battery YAMAHA XL 800 2001 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: XL 800, Model: YAMAHA XL 800 2001Pages: 131, PDF Size: 16.51 MB

Page 97 of 131

4-4

E

EJU00946

Fuel system

Draining the fuel system prevents buildup

of varnishes and other harmful deposits that

result when gasoline sits for a prolonged

period of time.

WARNING@Gasoline is highly flammable and explo-

sive. A fire or explosion can cause

severe injury or death. Shut the engine

off. Refuel in well-ventilated areas away

from flames or sparks. Do not smoke.

Avoid spilling gasoline. Wipe up spilled

gasoline immediately.

@

To drain the fuel system:

1. Place the fuel cock knob in the “OFF”

position.

2. Drain the fuel tank using a siphon.

EJU00530

Battery

When the watercraft is not to be used for

a month or more, remove the battery and

store it in a cool, dark place. Clean the bat-

tery casing using fresh water. Clean the bat-

tery terminals. Apply dielectric grease or

petroleum jelly to the battery terminals and

to all exposed battery leads.

If the battery is to be stored for a longer

period, check the specific gravity of the elec-

trolyte at least once a month and charge the

battery if necessary.

Specific gravity: 1.28 at 20 °C (68 °F)

E_F0P71-4.fm Page 4 Tuesday, July 18, 2000 7:17 PM

Page 101 of 131

4-8

E

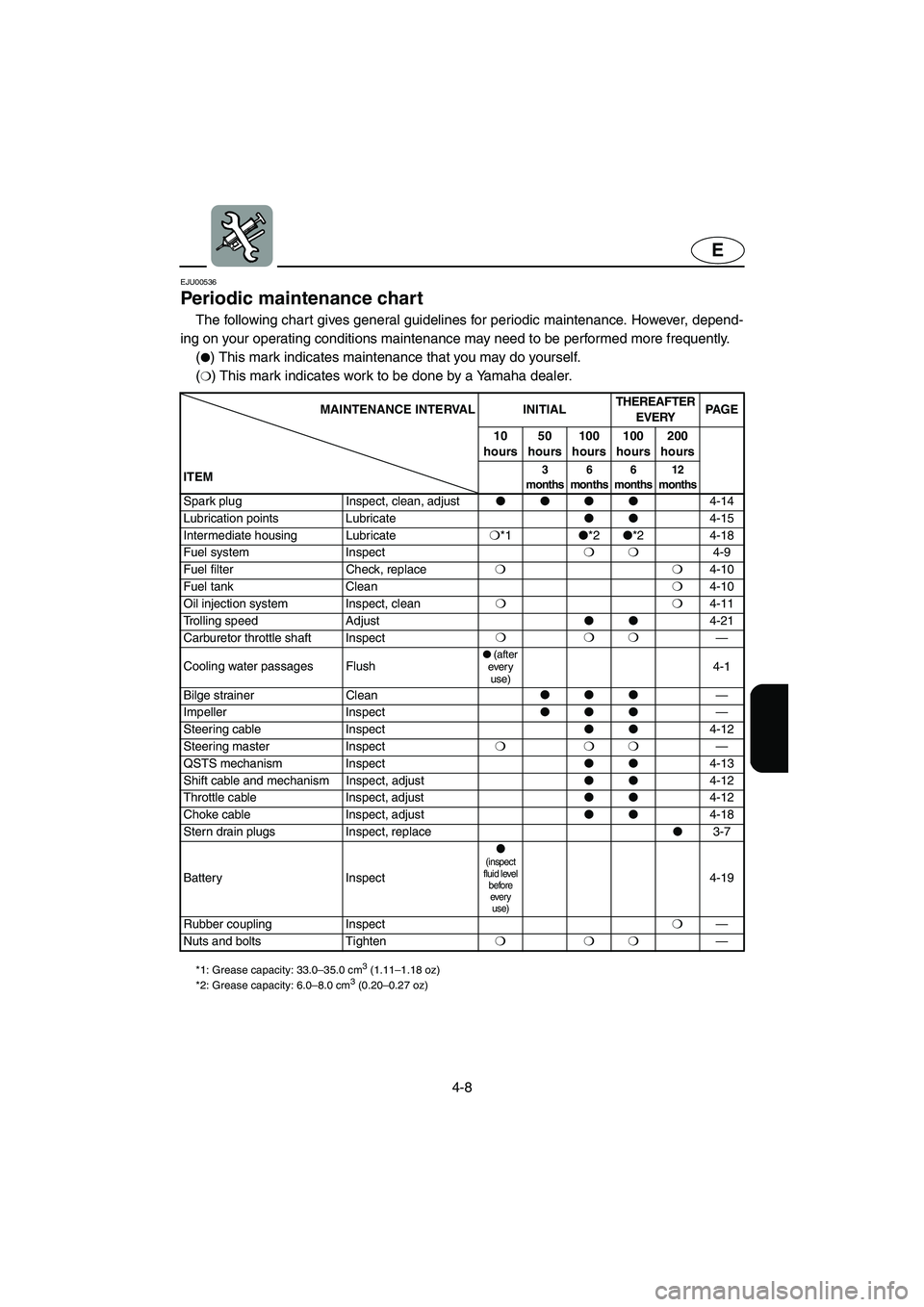

EJU00536

Periodic maintenance chart

The following chart gives general guidelines for periodic maintenance. However, depend-

ing on your operating conditions maintenance may need to be performed more frequently.

(

●) This mark indicates maintenance that you may do yourself.

(

❍) This mark indicates work to be done by a Yamaha dealer.

*1: Grease capacity: 33.0–35.0 cm3 (1.11–1.18 oz)

*2: Grease capacity: 6.0–8.0 cm3 (0.20–0.27 oz)

MAINTENANCE INTERVAL INITIALTHEREAFTER

EVERYPA G E

10

hours50

hours100

hours100

hours200

hours

ITEM

3

months6

months6

months12

months

Spark plug Inspect, clean, adjust●●●●

