ECU YAMAHA XJ900S 2000 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: XJ900S, Model: YAMAHA XJ900S 2000Pages: 97, PDF Size: 2.08 MB

Page 29 of 97

INSTRUMENT AND CONTROL FUNCTIONS

3-15

3

EAU02925

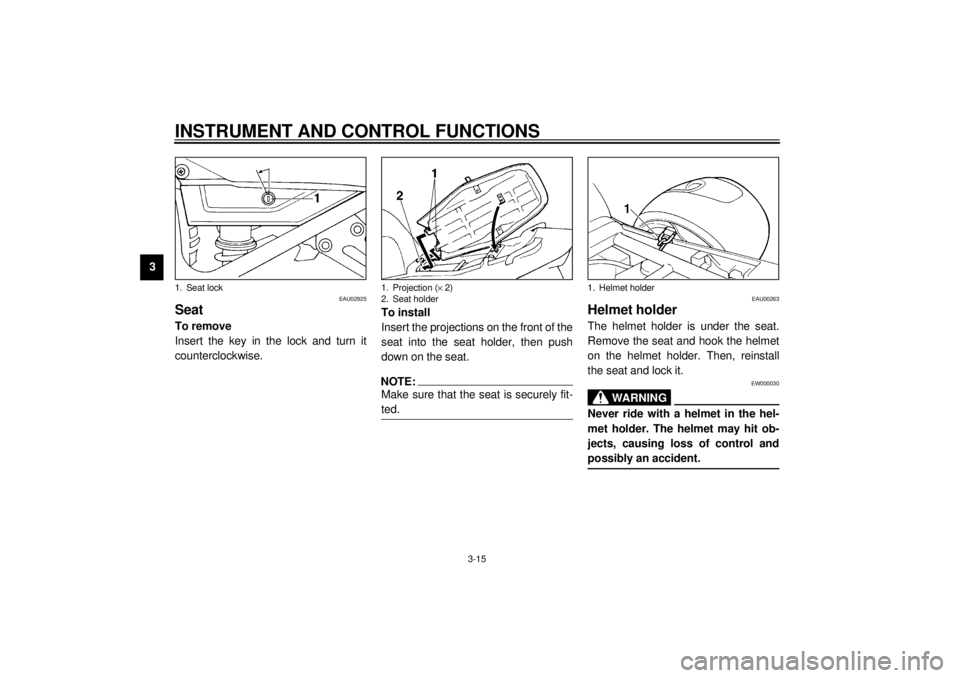

SeatTo remove

Insert the key in the lock and turn it

counterclockwise.To install

Insert the projections on the front of the

seat into the seat holder, then push

down on the seat.

NOTE:@ Make sure that the seat is securely fit-

ted. @

EAU00263

Helmet holderThe helmet holder is under the seat.

Remove the seat and hook the helmet

on the helmet holder. Then, reinstall

the seat and lock it.

