YAMAHA XJ900S 2000 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2000, Model line: XJ900S, Model: YAMAHA XJ900S 2000Pages: 97, PDF Size: 2.08 MB

Page 51 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-5

6

EAU01065

Cowling removal and

installationThe cowlings indicated in the illustra-

tion need to be removed to perform

some of the maintenance described in

this chapter. Refer to this section each

time a cowling has to be removed or re-

installed.

EAU00490*

Cowling ATo remove

1. Remove the seat. (See page 3-15

for seat removal and installation

procedures.)

2. Remove the screws shown.3. Pull the cowling up, and then slide

it back.

To install

1. Place the cowling in the original

position, and then install the

screws.

2. Install the seat.

1. Cowling A

2. Cowling B

1. Cowling A

2. Screw (´ 2)

Page 52 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-6

6

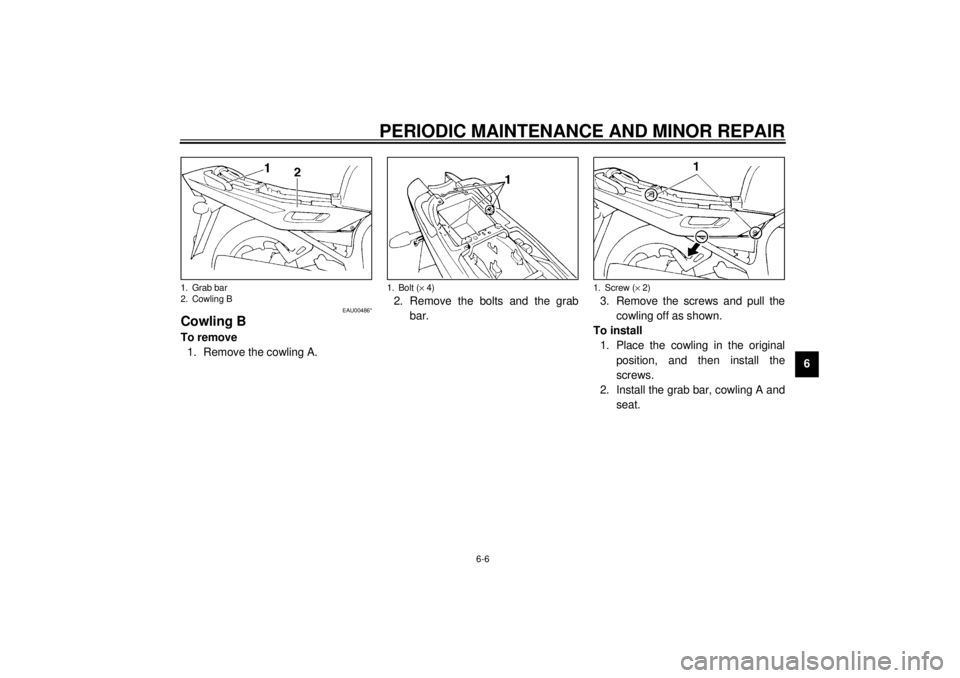

EAU00486*

Cowling BTo remove

1. Remove the cowling A.2. Remove the bolts and the grab

bar.3. Remove the screws and pull the

cowling off as shown.

To install

1. Place the cowling in the original

position, and then install the

screws.