4-14

Lubrication points Lubricate●●

4-15

Intermediate housing Lubricate❍

*1●

*2●

*2 4-18

Fuel system Inspect❍❍

4-9

Fuel filter Check, replace❍❍

4-10

Fuel tank Clean❍

4-10

Oil injection system Inspect, clean❍❍

4-11

Trolling speed Adjust●●

4-21

Carburetor throttle shaft Inspect❍❍❍

—

Cooling water passages Flush

●

(after

ever y

use)4-1

Bilge strainer Clean●●●

—

Impeller Inspect●●●

—

Steering cable Inspect●●

4-12

Steering master Inspect❍❍❍

—

QSTS mechanism Inspect●●

4-13

Shift cable and mechanism Inspect, adjust●●

4-12

Throttle cable Inspect, adjust●●

4-12

Choke cable Inspect, adjust●●

4-18

Stern drain plugs Inspect, replace●

3-7

Battery Inspect

●(inspect

fluid level

before

ever y

use)

4-19

Rubber coupling Inspect❍

—

Nuts and bolts Tighten❍❍❍

—

E_F0P71-4.fm Page 8 Tuesday, July 18, 2000 7:17 PM

Page 112 of 131

4-19

E

EJU00572

Inspecting the battery

Check the level of the battery electrolyte

and make sure the leads are secure.

WARNING

Battery electrolyte is poisonous and dan-

gerous, causing severe burns, etc. Elec-

trolyte contains sulfuric acid. Avoid

contact with skin, eyes or clothing.

Antidotes

External: Flush with water.

Internal: Drink large quantities of water

or milk. Follow with milk of magnesia,

beaten egg or vegetable oil. Call physi-

cian immediately.

Eyes: Flush with water for 15 minutes

and get prompt medical attention.

Batteries produce explosive gases. Keep

sparks, flame, cigarettes, etc., well away.

If using or charging the battery in an

enclosed space, make sure that it is well

ventilated. Always shield your eyes when

working near batteries.

KEEP OUT OF THE REACH OF CHIL-

DREN.

CAUTION:

Be careful not to place the battery on its

side.

Make sure to remove the battery from the

battery compartment when adding bat-

tery electrolyte or charging the battery.

When checking the battery, make sure

the breather hose is connected to the

battery and not obstructed.

