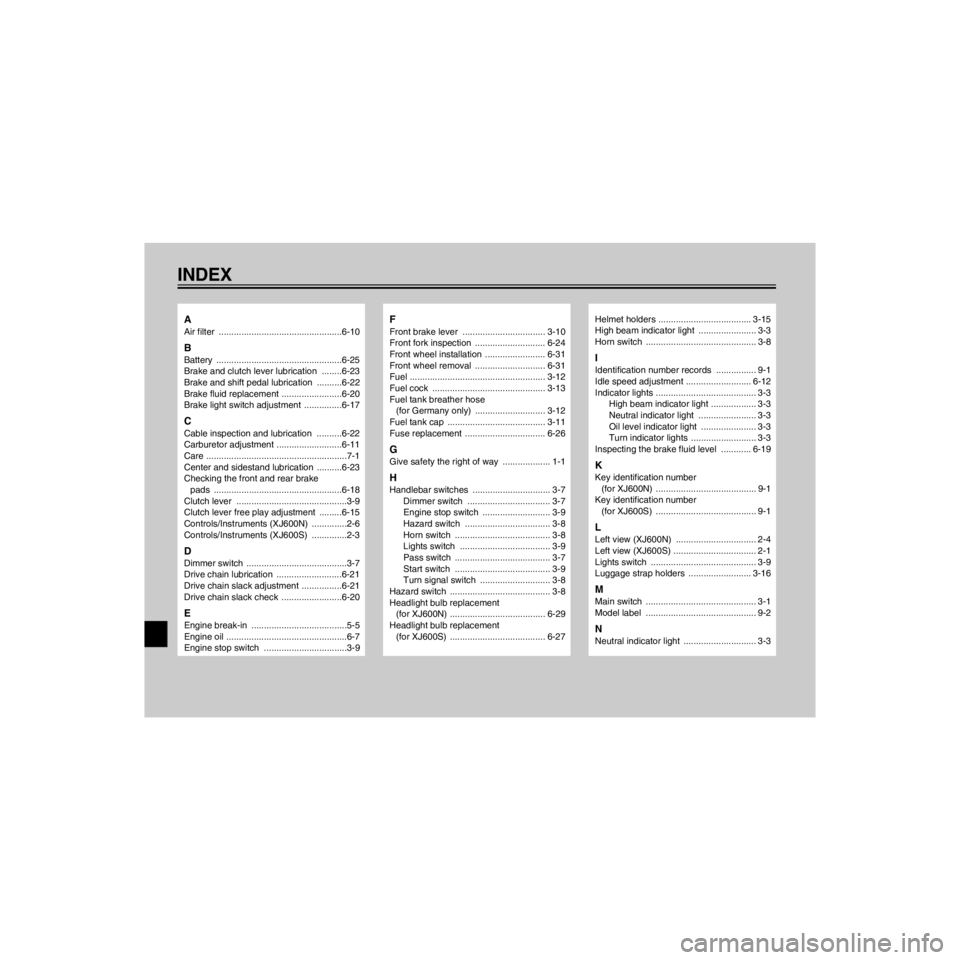

A

Air filter .................................................6-10

B

Battery ..................................................6-25

Brake and clutch lever lubrication ........6-23

Brake and shift pedal lubrication ..........6-22

Brake fluid replacement ........................6-20

Brake light switch adjustment ...............6-17

C

Cable inspection and lubrication ..........6-22

Carburetor adjustment ..........................6-11

Care ........................................................7-1

Center and sidestand lubrication ..........6-23

Checking the front and rear brake

pads ...................................................6-18

Clutch lever ............................................3-9

Clutch lever free play adjustment .........6-15

Controls/Instruments (XJ600N) ..............2-6

Controls/Instruments (XJ600S) ..............2-3

D

Dimmer switch ........................................3-7

Drive chain lubrication ..........................6-21

Drive chain slack adjustment ................6-21

Drive chain slack check ........................6-20

E

Engine break-in ......................................5-5

Engine oil ................................................6-7

Engine stop switch .................................3-9

F

Front brake lever ................................. 3-10

Front fork inspection ............................ 6-24

Front wheel installation ........................ 6-31

Front wheel removal ............................ 6-31

Fuel ...................................................... 3-12

Fuel cock ............................................. 3-13

Fuel tank breather hose

(for Germany only) ............................ 3-12

Fuel tank cap ....................................... 3-11

Fuse replacement ................................ 6-26

G

Give safety the right of way ................... 1-1

H

Handlebar switches ............................... 3-7

Dimmer switch ................................. 3-7

Engine stop switch ........................... 3-9

Hazard switch .................................. 3-8

Horn switch ...................................... 3-8

Lights switch .................................... 3-9

Pass switch ...................................... 3-7

Start switch ...................................... 3-9

Turn signal switch ............................ 3-8

Hazard switch ........................................ 3-8

Headlight bulb replacement

(for XJ600N) ...................................... 6-29

Headlight bulb replacement

(for XJ600S) ...................................... 6-27

Helmet holders ..................................... 3-15

High beam indicator light ....................... 3-3

Horn switch ............................................ 3-8

I

Identification number records ................ 9-1

Idle speed adjustment .......................... 6-12

Indicator lights ........................................ 3-3

High beam indicator light .................. 3-3

Neutral indicator light ....................... 3-3

Oil level indicator light ...................... 3-3

Turn indicator lights .......................... 3-3

Inspecting the brake fluid level ............ 6-19

K

Key identification number

(for XJ600N) ........................................ 9-1

Key identification number