2. Install the grab bar, cowling A and

seat.1. Grab bar

2. Cowling B

1. Bolt (´ 4)

1. Screw (´ 2)

Page 53 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-7

6

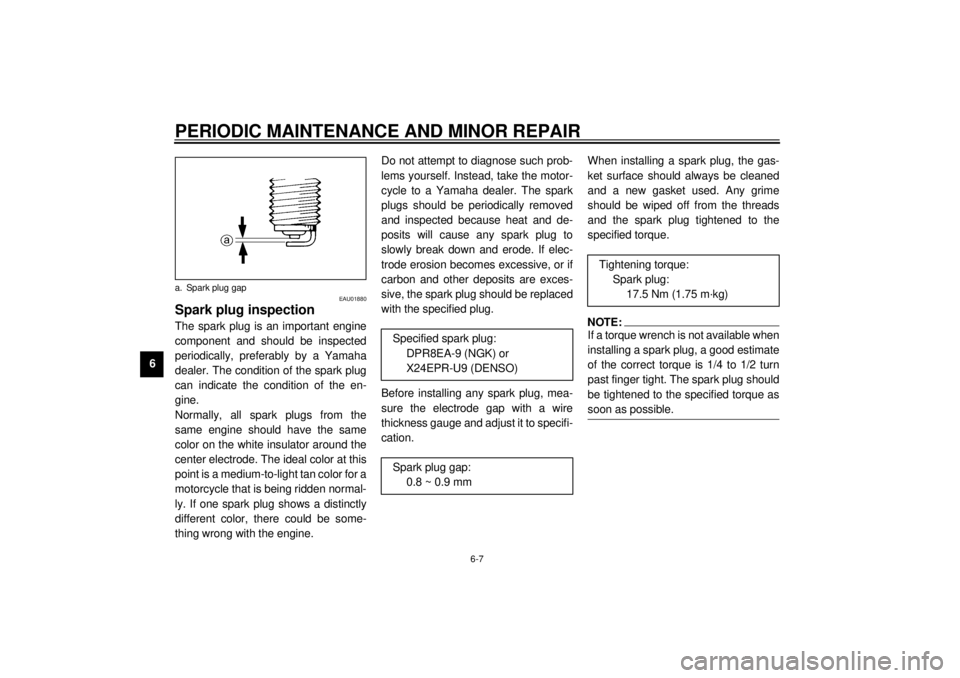

EAU01880

Spark plug inspectionThe spark plug is an important engine

component and should be inspected

periodically, preferably by a Yamaha

dealer. The condition of the spark plug

can indicate the condition of the en-

gine.

Normally, all spark plugs from the

same engine should have the same

color on the white insulator around the

center electrode. The ideal color at this

point is a medium-to-light tan color for a

motorcycle that is being ridden normal-

ly. If one spark plug shows a distinctly

different color, there could be some-

thing wrong with the engine.Do not attempt to diagnose such prob-

lems yourself. Instead, take the motor-

cycle to a Yamaha dealer. The spark

plugs should be periodically removed

and inspected because heat and de-

posits will cause any spark plug to

slowly break down and erode. If elec-

trode erosion becomes excessive, or if

carbon and other deposits are exces-

sive, the spark plug should be replaced

with the specified plug.

Before installing any spark plug, mea-

sure the electrode gap with a wire

thickness gauge and adjust it to specifi-

cation.When installing a spark plug, the gas-

ket surface should always be cleaned

and a new gasket used. Any grime

should be wiped off from the threads

and the spark plug tightened to the

specified torque.

NOTE:@ If a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4 to 1/2 turn

past finger tight. The spark plug should

be tightened to the specified torque as

soon as possible. @

a. Spark plug gap

Specified spark plug:

DPR8EA-9 (NGK) or

X24EPR-U9 (DENSO)

Spark plug gap:

0.8 ~ 0.9 mm

Tightening torque:

Spark plug:

17.5 Nm (1.75 m·kg)

Page 54 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-8

6

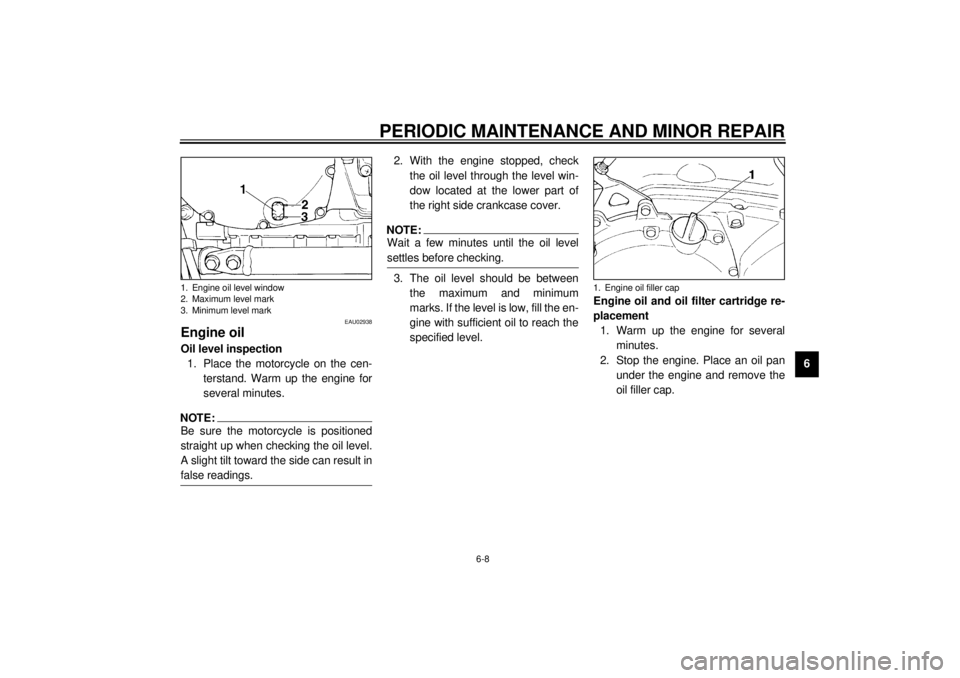

EAU02938

Engine oilOil level inspection

1. Place the motorcycle on the cen-

terstand. Warm up the engine for

several minutes.NOTE:@ Be sure the motorcycle is positioned

straight up when checking the oil level.

A slight tilt toward the side can result in

false readings. @

2. With the engine stopped, check

the oil level through the level win-

dow located at the lower part of

the right side crankcase cover.NOTE:@ Wait a few minutes until the oil level

settles before checking. @3. The oil level should be between

the maximum and minimum

marks. If the level is low, fill the en-

gine with sufficient oil to reach the

specified level.Engine oil and oil filter cartridge re-

placement

1. Warm up the engine for several

minutes.

2. Stop the engine. Place an oil pan

under the engine and remove the

oil filler cap.

1. Engine oil level window

2. Maximum level mark

3. Minimum level mark

1. Engine oil filler cap

Page 55 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-9

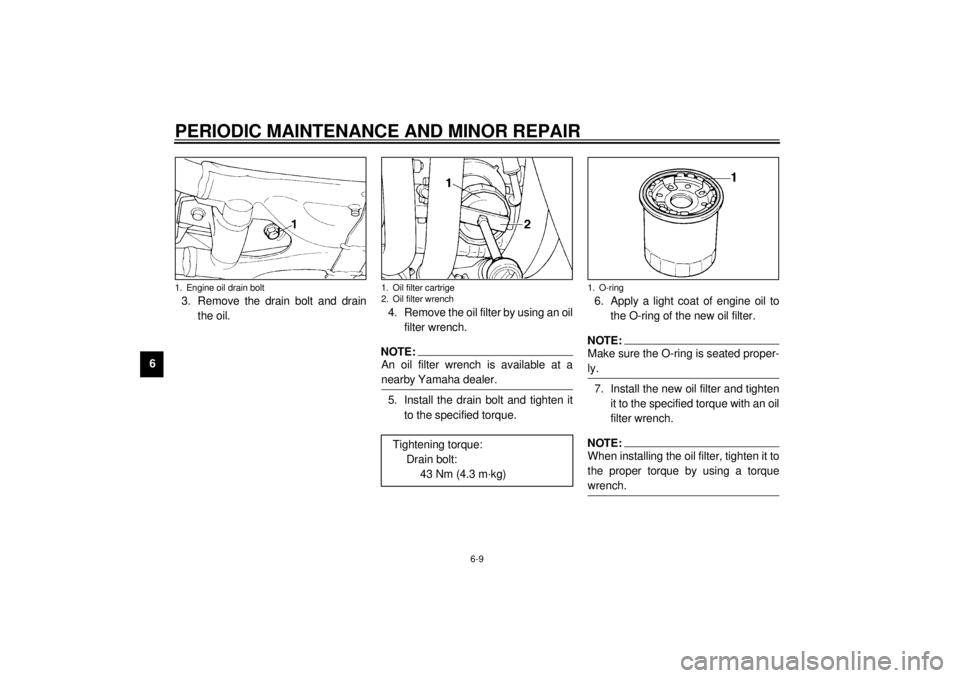

63. Remove the drain bolt and drain

the oil.4. Remove the oil filter by using an oil

filter wrench.

