YAMAHA XL 700 2001 Owners Manual

Manufacturer: YAMAHA, Model Year: 2001, Model line: XL 700, Model: YAMAHA XL 700 2001Pages: 111, PDF Size: 12.05 MB

Page 91 of 111

4-16

E

EJU00566a

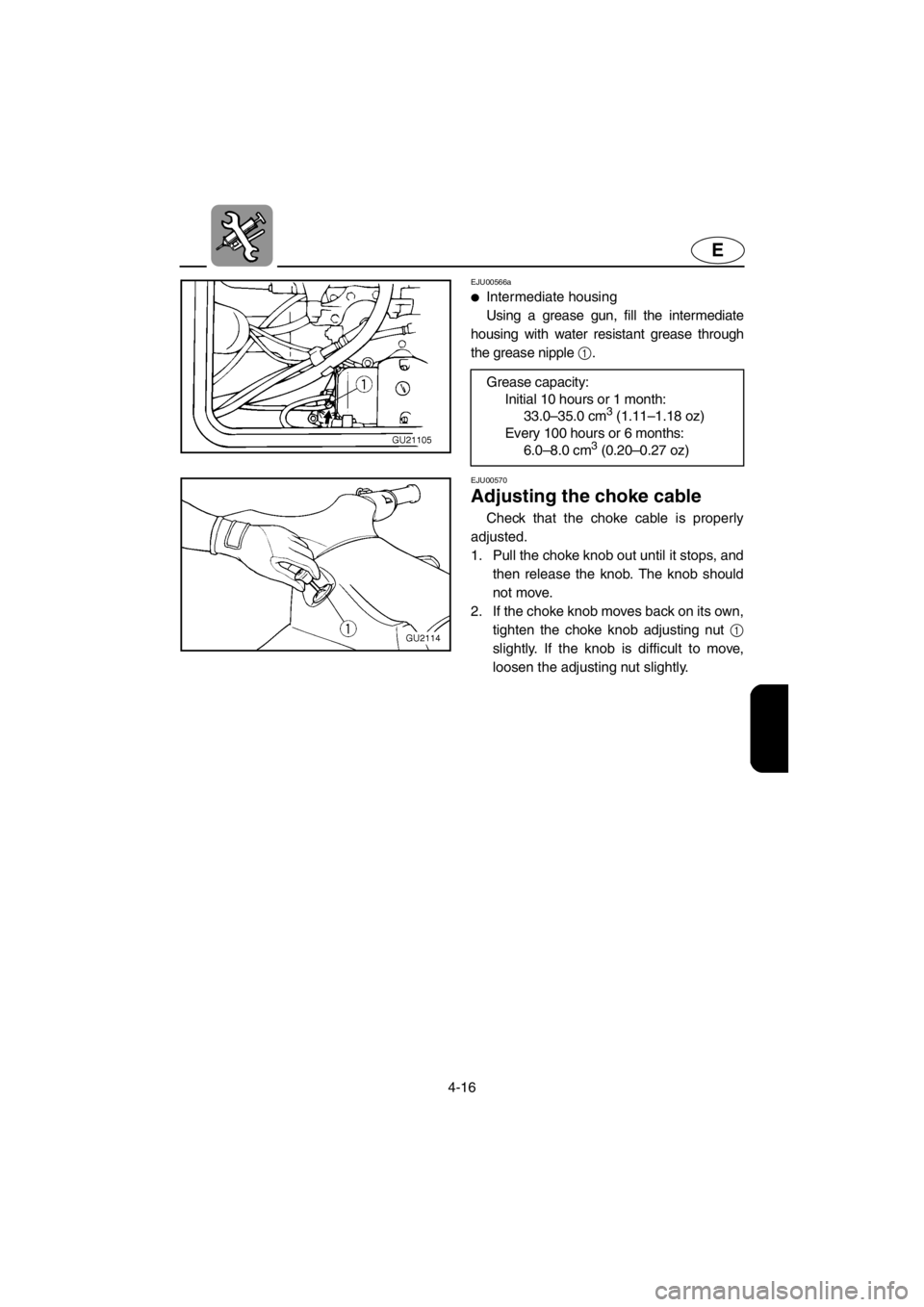

●Intermediate housing

Using a grease gun, fill the intermediate

housing with water resistant grease through

the grease nipple 1.

Grease capacity:

Initial 10 hours or 1 month:

33.0–35.0 cm

3 (1.11–1.18 oz)

Every 100 hours or 6 months:

6.0–8.0 cm

3 (0.20–0.27 oz)

EJU00570

Adjusting the choke cable

Check that the choke cable is properly

adjusted.

1. Pull the choke knob out until it stops, and

then release the knob. The knob should

not move.

2. If the choke knob moves back on its own,

tighten the choke knob adjusting nut 1

slightly. If the knob is difficult to move,

loosen the adjusting nut slightly.

E_F0M-72-4.fm Page 16 Thursday, July 27, 2000 9:53 AM

Page 92 of 111

4-17

E

EJU00572

Inspecting the battery

Check the level of the battery electrolyte

and make sure the leads are secure.

WARNING

Battery electrolyte is poisonous and dan-

gerous, causing severe burns, etc. Elec-

trolyte contains sulfuric acid. Avoid

contact with skin, eyes or clothing.

Antidotes

External: Flush with water.

Internal: Drink large quantities of water

or milk. Follow with milk of magnesia,

beaten egg or vegetable oil. Call physi-

cian immediately.