E_F0P71-4.fm Page 19 Tuesday, July 18, 2000 7:17 PM

Page 113 of 131

4-20

E

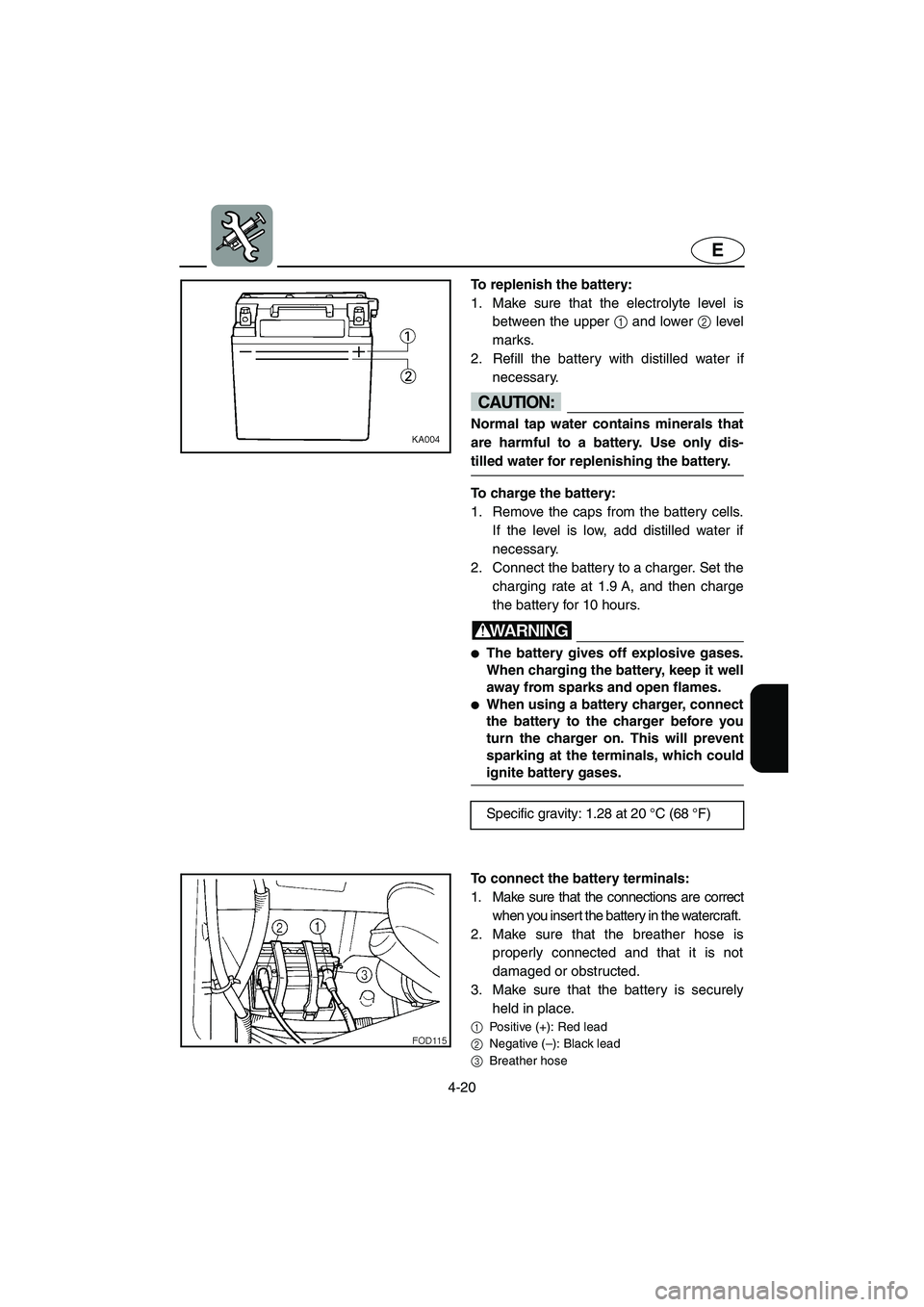

To replenish the battery:

1. Make sure that the electrolyte level is

between the upper 1 and lower 2 level

marks.

2. Refill the battery with distilled water if

necessary.

CAUTION:

Normal tap water contains minerals that

are harmful to a battery. Use only dis-

tilled water for replenishing the battery.

To charge the battery:

1. Remove the caps from the battery cells.

If the level is low, add distilled water if

necessary.

2. Connect the battery to a charger. Set the

charging rate at 1.9 A, and then charge

the battery for 10 hours.

WARNING

●The battery gives off explosive gases.

When charging the battery, keep it well

away from sparks and open flames.

●When using a battery charger, connect

the battery to the charger before you

turn the charger on. This will prevent

sparking at the terminals, which could

ignite battery gases.

Specific gravity: 1.28 at 20 °C (68 °F)

To connect the battery terminals:

1. Make sure that the connections are correct

when you insert the battery in the watercraft.

2. Make sure that the breather hose is

properly connected and that it is not

damaged or obstructed.

3. Make sure that the battery is securely

held in place.

