light YAMAHA XMAX 250 2008 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: XMAX 250, Model: YAMAHA XMAX 250 2008Pages: 88, PDF Size: 2.76 MB

Page 25 of 88

NOTE:

Even if the key is turned from “ON” to

“OFF” with the hazard lighting on, the

hazard lighting will continue to flash

regardless of the hazard switch posi-

tion. To cancel the hazard lighting, the

key must be turned to “ON” and the

hazard switch must be set to the “h”

position.

The hazard lighting is used in case of

an emergency or to warn other drivers

when your scooter is stopped where

it might be a traffic hazard.

ECA10060

CAUTION:

Do not use the hazard light for an

extended length of time, otherwise

the battery may discharge.

EAU12720

Start switch “g”

With the sidestand up, push this

switch while applying the front or rear

brake to crank the engine with the

starter.

ECA10050

CAUTION:

See page 5-1 for starting instruc-

tions prior to starting the engine.

EAU12900

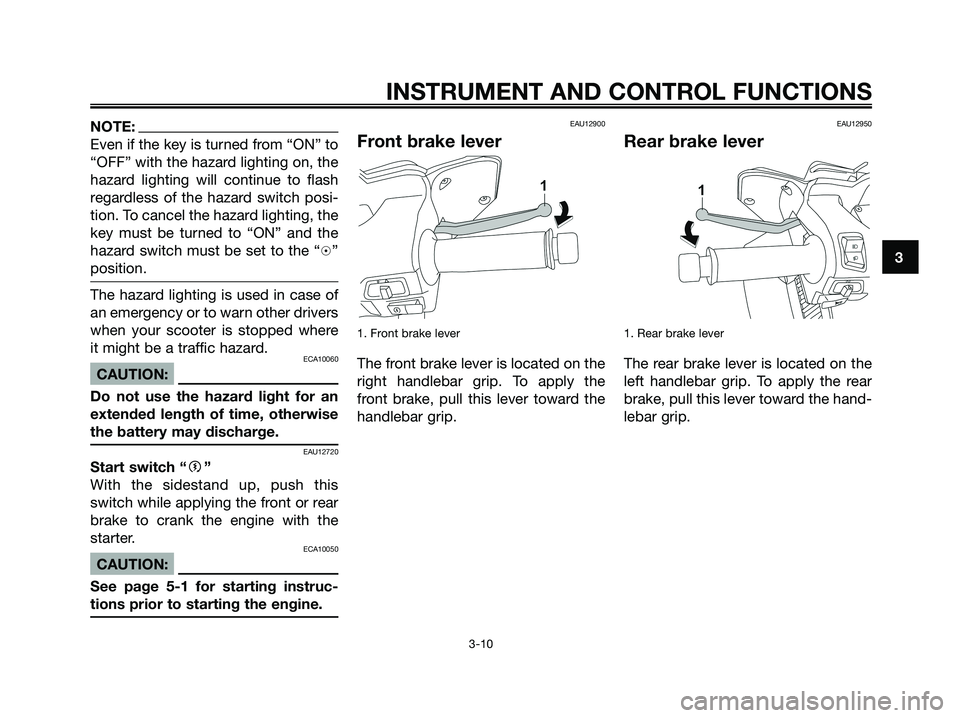

Front brake lever

1. Front brake lever

The front brake lever is located on the

right handlebar grip. To apply the

front brake, pull this lever toward the

handlebar grip.

EAU12950

Rear brake lever

1. Rear brake lever

The rear brake lever is located on the

left handlebar grip. To apply the rear

brake, pull this lever toward the hand-

lebar grip.

INSTRUMENT AND CONTROL FUNCTIONS

3-10

3

1C0-F8199-E4.qxd 22/11/07 05:41 Página 25

Page 33 of 88

EWA10240

s s

WARNING

The vehicle must not be ridden with

the sidestand down, or if the sides-

tand cannot be properly moved up

(or does not stay up), otherwise the

sidestand could contact the ground

and distract the operator, resulting

in a possible loss of control. Yama-

ha’s ignition circuit cut-off system

has been designed to assist the

operator in fulfilling the responsibi-

lity of raising the sidestand before

starting off. Therefore, check this

system regularly as described

below and have a Yamaha dealer

repair it if it does not function pro-

perly.