Eyes: Flush with water for 15 minutes

and get prompt medical attention.

Batteries produce explosive gases. Keep

sparks, flame, cigarettes, etc., well away.

If using or charging the battery in an

enclosed space, make sure that it is well

ventilated. Always shield your eyes when

working near batteries.

KEEP OUT OF THE REACH OF CHIL-

DREN.

CAUTION:

Be careful not to place the battery on its

side.

Make sure to remove the battery from the

battery compartment when adding bat-

tery electrolyte or charging the battery.

When checking the battery, make sure

the breather hose is connected to the

battery and not obstructed.

E_F0M-72-4.fm Page 17 Thursday, July 27, 2000 9:53 AM

Page 93 of 111

4-18

E

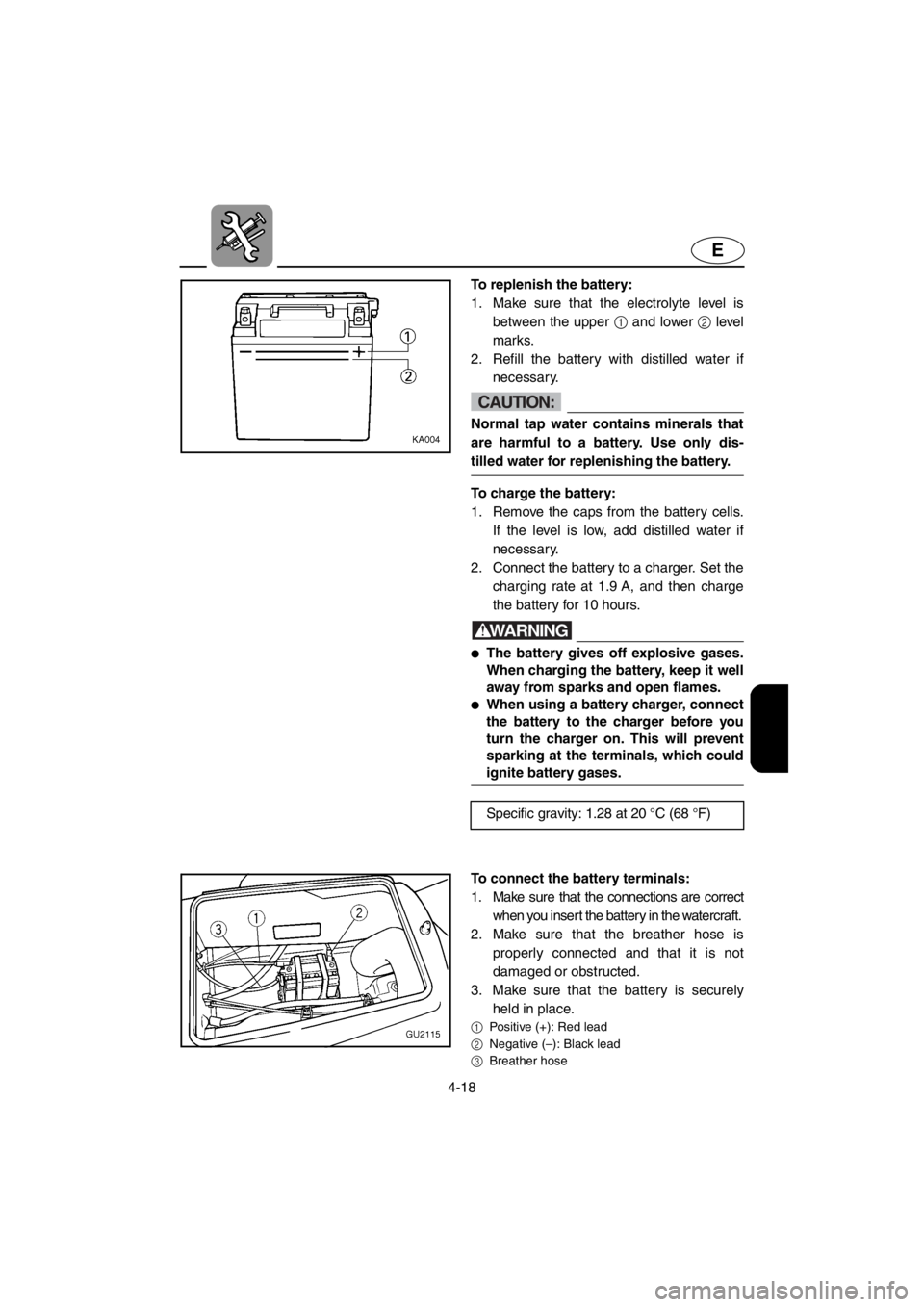

To replenish the battery:

1. Make sure that the electrolyte level is

between the upper 1 and lower 2 level

marks.

2. Refill the battery with distilled water if

necessary.

CAUTION:

Normal tap water contains minerals that

are harmful to a battery. Use only dis-

tilled water for replenishing the battery.

To charge the battery:

1. Remove the caps from the battery cells.

If the level is low, add distilled water if

necessary.

2. Connect the battery to a charger. Set the

charging rate at 1.9 A, and then charge

the battery for 10 hours.

WARNING

●The battery gives off explosive gases.

When charging the battery, keep it well

away from sparks and open flames.

●When using a battery charger, connect

the battery to the charger before you

turn the charger on. This will prevent

sparking at the terminals, which could

ignite battery gases.

Specific gravity: 1.28 at 20 °C (68 °F)

To connect the battery terminals:

1. Make sure that the connections are correct

when you insert the battery in the watercraft.

