lock YAMAHA XJR 1300 2013 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: XJR 1300, Model: YAMAHA XJR 1300 2013Pages: 98, PDF Size: 2.34 MB

Page 30 of 98

INSTRUMENT AND CONTROL FUNCTIONS

3-15

3

EAU13445

Catalytic converters This vehicle is equipped with catalytic

converters in the exhaust system.

WARNING

EWA10862

The exhaust system is hot after op-

eration. To prevent a fire hazard or

burns:●

Do not park the vehicle near

possible fire hazards such as

grass or other materials that

easily burn.

●

Park the vehicle in a place

where pedestrians or children

are not likely to touch the hot

exhaust system.

●

Make sure that the exhaust sys-

tem has cooled down before do-

ing any maintenance work.

●

Do not allow the engine to idle

more than a few minutes. Long

idling can cause a build-up of

heat.

NOTICE

ECA10701

Use only unleaded gasoline. The use

of leaded gasoline will cause unre-

pairable damage to the catalytic

converter.

EAU13900

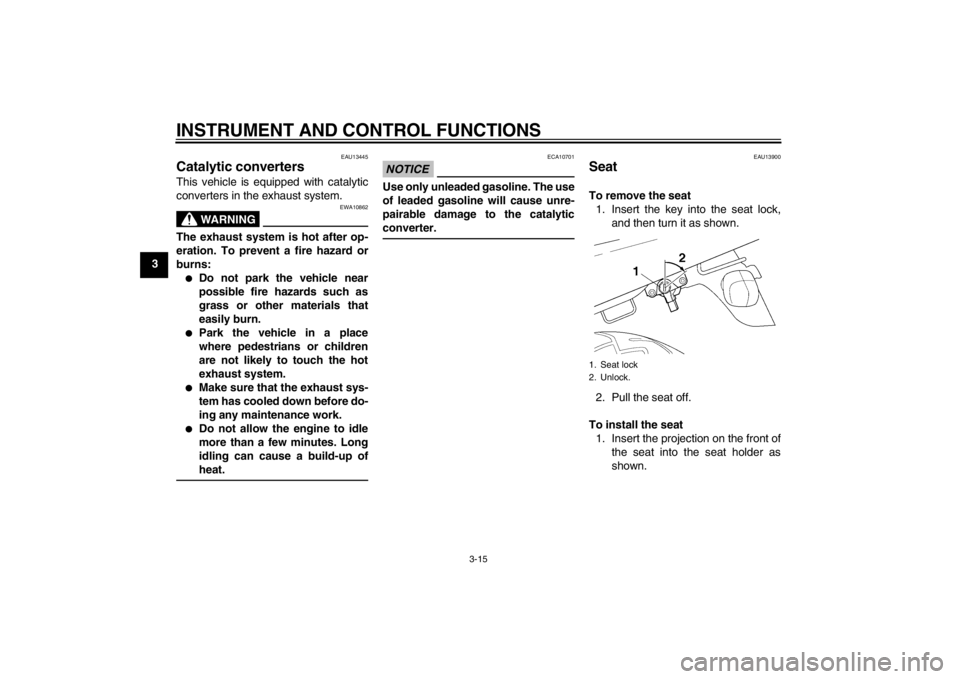

Seat To remove the seat1. Insert the key into the seat lock, and then turn it as shown.

2. Pull the seat off.

To install the seat 1. Insert the projection on the front of the seat into the seat holder as