EAU15372

Ignition circuit cut-off

system

The ignition circuit cut-off system

(comprising the sidestand switch and

brake light switches) has the following

functions.

●It prevents starting when the

sidestand is up, but neither brake

is applied.

●It prevents starting when either

brake is applied, but the sides-

tand is still down.

●It cuts the running engine when

the sidestand is moved down.

Periodically check the operation of

the ignition circuit cut-off system

according to the following procedure.

EWA10250

s s

WARNING

If a malfunction is noted, have a

Yamaha dealer check the system

before riding.

INSTRUMENT AND CONTROL FUNCTIONS

3-18

3

1C0-F8199-E4.qxd 22/11/07 05:41 Página 33

Page 37 of 88

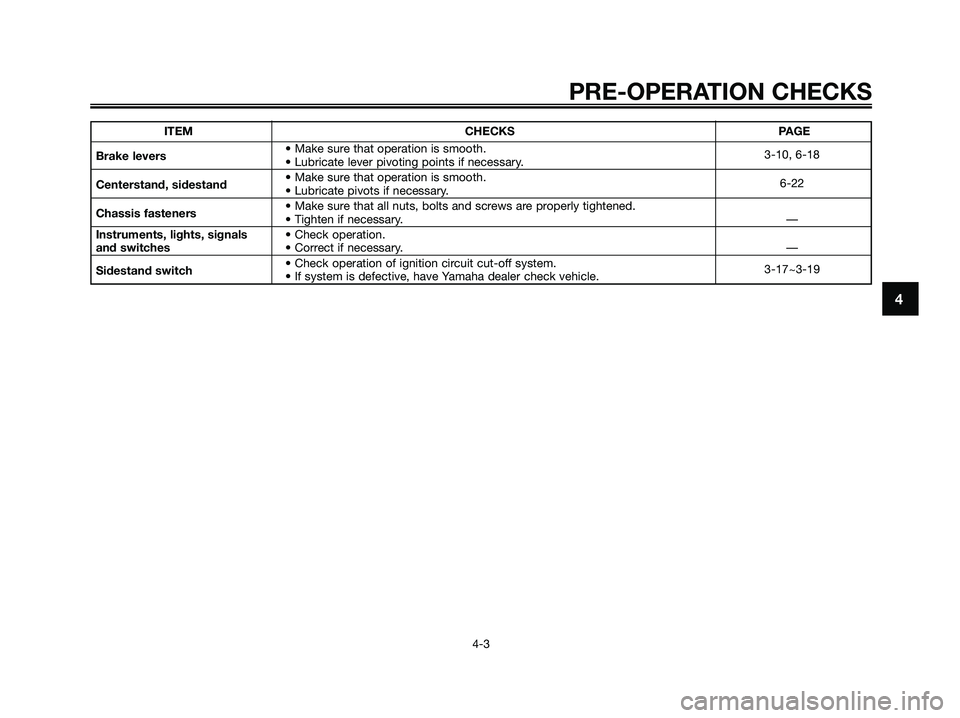

ITEM CHECKS PAGE

Brake levers• Make sure that operation is smooth.

• Lubricate lever pivoting points if necessary.3-10, 6-18

Centerstand, sidestand• Make sure that operation is smooth.

• Lubricate pivots if necessary.6-22

Chassis fasteners• Make sure that all nuts, bolts and screws are properly tightened.

• Tighten if necessary.—

Instruments, lights, signals • Check operation.

and switches• Correct if necessary.—

Sidestand switch• Check operation of ignition circuit cut-off system.

• If system is defective, have Yamaha dealer check vehicle.3-17~3-19

PRE-OPERATION CHECKS

4-3

4

1C0-F8199-E4.qxd 22/11/07 05:41 Página 37

Page 38 of 88

EAU15980

EWA10870

s s

WARNING

●Become thoroughly familiar

with all operating controls and

their functions before riding.