2. Make sure that the breather hose is

properly connected and that it is not

damaged or obstructed.

3. Make sure that the battery is securely

held in place.

1Positive (+): Red lead

2Negative (–): Black lead

3Breather hose

E_F0M-72-4.fm Page 18 Thursday, July 27, 2000 9:53 AM

Page 94 of 111

4-19

E

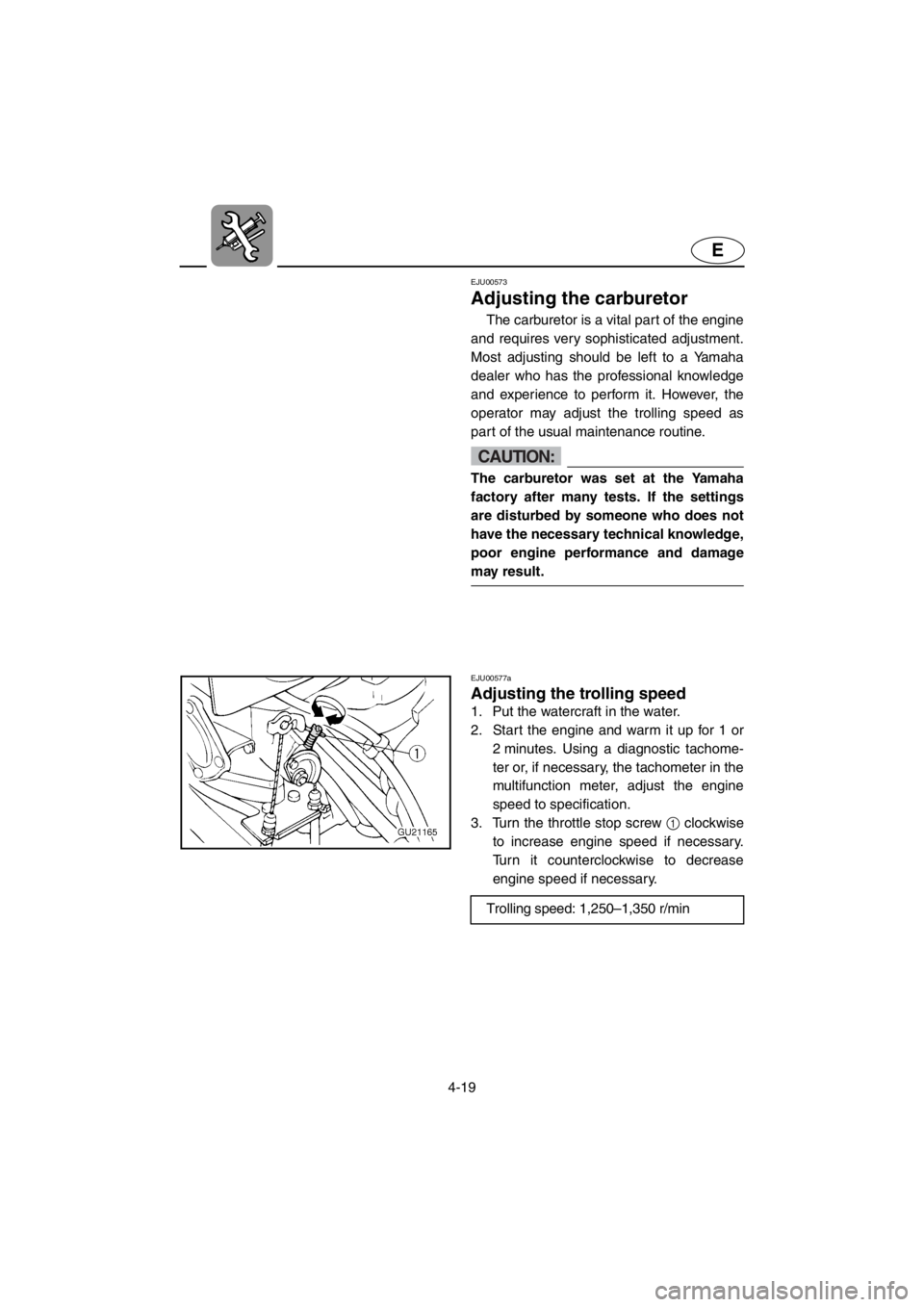

EJU00573

Adjusting the carburetor

The carburetor is a vital part of the engine

and requires very sophisticated adjustment.

Most adjusting should be left to a Yamaha

dealer who has the professional knowledge

and experience to perform it. However, the

operator may adjust the trolling speed as

part of the usual maintenance routine.

CAUTION:

The carburetor was set at the Yamaha

factory after many tests. If the settings

are disturbed by someone who does not

have the necessary technical knowledge,

poor engine performance and damage

may result.

EJU00577a

Adjusting the trolling speed

1. Put the watercraft in the water.

2. Start the engine and warm it up for 1 or

2 minutes. Using a diagnostic tachome-

ter or, if necessary, the tachometer in the

multifunction meter, adjust the engine

speed to specification.

3. Turn the throttle stop screw 1 clockwise

to increase engine speed if necessary.

Turn it counterclockwise to decrease

engine speed if necessary.