shown.1. Seat lock

2. Unlock.

U5WME9E0.book Page 15 Friday, December 7, 2012 3:50 PM

Page 31 of 98

INSTRUMENT AND CONTROL FUNCTIONS

3-16

3

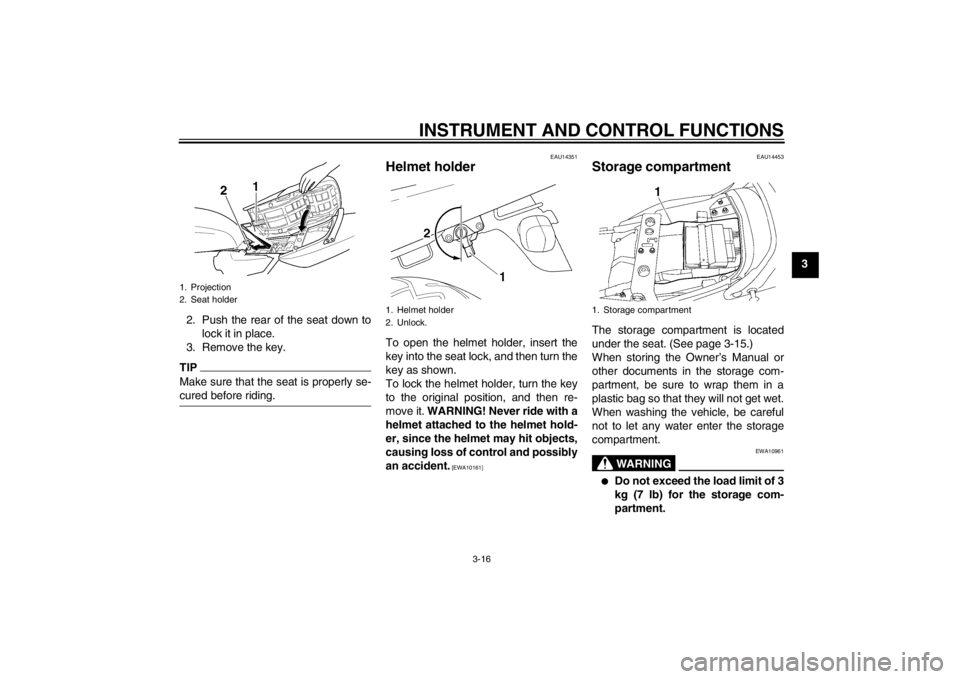

2. Push the rear of the seat down to lock it in place.

3. Remove the key.

TIPMake sure that the seat is properly se-

cured before riding.

EAU14351

Helmet holder To open the helmet holder, insert the

key into the seat lock, and then turn the

key as shown.

To lock the helmet holder, turn the key

to the original position, and then re-

move it. WARNING! Never ride with a

helmet attached to the helmet hold-

er, since the helmet may hit objects,

causing loss of control and possibly

an accident.

[EWA10161] EAU14453

Storage compartment The storage compartment is located

under the seat. (See page 3-15.)

When storing the Owner’s Manual or

other documents in the storage com-

partment, be sure to wrap them in a

plastic bag so that they will not get wet.

When washing the vehicle, be careful

not to let any water enter the storage

compartment.

WARNING

EWA10961

●

Do not exceed the load limit of 3

kg (7 lb) for the storage com-

partment.