EW000030

WARNING

@ Never ride with a helmet in the hel-

met holder. The helmet may hit ob-

jects, causing loss of control and

possibly an accident. @

1. Seat lock

1. Projection (´ 2)

2. Seat holder

1. Helmet holder

Page 30 of 97

INSTRUMENT AND CONTROL FUNCTIONS

3-16

3

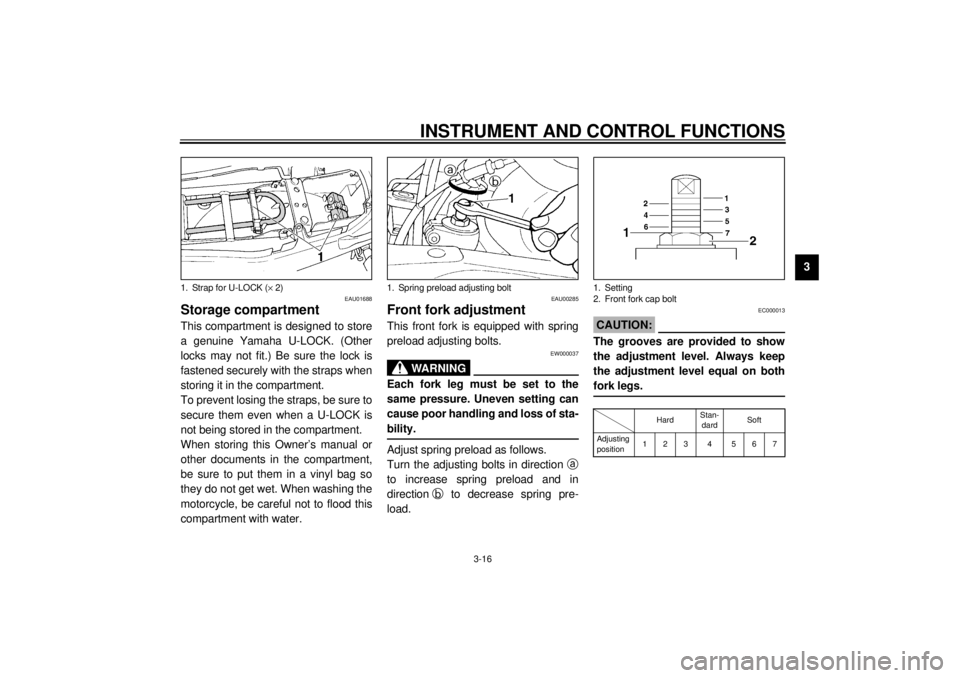

EAU01688

Storage compartmentThis compartment is designed to store

a genuine Yamaha U-LOCK. (Other

locks may not fit.) Be sure the lock is

fastened securely with the straps when

storing it in the compartment.

To prevent losing the straps, be sure to

secure them even when a U-LOCK is

not being stored in the compartment.

When storing this Owner’s manual or

other documents in the compartment,

be sure to put them in a vinyl bag so

they do not get wet. When washing the

motorcycle, be careful not to flood this

compartment with water.

EAU00285

Front fork adjustmentThis front fork is equipped with spring

preload adjusting bolts.

EW000037

WARNING

@ Each fork leg must be set to the

same pressure. Uneven setting can

cause poor handling and loss of sta-

bility. @Adjust spring preload as follows.

Turn the adjusting bolts in direction

a

to increase spring preload and in

direction

b to decrease spring pre-

load.

EC000013

CAUTION:@ The grooves are provided to show

the adjustment level. Always keep

the adjustment level equal on both

fork legs. @CI-18E

1. Strap for U-LOCK (´ 2)

1. Spring preload adjusting bolt

1. Setting

2. Front fork cap bolt

HardStan-

dardSoft

Adjusting

position123 4 567

Page 61 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-15

6

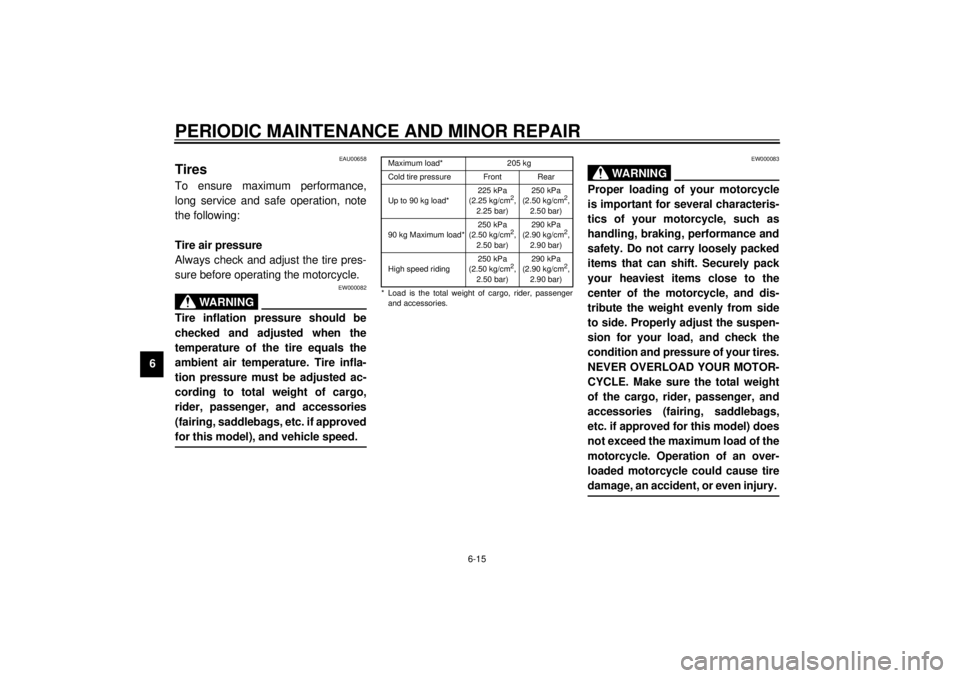

EAU00658

TiresTo ensure maximum performance,

long service and safe operation, note

the following:

Tire air pressure

Always check and adjust the tire pres-

sure before operating the motorcycle.