Trolling speed: 1,250–1,350 r/min

E_F0M-72-4.fm Page 19 Thursday, July 27, 2000 9:53 AM

Page 95 of 111

4-20

E

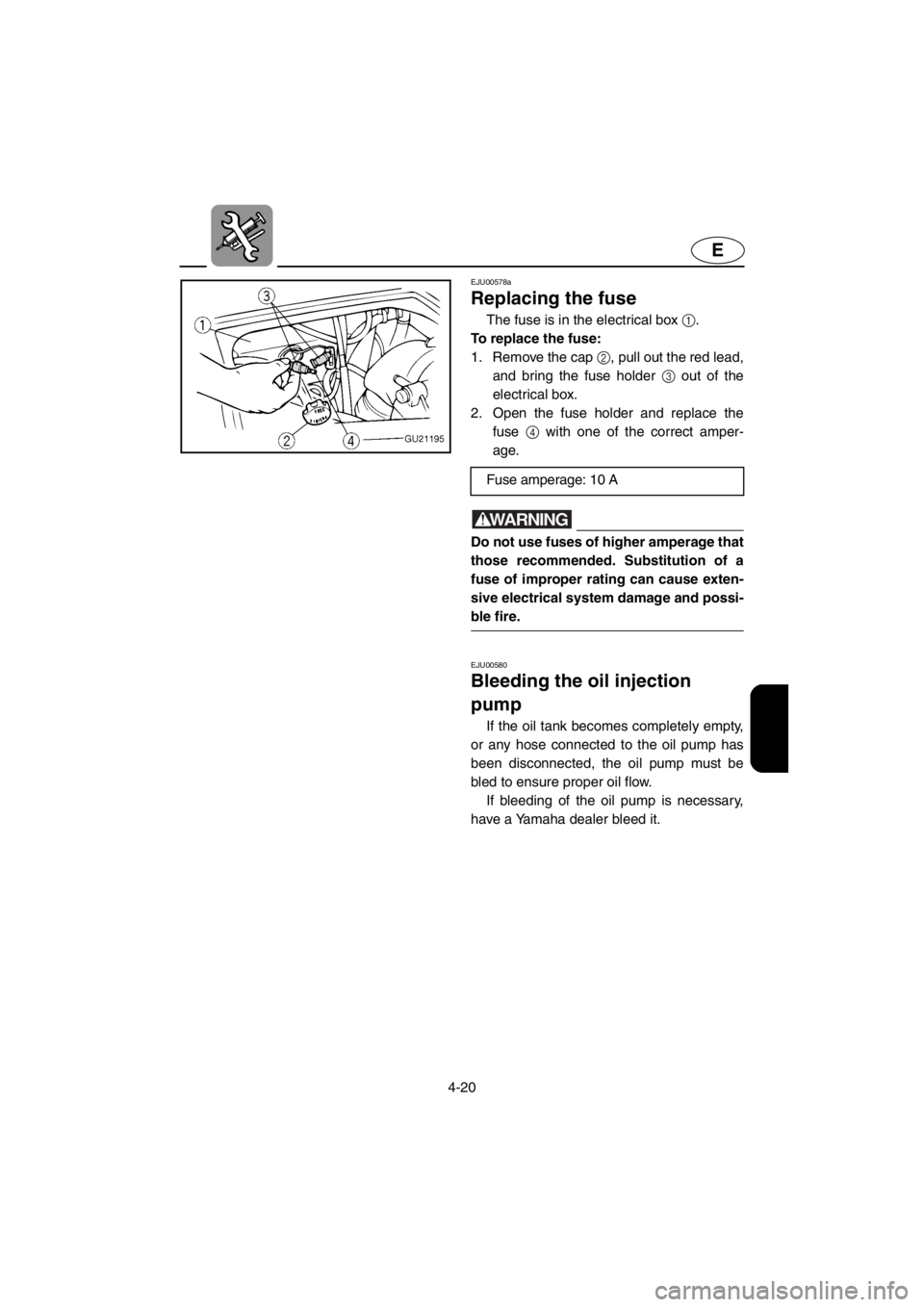

EJU00578a

Replacing the fuse

The fuse is in the electrical box 1.

To replace the fuse:

1. Remove the cap 2, pull out the red lead,

and bring the fuse holder 3 out of the

electrical box.

2. Open the fuse holder and replace the

fuse4 with one of the correct amper-

age.

WARNING

Do not use fuses of higher amperage that

those recommended. Substitution of a

fuse of improper rating can cause exten-

sive electrical system damage and possi-

ble fire.

EJU00580

Bleeding the oil injection

pump

If the oil tank becomes completely empty,

or any hose connected to the oil pump has

been disconnected, the oil pump must be

bled to ensure proper oil flow.