Consult a Yamaha dealer

regarding any control or func-

tion that you do not thoroughly

understand.

●Never start the engine or ope-

rate it in a closed area for any

length of time. Exhaust fumes

are poisonous, and inhaling

them can cause loss of cons-

ciousness and death within a

short time. Always make sure

that there is adequate ventila-

tion.

●For safety, always start the

engine with the centerstand

down.

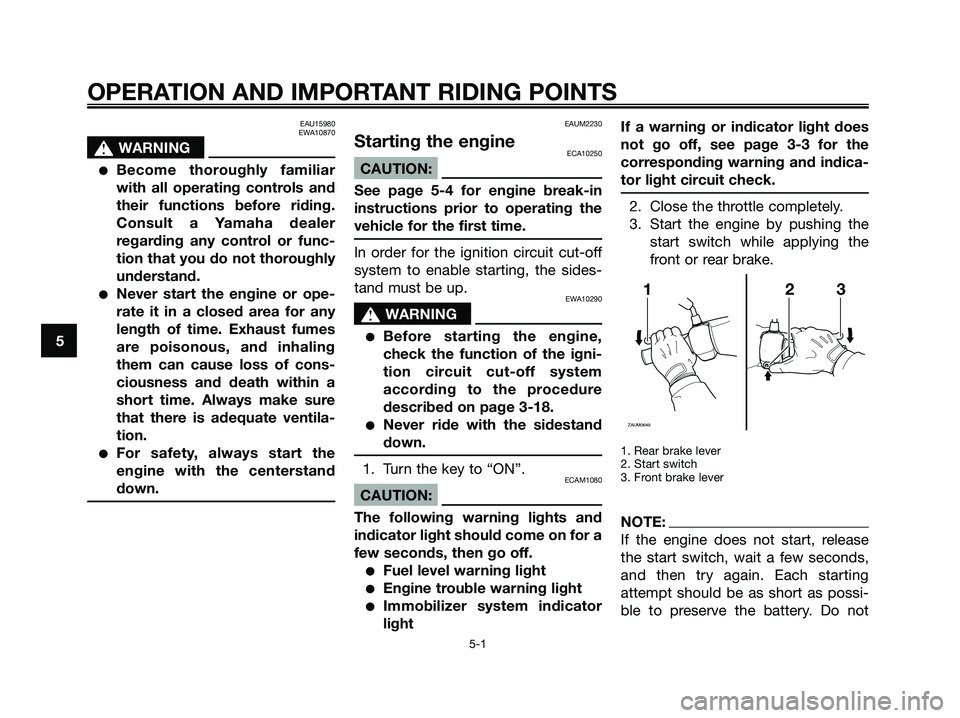

EAUM2230

Starting the engineECA10250

CAUTION:

See page 5-4 for engine break-in

instructions prior to operating the

vehicle for the first time.

In order for the ignition circuit cut-off

system to enable starting, the sides-

tand must be up.

EWA10290

s s

WARNING

●Before starting the engine,

check the function of the igni-

tion circuit cut-off system

according to the procedure

described on page 3-18.

●Never ride with the sidestand

down.

1. Turn the key to “ON”.ECAM1080

CAUTION:

The following warning lights and

indicator light should come on for a

few seconds, then go off.

●Fuel level warning light

●Engine trouble warning light

●Immobilizer system indicator

lightIf a warning or indicator light does

not go off, see page 3-3 for the

corresponding warning and indica-

tor light circuit check.

2. Close the throttle completely.

3. Start the engine by pushing the

start switch while applying the

front or rear brake.

