lock YAMAHA XJ6F 2013 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: XJ6F, Model: YAMAHA XJ6F 2013Pages: 106, PDF Size: 2.84 MB

Page 30 of 106

INSTRUMENT AND CONTROL FUNCTIONS

3-15

3

TIPThe ABS performs a self-diagno-

sis test each time the vehicle first

starts off after the key is turned to

“ON” and the vehicle has traveled

at a speed of 10 km/h (6 mi/h) or

higher. During this test, a “click-

ing” noise can be heard from un-

der the seat, and if the brake lever

or brake pedal is even slightly ap-

plied, a vibration can be felt at the

lever and pedal, but these do not

indicate a malfunction.

This ABS has a test mode which

allows the owner to experience

the pulsation at the brake lever or

brake pedal when the ABS is op-

erating. However, special tools are

required, so please consult your

Yamaha dealer.NOTICE

ECA16121

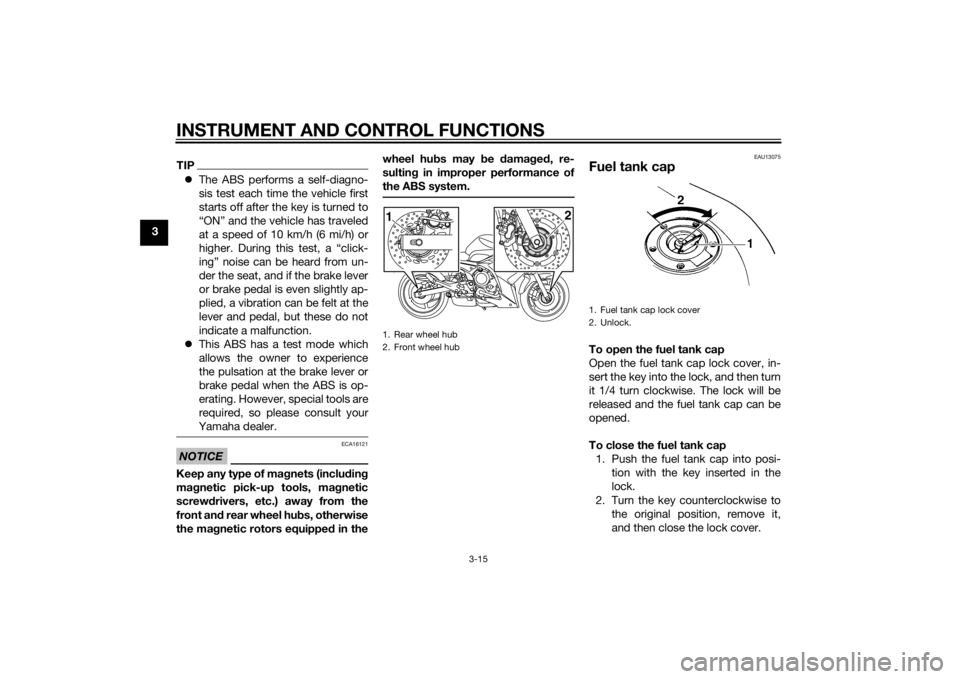

Keep any type of mag nets (includin g

ma gnetic pick-up tools, ma gnetic

screwd rivers, etc.) away from the

front an d rear wheel hu bs, otherwise

the ma gnetic rotors equippe d in the wheel hu

bs may b e damag ed , re-

sultin g in improper performance of

the ABS system.