If bleeding of the oil pump is necessary,

have a Yamaha dealer bleed it.Fuse amperage: 10 A

E_F0M-72-4.fm Page 20 Thursday, July 27, 2000 9:53 AM

Page 96 of 111

4-21

E

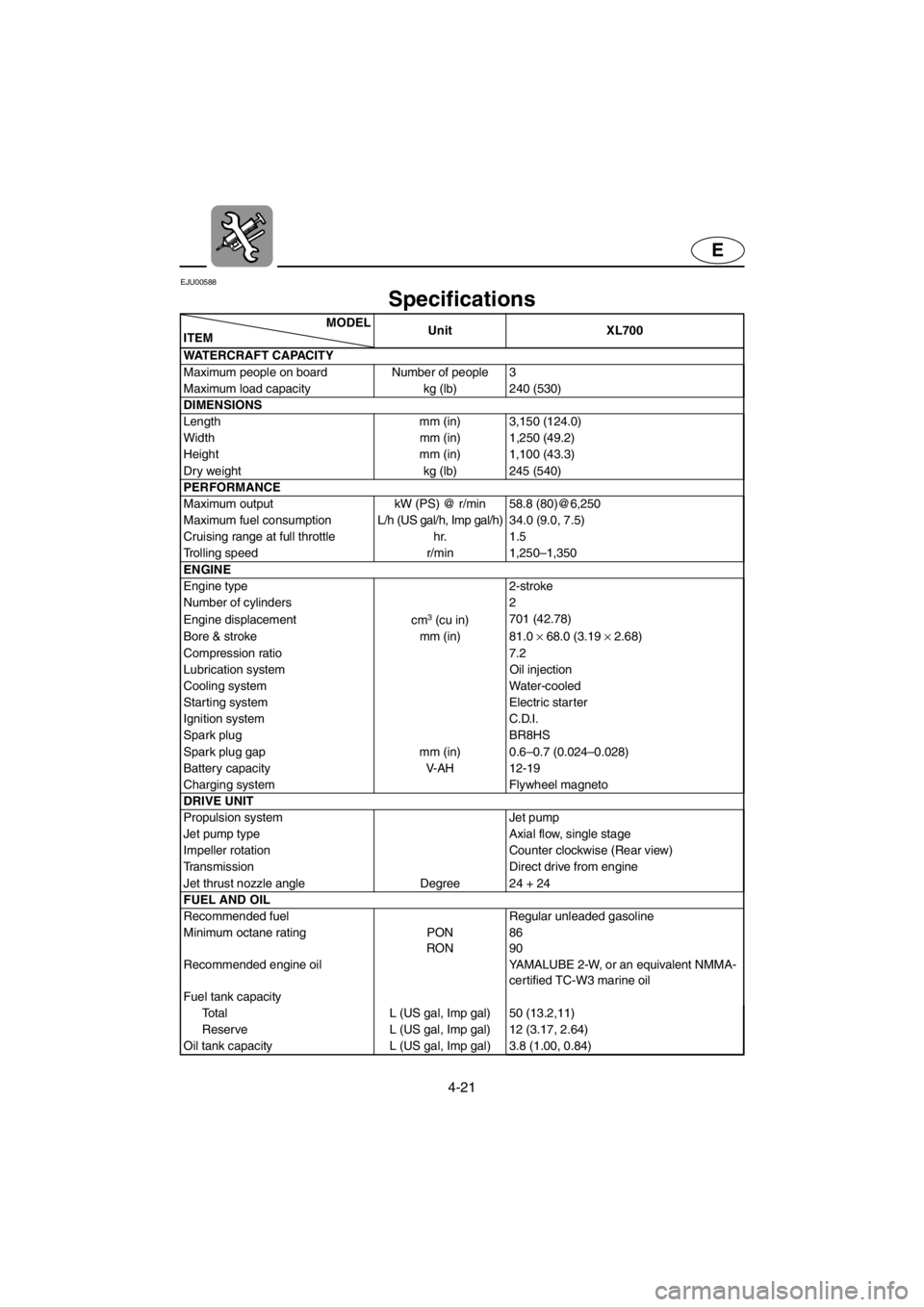

EJU00588

Specifications

MODEL

ITEMUnit XL700

WATERCRAFT CAPACITY

Maximum people on board Number of people 3

Maximum load capacity kg (lb) 240 (530)

DIMENSIONS

Length mm (in) 3,150 (124.0)

Width mm (in) 1,250 (49.2)

Height mm (in) 1,100 (43.3)

Dry weight kg (lb) 245 (540)

PERFORMANCE

Maximum output kW (PS) @ r/min 58.8 (80)@6,250

Maximum fuel consumption L/h (US gal/h, Imp gal/h) 34.0 (9.0, 7.5)

Cruising range at full throttle hr. 1.5

Trolling speed r/min 1,250–1,350

ENGINE

Engine type 2-stroke

Number of cylinders 2

Engine displacement

cm

3 (cu in)701 (42.78)

Bore & stroke mm (in) 81.0 ×

68.0 (3.19 ×

2.68)

Compression ratio 7.2

Lubrication system Oil injection

Cooling system Water-cooled

Starting system Electric starter

Ignition system C.D.I.

Spark plug BR8HS

Spark plug gap mm (in) 0.6–0.7 (0.024–0.028)

Battery capacity V-AH 12-19

Charging system Flywheel magneto

DRIVE UNIT

Propulsion system Jet pump

Jet pump type Axial flow, single stage

Impeller rotation Counter clockwise (Rear view)

Transmission Direct drive from engine

Jet thrust nozzle angle Degree 24 + 24

FUEL AND OIL

Recommended fuel Regular unleaded gasoline

Minimum octane rating PON

RON86

90

Recommended engine oil YAMALUBE 2-W, or an equivalent NMMA-

certified TC-W3 marine oil

Fuel tank capacity

Total L (US gal, Imp gal) 50 (13.2,11)

Reserve L (US gal, Imp gal) 12 (3.17, 2.64)

Oil tank capacity L (US gal, Imp gal) 3.8 (1.00, 0.84)