NOTE:@ An oil filter wrench is available at a

nearby Yamaha dealer. @5. Install the drain bolt and tighten it

to the specified torque.6. Apply a light coat of engine oil to

the O-ring of the new oil filter.

NOTE:@ Make sure the O-ring is seated proper-

ly. @7. Install the new oil filter and tighten

it to the specified torque with an oil

filter wrench.NOTE:@ When installing the oil filter, tighten it to

the proper torque by using a torque

wrench. @

1. Engine oil drain bolt

1. Oil filter cartrige

2. Oil filter wrench

Tightening torque:

Drain bolt:

43 Nm (4.3 m·kg)

1. O-ring

Page 56 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-10

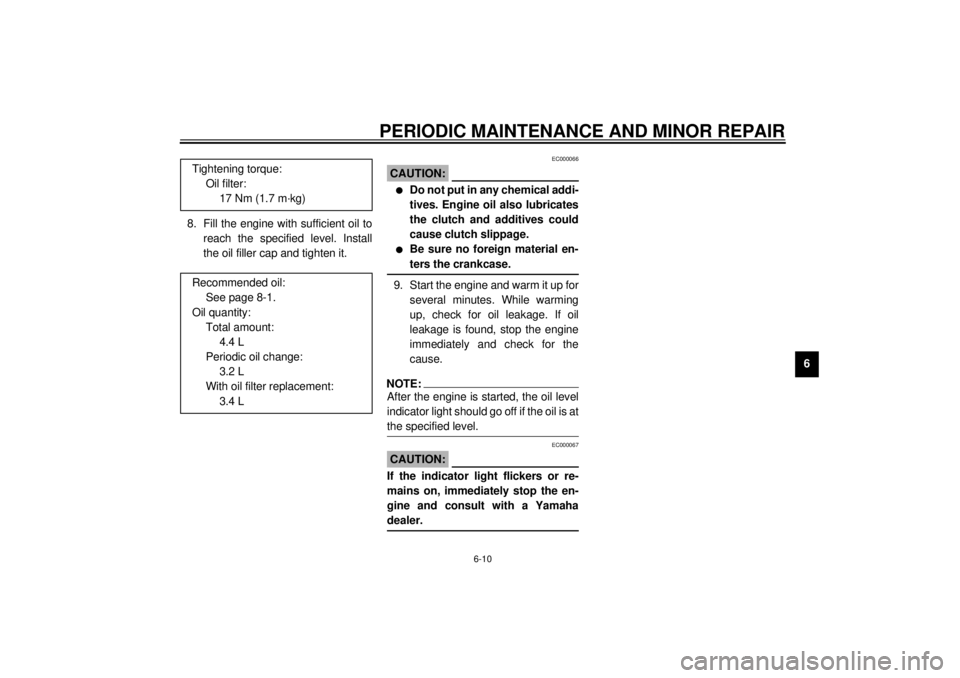

6 8. Fill the engine with sufficient oil to

reach the specified level. Install

the oil filler cap and tighten it.

EC000066

CAUTION:@ l

Do not put in any chemical addi-

tives. Engine oil also lubricates

the clutch and additives could

cause clutch slippage.

l

Be sure no foreign material en-

ters the crankcase.

@9. Start the engine and warm it up for

several minutes. While warming

up, check for oil leakage. If oil

leakage is found, stop the engine

immediately and check for the

cause.NOTE:@ After the engine is started, the oil level

indicator light should go off if the oil is at

the specified level. @

EC000067

CAUTION:@ If the indicator light flickers or re-

mains on, immediately stop the en-

gine and consult with a Yamaha

dealer. @

Tightening torque:

Oil filter:

17 Nm (1.7 m·kg)

Recommended oil:

See page 8-1.