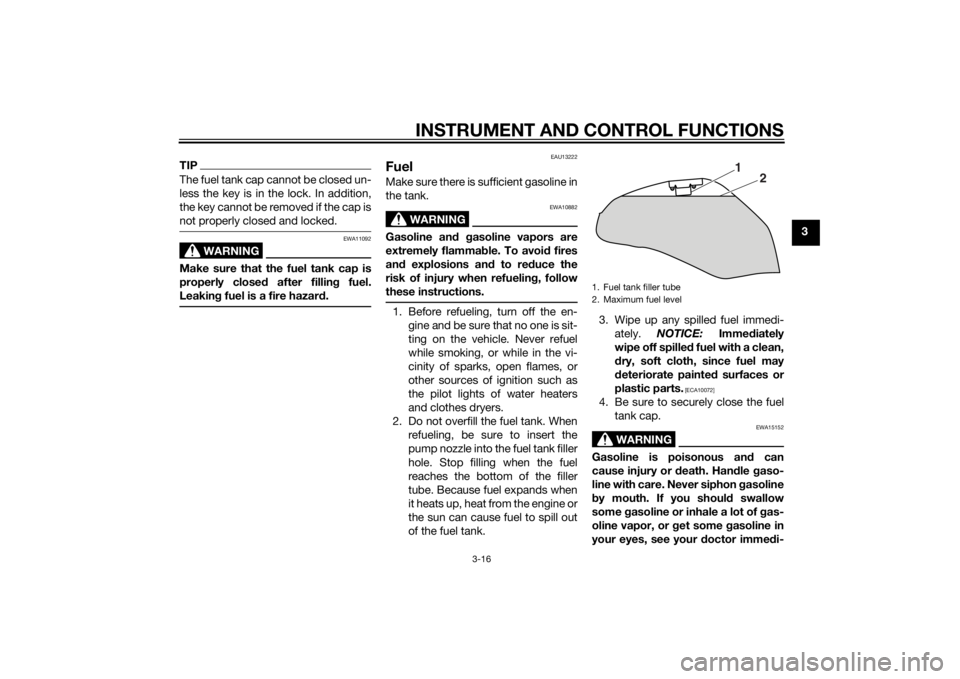

EAU13075

Fuel tank capTo open the fuel tank cap

Open the fuel tank cap lock cover, in-

sert the key into the lock, and then turn

it 1/4 turn clockwise. The lock will be

released and the fuel tank cap can be

opened.

To close the fuel tank cap 1. Push the fuel tank cap into posi- tion with the key inserted in the

lock.

2. Turn the key counterclockwise to the original position, remove it,

and then close the lock cover.

1. Rear wheel hub

2. Front wheel hub1

2

1. Fuel tank cap lock cover

2. Unlock.

U1CWE4E0.book Page 15 Wednesday, August 6, 2014 2:59 PM

Page 31 of 106

INSTRUMENT AND CONTROL FUNCTIONS

3-16

3

TIPThe fuel tank cap cannot be closed un-

less the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly closed and locked.

WARNING

EWA11092

Make sure that the fuel tank cap is

properly closed after filling fuel.

Leakin g fuel is a fire hazar d.

EAU13222

FuelMake sure there is sufficient gasoline in

the tank.

WARNING

EWA10882

Gasoline an d gasoline vapors are

extremely flammab le. To avoid fires

an d explosions an d to re duce the

risk of injury when refueling , follow

these instructions.1. Before refueling, turn off the en- gine and be sure that no one is sit-

ting on the vehicle. Never refuel

while smoking, or while in the vi-

cinity of sparks, open flames, or

other sources of ignition such as

the pilot lights of water heaters

and clothes dryers.

2. Do not overfill the fuel tank. When refueling, be sure to insert the

pump nozzle into the fuel tank filler

hole. Stop filling when the fuel

reaches the bottom of the filler

tube. Because fuel expands when

it heats up, heat from the engine or

the sun can cause fuel to spill out

of the fuel tank. 3. Wipe up any spilled fuel immedi-

ately. NOTICE: Immediately

wipe off spille d fuel with a clean,

d ry, soft cloth, since fuel may

d eteriorate painte d surfaces or

plastic parts.

[ECA10072]

4. Be sure to securely close the fuel tank cap.

WARNING

EWA15152

Gasoline is poisonous an d can

cause injury or death. Han dle gaso-

line with care. Never siphon gasoline

b y mouth. If you shoul d swallow

some gasoline or inhale a lot of g as-

oline vapor, or get some gasoline in

your eyes, see your doctor imme di-1. Fuel tank filler tube

2. Maximum fuel level

1

2

U1CWE4E0.book Page 16 Wednesday, August 6, 2014 2:59 PM

Page 32 of 106

INSTRUMENT AND CONTROL FUNCTIONS

3-17

3ately. If

gasoline spills on your skin,

wash with soap an d water. If gaso-

line spills on your clothin g, chan ge

your clothes.