E_F0M-72-4.fm Page 21 Thursday, July 27, 2000 9:53 AM

Page 97 of 111

E

5

EJU00594

TROUBLESHOOTING

AND EMERGENCY

PROCEDURES

Troubleshooting....................................... 5-1

Troubleshooting chart ............................. 5-1

Emergency procedures........................... 5-3

Cleaning the jet intake and impeller ....... 5-3

Jumping the battery ................................ 5-4

Towing the watercraft ............................. 5-6

Submerged watercraft ............................ 5-7

E_F0M-72-5TOC.fm Page 1 Thursday, July 27, 2000 9:57 AM

Page 98 of 111

5-1

E

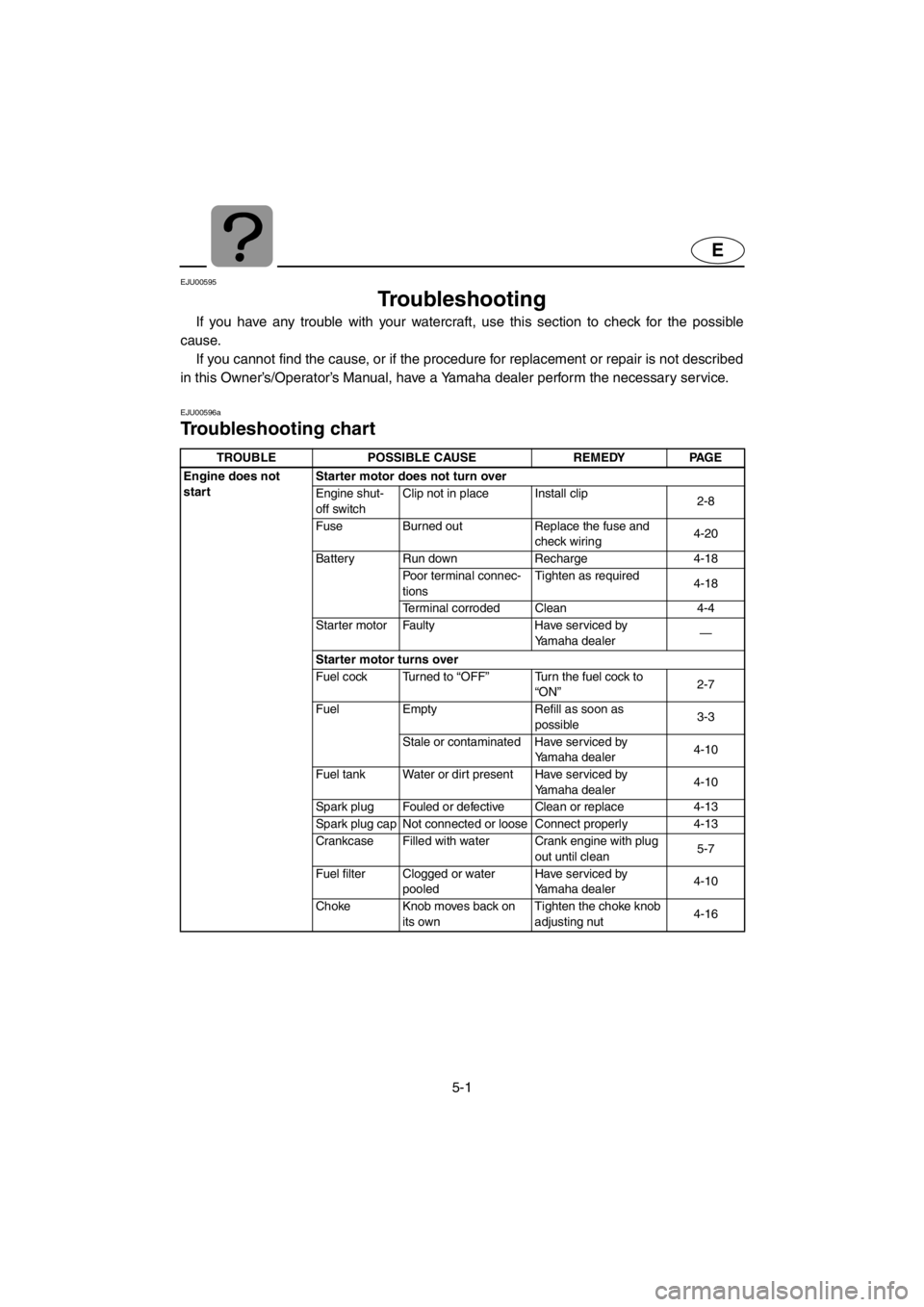

EJU00595

Troubleshooting

If you have any trouble with your watercraft, use this section to check for the possible

cause.

If you cannot find the cause, or if the procedure for replacement or repair is not described

in this Owner’s/Operator’s Manual, have a Yamaha dealer perform the necessary service.