1Positive (+): Red lead

2Negative (–): Black lead

3Breather hose

E_F0P71-4.fm Page 20 Tuesday, July 18, 2000 7:17 PM

Page 116 of 131

4-23

E

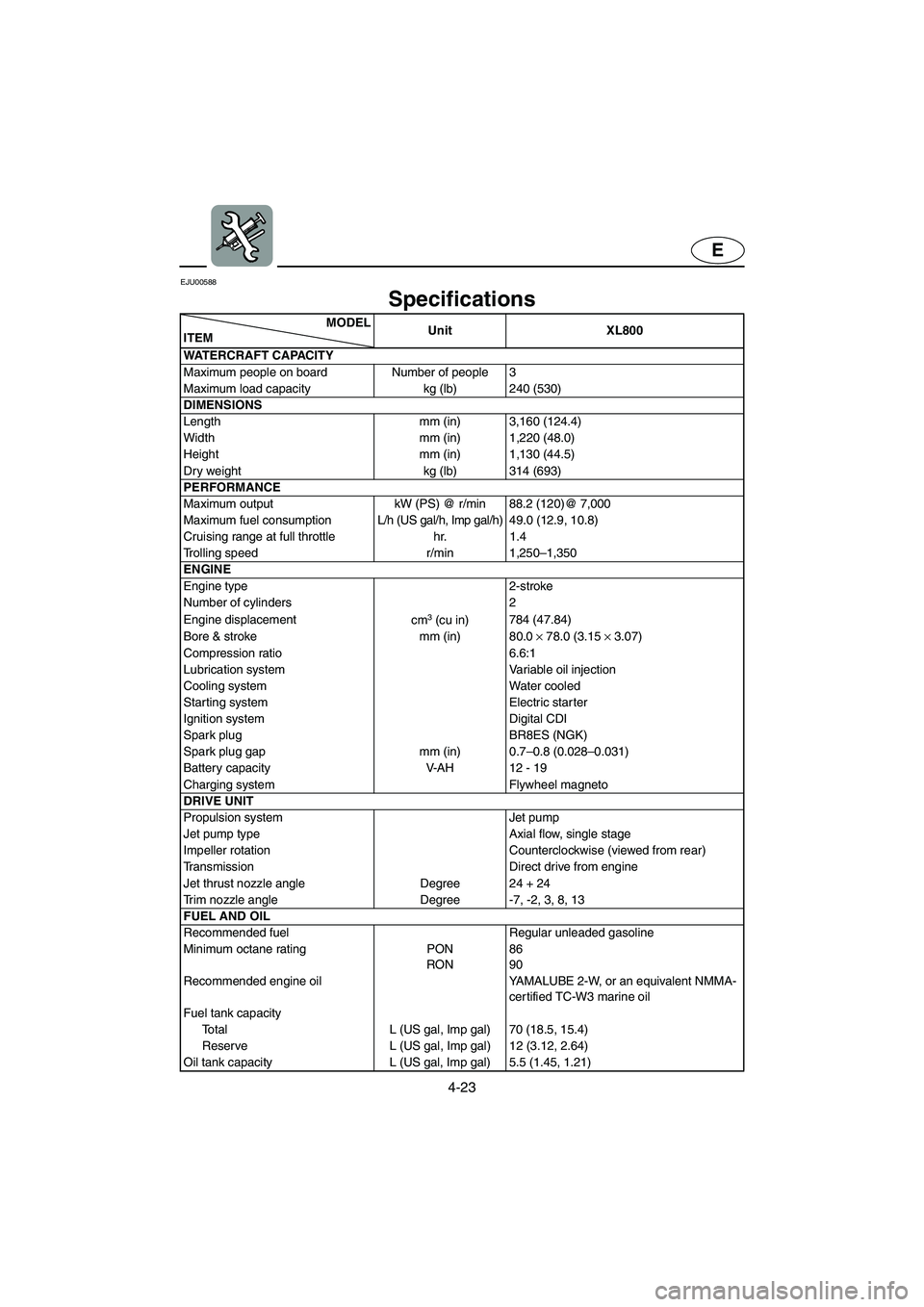

EJU00588

Specifications

MODEL

ITEMUnit XL800

WATERCRAFT CAPACITY

Maximum people on board Number of people 3

Maximum load capacity kg (lb) 240 (530)

DIMENSIONS

Length mm (in) 3,160 (124.4)

Width mm (in) 1,220 (48.0)

Height mm (in) 1,130 (44.5)

Dry weight kg (lb) 314 (693)

PERFORMANCE

Maximum output kW (PS) @ r/min 88.2 (120)@ 7,000

Maximum fuel consumption L/h (US gal/h, Imp gal/h) 49.0 (12.9, 10.8)

Cruising range at full throttle hr. 1.4

Trolling speed r/min 1,250–1,350

ENGINE

Engine type 2-stroke

Number of cylinders 2

Engine displacement

cm

3 (cu in)784 (47.84)

Bore & stroke mm (in) 80.0 × 78.0 (3.15 × 3.07)

Compression ratio 6.6:1

Lubrication system Variable oil injection

Cooling system Water cooled

Starting system Electric starter

Ignition system Digital CDI

Spark plug BR8ES (NGK)

Spark plug gap mm (in) 0.7–0.8 (0.028–0.031)

