check engine YAMAHA XMAX 300 2021 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2021, Model line: XMAX 300, Model: YAMAHA XMAX 300 2021Pages: 114, PDF Size: 4.65 MB

Page 59 of 114

Operation and important ri din g points

6-2

6

EAU86740

Startin g the en gineThe ignition circuit cut-off system will

enable starting when the sidestand is

be up.

To start the engine1. Turn the main switch on.

2. Confirm the indicator and warning

light(s) come on for a few sec-

onds, and the go off. (See page

4-1.)TIPDo not start the engine if the en-

gine trouble warning light remains

on.

The ABS warning light should

come on and stay on until the ve-

hicle reaches a speed of 10 km/h

(6 mi/h).NOTICE

ECA24110

If a warnin g or in dicator li ght does

not work as d escribed a bove, have a

Yamaha dealer check the vehicle.3. Close the throttle completely.

4. While applying the front or rear

brake, push the start switch. 5. Release the start switch when the

engine starts, or after 5 seconds.

Wait 10 seconds before pressing

the switch again to allow battery

voltage to restore.

NOTICE

ECA11043

For maximum en gine life, never ac-

celerate har d when the en gine is

col d!

EAUM4280

TIPThis model is equipped with a lean an-

gle sensor to stop the engine in case of

a turnover. In this case, the malfunction

Indicator light will come on but this is

not a malfunction. Turn the vehicle

power off and then back on again to

cancel the Indicator light. Failing to do

so will prevent the engine from starting

even though the engine will crank

when pushing the start switch.

UBBAE0E0.book Page 2 Thursday, September 24, 2020 3:19 PM

Page 65 of 114

Periodic maintenance an d a djustment

7-3

7

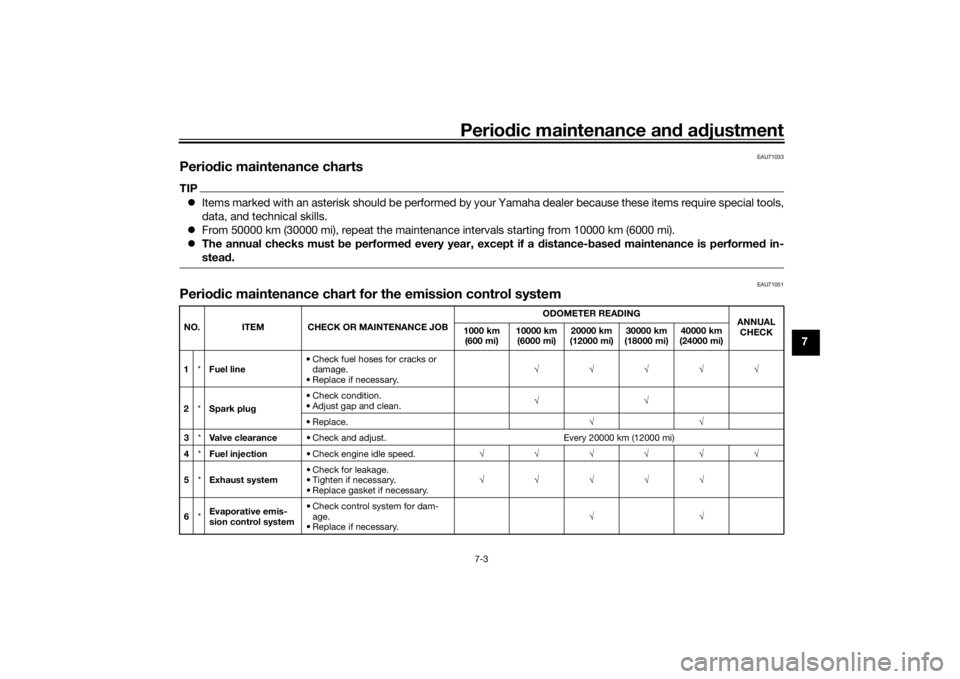

EAU71033

Perio dic maintenance chartsTIP Items marked with an asterisk should be performed by your Yamaha dealer because these items require special tools,

data, and technical skills.

From 50000 km (30000 mi), repeat the maintenance intervals starting from 10000 km (6000 mi).