Oil quantity:

Total amount:

4.4 L

Periodic oil change:

3.2 L

With oil filter replacement:

3.4 L

Page 57 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-11

6

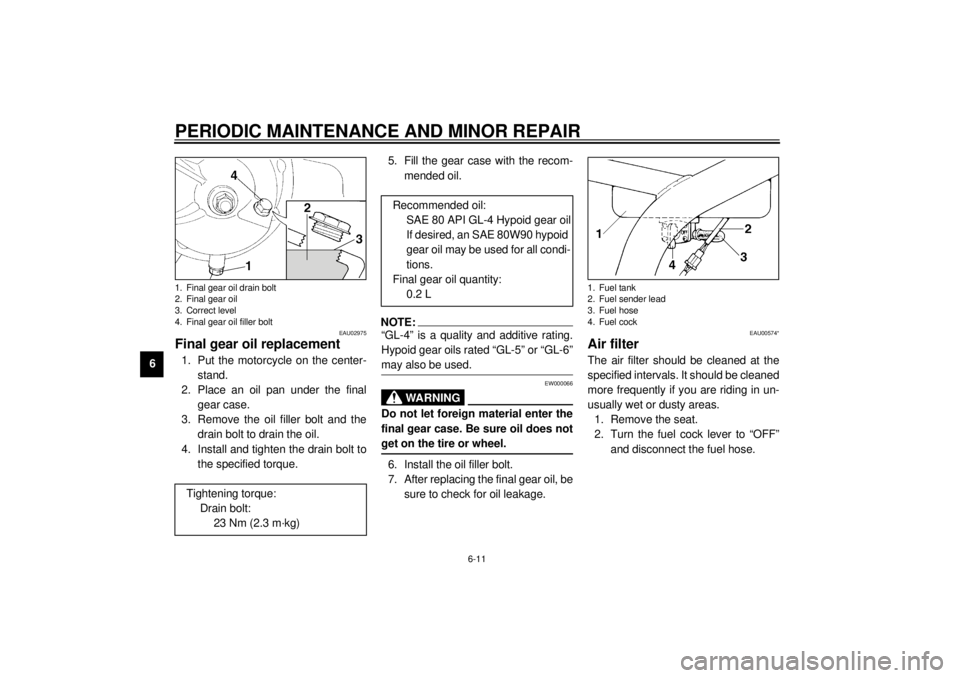

EAU02975

Final gear oil replacement1. Put the motorcycle on the center-

stand.

2. Place an oil pan under the final

gear case.

3. Remove the oil filler bolt and the

drain bolt to drain the oil.

4. Install and tighten the drain bolt to

the specified torque.5. Fill the gear case with the recom-

mended oil.

NOTE:@ “GL-4” is a quality and additive rating.

Hypoid gear oils rated “GL-5” or “GL-6”

may also be used. @

EW000066

WARNING

@ Do not let foreign material enter the

final gear case. Be sure oil does not

get on the tire or wheel. @6. Install the oil filler bolt.

7. After replacing the final gear oil, be

sure to check for oil leakage.

EAU00574*

Air filterThe air filter should be cleaned at the

specified intervals. It should be cleaned

more frequently if you are riding in un-

usually wet or dusty areas.

1. Remove the seat.

2. Turn the fuel cock lever to “OFF”

and disconnect the fuel hose.

1. Final gear oil drain bolt

2. Final gear oil

3. Correct level

4. Final gear oil filler boltTightening torque:

Drain bolt:

23 Nm (2.3 m·kg)

Recommended oil:

SAE 80 API GL-4 Hypoid gear oil

If desired, an SAE 80W90 hypoid

gear oil may be used for all condi-

tions.

Final gear oil quantity:

0.2 L

1. Fuel tank

2. Fuel sender lead

3. Fuel hose

4. Fuel cock

Page 58 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-12

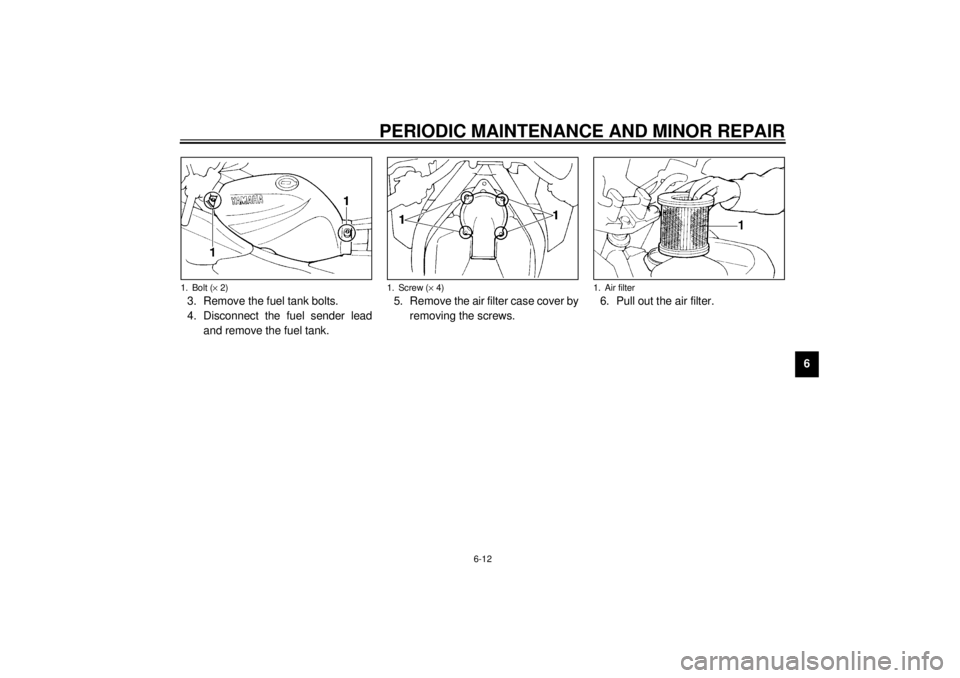

6 3. Remove the fuel tank bolts.

4. Disconnect the fuel sender lead

and remove the fuel tank.5. Remove the air filter case cover by

removing the screws.6. Pull out the air filter.

1. Bolt (´ 2)

1. Screw (´ 4)

1. Air filter

Page 59 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-13

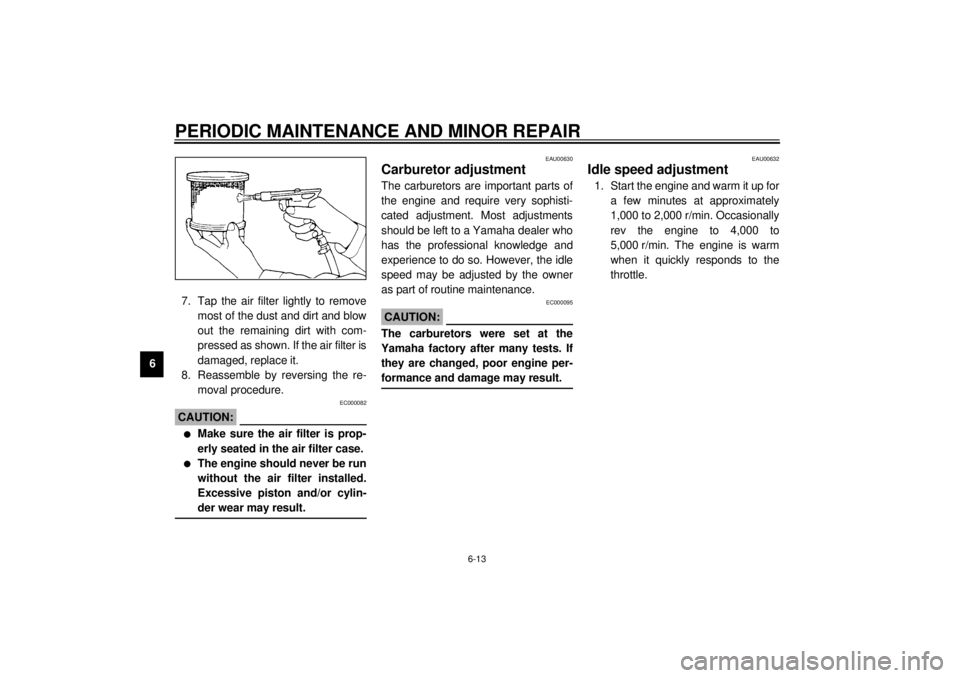

67. Tap the air filter lightly to remove

most of the dust and dirt and blow

out the remaining dirt with com-

pressed as shown. If the air filter is

damaged, replace it.