EAU49742

NOTICE

ECA11401

Use only unlea ded g asoline. The use

of lead ed g asoline will cause severe

d amag e to internal en gine parts,

such as the valves an d piston rin gs,

as well as to the exhaust system.Your Yamaha engine has been de-

signed to use regular unleaded gaso-

line with a research octane number of

95 or higher. If knocking (or pinging)

occurs, use a gasoline of a different brand or premium unleaded fuel. Use

of unleaded fuel will extend spark plug

life and reduce maintenance costs.

Gasohol

There are two types of gasohol: gaso-

hol containing ethanol and that con-

taining methanol. Gasohol containing

ethanol can be used if the ethanol con-

tent does not exceed 10% (E10). Gas-

ohol containing methanol is not

recommended by Yamaha because it

can cause damage to the fuel system

or vehicle performance problems.

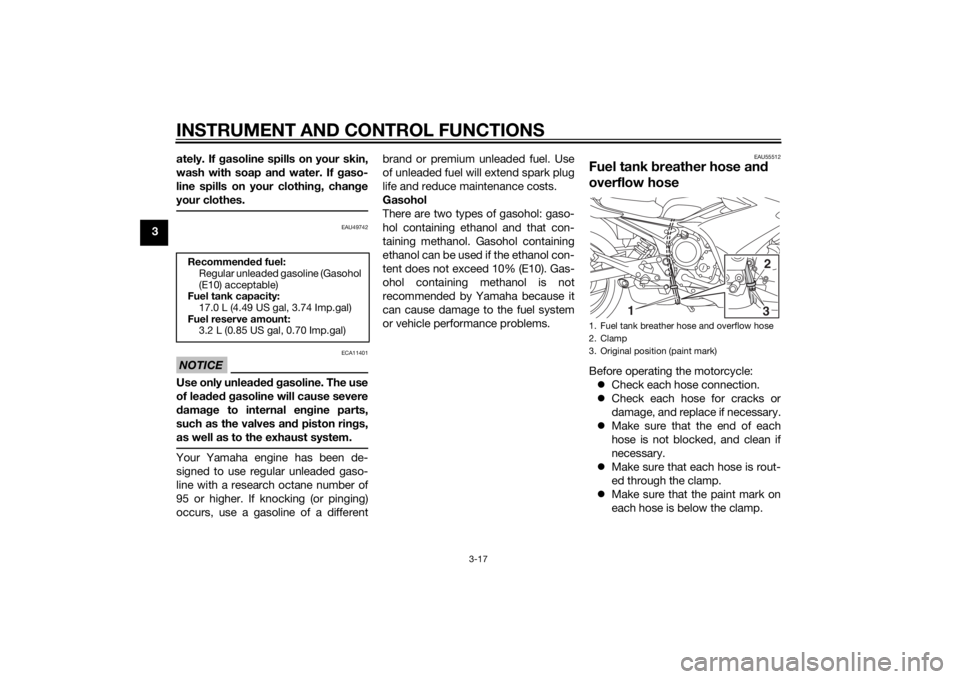

EAU55512

Fuel tank

breather hose an d

overflow hoseBefore operating the motorcycle:

Check each hose connection.

Check each hose for cracks or

damage, and replace if necessary.

Make sure that the end of each

hose is not blocked, and clean if

necessary.

Make sure that each hose is rout-

ed through the clamp.

Make sure that the paint mark on

each hose is below the clamp.

Recommen ded fuel:

Regular unleaded gasoline (Gasohol

(E10) acceptable)

Fuel tank capacity:

17.0 L (4.49 US gal, 3.74 Imp.gal)

Fuel reserve amount: 3.2 L (0.85 US gal, 0.70 Imp.gal)

1. Fuel tank breather hose and overflow hose

2. Clamp

3. Original position (paint mark)

1 1

23

U1CWE4E0.book Page 17 Wednesday, August 6, 2014 2:59 PM

Page 33 of 106

INSTRUMENT AND CONTROL FUNCTIONS

3-18

3

EAU13434

Catalytic converterThis model is equipped with a catalytic

converter in the exhaust system.

WARNING

EWA10863

The exhaust system is hot after op-

eration. To prevent a fire hazard or

b urns:

Do not park the vehicle near

possi ble fire hazar ds such as

g rass or other materials that

easily burn.

Park the vehicle in a place

where pe destrians or chil dren

are not likely to touch the hot

exhaust system.

Make sure that the exhaust sys-

tem has coole d down before

d oin g any maintenance work.

Do not allow the en gine to i dle

more than a few minutes. Lon g

i d lin g can cause a buil d-up of

heat.