The annual checks must be performe d every year, except if a distance- based maintenance is performe d in-

stea d.

EAU71051

Perio dic maintenance chart for the emission control systemNO. ITEM CHECK OR MAINTENANCE JOB ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

1 *Fuel line • Check fuel hoses for cracks or

damage.

• Replace if necessary. √√√√√

2 *Spark plu g • Check condition.

• Adjust gap and clean.

√√

•Replace. √√

3 *Valve clearance • Check and adjust. Every 20000 km (12000 mi)

4 *Fuel injection • Check engine idle speed. √√√√√√

5 *Exhaust system • Check for leakage.

• Tighten if necessary.

• Replace gasket if necessary. √√√√√

6 *Evaporative emis-

sion control system • Check control system for dam-

age.

• Replace if necessary. √√

UBBAE0E0.book Page 3 Thursday, September 24, 2020 3:19 PM

Page 68 of 114

Periodic maintenance an d a djustment

7-6

7

21 En gine oil • Change (warm engine before

draining).

• Check oil level and vehicle for oil leakage. At the initial interval and when the oil change indicator flashes or

comes on. √

22 En

gine oil filter ele-

ment • Replace.

√√√

23 *Final transmission

oil • Check vehicle for oil leakage.

√√√√√

• Change. √√√

24 *Coolin g system • Check coolant level and vehicle

for coolant leakage. √√√√√

• Change. Every 3 years

25 *V-belt • Replace. When the V-belt replacement indicator flashes [every 20000 km (12000 mi)]

26 *Front an

d rear

b rake switches • Check operation.

√√√√√√

27 *Movin

g parts an d

cab les • Lubricate.

√√√√√

28 *Throttle

grip hous-

in g an d cab le • Check operation and free play.

• Adjust the throttle cable free play

if necessary.

• Lubricate the throttle grip housing and cable. √√√√√

29 *Li

ghts, si gnals an d

switches • Check operation.

• Adjust headlight beam.

√√√√√√

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 3

0000 km

(18000 mi) 40000 km

(24000 mi)

UBBAE0E0.book Page 6 Thursday, September 24, 2020 3:19 PM

Page 69 of 114

Periodic maintenance an d a djustment

7-7

7

EAU79370

TIP Engine air filter and V-belt air filter

• This model’s engine air filter is equipped with a disposable oil-coated paper element, which must not be cleaned with compressed air to avoid damaging it.

• The engine air filter element and sub air filter element need to be replaced and the V-belt air filter element needs to be serviced more frequently when riding in unusually wet or dusty areas.

Hydraulic brake service

• After disassembling the brake master cylinders and calipers, always change the fluid. Regularly check the brake fluid levels and fill the reservoirs as required.

• Every two years replace the internal components of the brake master cylinders and calipers, and change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.

UBBAE0E0.book Page 7 Thursday, September 24, 2020 3:19 PM

Page 71 of 114

Periodic maintenance an d a djustment

7-9

7

EAU19623

Checkin g the spark plugThe spark plug is an important engine

component, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark plug to slowly erode,

it should be removed and checked in

accordance with the periodic mainte-

nance and lubrication chart. In addi-

tion, the condition of the spark plug

can reveal the condition of the engine.

The porcelain insulator around the

center electrode of the spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally). If the spark plug shows a

distinctly different color, the engine

could be operating improperly. Do not

attempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If the spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced. Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.

Specifie

d spark plu g:

NGK/LMAR8A-9

1. Spark plug gap

Spark plu g g ap:

0.8–0.9 mm (0.031–0.035 in)

Ti ghtenin g torque:

Spark plug: 12.5 N·m (1.25 kgf·m, 9.22 lb·ft)

UBBAE0E0.book Page 9 Thursday, September 24, 2020 3:19 PM

Page 72 of 114

Periodic maintenance an d a djustment

7-10

7

EAU36112

CanisterThis model is equipped with a canister

to prevent the discharging of fuel vapor

into the atmosphere. Before operating

this vehicle, make sure to check the

following:

Check each hose connection.

Check each hose and canister for

cracks or damage. Replace if

damaged.

Make sure that the canister

breather is not blocked, and if

necessary, clean it.