(for XJ600S) ........................................ 9-1

L

Left view (XJ600N) ................................ 2-4

Left view (XJ600S) ................................. 2-1

Lights switch .......................................... 3-9

Luggage strap holders ......................... 3-16

M

Main switch ............................................ 3-1

Model label ............................................ 9-2

N

Neutral indicator light ............................. 3-3

Page 100 of 101

R

INDEX

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9156_XJ600SN-E6/English/EEIX.frame

O

Oil level indicator circuit check .............. 3-5

Oil level indicator light ............................ 3-3

P

Panel A .................................................. 6-5

Panel removal and installation ............... 6-5

Parking .................................................. 5-6

Pass switch ............................................ 3-7

Periodic maintenance and lubrication .... 6-2

Pre-operation check list ......................... 4-1

R

Rear brake pedal ................................. 3-11

Rear brake pedal height adjustment .... 6-17

Rear shock absorber adjustment ......... 3-15

Rear suspension lubrication ................ 6-23

Rear wheel installation ........................ 6-34

Rear wheel removal ............................. 6-33

Recommended shift points

(for Switzerland only) .......................... 5-5

Right view (XJ600N) .............................. 2-5

Right view (XJ600S) .............................. 2-2

S

Seat ..................................................... 3-14

Shift pedal ............................................ 3-10

Shifting ................................................... 5-4

Sidestand ............................................. 3-17

Sidestand/clutch switch operation

check ................................................. 3-17

Spark plug inspection ............................ 6-6

Specifications ......................................... 8-1

Speedometer (for XJ600N) .................... 3-6

Speedometer (for XJ600S) .................... 3-6

Start switch ............................................ 3-9

Starter (choke) Ò Ó ............................ 3-14

Starting a warm engine .......................... 5-4

Starting the engine ................................. 5-1

Steering inspection .............................. 6-24

Steering lock (for XJ600N) ..................... 3-3

Storage ................................................... 7-4

Storage compartment .......................... 3-15

T

Tachometer ............................................ 3-7

Throttle cable and grip lubrication ........ 6-22

Throttle cable free play inspection ....... 6-12

Tips for reducing fuel consumption ........ 5-5

Tires ..................................................... 6-13

Tool kit ................................................... 6-1

Troubleshooting ................................... 6-34

Troubleshooting chart .......................... 6-35

Turn indicator lights ............................... 3-3

Turn signal switch .................................. 3-8

V

Valve clearance adjustment ................. 6-13

Vehicle identification number ................. 9-2

W

Wheel bearings .................................... 6-25

Wheels ................................................. 6-15