NOTICE

ECA10702

Use only unlea ded g asoline. The use

of lead ed g asoline will cause unre-

paira ble damag e to the catalytic

converter.

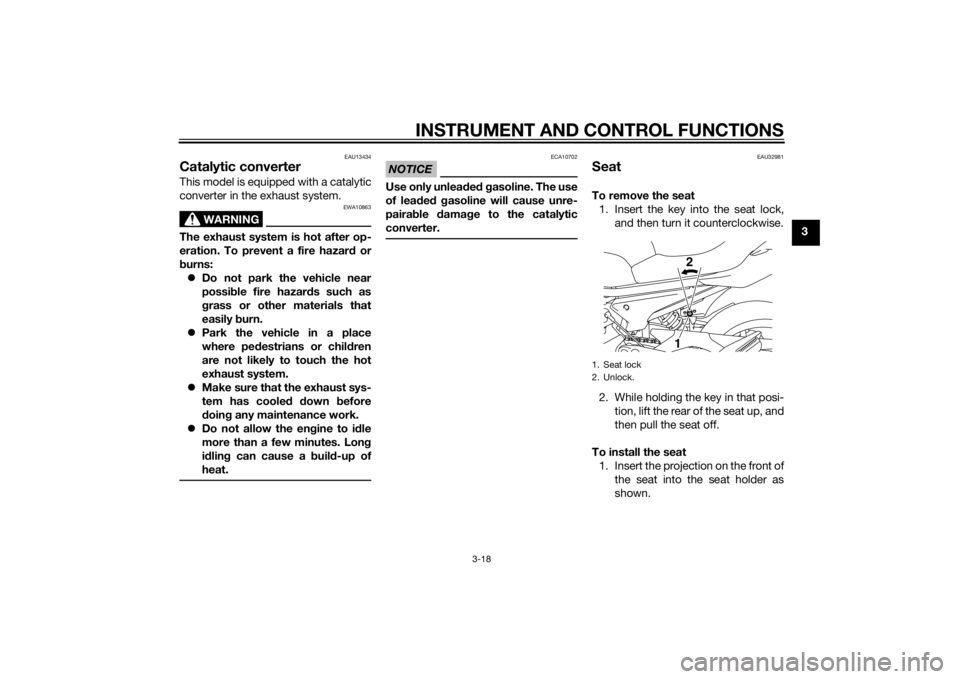

EAU32981

SeatTo remove the seat 1. Insert the key into the seat lock, and then turn it counterclockwise.

2. While holding the key in that posi- tion, lift the rear of the seat up, and

then pull the seat off.

To install the seat 1. Insert the projection on the front of the seat into the seat holder as