EAUM3980

Engine oil an d oil filter ele-

mentThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart.

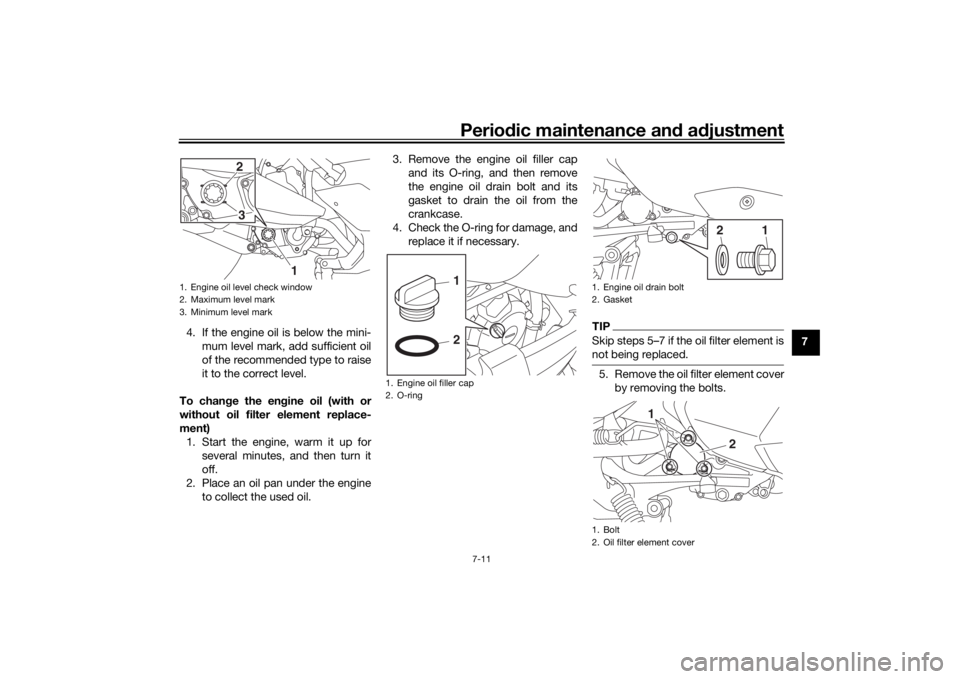

To check the en gine oil level

1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes until the oil set- tles, and then check the oil level

through the check window locat-

ed at the bottom-right side of the

crankcase.TIPThe engine oil should be between the

minimum and maximum level marks.

1. Canister

2. Canister breather hose

2

1

ZAUM1458

UBBAE0E0.book Page 10 Thursday, September 24, 2020 3:19 PM

Page 73 of 114

Periodic maintenance an d a djustment

7-11

7

4. If the engine oil is below the mini-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

To chan ge the en gine oil (with or

without oil filter element replace-

ment) 1. Start the engine, warm it up for several minutes, and then turn it

off.

2. Place an oil pan under the engine to collect the used oil. 3. Remove the engine oil filler cap

and its O-ring, and then remove

the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.

4. Check the O-ring for damage, and replace it if necessary.

TIPSkip steps 5–7 if the oil filter element is

not being replaced.5. Remove the oil filter element coverby removing the bolts.