Battery capacity V-AH 12 - 19

Charging system Flywheel magneto

DRIVE UNIT

Propulsion system Jet pump

Jet pump type Axial flow, single stage

Impeller rotation Counterclockwise (viewed from rear)

Transmission Direct drive from engine

Jet thrust nozzle angle Degree 24 + 24

Trim nozzle angle Degree -7, -2, 3, 8, 13

FUEL AND OIL

Recommended fuel Regular unleaded gasoline

Minimum octane rating PON

RON86

90

Recommended engine oil YAMALUBE 2-W, or an equivalent NMMA-

certified TC-W3 marine oil

Fuel tank capacity

Total L (US gal, Imp gal) 70 (18.5, 15.4)

Reserve L (US gal, Imp gal) 12 (3.12, 2.64)

Oil tank capacity L (US gal, Imp gal) 5.5 (1.45, 1.21)

E_F0P71-4.fm Page 23 Tuesday, July 18, 2000 7:17 PM

Page 117 of 131

E

5

EJU00594

TROUBLESHOOTING

AND EMERGENCY

PROCEDURES

Troubleshooting....................................... 5-1

Troubleshooting chart ............................. 5-1

Emergency procedures........................... 5-4

Cleaning the jet intake and impeller ....... 5-4

Jumping the battery ................................ 5-5

Towing the watercraft ............................. 5-7

Submerged watercraft ............................ 5-8

E_F0P71-5TOC.fm Page 1 Tuesday, July 18, 2000 7:18 PM

Page 118 of 131

5-1

E

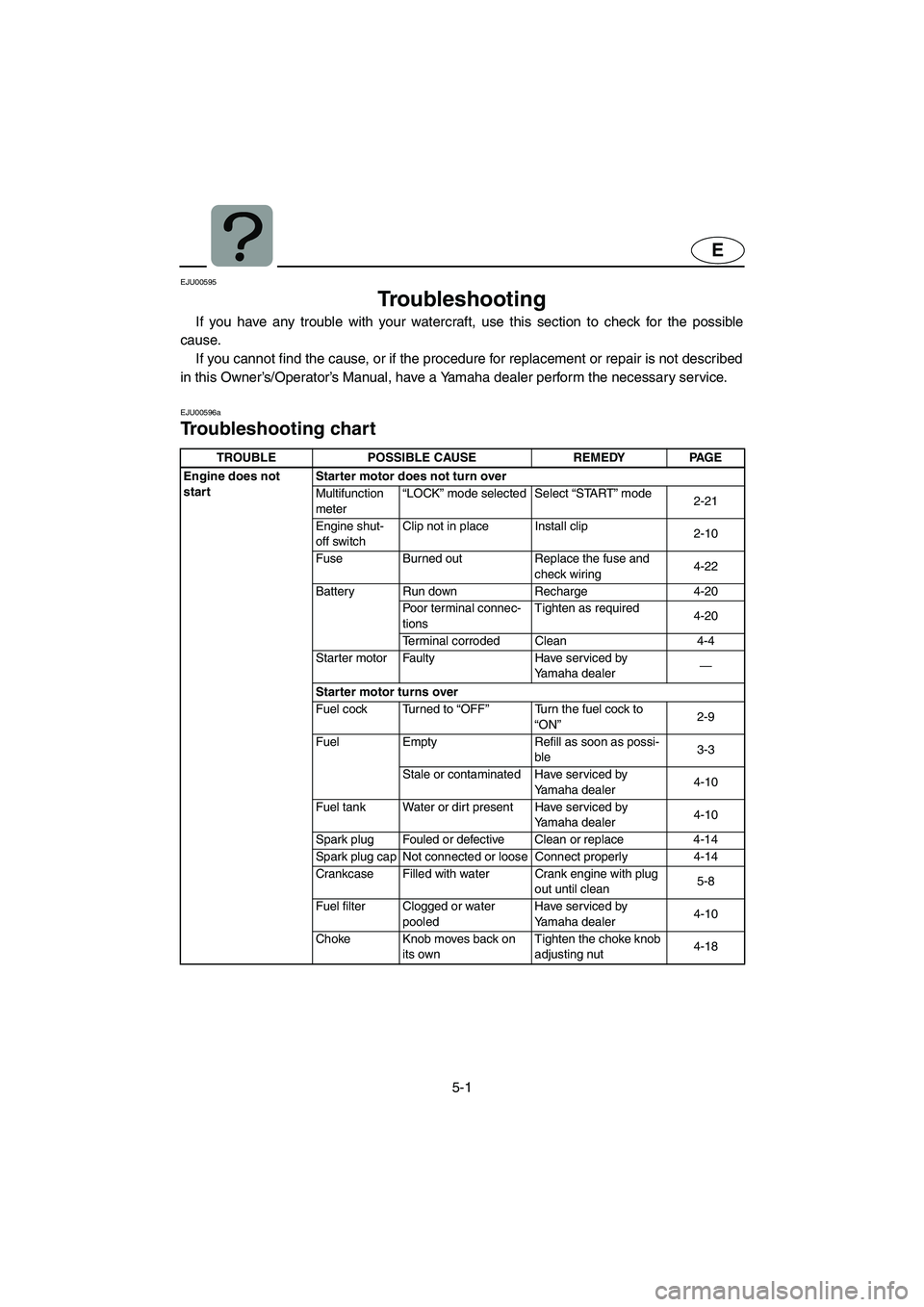

EJU00595

Troubleshooting

If you have any trouble with your watercraft, use this section to check for the possible

cause.

If you cannot find the cause, or if the procedure for replacement or repair is not described

in this Owner’s/Operator’s Manual, have a Yamaha dealer perform the necessary service.