1. Projection

2. Seat holder

1. Helmet holder

2. Unlock.

1. Storage compartment

U5WME9E0.book Page 16 Friday, December 7, 2012 3:50 PM

Page 34 of 98

INSTRUMENT AND CONTROL FUNCTIONS

3-19

3

EAU43256

Adjusting the shock absorber

assembly

WARNING

EWA10210

Always adjust both shock absorber

assemblies equally, otherwise poor

handling and loss of stability may

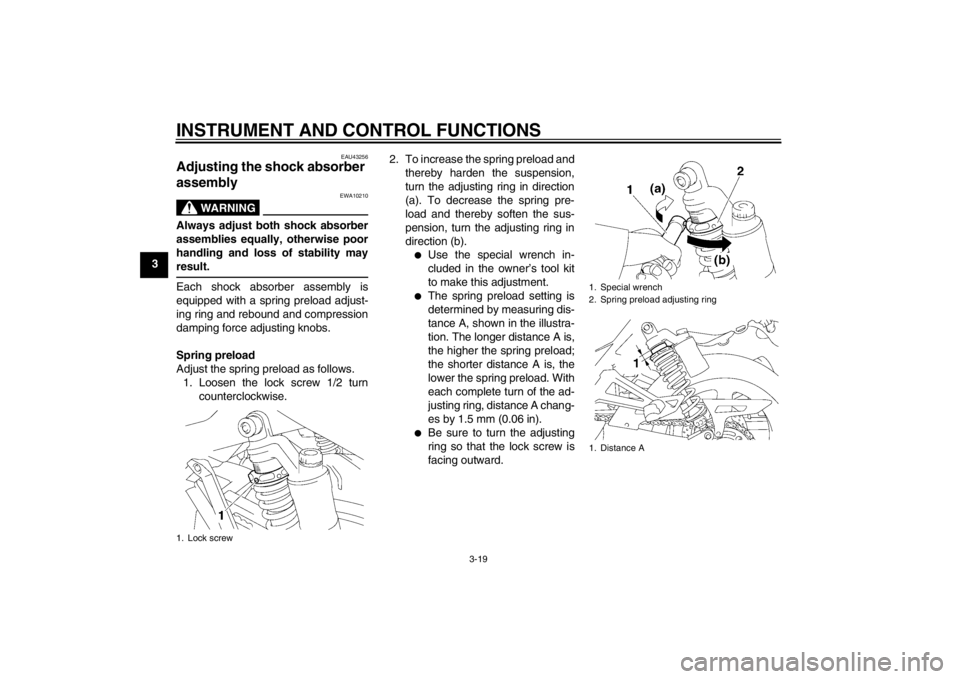

result.Each shock absorber assembly is

equipped with a spring preload adjust-

ing ring and rebound and compression

damping force adjusting knobs.

Spring preload

Adjust the spring preload as follows.1. Loosen the lock screw 1/2 turn counterclockwise. 2. To increase the spring preload and

thereby harden the suspension,

turn the adjusting ring in direction

(a). To decrease the spring pre-

load and thereby soften the sus-

pension, turn the adjusting ring in

direction (b).

●

Use the special wrench in-

cluded in the owner’s tool kit

to make this adjustment.

●

The spring preload setting is

determined by measuring dis-

tance A, shown in the illustra-

tion. The longer distance A is,

the higher the spring preload;

the shorter distance A is, the

lower the spring preload. With

each complete turn of the ad-

justing ring, distance A chang-

es by 1.5 mm (0.06 in).

●

Be sure to turn the adjusting

ring so that the lock screw is

facing outward.

1. Lock screw

1. Special wrench

2. Spring preload adjusting ring

1. Distance A

U5WME9E0.book Page 19 Friday, December 7, 2012 3:50 PM

Page 35 of 98

INSTRUMENT AND CONTROL FUNCTIONS

3-20

3

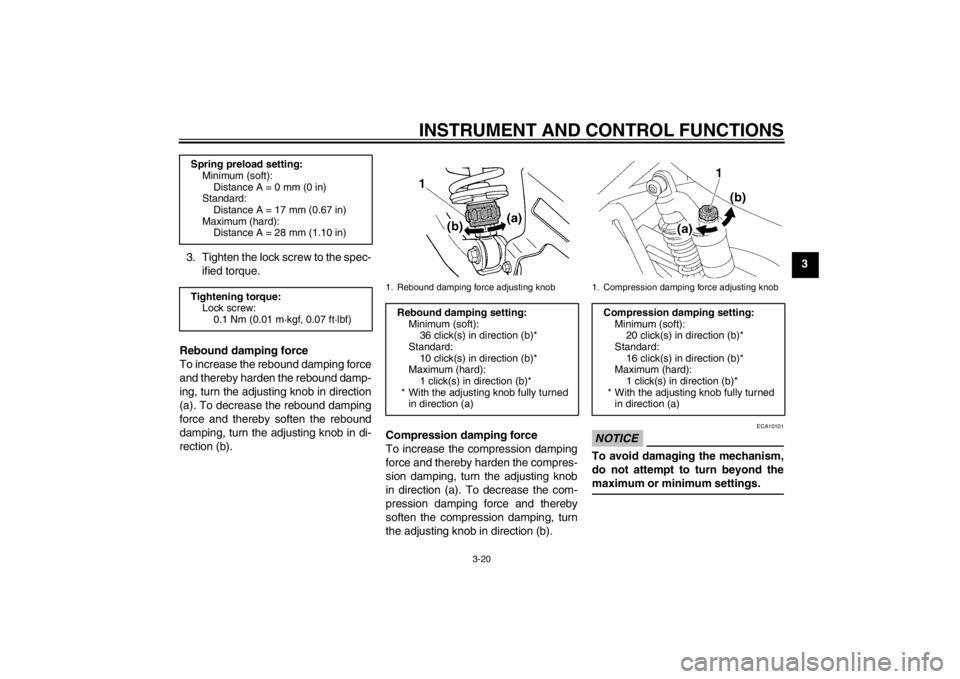

3. Tighten the lock screw to the spec-

ified torque.