EJU00596a

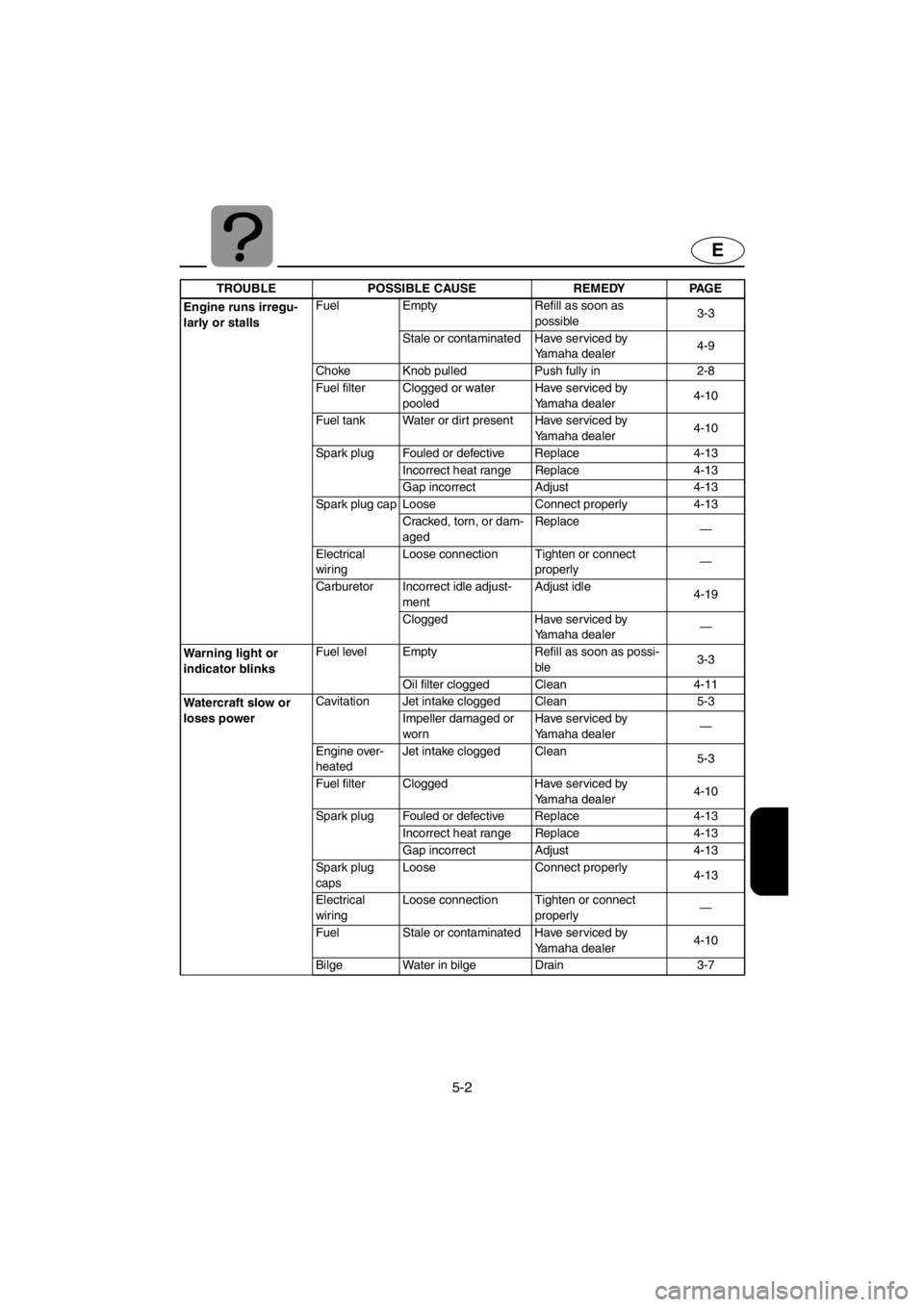

Troubleshooting chart

TROUBLE POSSIBLE CAUSE REMEDY PAGE

Engine does not

startStarter motor does not turn over

Engine shut-

off switchClip not in place Install clip

2-8

Fuse Burned out Replace the fuse and

check wiring4-20

Battery Run down Recharge 4-18

Poor terminal connec-

tionsTighten as required

4-18

Terminal corroded Clean 4-4

Starter motor Faulty Have serviced by

Yamaha dealer—

Starter motor turns over

Fuel cock Turned to “OFF” Turn the fuel cock to

“ON”2-7

Fuel Empty Refill as soon as

possible3-3

Stale or contaminated Have serviced by

Yamaha dealer4-10

Fuel tank Water or dirt present Have serviced by

Yamaha dealer4-10

Spark plug Fouled or defective Clean or replace 4-13

Spark plug cap Not connected or loose Connect properly 4-13

Crankcase Filled with water Crank engine with plug

out until clean5-7

Fuel filter Clogged or water

pooledHave serviced by

Yamaha dealer4-10

Choke Knob moves back on

its ownTighten the choke knob

adjusting nut4-16

E_F0M-72-5.fm Page 1 Thursday, July 27, 2000 9:58 AM

Page 99 of 111

5-2

E

Engine runs irregu-

larly or stallsFuel Empty Refill as soon as

possible3-3

Stale or contaminated Have serviced by

Yamaha dealer4-9

Choke Knob pulled Push fully in 2-8

Fuel filter Clogged or water

pooledHave serviced by

Yamaha dealer4-10

Fuel tank Water or dirt present Have serviced by

Yamaha dealer4-10

Spark plug Fouled or defective Replace 4-13

Incorrect heat range Replace 4-13

Gap incorrect Adjust 4-13

Spark plug cap Loose Connect properly 4-13

Cracked, torn, or dam-

agedReplace

—

Electrical

wiringLoose connection Tighten or connect

properly—

Carburetor Incorrect idle adjust-

mentAdjust idle

4-19

Clogged Have serviced by

Yamaha dealer—

Warning light or

indicator blinksFuel level Empty Refill as soon as possi-

ble3-3

Oil filter clogged Clean 4-11