EJU00596a

Troubleshooting chart

TROUBLE POSSIBLE CAUSE REMEDY PAGE

Engine does not

startStarter motor does not turn over

Multifunction

meter“LOCK” mode selected Select “START” mode

2-21

Engine shut-

off switchClip not in place Install clip

2-10

Fuse Burned out Replace the fuse and

check wiring4-22

Battery Run down Recharge 4-20

Poor terminal connec-

tionsTighten as required

4-20

Terminal corroded Clean 4-4

Starter motor Faulty Have serviced by

Yamaha dealer—

Starter motor turns over

Fuel cock Turned to “OFF” Turn the fuel cock to

“ON”2-9

Fuel Empty Refill as soon as possi-

ble3-3

Stale or contaminated Have serviced by

Yamaha dealer4-10

Fuel tank Water or dirt present Have serviced by

Yamaha dealer4-10

Spark plug Fouled or defective Clean or replace 4-14

Spark plug cap Not connected or loose Connect properly 4-14

Crankcase Filled with water Crank engine with plug

out until clean5-8

Fuel filter Clogged or water

pooledHave serviced by

Yamaha dealer4-10

Choke Knob moves back on

its ownTighten the choke knob

adjusting nut4-18

E_F0P71-5.fm Page 1 Tuesday, July 18, 2000 7:19 PM

Page 119 of 131

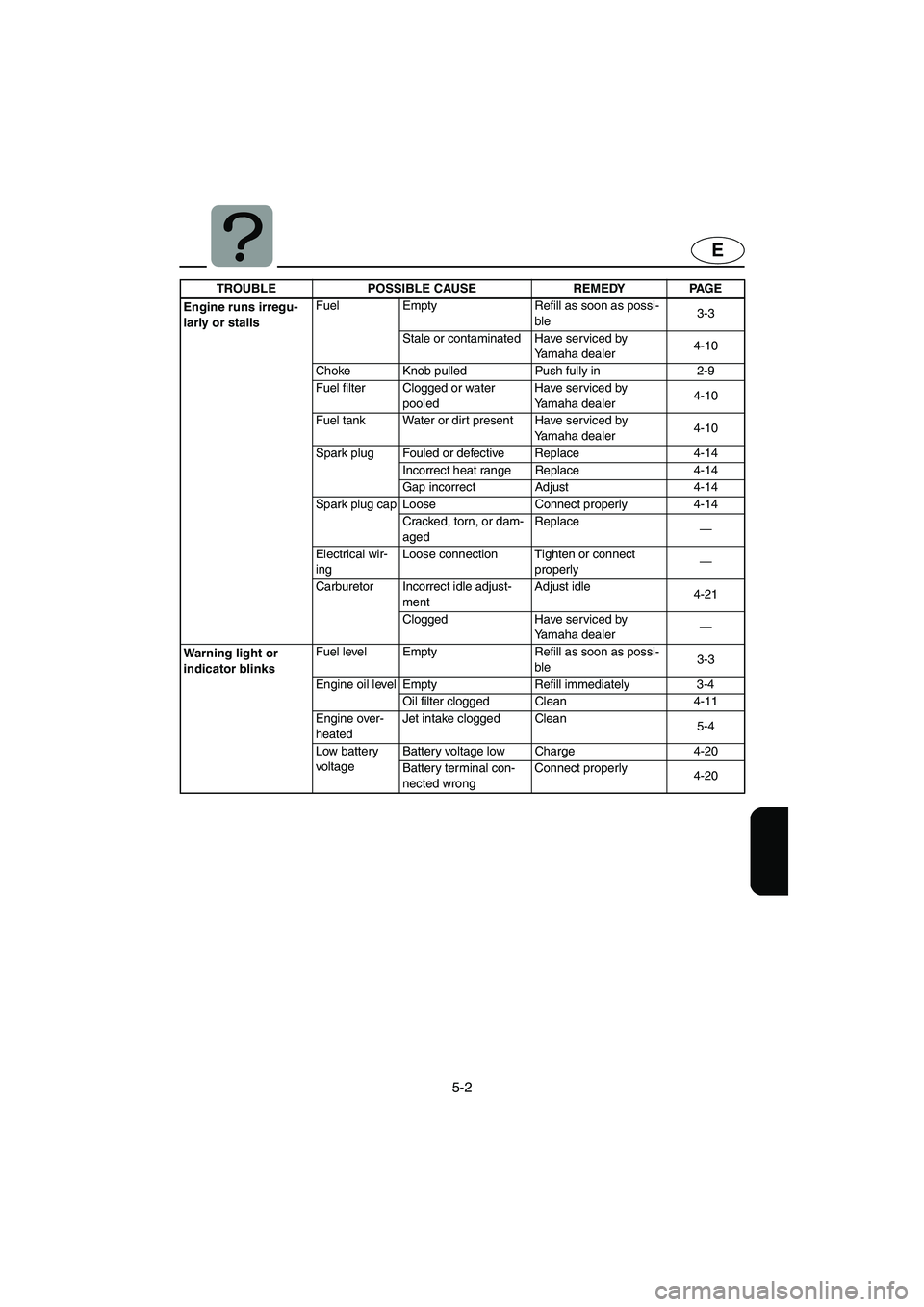

5-2

E

Engine runs irregu-

larly or stallsFuel Empty Refill as soon as possi-

ble3-3

Stale or contaminated Have serviced by

Yamaha dealer4-10

Choke Knob pulled Push fully in 2-9

Fuel filter Clogged or water

pooledHave serviced by

Yamaha dealer4-10

Fuel tank Water or dirt present Have serviced by

Yamaha dealer4-10

Spark plug Fouled or defective Replace 4-14

Incorrect heat range Replace 4-14

Gap incorrect Adjust 4-14

Spark plug cap Loose Connect properly 4-14

Cracked, torn, or dam-

agedReplace

—

Electrical wir-

ingLoose connection Tighten or connect

properly—

Carburetor Incorrect idle adjust-

mentAdjust idle

4-21

Clogged Have serviced by