8. Reassemble by reversing the re-

moval procedure.

EC000082

CAUTION:@ l

Make sure the air filter is prop-

erly seated in the air filter case.

l

The engine should never be run

without the air filter installed.

Excessive piston and/or cylin-

der wear may result.

@

EAU00630

Carburetor adjustmentThe carburetors are important parts of

the engine and require very sophisti-

cated adjustment. Most adjustments

should be left to a Yamaha dealer who

has the professional knowledge and

experience to do so. However, the idle

speed may be adjusted by the owner

as part of routine maintenance.

EC000095

CAUTION:@ The carburetors were set at the

Yamaha factory after many tests. If

they are changed, poor engine per-

formance and damage may result. @

EAU00632

Idle speed adjustment1. Start the engine and warm it up for

a few minutes at approximately

1,000 to 2,000 r/min. Occasionally

rev the engine to 4,000 to

5,000 r/min. The engine is warm

when it quickly responds to the

throttle.

Page 60 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-14

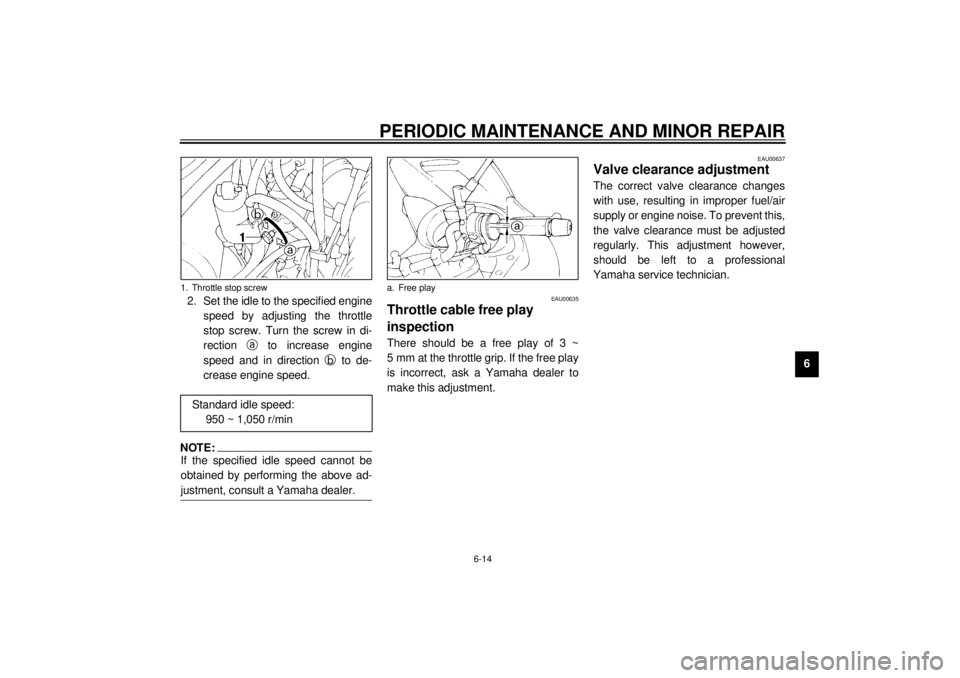

6 2. Set the idle to the specified engine

speed by adjusting the throttle

stop screw. Turn the screw in di-

rection

a to increase engine

speed and in direction

b to de-

crease engine speed.

NOTE:@ If the specified idle speed cannot be

obtained by performing the above ad-

justment, consult a Yamaha dealer. @

EAU00635

Throttle cable free play

inspectionThere should be a free play of 3 ~

5 mm at the throttle grip. If the free play

is incorrect, ask a Yamaha dealer to

make this adjustment.

EAU00637

Valve clearance adjustmentThe correct valve clearance changes

with use, resulting in improper fuel/air

supply or engine noise. To prevent this,

the valve clearance must be adjusted

regularly. This adjustment however,

should be left to a professional

Yamaha service technician.

1. Throttle stop screw

Standard idle speed:

950 ~ 1,050 r/min

a. Free play