1. Engine oil level check window

2. Maximum level mark

3. Minimum level mark

3

1

2

1. Engine oil filler cap

2. O-ring

1

2

1. Engine oil drain bolt

2. Gasket

1. Bolt

2. Oil filter element cover

1

2

2

1

UBBAE0E0.book Page 11 Thursday, September 24, 2020 3:19 PM

Page 74 of 114

Periodic maintenance an d a djustment

7-12

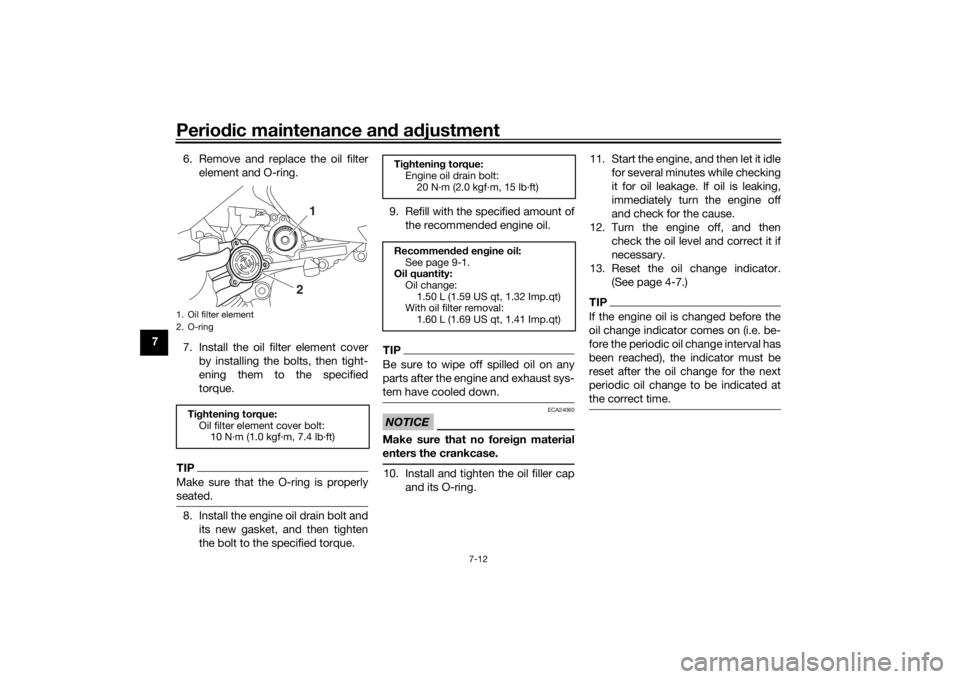

7 6. Remove and replace the oil filter

element and O-ring.

7. Install the oil filter element cover by installing the bolts, then tight-

ening them to the specified

torque.

TIPMake sure that the O-ring is properly

seated.8. Install the engine oil drain bolt andits new gasket, and then tighten

the bolt to the specified torque. 9. Refill with the specified amount of

the recommended engine oil.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA24060

Make sure that no forei gn material

enters the crankcase.10. Install and tighten the oil filler cap and its O-ring. 11. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

12. Turn the engine off, and then check the oil level and correct it if

necessary.

13. Reset the oil change indicator. (See page 4-7.)

TIPIf the engine oil is changed before the

oil change indicator comes on (i.e. be-

fore the periodic oil change interval has

been reached), the indicator must be

reset after the oil change for the next

periodic oil change to be indicated at

the correct time.

1. Oil filter element

2. O-ringTightenin g torque:

Oil filter element cover bolt: 10 N·m (1.0 kgf·m, 7.4 lb·ft)

1

2

Tightenin g torque:

Engine oil drain bolt:

20 N·m (2.0 kgf·m, 15 lb·ft)

Recommen ded en gine oil:

See page 9-1.

Oil quantity:

Oil change:1.50 L (1.59 US qt, 1.32 Imp.qt)

With oil filter removal:

1.60 L (1.69 US qt, 1.41 Imp.qt)

UBBAE0E0.book Page 12 Thursday, September 24, 2020 3:19 PM

Page 75 of 114

Periodic maintenance an d a djustment

7-13

7

EAU20067

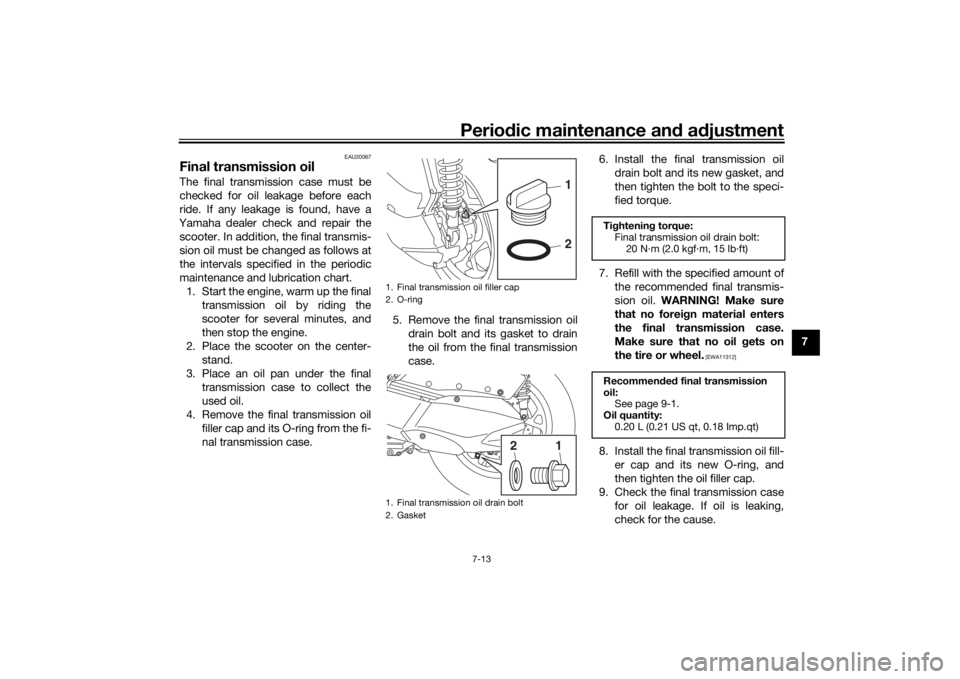

Final transmission oilThe final transmission case must be

checked for oil leakage before each

ride. If any leakage is found, have a

Yamaha dealer check and repair the scooter. In addition, the final transmis-

sion oil must be changed as follows at

the intervals specified in the periodic

maintenance and lubrication chart. 1. Start the engine, warm up the final transmission oil by riding the

scooter for several minutes, and

then stop the engine.

2. Place the scooter on the center- stand.

3. Place an oil pan under the final transmission case to collect the

used oil.

4. Remove the final transmission oil filler cap and its O-ring from the fi-

nal transmission case. 5. Remove the final transmission oil

drain bolt and its gasket to drain

the oil from the final transmission

case. 6. Install the final transmission oil

drain bolt and its new gasket, and

then tighten the bolt to the speci-

fied torque.

7. Refill with the specified amount of the recommended final transmis-

sion oil. WARNING! Make sure

that no forei gn material enters

the final transmission case.

Make sure that no oil gets on

the tire or wheel.

[EWA11312]

8. Install the final transmission oil fill- er cap and its new O-ring, and

then tighten the oil filler cap.

9. Check the final transmission case for oil leakage. If oil is leaking,

check for the cause.

1. Final transmission oil filler cap

2. O-ring

1. Final transmission oil drain bolt

2. Gasket

1

21

2

Tightenin g torque:

Final transmission oil drain bolt: 20 N·m (2.0 kgf·m, 15 lb·ft)

Recommen ded final transmission

oil: See page 9-1.

Oil quantity: 0.20 L (0.21 US qt, 0.18 Imp.qt)

UBBAE0E0.book Page 13 Thursday, September 24, 2020 3:19 PM

Page 76 of 114

Periodic maintenance an d a djustment

7-14

7

EAUS1203

CoolantThe coolant level should be checked

regularly. In addition, the coolant must

be changed at the intervals specified in

the periodic maintenance chart.TIPIf genuine Yamaha coolant is not avail-

able, use an ethylene glycol antifreeze

containing corrosion inhibitors for alu-

minum engines and mix with distilled

water at a 1:1 ratio.

EAU78580

To check the coolant level

1. Place the vehicle on the center- stand.

TIPThe coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.2. Check the coolant level through

the check window.TIPThe coolant should be between the

minimum and maximum level marks.

3. If the coolant is at or below theminimum level mark, remove the

left floorboard mat by pulling it up.

4. Remove the coolant reservoir cov- er.

Recommen ded coolant:

YAMALUBE coolant

Coolant quantity: Coolant reservoir (max level mark):0.18 L (0.19 US qt, 0.16 Imp.qt)

Radiator (including all routes): 1.10 L (1.16 US qt, 0.97 Imp.qt)

1. Coolant level check window

2. Maximum level mark

3. Minimum level mark

1

23

1. Floorboard mat

1. Coolant reservoir cover

1

1

UBBAE0E0.book Page 14 Thursday, September 24, 2020 3:19 PM