Rebound damping force

To increase the rebound damping force

and thereby harden the rebound damp-

ing, turn the adjusting knob in direction

(a). To decrease the rebound damping

force and thereby soften the rebound

damping, turn the adjusting knob in di-

rection (b). Compression damping force

To increase the compression damping

force and thereby harden the compres-

sion damping, turn the adjusting knob

in direction (a). To decrease the com-

pression damping force and thereby

soften the compression damping, turn

the adjusting knob in direction (b).

NOTICE

ECA10101

To avoid damaging the mechanism,

do not attempt to turn beyond the

maximum or minimum settings.

Spring preload setting:

Minimum (soft):

Distance A = 0 mm (0 in)

Standard:

Distance A = 17 mm (0.67 in)

Maximum (hard): Distance A = 28 mm (1.10 in)

Tightening torque: Lock screw:

0.1 Nm (0.01 m·kgf, 0.07 ft·lbf)

1. Rebound damping force adjusting knob

Rebound damping setting: Minimum (soft):36 click(s) in direction (b)*

Standard: 10 click(s) in direction (b)*

Maximum (hard):

1 click(s) in direction (b)*

* With the adjusting knob fully turned in direction (a)

1. Compression damping force adjusting knob

Compression damping setting: Minimum (soft): 20 click(s) in direction (b)*

Standard: 16 click(s) in direction (b)*

Maximum (hard):

1 click(s) in direction (b)*

* With the adjusting knob fully turned in direction (a)

U5WME9E0.book Page 20 Friday, December 7, 2012 3:50 PM

Page 67 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-21

6

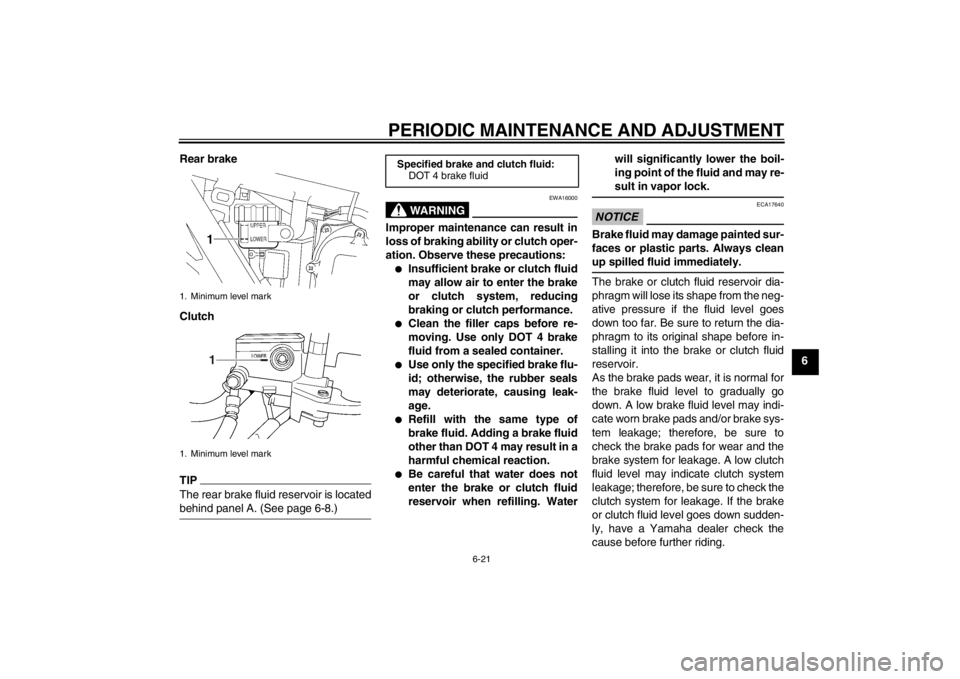

Rear brake

Clutch

TIPThe rear brake fluid reservoir is located

behind panel A. (See page 6-8.)

WARNING

EWA16000

Improper maintenance can result in

loss of braking ability or clutch oper-

ation. Observe these precautions:●

Insufficient brake or clutch fluid

may allow air to enter the brake

or clutch system, reducing

braking or clutch performance.

●

Clean the filler caps before re-

moving. Use only DOT 4 brake

fluid from a sealed container.

●

Use only the specified brake flu-

id; otherwise, the rubber seals

may deteriorate, causing leak-

age.

●

Refill with the same type of

brake fluid. Adding a brake fluid

other than DOT 4 may result in a

harmful chemical reaction.