EW000082

WARNING

@ Tire inflation pressure should be

checked and adjusted when the

temperature of the tire equals the

ambient air temperature. Tire infla-

tion pressure must be adjusted ac-

cording to total weight of cargo,

rider, passenger, and accessories

(fairing, saddlebags, etc. if approved

for this model), and vehicle speed. @

CE-33EEW000083

WARNING

@ Proper loading of your motorcycle

is important for several characteris-

tics of your motorcycle, such as

handling, braking, performance and

safety. Do not carry loosely packed

items that can shift. Securely pack

your heaviest items close to the

center of the motorcycle, and dis-

tribute the weight evenly from side

to side. Properly adjust the suspen-

sion for your load, and check the

condition and pressure of your tires.

NEVER OVERLOAD YOUR MOTOR-

CYCLE. Make sure the total weight

of the cargo, rider, passenger, and

accessories (fairing, saddlebags,

etc. if approved for this model) does

not exceed the maximum load of the

motorcycle. Operation of an over-

loaded motorcycle could cause tire

damage, an accident, or even injury. @

Maximum load* 205 kg

Cold tire pressure Front Rear

Up to 90 kg load*225 kPa

(2.25 kg/cm

2,

2.25 bar)250 kPa

(2.50 kg/cm

2,

2.50 bar)

90 kg Maximum load*250 kPa

(2.50 kg/cm

2,

2.50 bar)290 kPa

(2.90 kg/cm

2,

2.90 bar)

High speed riding250 kPa

(2.50 kg/cm

2,

2.50 bar)290 kPa

(2.90 kg/cm

2,

2.90 bar)

* Load is the total weight of cargo, rider, passenger

and accessories.

Page 63 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-17

6

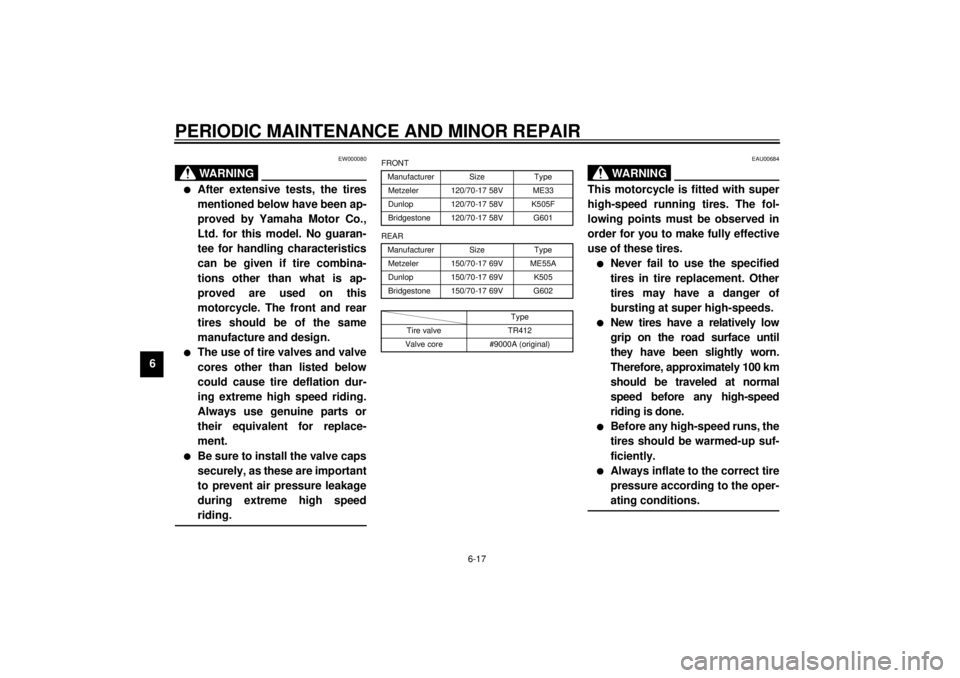

EW000080

WARNING

@ l

After extensive tests, the tires

mentioned below have been ap-

proved by Yamaha Motor Co.,

Ltd. for this model. No guaran-

tee for handling characteristics

can be given if tire combina-

tions other than what is ap-

proved are used on this

motorcycle. The front and rear

tires should be of the same

manufacture and design.

l

The use of tire valves and valve

cores other than listed below

could cause tire deflation dur-

ing extreme high speed riding.