Yamaha dealer—

Warning light or

indicator blinksFuel level Empty Refill as soon as possi-

ble3-3

Engine oil level Empty Refill immediately 3-4

Oil filter clogged Clean 4-11

Engine over-

heatedJet intake clogged Clean

5-4

Low battery

voltageBattery voltage low Charge 4-20

Battery terminal con-

nected wrongConnect properly

4-20 TROUBLE POSSIBLE CAUSE REMEDY PAGE

E_F0P71-5.fm Page 2 Tuesday, July 18, 2000 7:19 PM

Page 122 of 131

5-5

E

2. Remove any weeds or debris from

around the drive shaft, impeller, pump

housing, and jet thrust nozzle.

If debris is difficult to remove, consult

your Yamaha dealer.

CAUTION:

Always avoid operating your watercraft in

areas where weed growth is thick. If trav-

eling in weeded areas is unavoidable,

operate the engine alternately at partial

throttle and full throttle. Weeds tend to

accumulate more at a steady speed and

at trolling speed. If weeds clog the intake

or impeller area and cause cavitation, fol-

low the cleaning procedure above.

EJU00599

Jumping the battery

If the watercraft battery has run down, the

engine can be started using a 12-volt bat-

tery and jumper cables.

WARNING

Battery electrolyte is poisonous and dan-

gerous, causing severe burns, etc. Elec-

trolyte contains sulfuric acid. Avoid

contact with skin, eyes or clothing.

Antidotes

External: Flush with water.

Internal: Drink large quantities of water

or milk. Follow with milk of magnesia,

beaten egg or vegetable oil. Call physi-

cian immediately.

Eyes: Flush with water for 15 minutes

and get prompt medical attention.

Batteries give off explosive gases. Keep

sparks, flame, cigarettes, etc. well away.

If using or charging the battery in an

enclosed area, make sure that it is well

ventilated. Always shield your eyes when

working near batteries.

KEEP OUT OF THE REACH OF CHILDREN.