●

Be careful that water does not

enter the brake or clutch fluid

reservoir when refilling. Water will significantly lower the boil-

ing point of the fluid and may re-

sult in vapor lock.

NOTICE

ECA17640

Brake fluid may damage painted sur-

faces or plastic parts. Always clean

up spilled fluid immediately.The brake or clutch fluid reservoir dia-

phragm will lose its shape from the neg-

ative pressure if the fluid level goes

down too far. Be sure to return the dia-

phragm to its original shape before in-

stalling it into the brake or clutch fluid

reservoir.

As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake sys-

tem leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. A low clutch

fluid level may indicate clutch system

leakage; therefore, be sure to check the

clutch system for leakage. If the brake

or clutch fluid level goes down sudden-

ly, have a Yamaha dealer check the

cause before further riding.

1. Minimum level mark

1. Minimum level mark

1

Specified brake and clutch fluid:

DOT 4 brake fluid

U5WME9E0.book Page 21 Friday, December 7, 2012 3:50 PM

Page 68 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-22

6

EAU22752

Changing the brake and

clutch fluids Have a Yamaha dealer change the

brake and clutch fluids at the intervals

specified in the periodic maintenance

and lubrication chart or in the TIP after

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the brake and clutch master cylin-

ders and calipers as well as the brake

and clutch hoses replaced at the inter-

vals listed below or whenever they are

damaged or leaking.●

Oil seals: Replace every two

years.

●

Brake and clutch hoses: Replace

every four years.

EAU22760

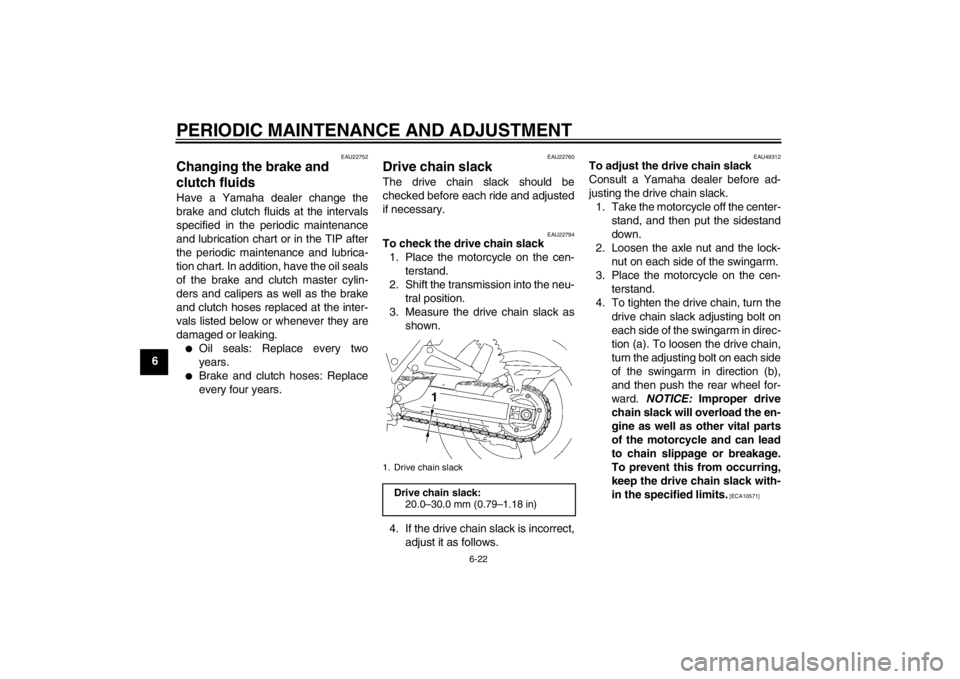

Drive chain slack The drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU22794

To check the drive chain slack1. Place the motorcycle on the cen- terstand.

2. Shift the transmission into the neu- tral position.

3. Measure the drive chain slack as shown.

4. If the drive chain slack is incorrect, adjust it as follows.

EAU49312

To adjust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack.1. Take the motorcycle off the center- stand, and then put the sidestand

down.

2. Loosen the axle nut and the lock- nut on each side of the swingarm.

3. Place the motorcycle on the cen- terstand.

4. To tighten the drive chain, turn the drive chain slack adjusting bolt on

each side of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting bolt on each side

of the swingarm in direction (b),

and then push the rear wheel for-

ward. NOTICE: Improper drive

chain slack will overload the en-

gine as well as other vital parts

of the motorcycle and can lead

to chain slippage or breakage.