Always use genuine parts or

their equivalent for replace-

ment.

l

Be sure to install the valve caps

securely, as these are important

to prevent air pressure leakage

during extreme high speed

riding.

@

CE-10E

CE-12EEAU00684

WARNING

@ This motorcycle is fitted with super

high-speed running tires. The fol-

lowing points must be observed in

order for you to make fully effective

use of these tires.l

Never fail to use the specified

tires in tire replacement. Other

tires may have a danger of

bursting at super high-speeds.

l

New tires have a relatively low

grip on the road surface until

they have been slightly worn.

Therefore, approximately 100 km

should be traveled at normal

speed before any high-speed

riding is done.

l

Before any high-speed runs, the

tires should be warmed-up suf-

ficiently.

l

Always inflate to the correct tire

pressure according to the oper-

ating conditions.

@

FRONT

Manufacturer Size Type

Metzeler 120/70-17 58V ME33

Dunlop 120/70-17 58V K505F

Bridgestone 120/70-17 58V G601

REAR

Manufacturer Size Type

Metzeler 150/70-17 69V ME55A

Dunlop 150/70-17 69V K505

Bridgestone 150/70-17 69V G602

Type

Tire valve TR412

Valve core #9000A (original)

Page 69 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-23

6

EAU02939

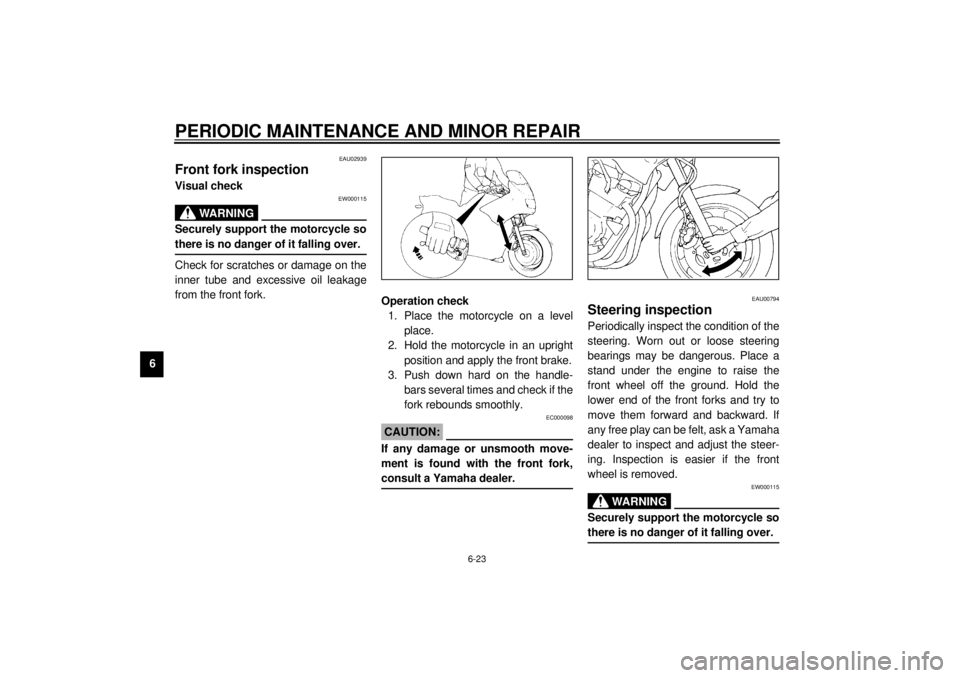

Front fork inspectionVisual check

EW000115

WARNING

@ Securely support the motorcycle so

there is no danger of it falling over. @Check for scratches or damage on the

inner tube and excessive oil leakage

from the front fork.

Operation check

1. Place the motorcycle on a level

place.