1. Rear brake lever

2. Start switch

3. Front brake lever

NOTE:

If the engine does not start, release

the start switch, wait a few seconds,

and then try again. Each starting

attempt should be as short as possi-

ble to preserve the battery. Do not

123

ZAUM0649

OPERATION AND IMPORTANT RIDING POINTS

5-1

5

1C0-F8199-E4.qxd 22/11/07 05:41 Página 38

Page 40 of 88

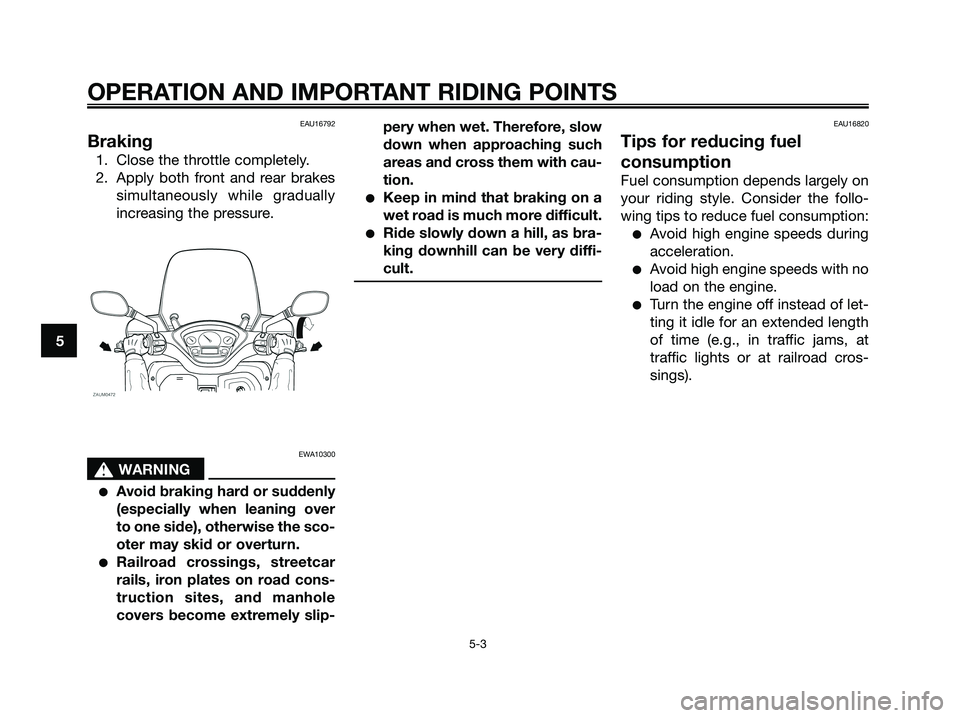

EAU16792

Braking

1. Close the throttle completely.

2. Apply both front and rear brakes

simultaneously while gradually

increasing the pressure.

EWA10300

s s

WARNING

●Avoid braking hard or suddenly

(especially when leaning over

to one side), otherwise the sco-

oter may skid or overturn.

●Railroad crossings, streetcar

rails, iron plates on road cons-

truction sites, and manhole

covers become extremely slip-pery when wet. Therefore, slow

down when approaching such

areas and cross them with cau-

tion.

●Keep in mind that braking on a

wet road is much more difficult.

●Ride slowly down a hill, as bra-

king downhill can be very diffi-

cult.

EAU16820

Tips for reducing fuel

consumption

Fuel consumption depends largely on

your riding style. Consider the follo-

wing tips to reduce fuel consumption:

●Avoid high engine speeds during

acceleration.

●Avoid high engine speeds with no

load on the engine.

●Turn the engine off instead of let-

ting it idle for an extended length

of time (e.g., in traffic jams, at

traffic lights or at railroad cros-

sings).