To prevent this from occurring,

keep the drive chain slack with-

in the specified limits.

[ECA10571]

1. Drive chain slackDrive chain slack: 20.0–30.0 mm (0.79–1.18 in)

1

U5WME9E0.book Page 22 Friday, December 7, 2012 3:50 PM

Page 69 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-23

6

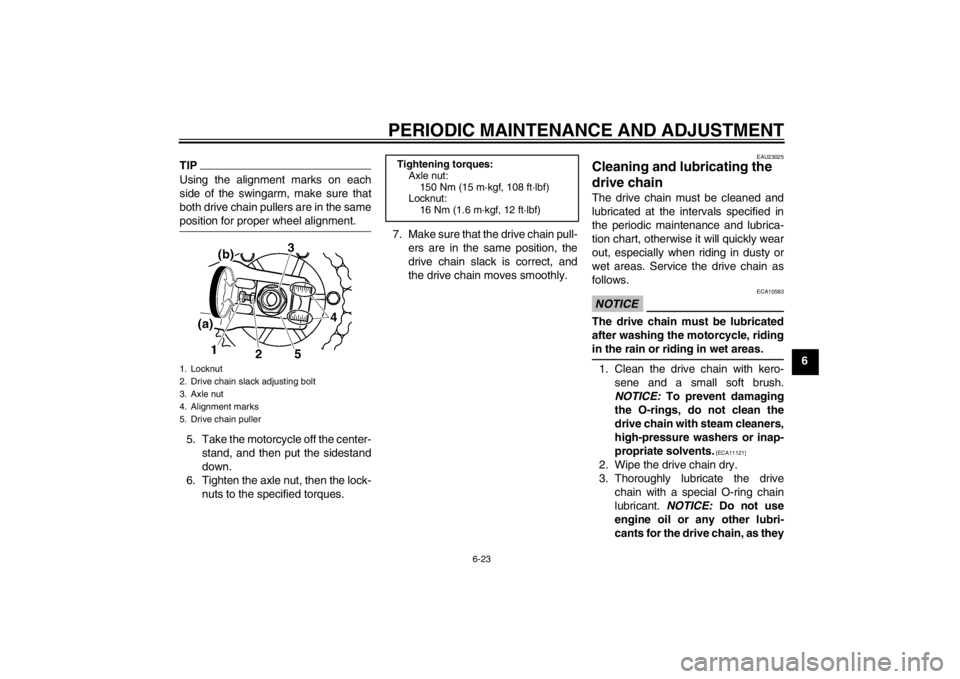

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain pullers are in the same

position for proper wheel alignment.5. Take the motorcycle off the center-stand, and then put the sidestand

down.

6. Tighten the axle nut, then the lock- nuts to the specified torques. 7. Make sure that the drive chain pull-

ers are in the same position, the

drive chain slack is correct, and

the drive chain moves smoothly.

EAU23025

Cleaning and l ubricating the

drive chain The drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10583

The drive chain must be lubricated

after washing the motorcycle, riding

in the rain or riding in wet areas.1. Clean the drive chain with kero-

sene and a small soft brush.

NOTICE: To prevent damaging

the O-rings, do not clean the

drive chain with steam cleaners,

high-pressure washers or inap-

propriate solvents.

[ECA11121]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

engine oil or any other lubri-

cants for the drive chain, as they

1. Locknut

2. Drive chain slack adjusting bolt

3. Axle nut

4. Alignment marks

5. Drive chain puller

Tightening torques: Axle nut:

150 Nm (15 m·kgf, 108 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

U5WME9E0.book Page 23 Friday, December 7, 2012 3:50 PM

Page 76 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-30

6

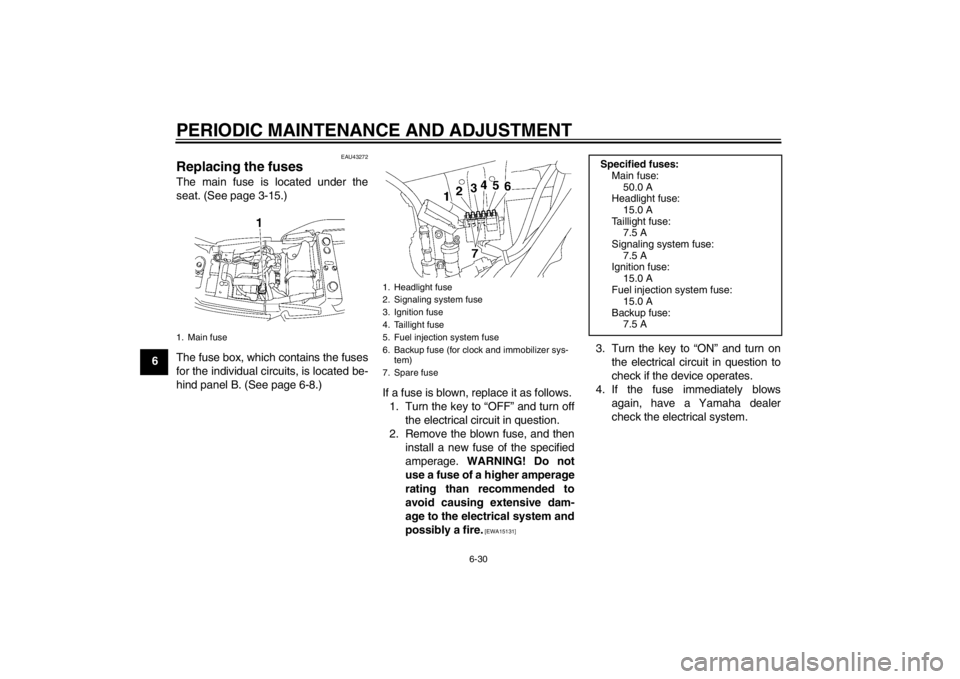

EAU43272

Replacing the fuses The main fuse is located under the

seat. (See page 3-15.)

The fuse box, which contains the fuses

for the individual circuits, is located be-

hind panel B. (See page 6-8.)If a fuse is blown, replace it as follows.

1. Turn the key to “OFF” and turn off the electrical circuit in question.

2. Remove the blown fuse, and then install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a higher amperage

rating than recommended to

avoid causing extensive dam-

age to the electrical system and

possibly a fire.

[EWA15131]

3. Turn the key to “ON” and turn on the electrical circuit in question to

check if the device operates.

4. If the fuse immediately blows again, have a Yamaha dealer

check the electrical system.

1. Main fuse

1. Headlight fuse

2. Signaling system fuse

3. Ignition fuse

4. Taillight fuse

5. Fuel injection system fuse

6. Backup fuse (for clock and immobilizer sys-tem)

7. Spare fuse

Specified fuses: Main fuse:

50.0 A

Headlight fuse:

15.0 A

Taillight fuse: 7.5 A

Signaling system fuse: 7.5 A

Ignition fuse:

15.0 A

Fuel injection system fuse: 15.0 A

Backup fuse: 7.5 A

U5WME9E0.book Page 30 Friday, December 7, 2012 3:50 PM

Page 78 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-32

65. Install the bulb cover, and then

connect the coupler.

6. Install the headlight unit by install- ing the screws.

7. Have a Yamaha dealer adjust the headlight beam if necessary.

EAU24181

Tail/brake light This model is equipped with an LED-

type tail/brake light.

If the tail/brake light does not come on,

have a Yamaha dealer check it.