shown.1. Seat lock

2. Unlock.

12

U1CWE4E0.book Page 18 Wednesday, August 6, 2014 2:59 PM

Page 34 of 106

INSTRUMENT AND CONTROL FUNCTIONS

3-19

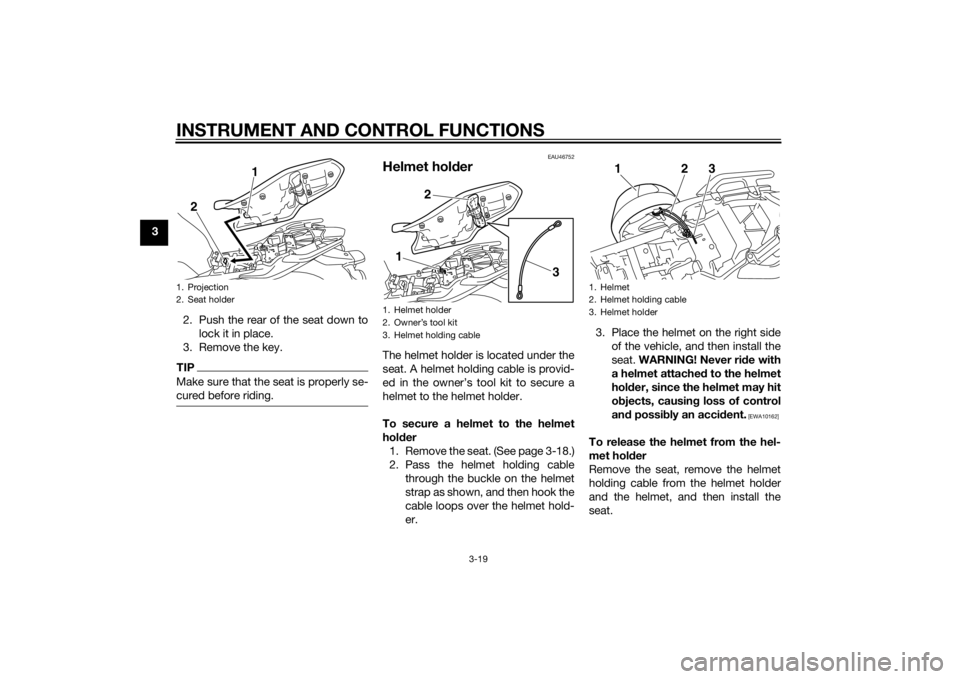

32. Push the rear of the seat down tolock it in place.

3. Remove the key.

TIPMake sure that the seat is properly se-

cured before riding.

EAU46752

Helmet hold erThe helmet holder is located under the

seat. A helmet holding cable is provid-

ed in the owner’s tool kit to secure a

helmet to the helmet holder.

To secure a helmet to the helmet

holder

1. Remove the seat. (See page 3-18.)

2. Pass the helmet holding cable through the buckle on the helmet

strap as shown, and then hook the

cable loops over the helmet hold-

er. 3. Place the helmet on the right side

of the vehicle, and then install the

seat. WARNING! Never ri de with

a helmet attached to the helmet

hol der, since the helmet may hit

o bjects, causin g loss of control

an d possi bly an acci dent.

[EWA10162]

To release the helmet from the hel-

met hol der

Remove the seat, remove the helmet

holding cable from the helmet holder

and the helmet, and then install the

seat.

1. Projection

2. Seat holder

1

2

1. Helmet holder

2. Owner’s tool kit

3. Helmet holding cable

2

3

1

1. Helmet

2. Helmet holding cable

3. Helmet holder

123

U1CWE4E0.book Page 19 Wednesday, August 6, 2014 2:59 PM

Page 69 of 106

PERIODIC MAINTENANCE AND ADJUSTMENT

6-23

6

EAU21963

Cast wheelsTo maximize the performance, durabil-

ity, and safe operation of your vehicle,

note the following points regarding the

specified wheels. The wheel rims should be

checked for cracks, bends, warp-

age or other damage before each

ride. If any damage is found, have

a Yamaha dealer replace the

wheel. Do not attempt even the

smallest repair to the wheel. A de-

formed or cracked wheel must be

replaced.

The wheel should be balanced

whenever either the tire or wheel

has been changed or replaced. An

unbalanced wheel can result in

poor performance, adverse han-

dling characteristics, and a short-

ened tire life.