OPERATION AND IMPORTANT RIDING POINTS

5-3

5

1C0-F8199-E4.qxd 22/11/07 05:41 Página 40

Page 46 of 88

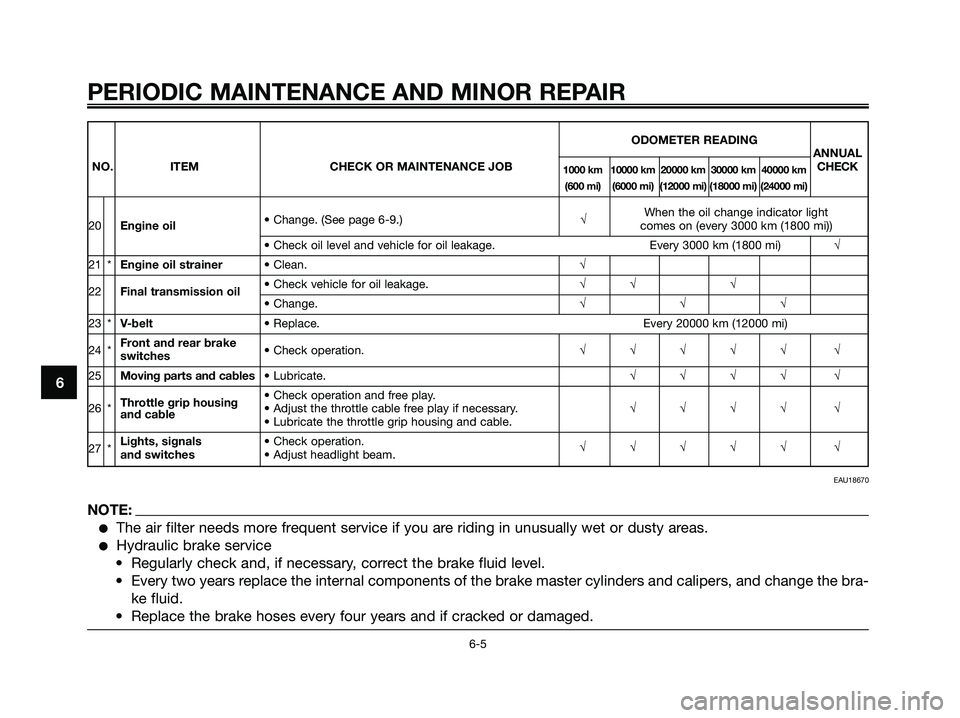

ODOMETER READING

ANNUAL

NO. ITEM CHECK OR MAINTENANCE JOB

1000 km 10000 km 20000 km 30000 km 40000 kmCHECK

(600 mi) (6000 mi) (12000 mi) (18000 mi) (24000 mi)

• Change. (See page 6-9.)√When the oil change indicator light 20Engine oilcomes on (every 3000 km (1800 mi))

• Check oil level and vehicle for oil leakage. Every 3000 km (1800 mi)√

21 *Engine oil strainer• Clean.√

22Final transmission oil• Check vehicle for oil leakage.√√ √• Change.√√√

23 *V-belt• Replace. Every 20000 km (12000 mi)

24 *Front and rear brake

• Check operation.√√√√√ √

switches

25Moving parts and cables• Lubricate.√√√√ √

Throttle grip housing• Check operation and free play.

26 * • Adjust the throttle cable free play if necessary.√√√√ √

and cable

• Lubricate the throttle grip housing and cable.

27 *Lights, signals • Check operation.

and switches• Adjust headlight beam.√√√√√ √

PERIODIC MAINTENANCE AND MINOR REPAIR

6-5

6

EAU18670

NOTE:

●The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

●Hydraulic brake service

• Regularly check and, if necessary, correct the brake fluid level.

• Every two years replace the internal components of the brake master cylinders and calipers, and change the bra-

ke fluid.

• Replace the brake hoses every four years and if cracked or damaged.