Wate rcr af t slow or

loses powerCavitation Jet intake clogged Clean 5-3

Impeller damaged or

wornHave serviced by

Yamaha dealer—

Engine over-

heatedJet intake clogged Clean

5-3

Fuel filter Clogged Have serviced by

Yamaha dealer4-10

Spark plug Fouled or defective Replace 4-13

Incorrect heat range Replace 4-13

Gap incorrect Adjust 4-13

Spark plug

capsLoose Connect properly

4-13

Electrical

wiringLoose connection Tighten or connect

properly—

Fuel Stale or contaminated Have serviced by

Yamaha dealer4-10

Bilge Water in bilge Drain 3-7 TROUBLE POSSIBLE CAUSE REMEDY PAGE

E_F0M-72-5.fm Page 2 Thursday, July 27, 2000 9:58 AM

Page 100 of 111

5-3

E

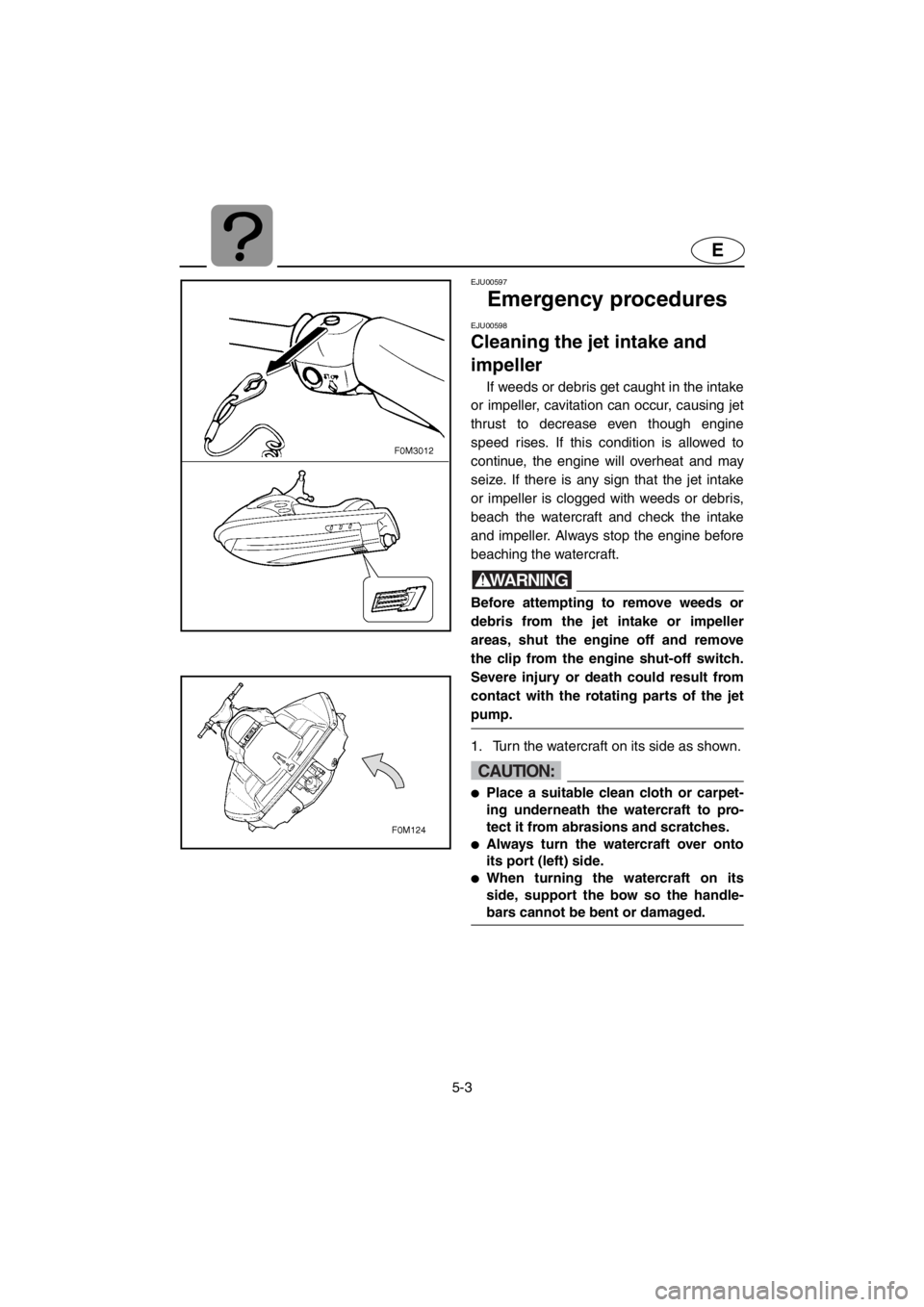

EJU00597

Emergency procedures

EJU00598

Cleaning the jet intake and

impeller

If weeds or debris get caught in the intake

or impeller, cavitation can occur, causing jet

thrust to decrease even though engine

speed rises. If this condition is allowed to

continue, the engine will overheat and may

seize. If there is any sign that the jet intake

or impeller is clogged with weeds or debris,

beach the watercraft and check the intake

and impeller. Always stop the engine before

beaching the watercraft.

WARNING

Before attempting to remove weeds or

debris from the jet intake or impeller

areas, shut the engine off and remove

the clip from the engine shut-off switch.

Severe injury or death could result from

contact with the rotating parts of the jet

pump.

1. Turn the watercraft on its side as shown.

CAUTION:

●Place a suitable clean cloth or carpet-

ing underneath the watercraft to pro-

tect it from abrasions and scratches.

●Always turn the watercraft over onto

its port (left) side.

●When turning the watercraft on its

side, support the bow so the handle-

bars cannot be bent or damaged.

E_F0M-72-5.fm Page 3 Thursday, July 27, 2000 9:58 AM