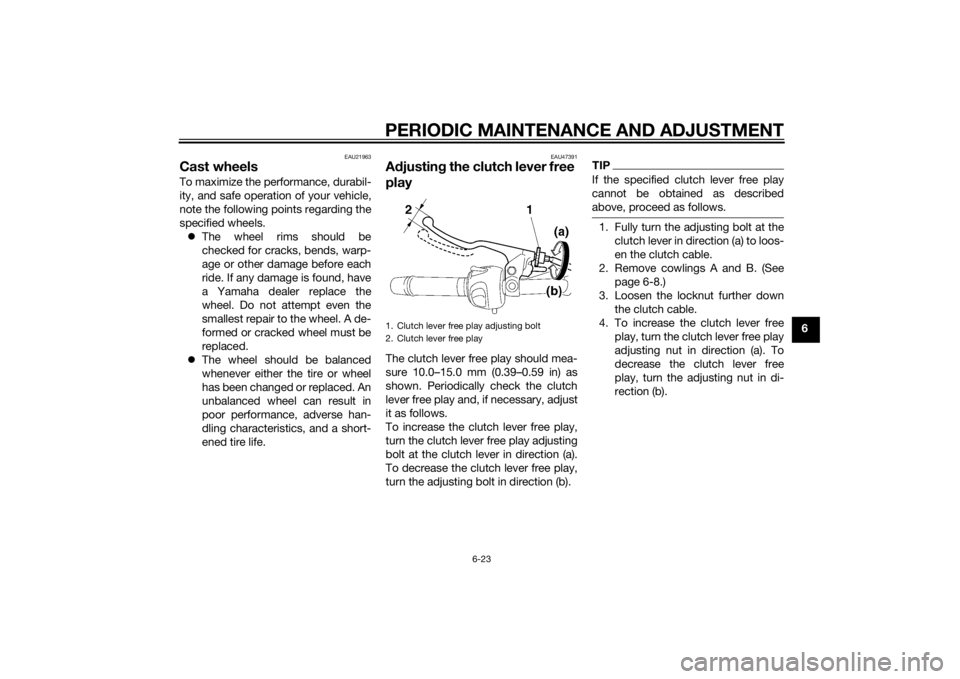

EAU47391

Adjustin g the clutch lever free

playThe clutch lever free play should mea-

sure 10.0–15.0 mm (0.39–0.59 in) as

shown. Periodically check the clutch

lever free play and, if necessary, adjust

it as follows.

To increase the clutch lever free play,

turn the clutch lever free play adjusting

bolt at the clutch lever in direction (a).

To decrease the clutch lever free play,

turn the adjusting bolt in direction (b).

TIPIf the specified clutch lever free play

cannot be obtained as described

above, proceed as follows.1. Fully turn the adjusting bolt at the

clutch lever in direction (a) to loos-

en the clutch cable.

2. Remove cowlings A and B. (See page 6-8.)

3. Loosen the locknut further down the clutch cable.

4. To increase the clutch lever free play, turn the clutch lever free play

adjusting nut in direction (a). To

decrease the clutch lever free

play, turn the adjusting nut in di-

rection (b).

1. Clutch lever free play adjusting bolt

2. Clutch lever free play

U1CWE4E0.book Page 23 Wednesday, August 6, 2014 2:59 PM

Page 70 of 106

PERIODIC MAINTENANCE AND ADJUSTMENT

6-24

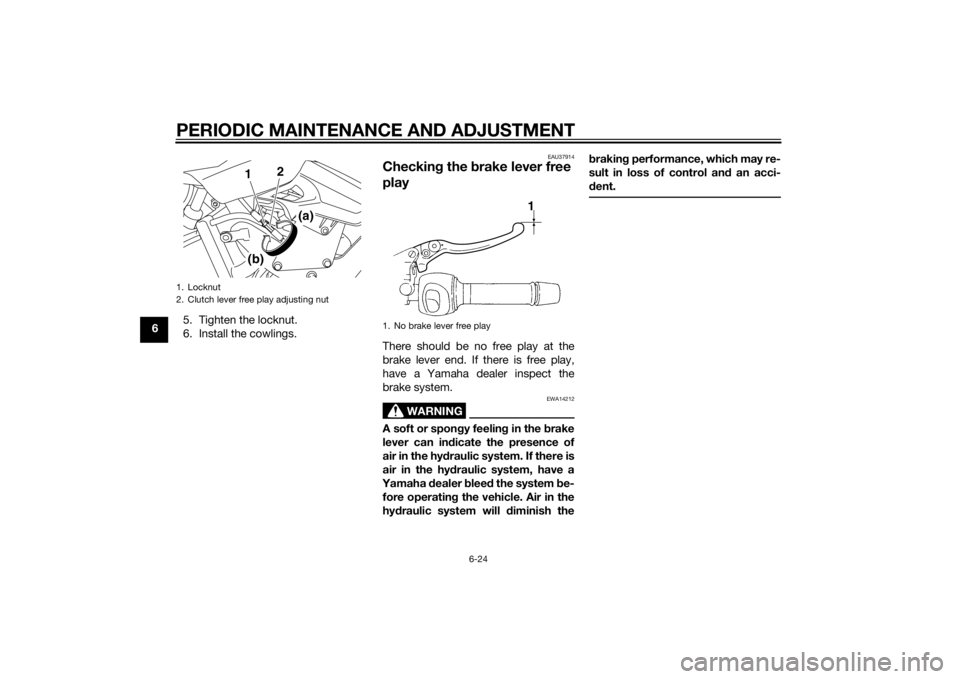

65. Tighten the locknut.

6. Install the cowlings.

EAU37914

Checkin

g the brake lever free

playThere should be no free play at the

brake lever end. If there is free play,

have a Yamaha dealer inspect the

brake system.