1C0-F8199-E4.qxd 22/11/07 05:41 Página 46

Page 47 of 88

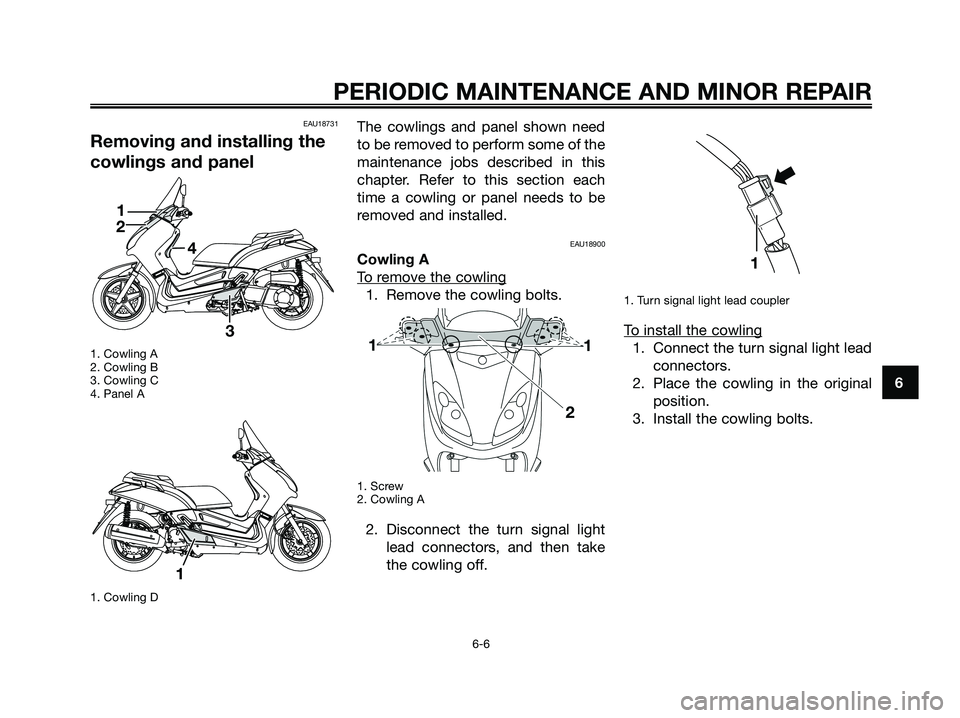

EAU18731

Removing and installing the

cowlings and panel

1. Cowling A

2. Cowling B

3. Cowling C

4. Panel A

1. Cowling D

The cowlings and panel shown need

to be removed to perform some of the

maintenance jobs described in this

chapter. Refer to this section each

time a cowling or panel needs to be

removed and installed.

EAU18900

Cowling A

T

o remove the cowling

1. Remove the cowling bolts.

1. Screw

2. Cowling A

2. Disconnect the turn signal light

lead connectors, and then take

the cowling off.

1. Turn signal light lead coupler

To install the cowling

1. Connect the turn signal light lead

connectors.

2. Place the cowling in the original

position.

3. Install the cowling bolts.

1

1

1

2

4

3

PERIODIC MAINTENANCE AND MINOR REPAIR

6-6

6

1C0-F8199-E4.qxd 22/11/07 05:41 Página 47

Page 50 of 88

the spark plug is a medium-to-

light tan (the ideal color when the

vehicle is ridden normally).

NOTE:

If the spark plug shows a distinctly

different color, the engine could be

operating improperly. Do not attempt

to diagnose such problems yourself.

Instead, have a Yamaha dealer check

the vehicle.

2. Check the spark plug for electro-

de erosion and excessive carbon

or other deposits, and replace it if

necessary.

To install the spark plug

1. Measure the spark plug gap with

a wire thickness gauge and, if

necessary, adjust the gap to spe-

cification.

2. Clean the surface of the sparkplug gasket and its mating surfa-

ce, and then wipe off any grime

from the spark plug threads.

3. Install the spark plug with the

spark plug wrench, and then

tighten it to the specified torque.NOTE:

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is

1/4~1/2 turn past finger tight. Howe-

ver, the spark plug should be tighte-

ned to the specified torque as soon

as possible.

4. Install the spark plug cap.

5. Install the cowling.

EAUM1550

Engine oil

The engine oil level should be chec-

ked before each ride. In addition, the

oil must be changed at the intervals

specified in the periodic maintenance

and lubrication chart and when the

service indicator light comes on.

To check the engine oil level

1. Place the scooter on the centers-

tand.