2. Hold the motorcycle in an upright

position and apply the front brake.

3. Push down hard on the handle-

bars several times and check if the

fork rebounds smoothly.

EC000098

CAUTION:@ If any damage or unsmooth move-

ment is found with the front fork,

consult a Yamaha dealer. @

EAU00794

Steering inspectionPeriodically inspect the condition of the

steering. Worn out or loose steering

bearings may be dangerous. Place a

stand under the engine to raise the

front wheel off the ground. Hold the

lower end of the front forks and try to

move them forward and backward. If

any free play can be felt, ask a Yamaha

dealer to inspect and adjust the steer-

ing. Inspection is easier if the front

wheel is removed.

EW000115

WARNING

@ Securely support the motorcycle so

there is no danger of it falling over. @

Page 73 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-27

63. Put a new bulb into position and

secure it in place with the bulb

holder.

EC000105

CAUTION:@ Avoid touching the glass part of a

bulb. Keep it free from oil; other-

wise, the transparency of the glass,

life of the bulb, and luminous flux

will be adversely affected. If oil gets

on a bulb, thoroughly clean it with a

cloth moistened with alcohol or lac-

quer thinner. @

4. Install the bulb holder cover and

the headlight connector.

If a headlight beam adjustment is

necessary, ask a Yamaha dealer

to make adjustment.

EAU00869

Front wheel removal

EW000122

WARNING

@ l

It is advisable to have a Yamaha

dealer service the wheel.

l

Securely support the motor-

cycle so there is no danger of it

falling over.

@1. Place the motorcycle on the cen-

terstand.

2. Remove the speedometer cable

from the front wheel side.

1. Don’t touch

1. Speedometer cable

Page 76 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-30

6

EAU01557

Rear wheel removal

EW000122

WARNING

@ l

It is advisable to have a Yamaha

dealer service the wheel.

l

Securely support the motor-

cycle so there is no danger of it

falling over.

@1. Loosen the wheel axle nut and

pinch bolt.

2. Place the motorcycle on the cen-

terstand.3. Remove the caliper bolts and

wheel axle nut.

4. Remove the brake torque rod cot-

ter pin, nut and bolt.

5. While supporting the brake cali-

per, pull out the wheel axle.

6. Move the wheel to the right to sep-

arate it from the final gear case,

then remove the wheel.

NOTE:@ Do not depress the brake pedal when

the disc and caliper are separated. @

1. Axle nut

1. Pinch bolt

1. Nut

2. Brake torque rod

3. Cotter pin

4. Bolt (´ 2)

Page 77 of 97

PERIODIC MAINTENANCE AND MINOR REPAIR

6-31

6

EAU01558*

Rear wheel installation1. Apply a light coating of lithium

soap base grease to the final gear

case splines and the rear wheel

hub splines.

2. Install the wheel and the wheel ax-

le.

3. Install the caliper and caliper bolts.

Make sure there is enough gap

between the brake pads before in-

stalling the caliper onto the brake

disc.4. Install the brake torque rod bolt

and nut.

5. Install the pinch bolt and tighten it

to the specified torque.

6. Take the motorcycle off the cen-

terstand.

7. Tighten the axle nut, caliper bolts

and brake torque rod nut to the

specified torques.

8. Secure the brake torque rod nut

with a new cotter pin.

EAU01008

TroubleshootingAlthough Yamaha motorcycles receive

a rigid inspection before shipment from

the factory, trouble may occur during

operation.

Any problem in the fuel, compression,

or ignition systems can cause poor

starting and loss of power. The trouble-

shooting chart describes a quick, easy

procedure for making checks.

If your motorcycle requires any repair,

bring it to a Yamaha dealer. The skilled

technicians at a Yamaha dealership

have the tools, experience, and know-

how to properly service your motor-

cycle. Use only genuine Yamaha parts

on your motorcycle. Imitation parts may

look like Yamaha parts, but they are of-

ten inferior. Consequently, they have a

shorter service life and can lead to ex-

pensive repair bills.

1. Splines

Tightening torque:

Pinch bolt:

16 Nm (1.6 m·kg)

Axle nut:

105 Nm (10.5 m·kg)

Caliper bolt:

35 Nm (3.5 m·kg)

Brake torque rod nut:

23 Nm (2.3 m·kg)