E_F0P71-5.fm Page 5 Tuesday, July 18, 2000 7:19 PM

Page 123 of 131

5-6

E

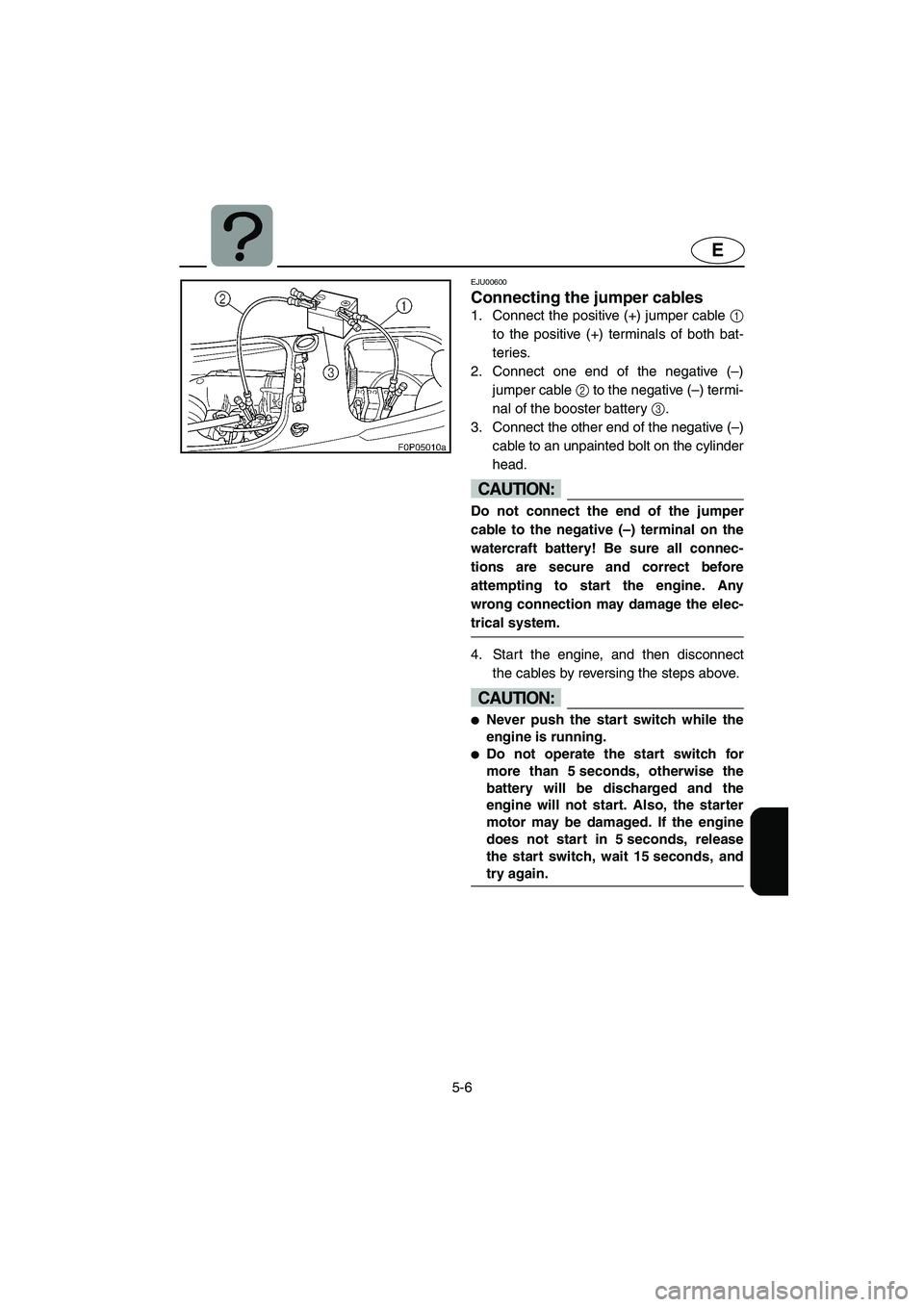

EJU00600

Connecting the jumper cables

1. Connect the positive (+) jumper cable 1

to the positive (+) terminals of both bat-

teries.

2. Connect one end of the negative (–)

jumper cable 2 to the negative (–) termi-

nal of the booster battery 3.

3. Connect the other end of the negative (–)

cable to an unpainted bolt on the cylinder

head.

CAUTION:

Do not connect the end of the jumper

cable to the negative (–) terminal on the

watercraft battery! Be sure all connec-

tions are secure and correct before

attempting to start the engine. Any

wrong connection may damage the elec-

trical system.

4. Start the engine, and then disconnect

the cables by reversing the steps above.

CAUTION:

●Never push the start switch while the

engine is running.

●Do not operate the start switch for

more than 5 seconds, otherwise the

battery will be discharged and the

engine will not start. Also, the starter

motor may be damaged. If the engine

does not start in 5 seconds, release

the start switch, wait 15 seconds, and

try again.

E_F0P71-5.fm Page 6 Tuesday, July 18, 2000 7:19 PM