NOTE:

Make sure that the scooter is positio-

ned straight up when checking the oil

level. A slight tilt to the side can result

in a false reading.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

Tightening torque:

Spark plug:

17.5 Nm (1.75 m·kgf, 12.5 ft·lbf)

Spark plug gap:

0.8 -0.9 mm (0.031 -0.035 in)

Specified spark plug:

NGK/DPR8EA-9

PERIODIC MAINTENANCE AND MINOR REPAIR

6-9

6

1C0-F8199-E4.qxd 22/11/07 05:41 Página 50

Page 53 of 88

6. Add the specified amount of the

recommended final transmission

oil, and then install and tighten

the oil filler cap.

EWA11310

s s

WARNING

●Make sure that no foreign

material enters the final trans-

mission case.

●Make sure that no oil gets on

the tire or wheel.

7. Check the final transmission case

for oil leakage. If oil is leaking,

check for the cause.

EAU20070

Coolant

The coolant level should be checked

before each ride. In addition, the coo-

lant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

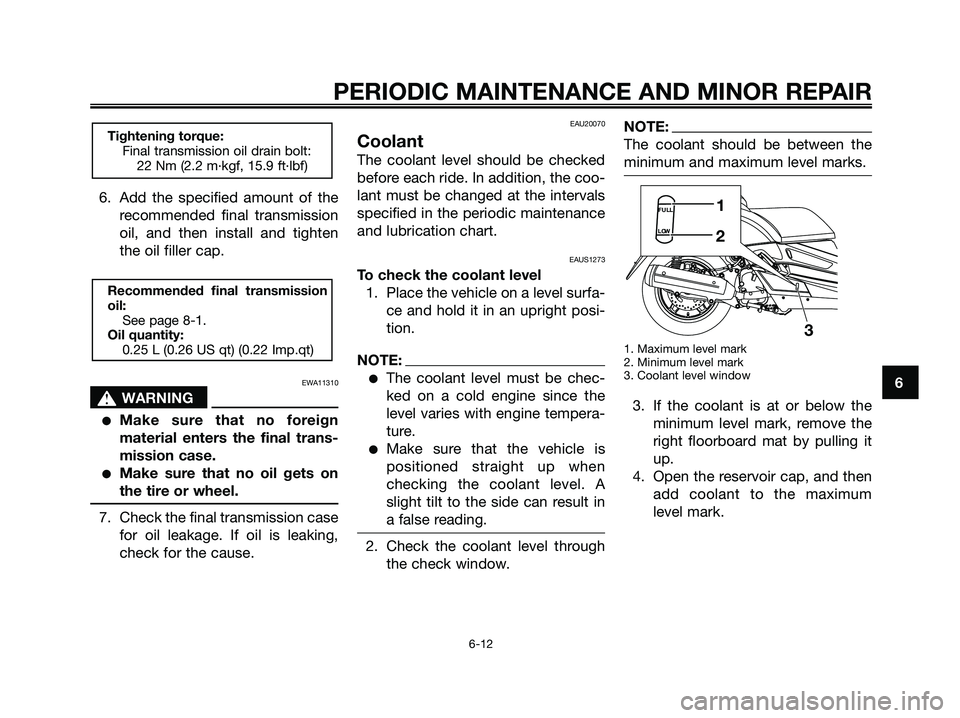

EAUS1273

To check the coolant level

1. Place the vehicle on a level surfa-

ce and hold it in an upright posi-

tion.

NOTE:

●The coolant level must be chec-

ked on a cold engine since the

level varies with engine tempera-

ture.

●Make sure that the vehicle is

positioned straight up when

checking the coolant level. A

slight tilt to the side can result in

a false reading.

2. Check the coolant level through

the check window.

NOTE:

The coolant should be between the

minimum and maximum level marks.

1. Maximum level mark

2. Minimum level mark

3. Coolant level window

3. If the coolant is at or below the

minimum level mark, remove the

right floorboard mat by pulling it

up.

4. Open the reservoir cap, and then

add coolant to the maximum

level mark.

3

FULL1

LOW2

Recommended final transmission

oil:

See page 8-1.