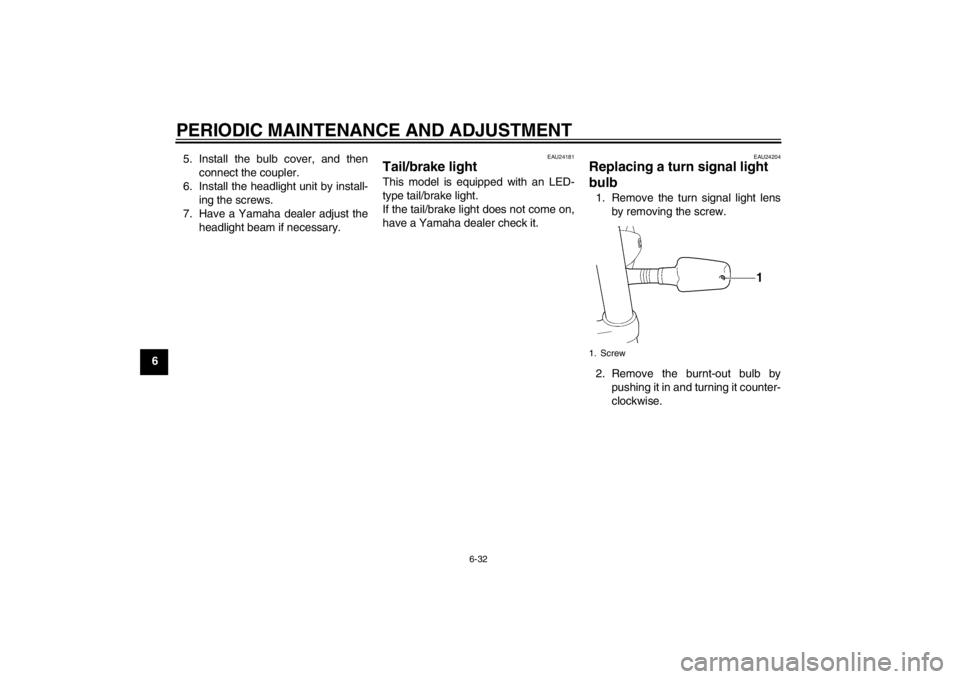

EAU24204

Replacing a turn signal light

bulb 1. Remove the turn signal light lensby removing the screw.

2. Remove the burnt-out bulb by pushing it in and turning it counter-

clockwise.1. Screw

U5WME9E0.book Page 32 Friday, December 7, 2012 3:50 PM

Page 79 of 98

PERIODIC MAINTENANCE AND ADJUSTMENT

6-33

6

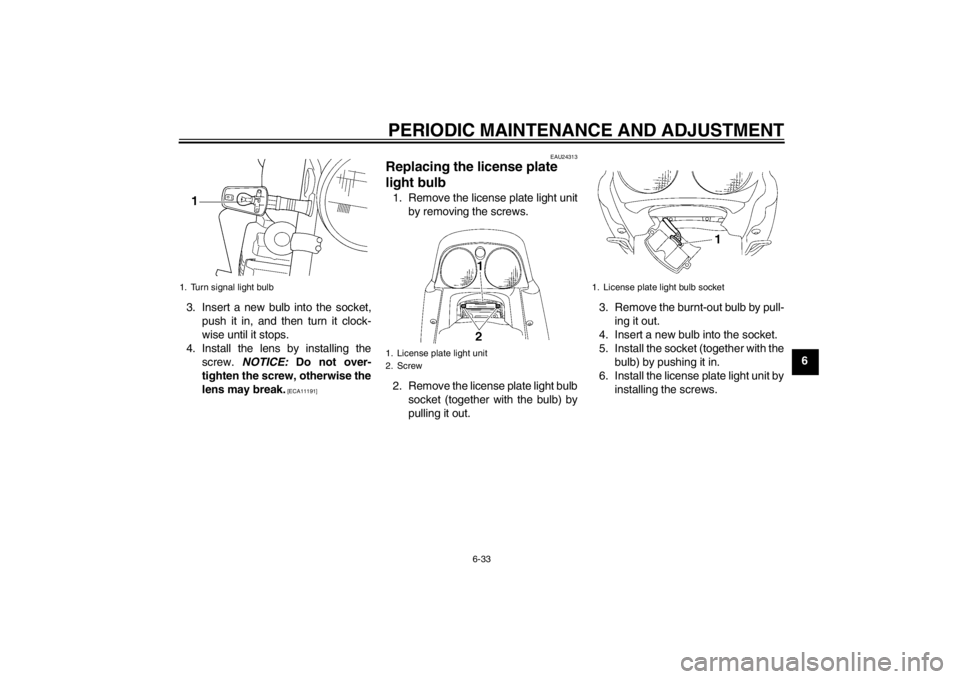

3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the screw. NOTICE: Do not over-

tighten the screw, otherwise the

lens may break.

[ECA11191] EAU24313

Replacing the license plate

light bulb 1. Remove the license plate light unit

by removing the screws.

2. Remove the license plate light bulb socket (together with the bulb) by

pulling it out. 3. Remove the burnt-out bulb by pull-

ing it out.

4. Insert a new bulb into the socket.

5. Install the socket (together with the bulb) by pushing it in.

6. Install the license plate light unit by installing the screws.

1. Turn signal light bulb

1. License plate light unit

2. Screw

1. License plate light bulb socket

U5WME9E0.book Page 33 Friday, December 7, 2012 3:50 PM