WARNING

EWA14212

A soft or spon gy feelin g in the b rake

lever can in dicate the presence of

air in the hy draulic system. If there is

air in the hy draulic system, have a

Yamaha dealer blee d the system be-

fore operatin g the vehicle. Air in the

hy draulic system will diminish the b

rakin g performance, which may re-

sult in loss of control an d an acci-

d ent.

1. Locknut

2. Clutch lever free play adjusting nut

1 2

(a)

(b)

1. No brake lever free play

1

U1CWE4E0.book Page 24 Wednesday, August 6, 2014 2:59 PM

Page 73 of 106

PERIODIC MAINTENANCE AND ADJUSTMENT

6-27

6

Clean the filler cap before re-

movin g. Use only DOT 4 brake

flui d from a seale d container.

Use only the specifie d b rake flu-

i d ; otherwise, the ru bber seals

may deteriorate, causin g leak-

a g e.

Refill with the same type of

brake flui d. A ddin g a brake flui d

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water or dust

d oes not enter the brake flui d

reservoir when refillin g. Water

will si gnificantly lower the boil-

in g point of the flui d an d may re-

sult in vapor lock, an d d irt may

clo g the ABS hy draulic unit

valves.

NOTICE

ECA17641

Brake flui d may d amage painte d

surfaces or plastic parts. Always

clean up spille d flui d imme diately.As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake system leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brake

fluid level goes down suddenly, have a

Yamaha dealer check the cause before

further riding.

EAU22733

Chan

gin g the brake flui dHave a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the master cylinders and calipers as

well as the brake hoses replaced at the

intervals listed below or whenever they

are damaged or leaking.

Oil seals: Replace every two

years.

Brake hoses: Replace every four

years.

U1CWE4E0.book Page 27 Wednesday, August 6, 2014 2:59 PM

Page 74 of 106

PERIODIC MAINTENANCE AND ADJUSTMENT

6-28

6

EAU22762

Drive chain slackThe drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU22795

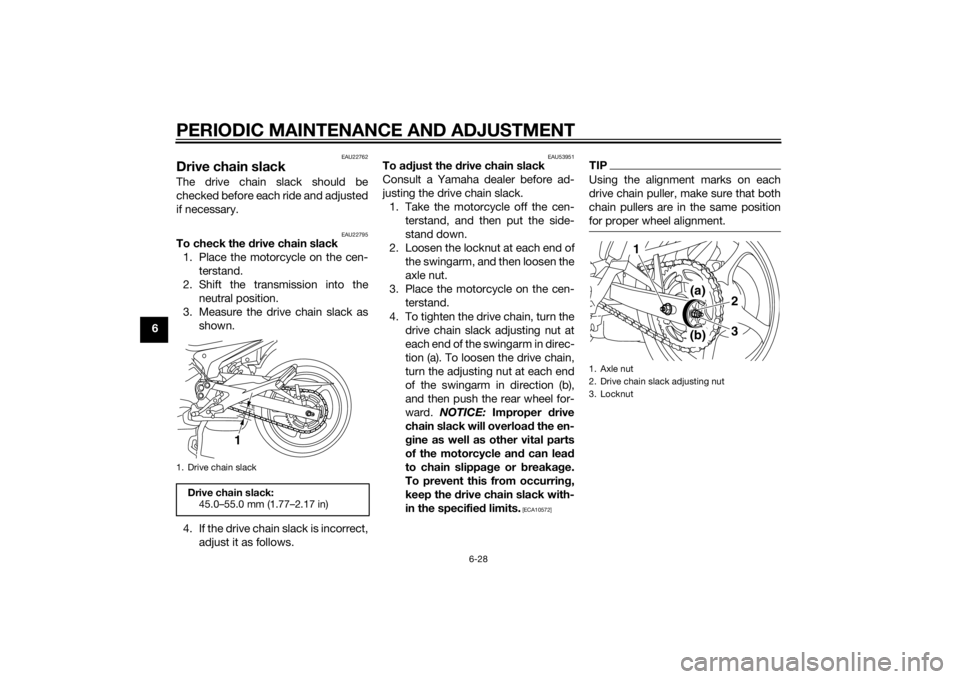

To check the drive chain slack

1. Place the motorcycle on the cen- terstand.

2. Shift the transmission into the neutral position.

3. Measure the drive chain slack as shown.

4. If the drive chain slack is incorrect, adjust it as follows.

EAU53951

To a djust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Take the motorcycle off the cen- terstand, and then put the side-

stand down.