Oil quantity:

0.25 L (0.26 US qt) (0.22 Imp.qt)

Tightening torque:

Final transmission oil drain bolt:

22 Nm (2.2 m·kgf, 15.9 ft·lbf)

PERIODIC MAINTENANCE AND MINOR REPAIR

6-12

6

1C0-F8199-E4.qxd 22/11/07 05:41 Página 53

Page 67 of 88

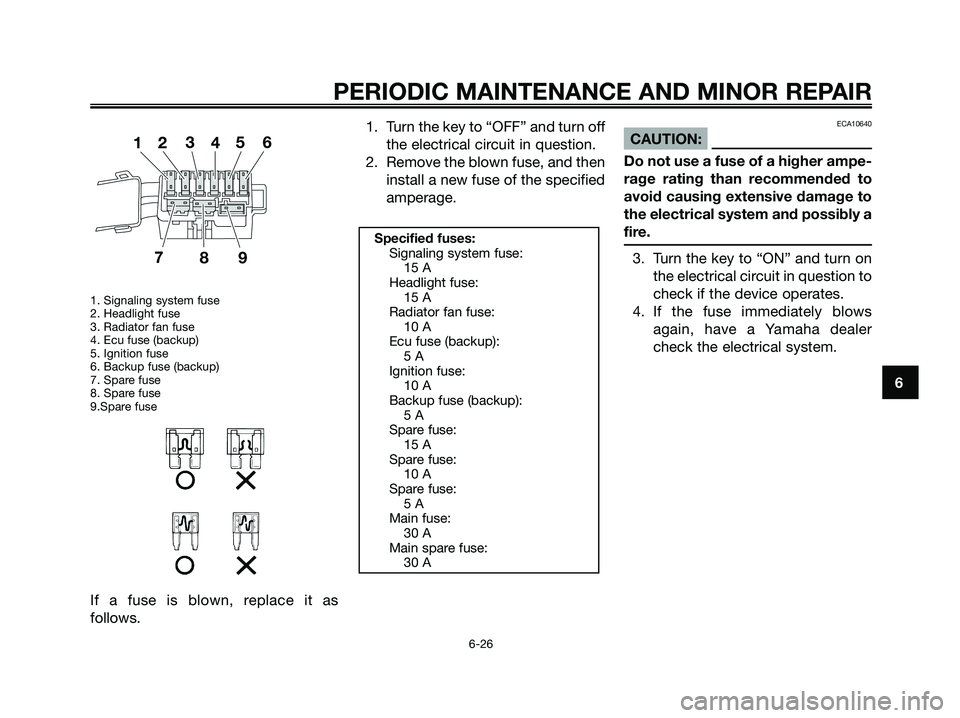

1. Signaling system fuse

2. Headlight fuse

3. Radiator fan fuse

4. Ecu fuse (backup)

5. Ignition fuse

6. Backup fuse (backup)

7. Spare fuse

8. Spare fuse

9.Spare fuse

If a fuse is blown, replace it as

follows.1. Turn the key to “OFF” and turn off

the electrical circuit in question.

2. Remove the blown fuse, and then

install a new fuse of the specified

amperage.

ECA10640

CAUTION:

Do not use a fuse of a higher ampe-

rage rating than recommended to

avoid causing extensive damage to

the electrical system and possibly a

fire.

3. Turn the key to “ON” and turn on

the electrical circuit in question to

check if the device operates.

4. If the fuse immediately blows

again, have a Yamaha dealer

check the electrical system.

Specified fuses:

Signaling system fuse:

15 A

Headlight fuse:

15 A

Radiator fan fuse:

10 A

Ecu fuse (backup):

5 A

Ignition fuse:

10 A

Backup fuse (backup):

5 A

Spare fuse:

15 A

Spare fuse:

10 A

Spare fuse:

5 A

Main fuse:

30 A

Main spare fuse:

30 A

PERIODIC MAINTENANCE AND MINOR REPAIR

6-26

6

1C0-F8199-E4.qxd 22/11/07 05:41 Página 67