2. Loosen the locknut at each end of the swingarm, and then loosen the

axle nut.

3. Place the motorcycle on the cen- terstand.

4. To tighten the drive chain, turn the drive chain slack adjusting nut at

each end of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting nut at each end

of the swingarm in direction (b),

and then push the rear wheel for-

ward. NOTICE: Improper drive

chain slack will overload the en-

g ine as well as other vital parts

of the motorcycle an d can lead

to chain slippa ge or breakag e.

To prevent this from occurrin g,

keep the d rive chain slack with-

in the specifie d limits.

[ECA10572]

TIPUsing the alignment marks on each

drive chain puller, make sure that both

chain pullers are in the same position

for proper wheel alignment.

1. Drive chain slackDrive chain slack:

45.0–55.0 mm (1.77–2.17 in)

1

1. Axle nut

2. Drive chain slack adjusting nut

3. Locknut

3

1

2

(a)(b)

U1CWE4E0.book Page 28 Wednesday, August 6, 2014 2:59 PM

Page 75 of 106

PERIODIC MAINTENANCE AND ADJUSTMENT

6-29

6

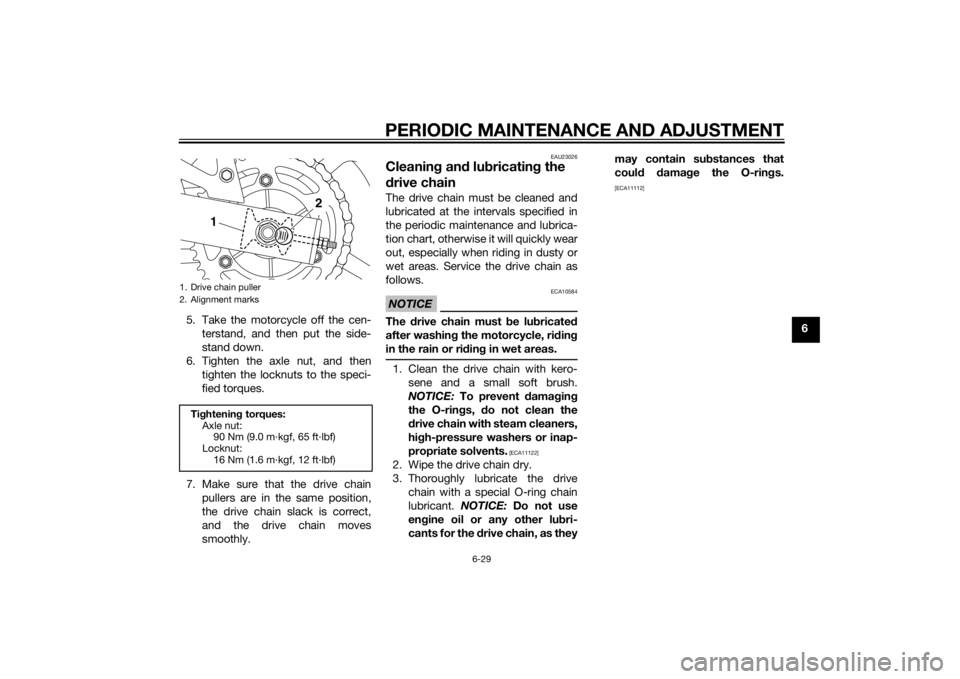

5. Take the motorcycle off the cen-

terstand, and then put the side-

stand down.

6. Tighten the axle nut, and then tighten the locknuts to the speci-

fied torques.

7. Make sure that the drive chain pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23026

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must b e lubricate d

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Clean the drive chain with kero-

sene and a small soft brush.

NOTICE: To prevent d amaging

the O-rin gs, do not clean the

d rive chain with steam cleaners,

hi gh-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

en gine oil or any other lu bri-

cants for the d rive chain, as they may contain su

bstances that

coul d damag e the O-rin gs.

[ECA11112]

1. Drive chain puller

2. Alignment marksTi ghtenin g torques:

Axle nut: 90 Nm (9.0 m·kgf, 65 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

1

2

U1CWE4E0.book Page 29 Wednesday, August 6, 2014 2:59 PM